Double-sided laminated airtight brazing system and method in 3D microwave radio frequency module

A microwave radio frequency, 3D technology, applied in welding equipment, auxiliary devices, manufacturing tools, etc., can solve the problems of energy waste, low efficiency, complex welding process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

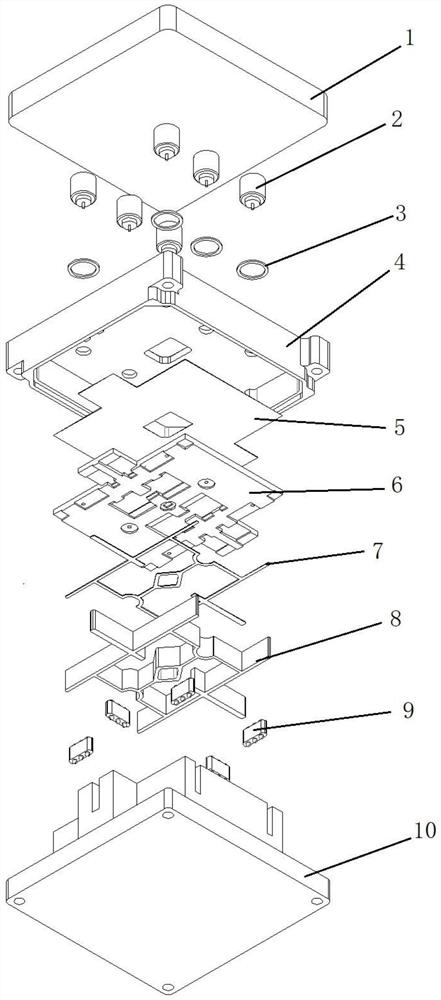

[0029] Such as figure 1 as shown, figure 1 It is a structural exploded view of the double-sided laminated airtight brazing system in the 3D microwave radio frequency module; the double-sided laminated airtight brazing system in the 3D microwave radio frequency module of the present invention includes an upper tooling 1, a connector 2, a connecting Device solder ring 3, module shell 4, substrate solder 5, substrate 6, surface device solder 7, surface device 8, elastic tooling 9, and lower tooling 10. The connector 2 and the connector solder ring 3 are arranged between the upper tooling 1 and the module shell 4, the substrate solder 5, the substrate 6, the surface component solder 7, the The surface device 8 and the elastic tooling 9 are arranged between the lower tooling 10 and the module shell 4 .

[0030] Specifically, the lower end surface of the module shell 4 is provided with a concave cavity, and the cavity is sequentially provided with the substrate solder 5, the subst...

Embodiment 2

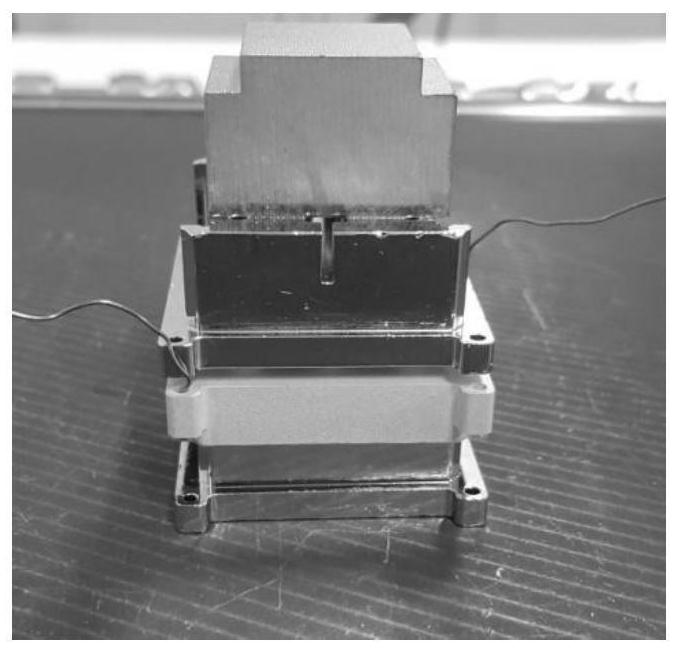

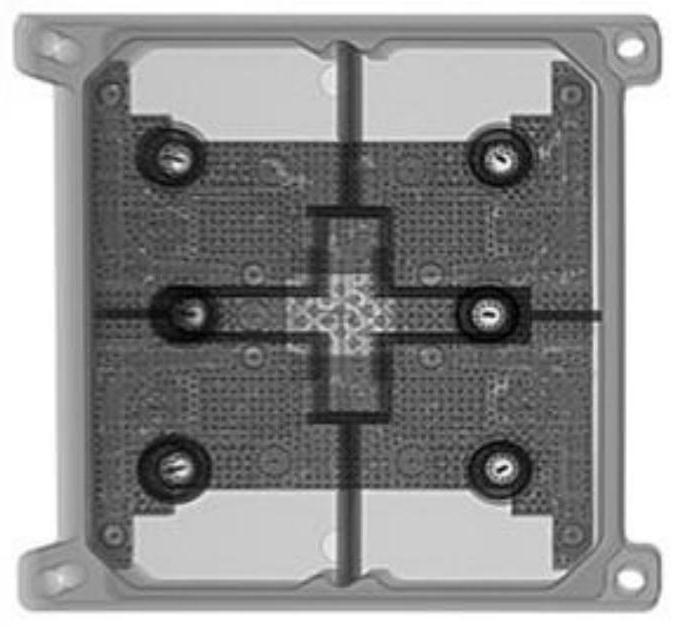

[0039] Such as figure 2 , image 3 as shown, figure 2 It is the actual welding schematic diagram of the double-sided laminated airtight brazing method in the 3D microwave radio frequency module; image 3 It is the X-ray inspection diagram of the assembly after welding by the double-sided laminated airtight brazing method in the 3D microwave radio frequency module; the brazing method of the double-sided laminated airtight brazing system in the 3D microwave radio frequency module of the present invention, according to Follow the steps below:

[0040] S1, placing the cavity of the module shell 4 facing upwards on a flat surface;

[0041] S2, sequentially place the substrate solder 5, the substrate 6, the surface device solder 7, the surface device 8, the elastic tooling 9 and the lower tooling 10 into the cavity of the module shell 4 ;

[0042]S3, the substrate solder 5, the substrate 6, the surface device solder 7, the surface device 8, the elastic tooling 9, the lower to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com