Power device and welding positioning method thereof

A power device and limit protrusion technology, which is applied to electrical components, workpiece edge parts, and electrical components to assemble printed circuits, etc., can solve the problems of low reliability, complicated production process, tool wear, etc., to avoid tool wear, The effect of improving welding consistency and welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

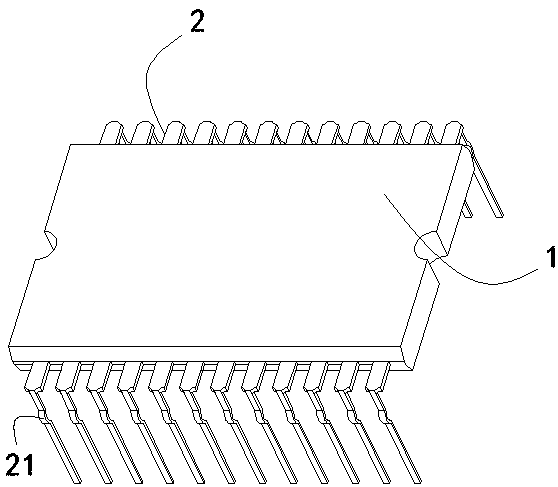

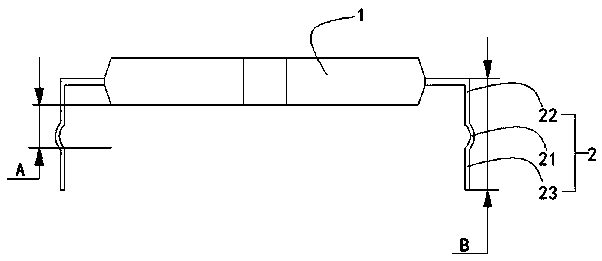

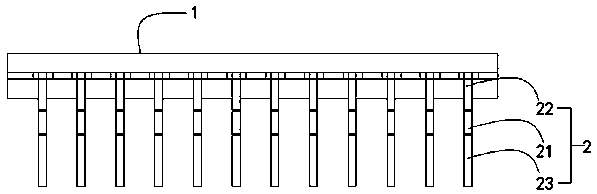

[0037] Such as Figure 1-4 As shown, the embodiment of the present invention provides a welding positioning method for power devices, including the following steps:

[0038] (a) Select the power device: According to the needs of the production model, select the power device suitable for the production model; the power device is composed of a power device body 1 and a plurality of pins 2, and the pin 2 is set to limit the power device The limit protrusion 21 of the installation height of the body 1, further, the height B of the pin 2 is 11 mm, the height A between the end face of the power device body 1 and the end of the limit protrusion 21 is 6.0 mm, and the height of the pin 2 The number is 24, and pin 2 is IPM material pin 2.

[0039] (b) Plug-in positioning: Insert the pin 2 on the power device selected in step (a) directly into the PCB board 3 of the production model, and make the power device body 1 through the limit protrusion 21 on the pin 2 The height between the po...

Embodiment 2

[0042] Such as Figure 1-4 As shown, the embodiment of the present invention provides a welding positioning method for power devices, including the following steps:

[0043] (a) Select the power device: According to the needs of the production model, select the power device suitable for the production model; the power device is composed of a power device body 1 and a plurality of pins 2, and the pin 2 is set to limit the power device The limit protrusion 21 of the installation height of the body 1, further, the height B of the pin 2 is 12.2 mm, the height A between the end face of the power device body 1 and the end of the limit protrusion 21 is 7.2 mm, the pin 2 The number is 25, and pin 2 is IPM material pin 2.

[0044] (b) Plug-in positioning: Insert the pin 2 on the power device selected in step (a) directly into the PCB board 3 of the production model, and make the power device body 1 through the limit protrusion 21 on the pin 2 The height between the power device body ...

Embodiment 3

[0047] Such as Figure 1-4 As shown, the embodiment of the present invention provides a welding positioning method for power devices, including the following steps:

[0048](a) Select the power device: According to the needs of the production model, select the power device suitable for the production model; the power device is composed of a power device body 1 and a plurality of pins 2, and the pin 2 is set to limit the power device The limit protrusion 21 of the installation height of the body 1, further, the height B of the pin 2 is 14.5 mm, the height A between the end face of the power device body 1 and the end of the limit protrusion 21 is 9.5 mm, and the pin 2 The number is 30, and pin 2 is IPM material pin 2.

[0049] (b) Plug-in positioning: Insert the pin 2 on the power device selected in step (a) directly into the PCB board 3 of the production model, and make the power device body 1 through the limit protrusion 21 on the pin 2 The height between the power device bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com