Automatic welding device of circular weld beads

An automatic welding and welding bead technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of large influence on welding quality and welding consistency, lack of effective guarantee, and low labor intensity. Improve welding quality and welding consistency, simple structure, good weld bead quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

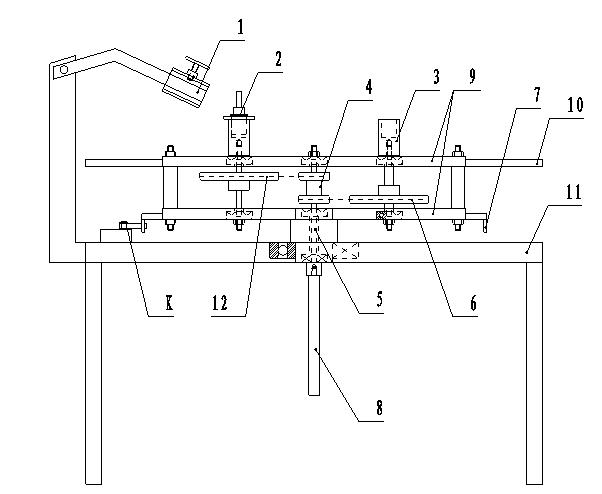

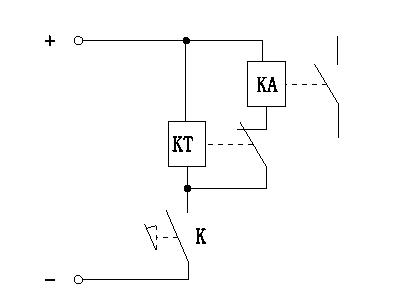

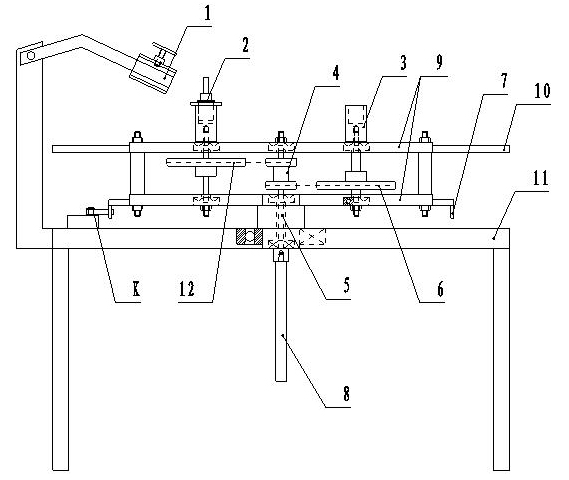

[0016] see figure 1 , figure 2 , Assembly of the present invention: the wire feeding motor of the carbon dioxide shielded welding machine is connected with the vertical shaft 5 through the transmission shaft 8 . Fasten the welding torch of the welding machine on the welding torch bracket 1, and adjust the relative position of the welding torch and the workpiece positioning seat 3 to ensure the angle and distance of welding. Unplug the circuit control plug of the welding torch, and plug in the control circuit of the circular bead automatic welding device. Adjust the delay time of the time relay KT through test welding. The workpiece speed can be controlled by adjusting the current of the welding machine and the size of the proportioning sprocket.

[0017] Welding of the workpiece: Rotate the welding platform 9 out of the welding position by 90 degrees clockwise / counterclockwise, install the workpiece at a position that does not hinder the upper part, and place the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com