Auxiliary welding active agent and novel nut projection welding method for enhancing welding penetration

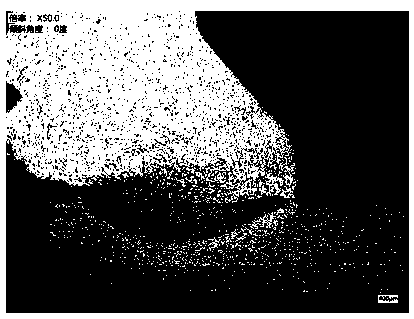

An active agent and nut technology, applied in the field of resistance welding, can solve the problems affecting the assembly quality of the entire workpiece or even the whole vehicle, short welding time of nut projection welding, and small nucleation size, so as to improve welding consistency, short welding time, Effect of increasing weld nugget penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of preparation method of welding auxiliary active agent, by mass percentage, its preparation steps are as follows:

[0027] 1) The powder and the binder are mixed according to the mass ratio of 1:4~6 to form the active agent;

[0028] 2) Dilute the active agent in step 1) with acetone at a ratio of 1.5 to 3:1;

[0029] The powder includes the following components by mass percentage: 50%-65% of carbon black, 4%-10% of CaF2, 16%-25% of TiO2, and 15%-27% of Mn.

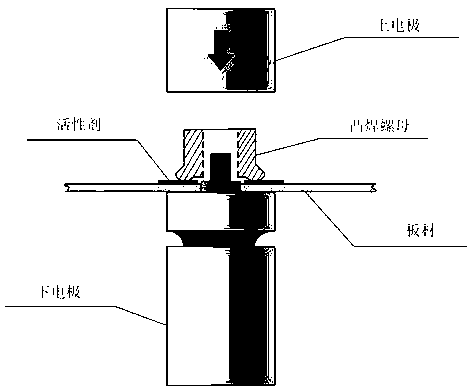

[0030] A novel nut projection welding method for increasing welding penetration, comprising the following steps:

[0031] 1) Preparation of auxiliary active agent;

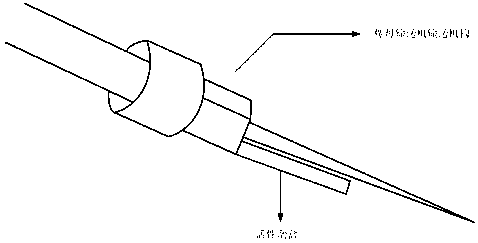

[0032] 2) Place the prepared active agent in a special active agent box;

[0033] 3) Install the active agent box on the nut conveyor conveying structure;

[0034] 4) When performing nut projection welding, the nut passes through the activator box during the conveying process, so that the nut bumps are dipped into the activator.

Embodiment 1

[0036] Weigh the powder according to the following mass percentages: carbon black 50%, CaF2 5%, TiO2 18%, Mn 22%. After mixing the powder evenly, mix it with the binder at a ratio of 1:4 to 6 to form an active agent, then dilute the active agent with acetone at a ratio of 1.5 to 3:1 for nut projection welding.

Embodiment 2

[0038] Weigh the powder according to the following mass percentages: carbon black 56%, CaF2 6%, TiO2 17%, Mn 21%. After mixing the powder evenly, mix it with the binder at a ratio of 1:4 to 6 to form an active agent, then dilute the active agent with acetone at a ratio of 1.5 to 3:1 for nut projection welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com