Harness wire-free jacquard head

A jacquard faucet, no heald technology, applied in jacquard machines, textiles, textiles and papermaking, etc., can solve the problems of energy consumption, environmental protection, complex structure, large mechanical impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

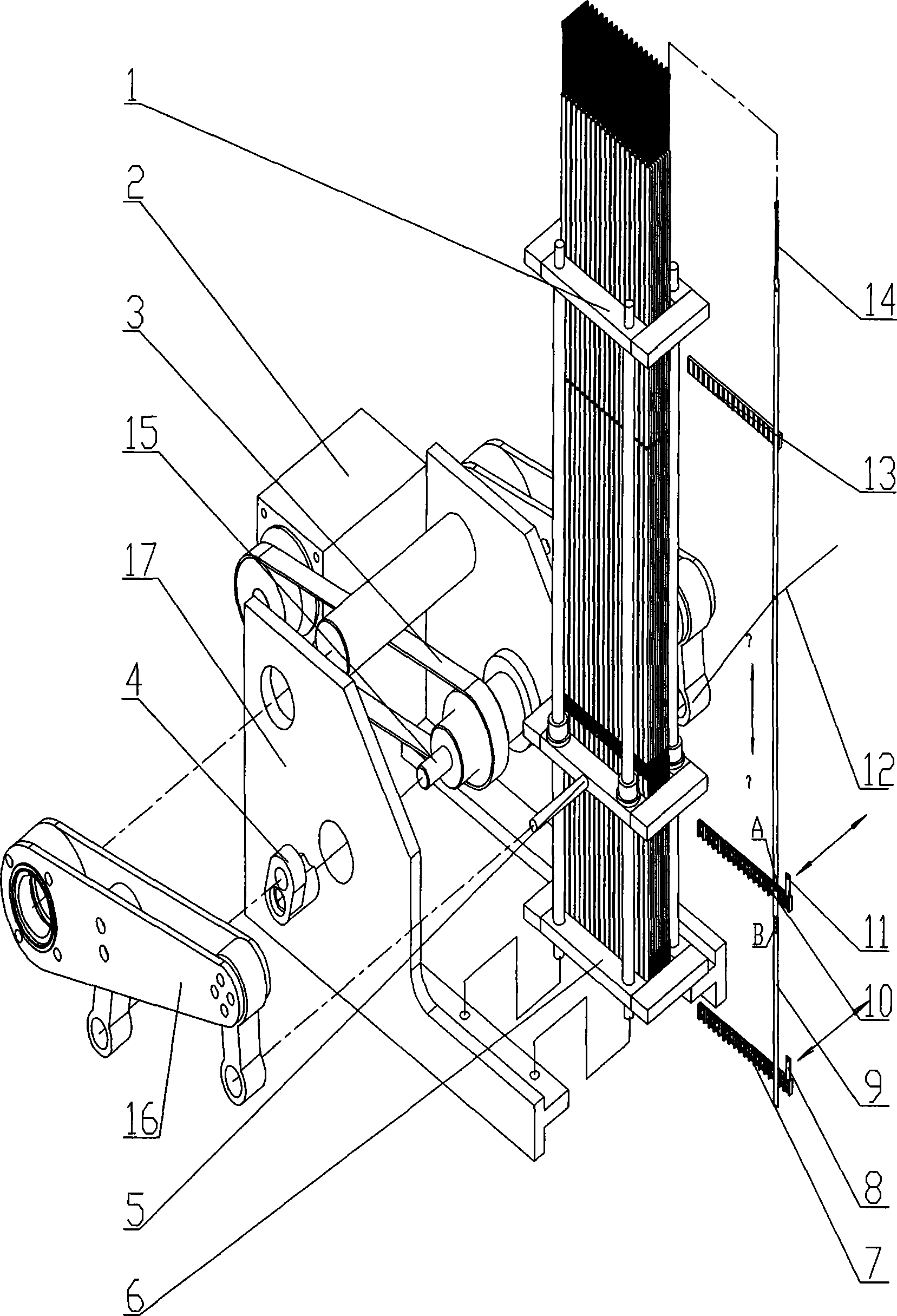

[0008] Below in conjunction with accompanying drawing the present invention is described further, there is a drive motor 2 at the front portion of body frame 17, has hook plate slideway linkage mechanism 16 at the both sides of body frame. The drive motor is connected with the hook piece slideway linkage mechanism through the toothed belt. There is an eccentric block 4 on the main shaft 15 of the linkage mechanism. There is a hook plate installation frame at the rear part of the body frame. The upper part of the hook plate installation frame has a fixed frame 1 for the upper slideway of the hook plate, and the lower part of the hook plate installation frame has a fixed frame 6 for the slideway of the hook plate. There is an intermediate slideway movable frame 5 between the upper and lower slideway fixed frames. Hook piece 9 is housed in the hook piece installation frame. There is a lifting spring 14 on the top of the hook plate. There is a slideway 13 on the hook piece on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com