Vibrating screen with vibration exciters

A vibrating exciter and vibrating screen technology, which is applied in the direction of fluid, filter screen, chemical instrument and method using vibration, can solve the problems such as the inability to perform stepless adjustment, the labor intensity of workers, and the need for manual adjustment, so as to reduce the operation time. cost, eliminate mechanical transmission, reduce equipment failure rate and the effect of floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

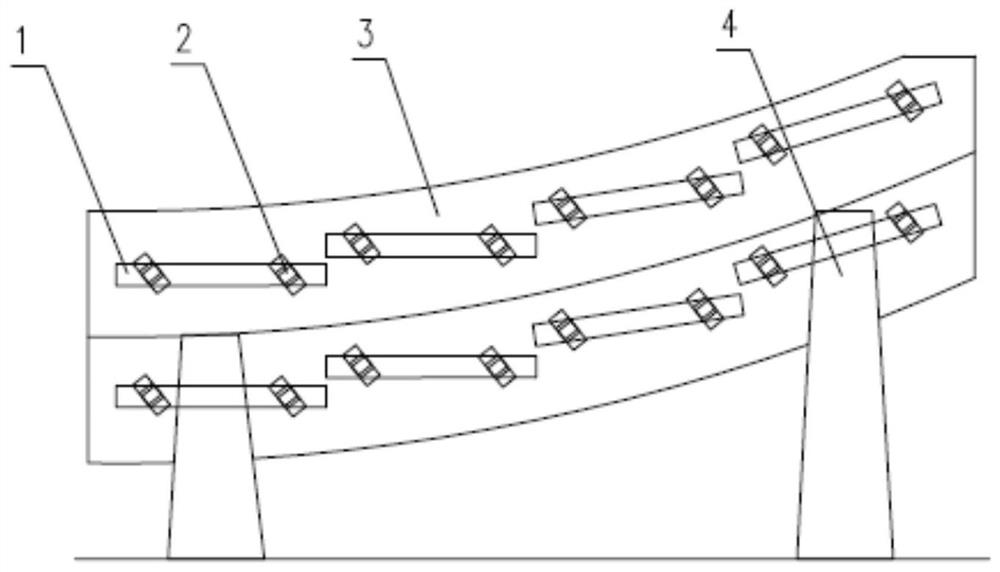

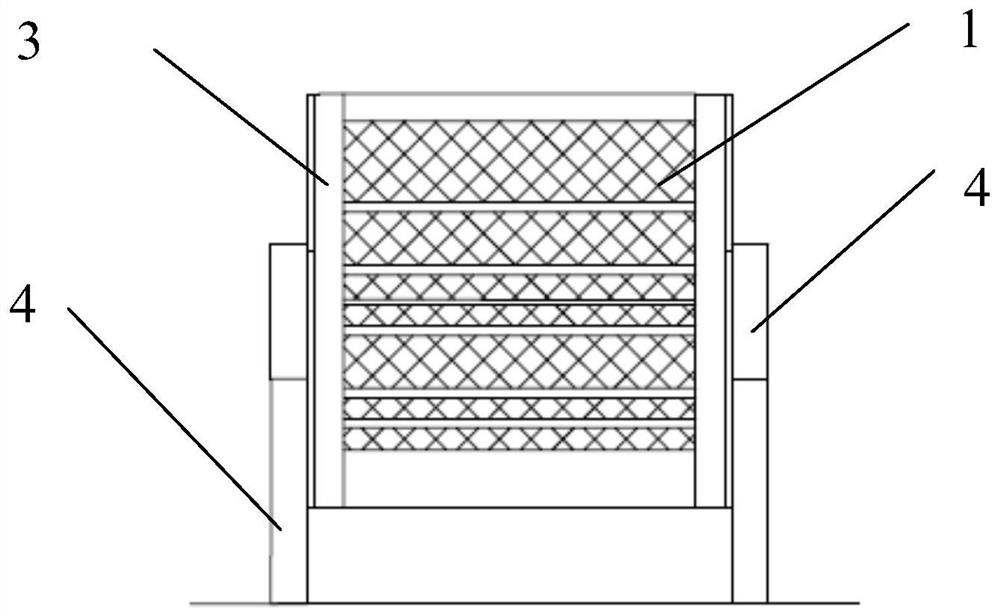

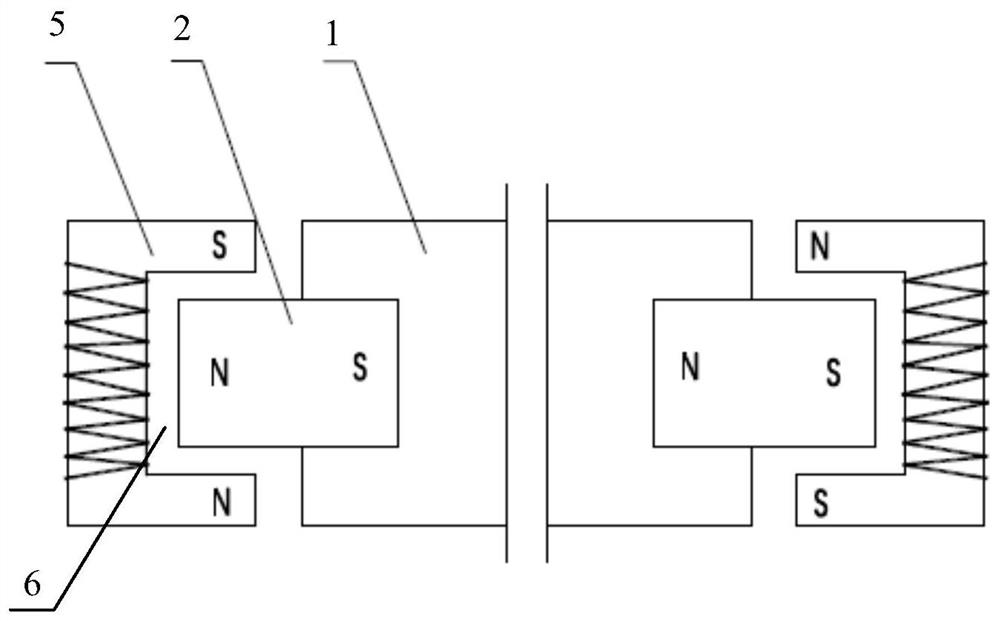

[0021] Example: as attached figure 1 , 2 As shown, this vibrating screen with an exciter includes a screen 1, an exciter, a screen frame 3 and a support 4, and the screen frame 3 is provided with two layers of screen surfaces (in this embodiment, two layers , can also be more layers), and each layer of screen surface is formed by several stages (four stages in this embodiment) of screen mesh 1 connected from bottom to top at a certain angle, so that the screen surface gradually moves from left to right. Upturned and curved, the support 4 is arranged on the left and right sides of the screen frame 3 for supporting the screen frame 3, the height of the right support 4 is higher than the left support 4; each screen 1 There is an exciter on each of them, the exciter includes permanent magnets 2 fixed on both sides of the screen 1 and winding conductors 5 fixed at the corresponding positions on the screen frame 3, each winding conductor 5 has a concave Groove 6, each permanent ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com