Stainless steel hard-seal pipe joint

A kind of stainless steel and pipe joint technology, applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of water leakage, insufficient gripping force, inability to tighten pipe joints, etc., and achieve the effect of reasonable mechanical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail by the following examples.

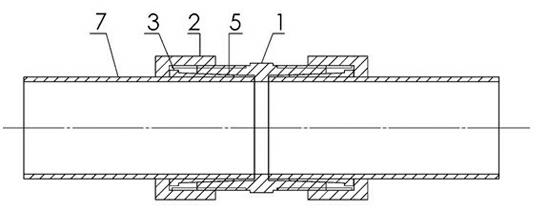

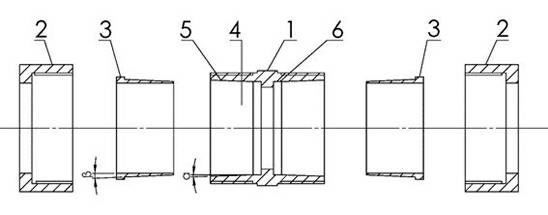

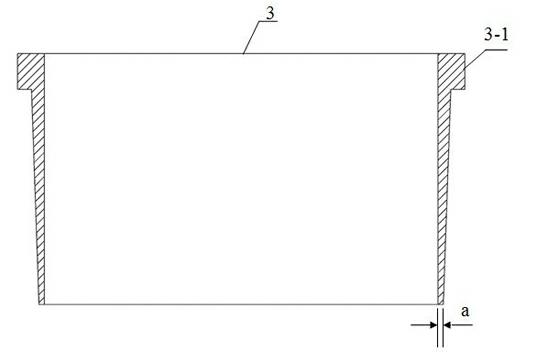

[0022] see Figure 1~Figure 2 As shown, a stainless steel hard-sealed pipe joint is composed of a stainless steel joint body 1 , a stainless steel nut 2 and a stainless steel sealing ring 3 . The two ends of the joint body 1 are provided with external threads and a socket 4, the outer end of the inner wall 5 of the socket 4 is a conical surface, the diameter of the outer end of the conical surface is greater than the diameter of the inner end, and its slope α=0.1 0 ~8 0 Angle, the inward extension part 6 of the conical surface is a cylindrical surface. There is an internal thread in the cavity of the nut 2, and a relief groove is provided between the thread and the bottom. The bottom of the cavity is flat, and a hole is opened in the middle to become the end cover of the nut 2. The external thread on the end is connected. A conical cylinder-shaped sealing ring 3 is installed in the cav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com