Patents

Literature

64results about How to "Improve welding accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

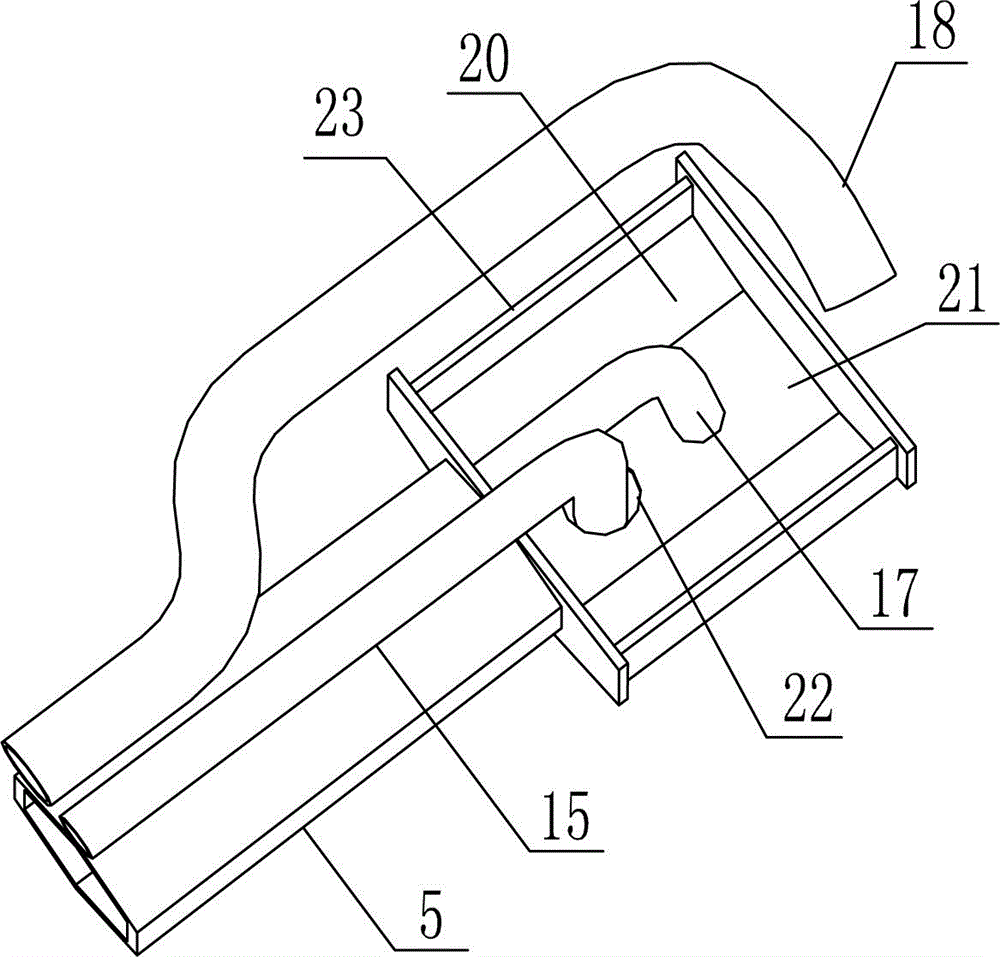

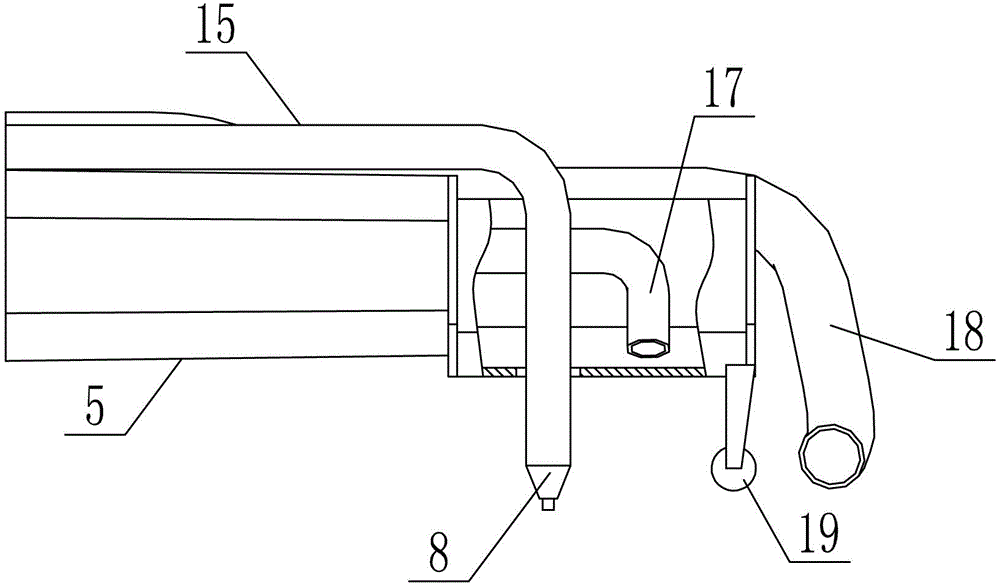

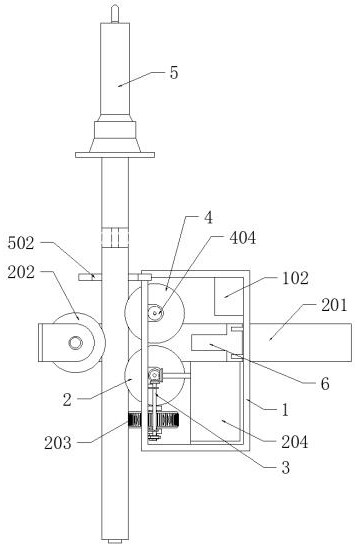

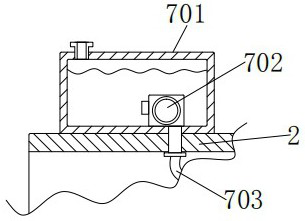

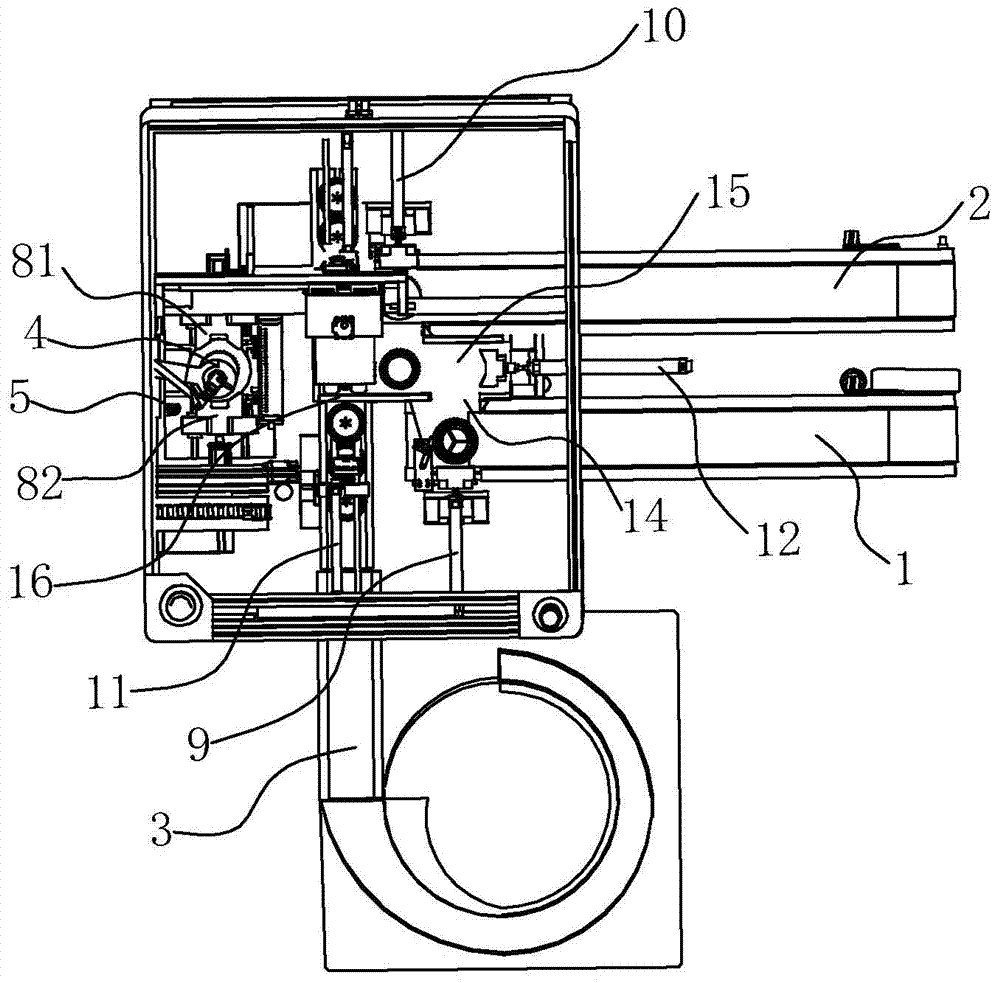

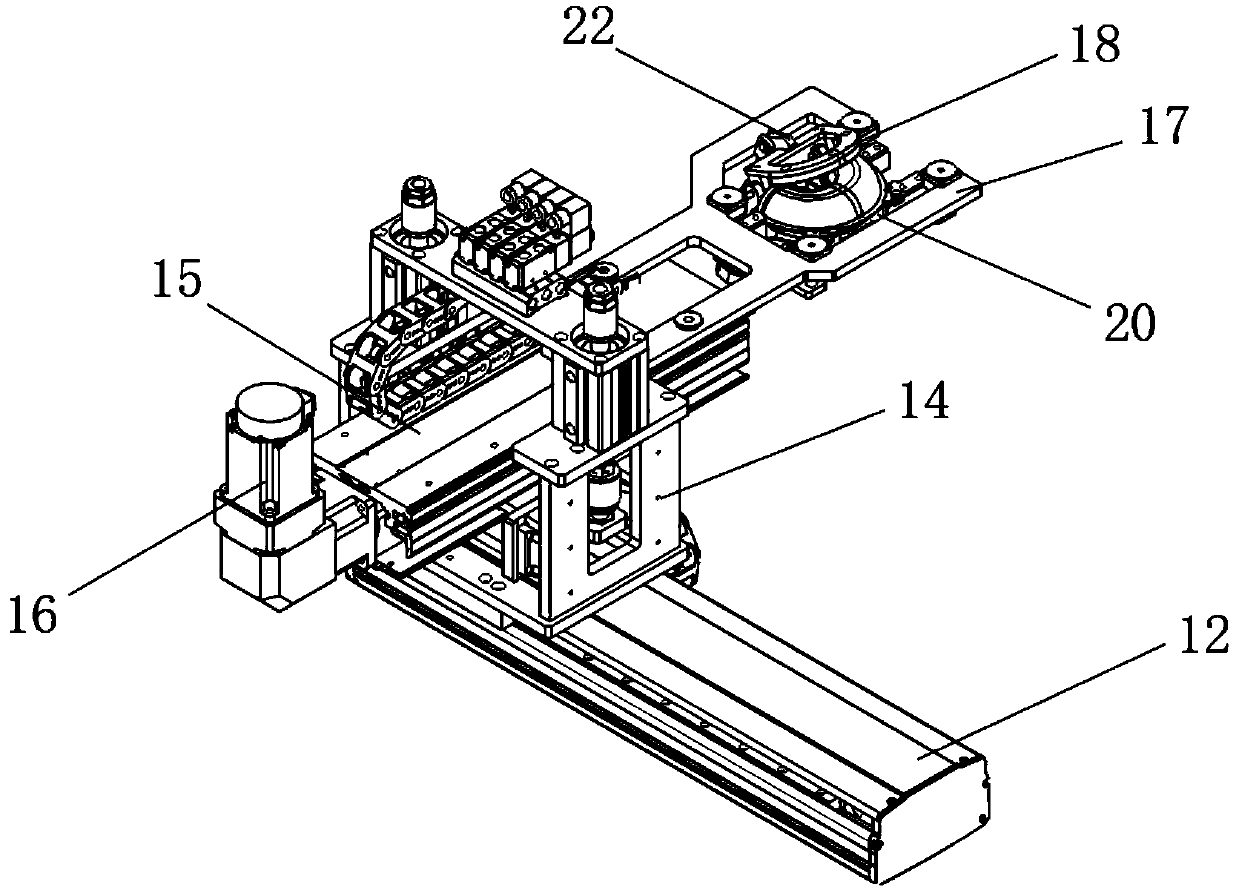

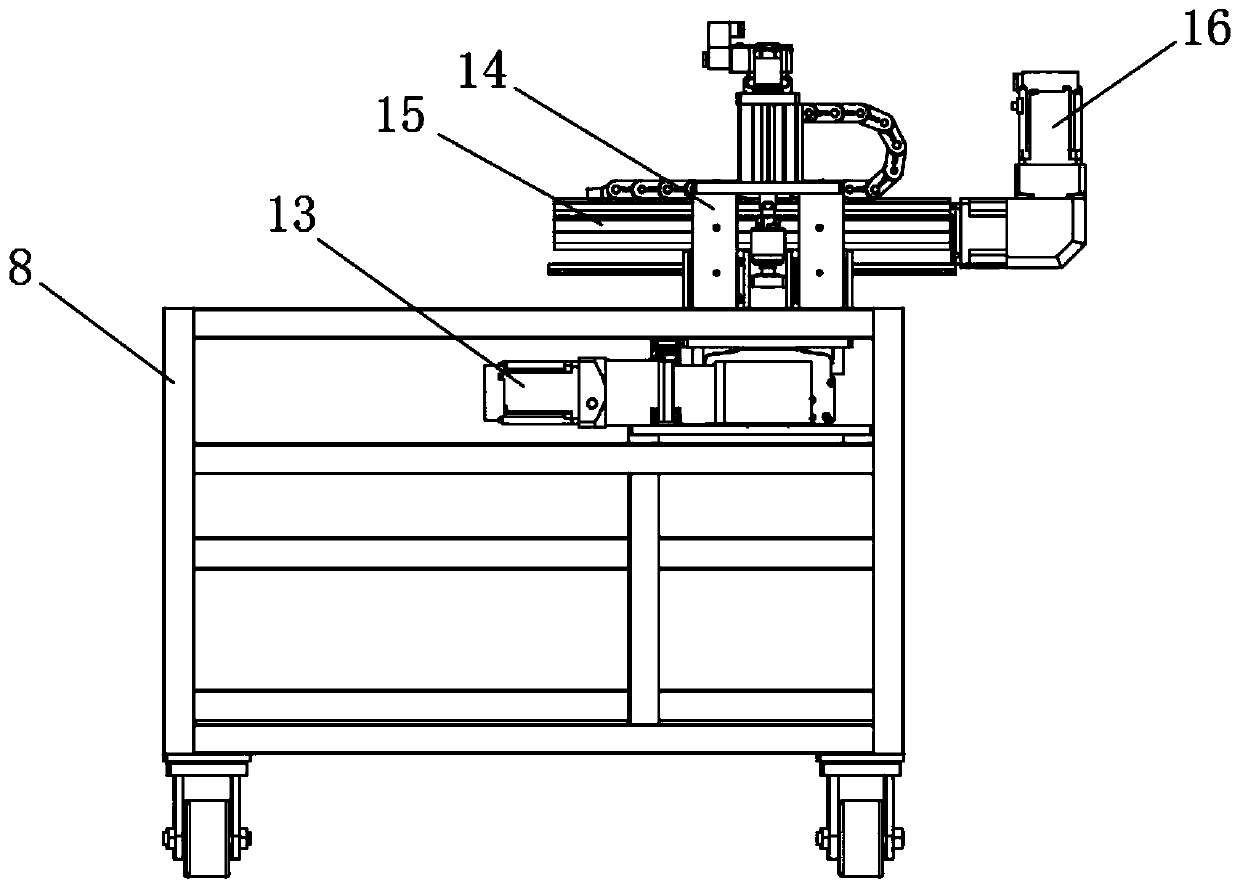

Automatic gas shielded welding device of longitudinal gap in steel pipe cavity

InactiveCN104493337AEasy to liftIncrease stiffnessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

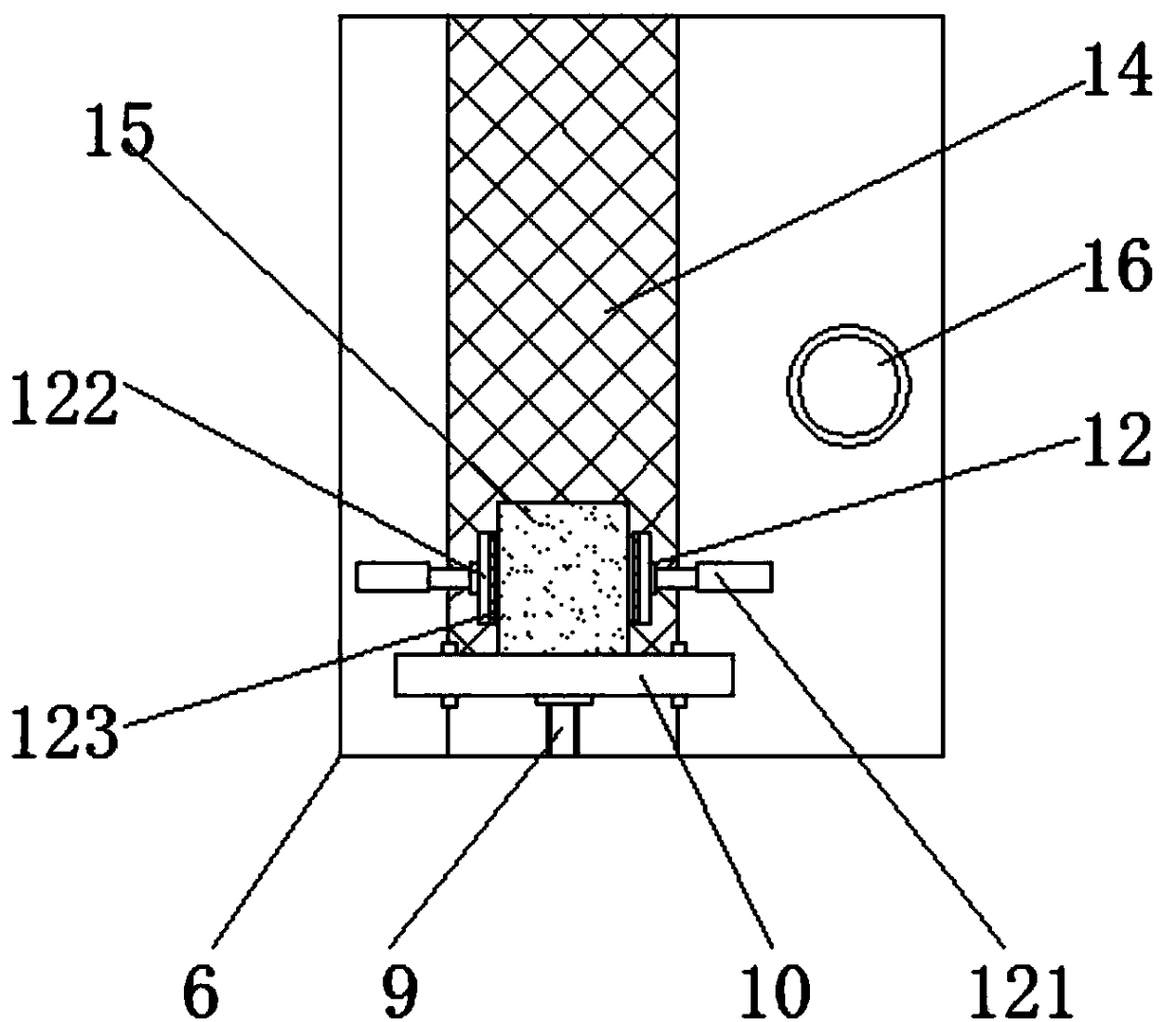

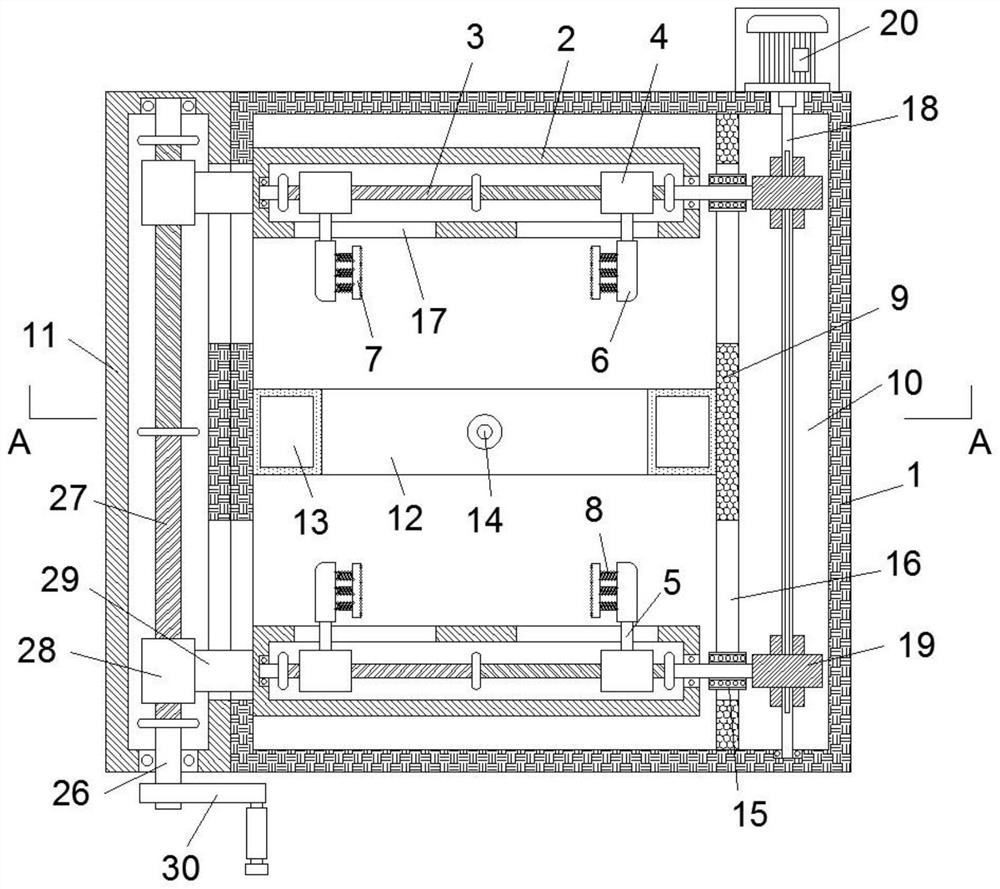

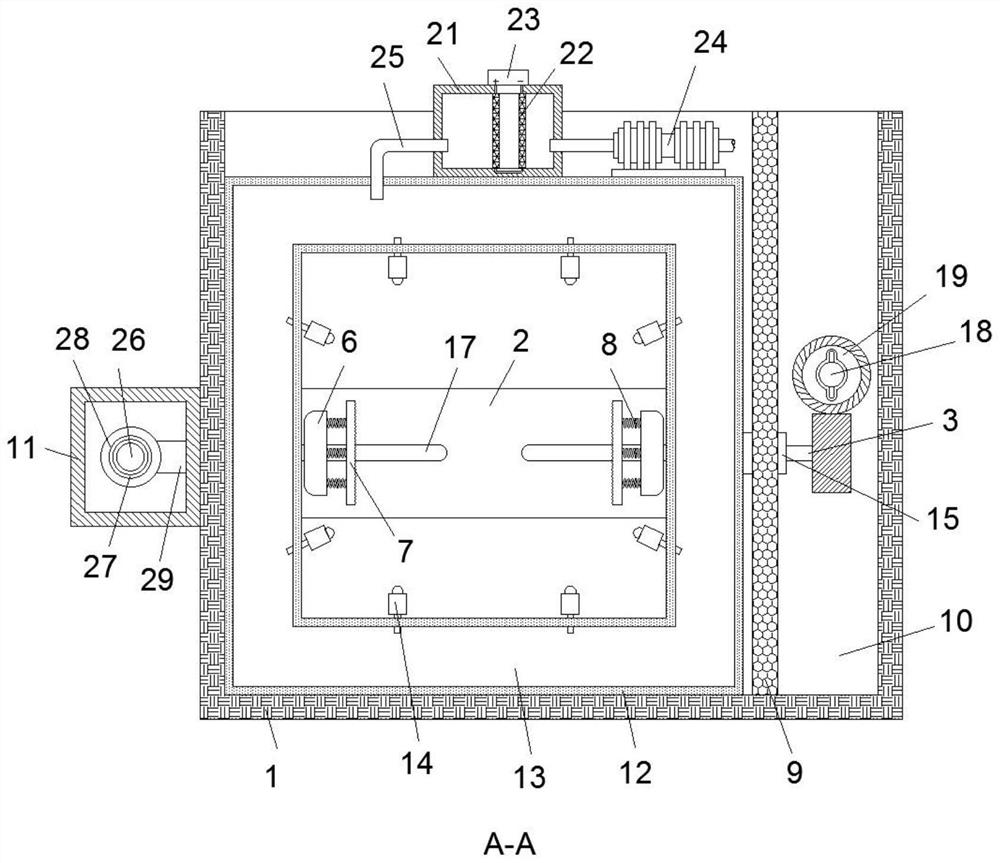

The invention relates to an automatic gas shielded welding device of a longitudinal gap in a steel pipe cavity. The device comprises a machine head, a support arm, a walking device, a welding machine, a welding gun, a control box and a support wheel frame, wherein the machine head consists of an outer machine head and an inner machine head; one end of the support arm is fixed at the other side of the inner machine head; the support wheel frame is fixed at the other end of the support arm; an oscillator and a fixture fixed at one side of the oscillator are fixed in the support wheel frame; the welding gun is fixed in the middle of the fixture; a welding gun observing probe is fixed below the end of the support arm; and an automatic wire feeding machine is fixed in a mounting groove hole in the support arm. The device is simple in structure and convenient for operation, can largely improve the welding efficiency and reduce the labor intensity, needs no welding workers to enter steel pipes for welding to prevent harmful gas from harming the workers, and improves the product quality.

Owner:河北省景县宏远通讯有限公司

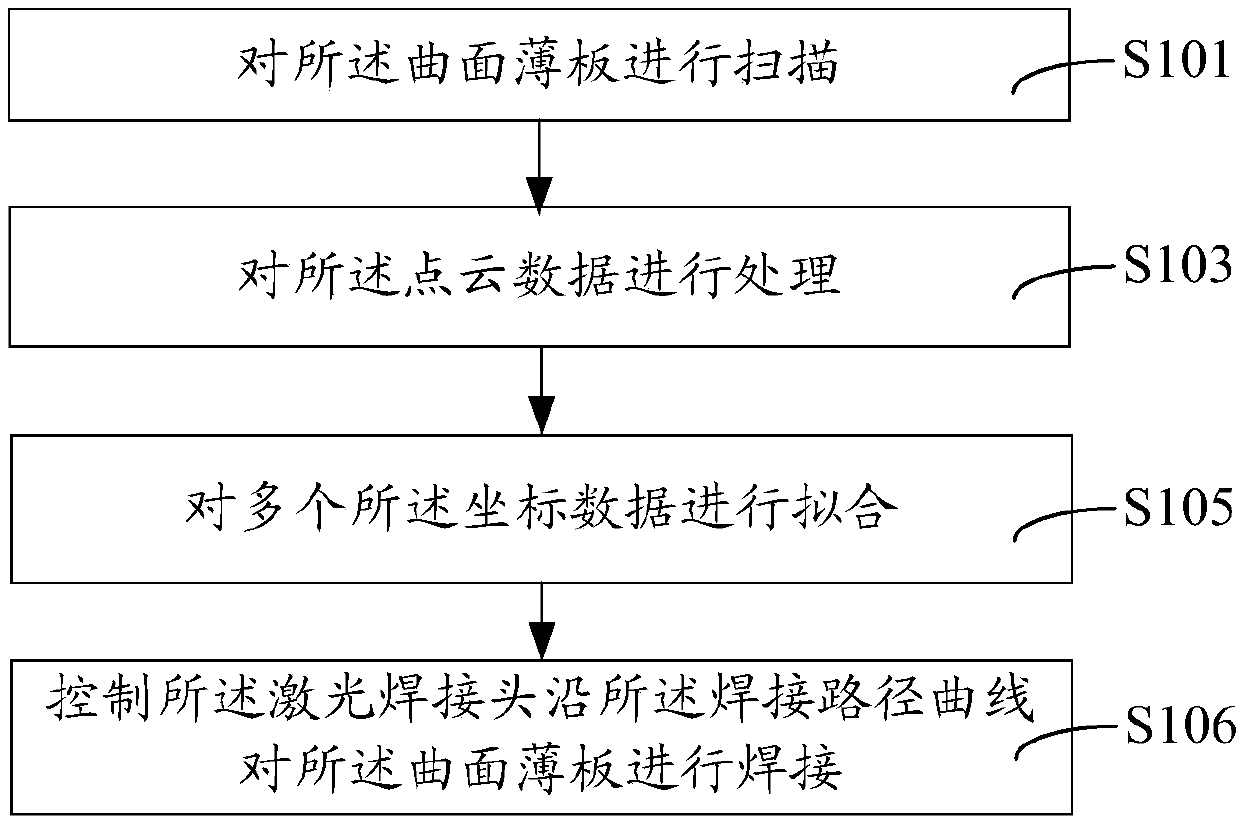

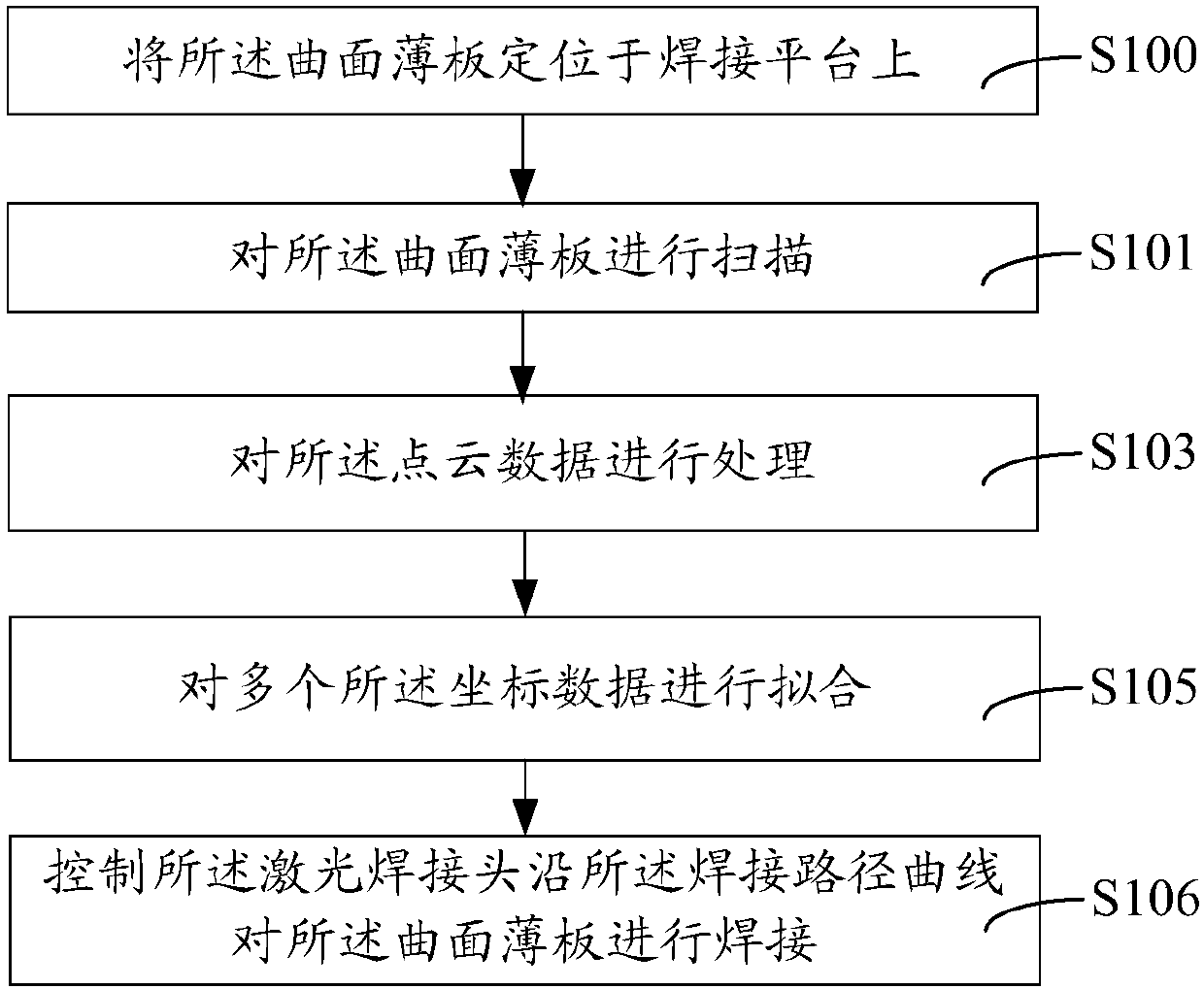

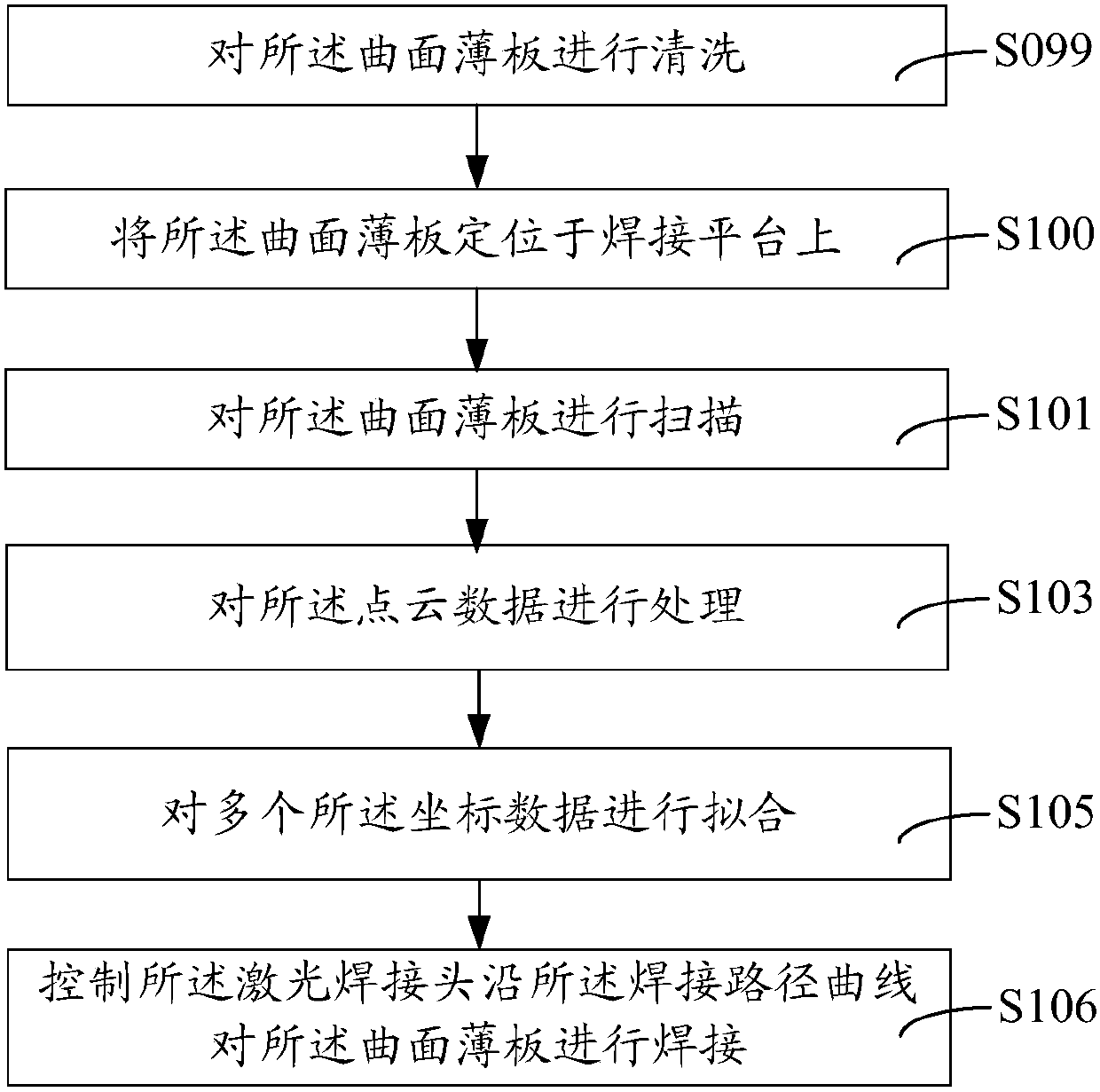

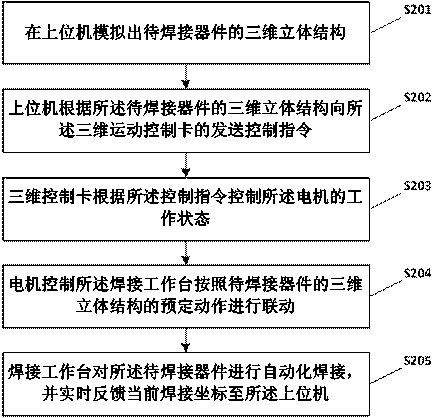

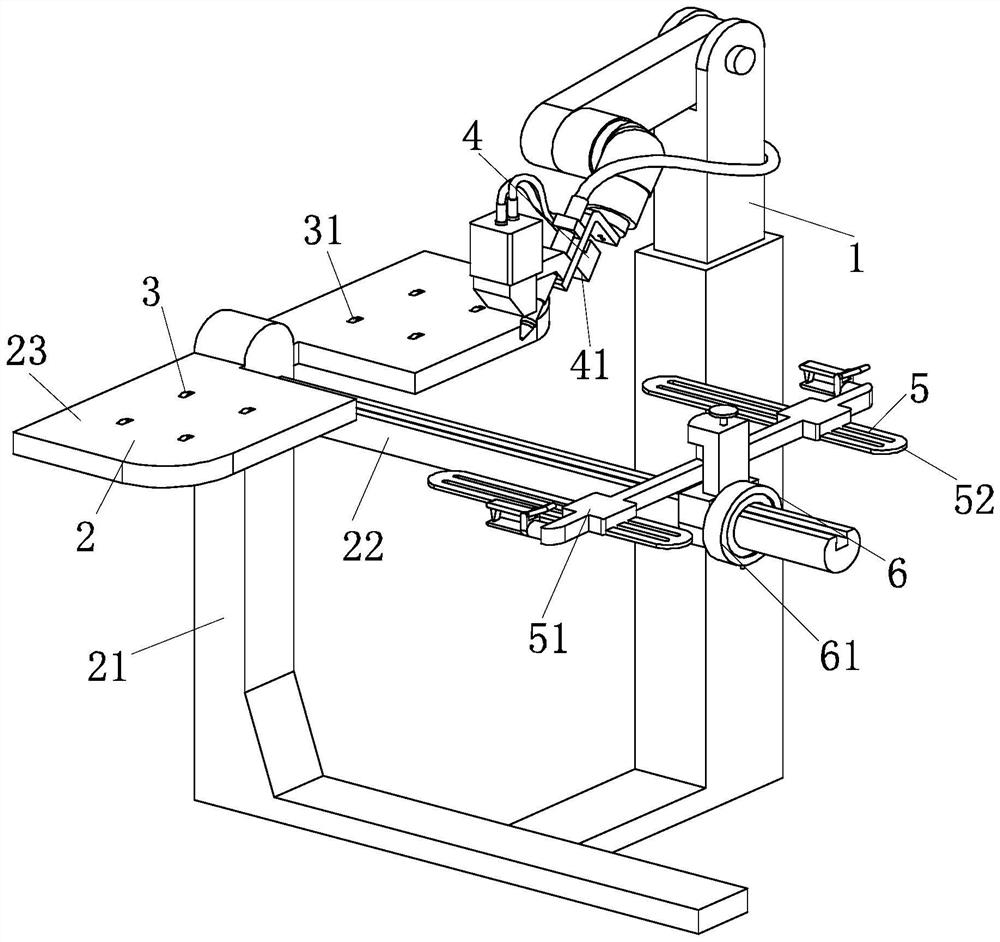

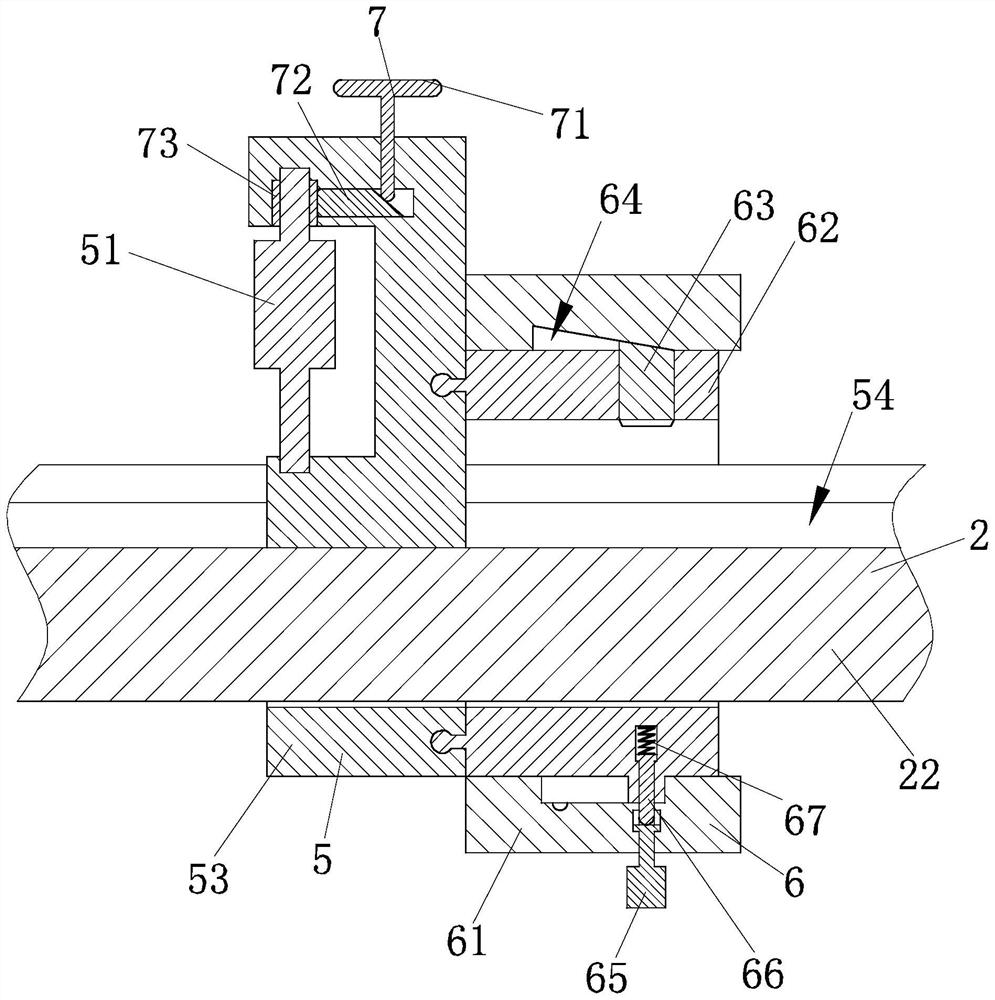

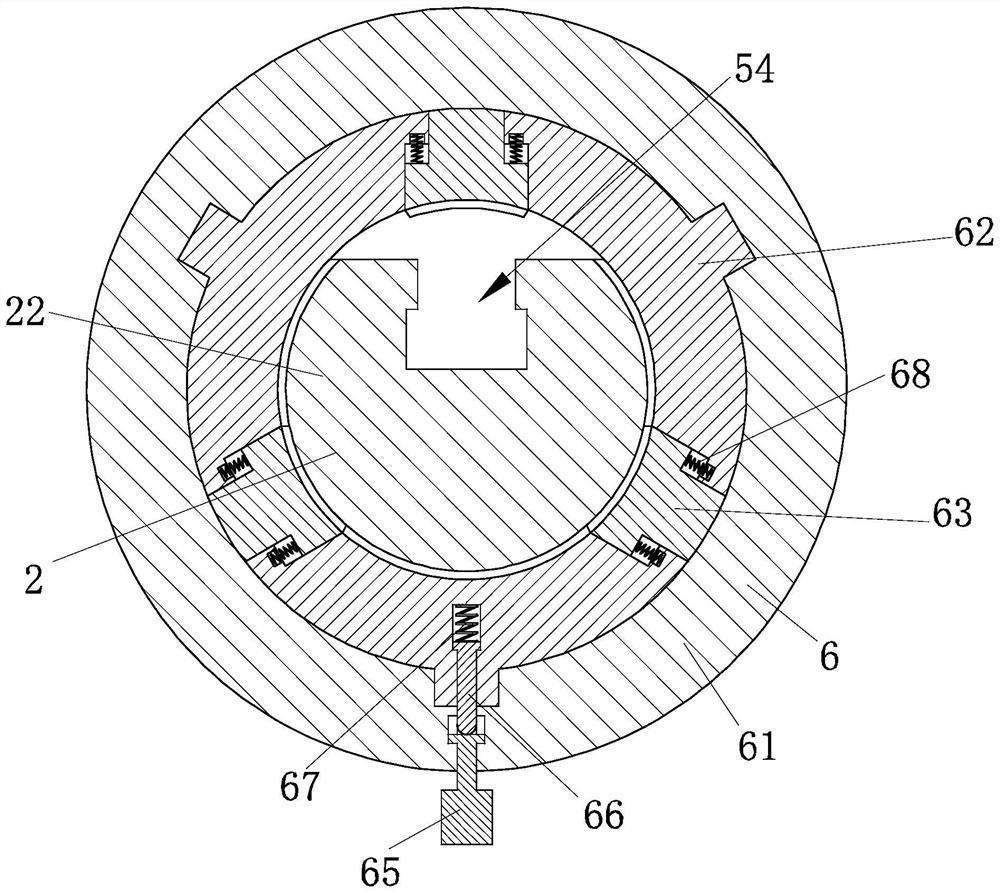

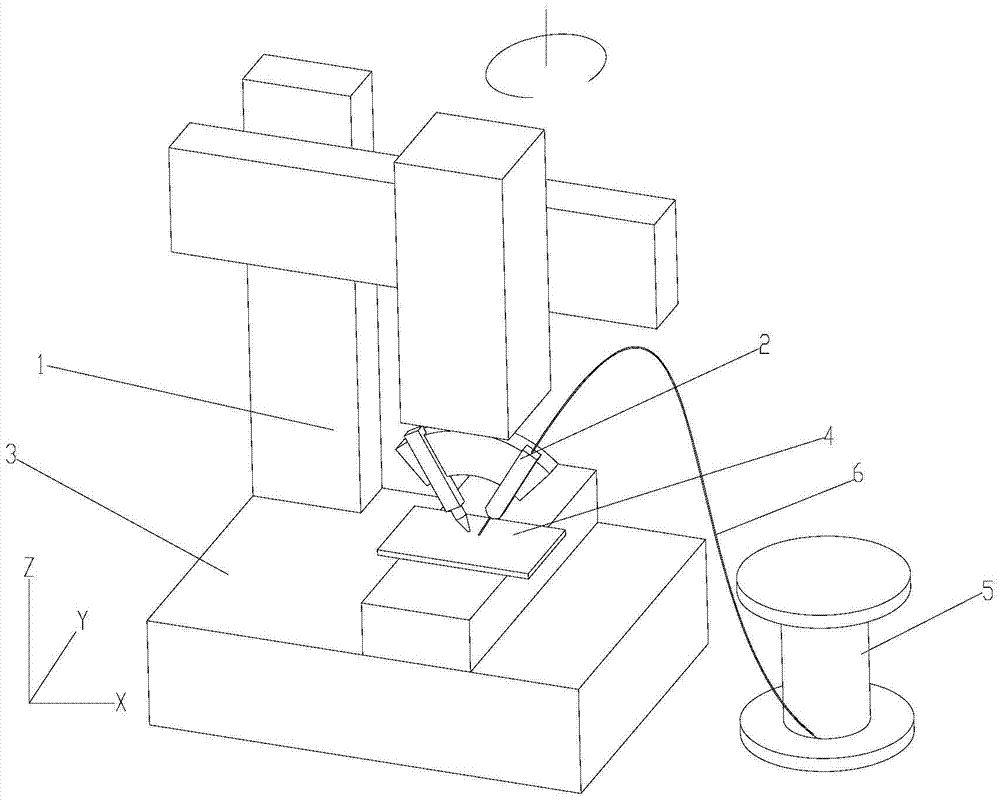

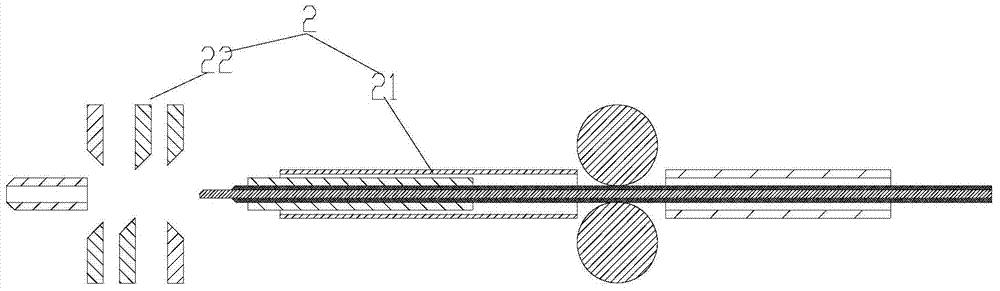

Curve thin board and laser welding method and laser welding system thereof

InactiveCN107914084AImprove welding accuracyImprove welding precisionWelding/soldering/cutting articlesMetal working apparatusPoint cloudEngineering

The invention relates to a curve thin board and a laser welding method and laser welding system thereof. The laser welding method of the curve thin board comprises the steps of scanning the curve thinboard, and obtaining curve point cloud data of the curve thin board; treating the point cloud data, and obtaining multiple coordinate data of the curve welding path; fitting the multiple coordinate data, and obtaining the curve welding path curve; controlling a laser welding head to weld the curve thin board along the welding path curve. According to the curve thin board and the laser welding method and laser welding system thereof, the distance between the laser welding head and the curve thin board can be adjusted, the laser welding head adapts to the welding line of the curve thin board, the welding precision of the welding line of the curve thin board is higher, and the problem that the welding precision of the curve thin board is poor is solved.

Owner:惠州市顺步科技有限公司

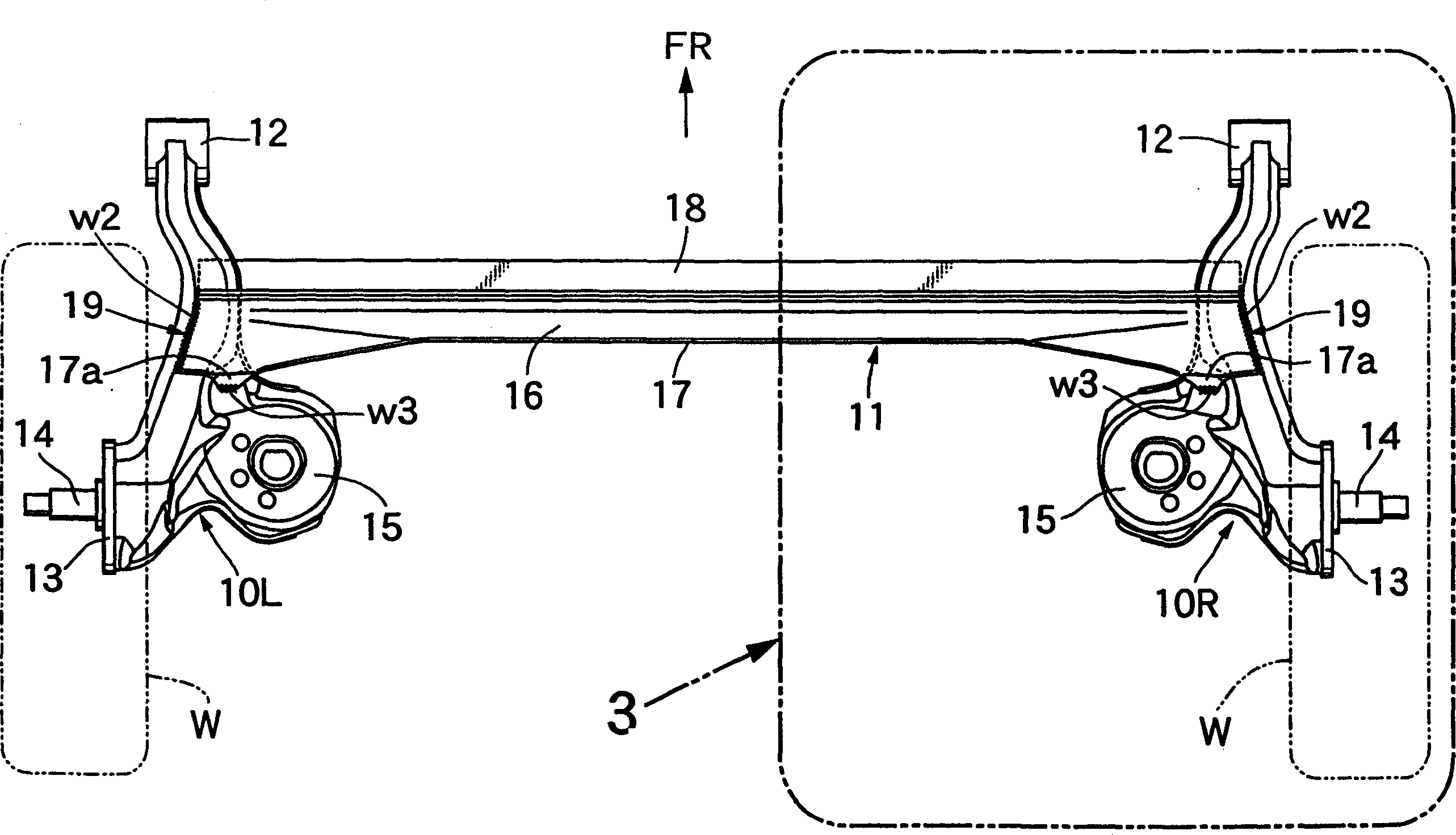

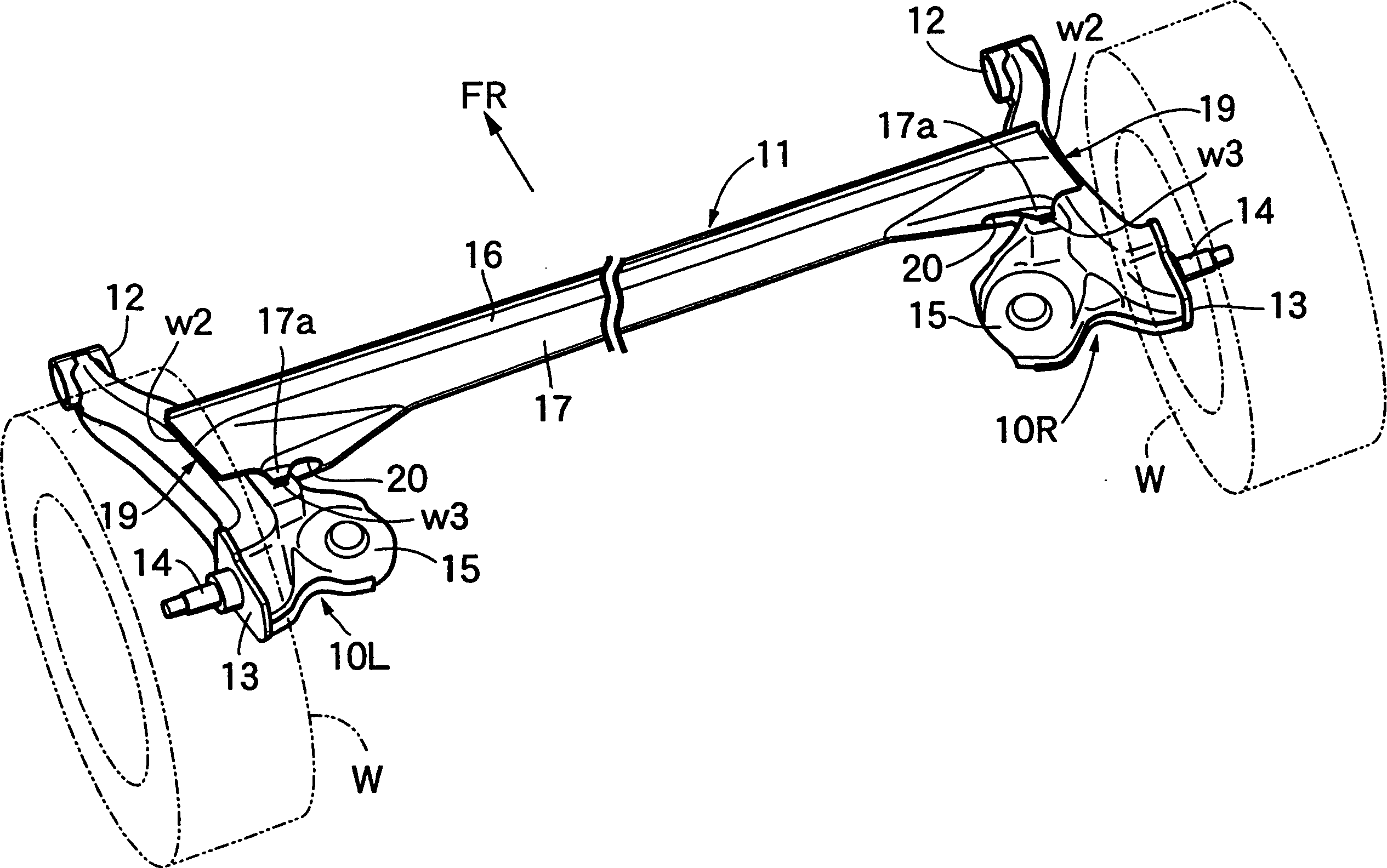

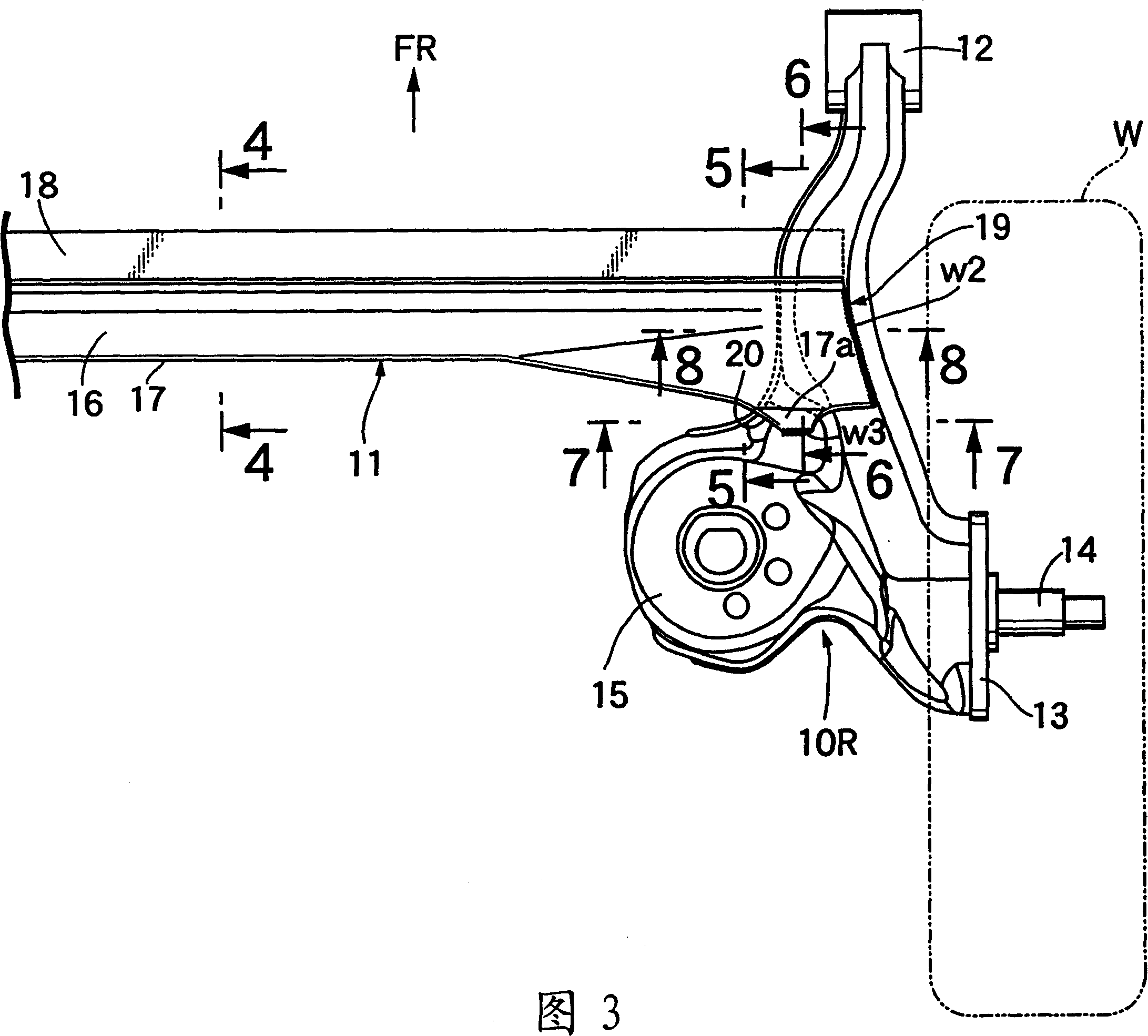

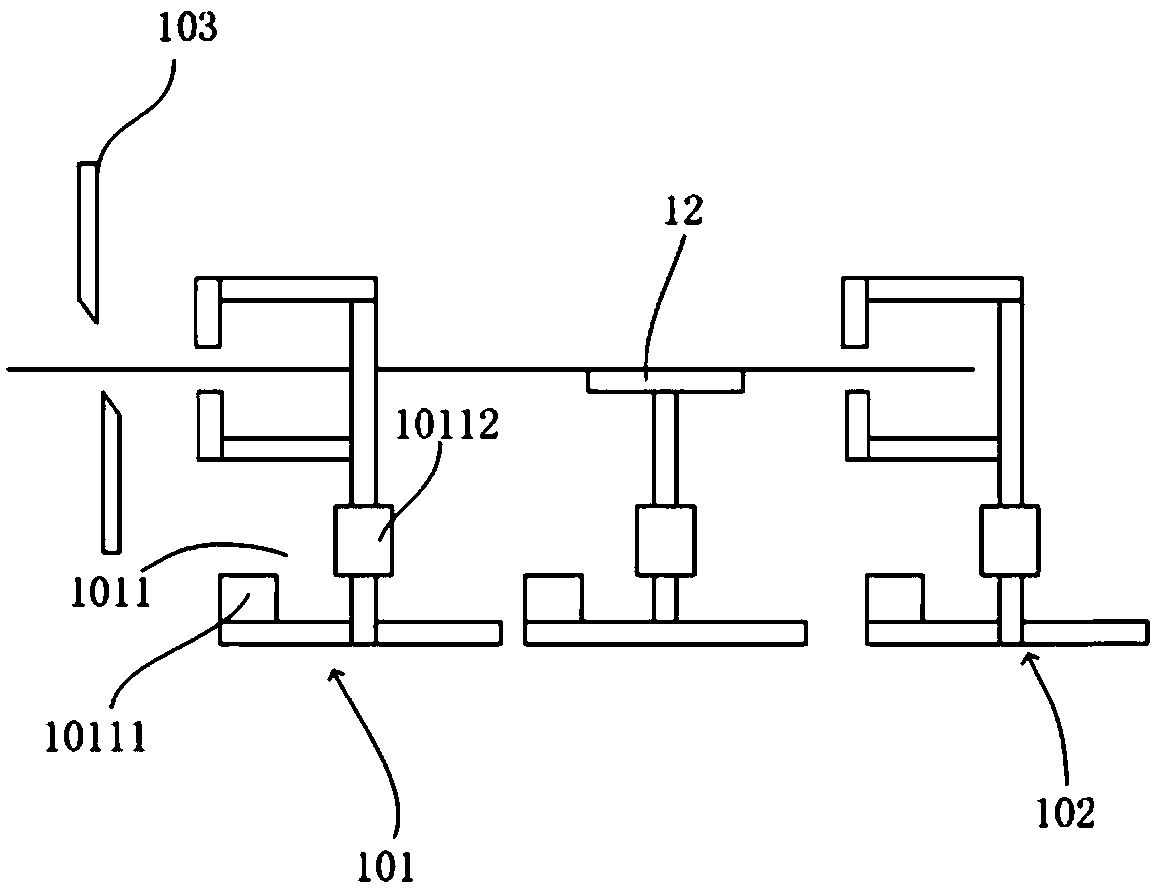

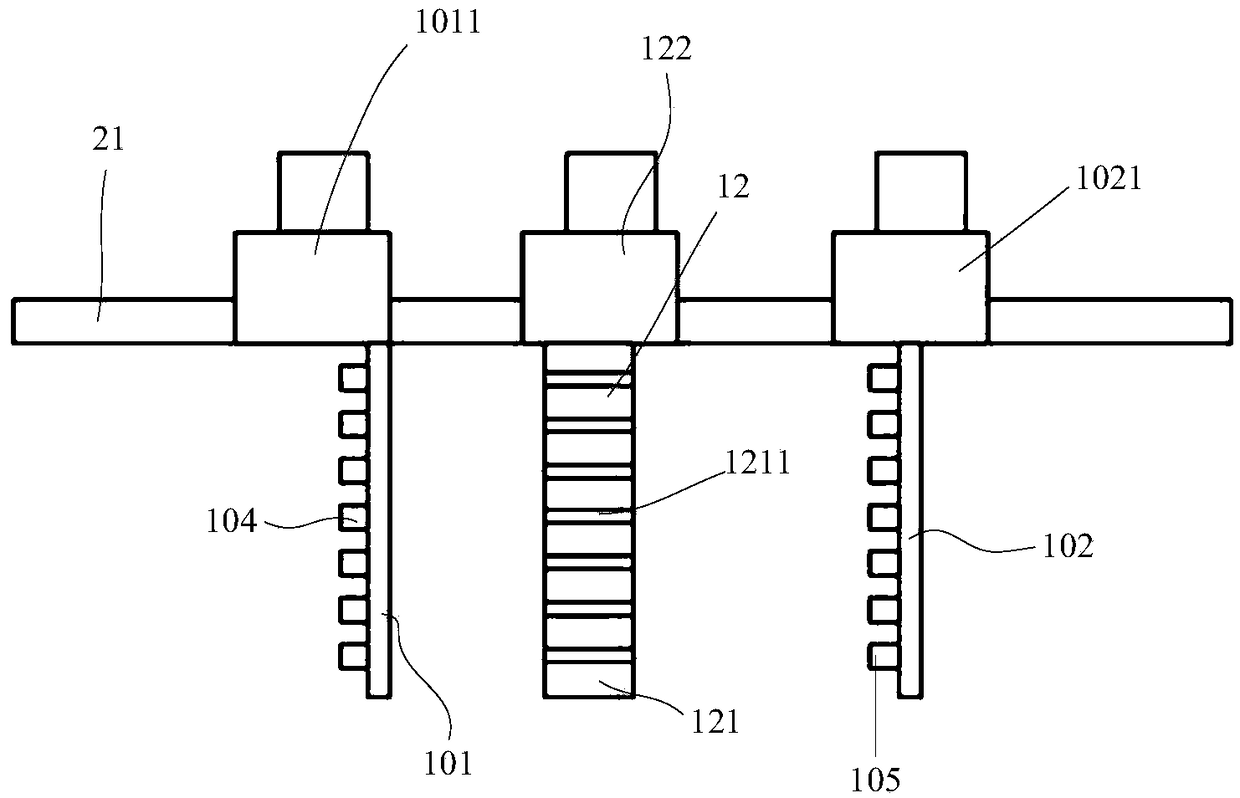

Torque beam suspension

InactiveCN1495054AIncrease toe-in rigidityImprove welding accuracyResilient suspensionsEffective lengthEngineering

To suppress increase in size of both end parts of a torsion beam to the minimum extent to reduce material cost and welding cost and increase effective length of the torsion beam capable of being twisted and deformed to ensure durability of a welded part. A torsion beam type suspension is constituted by connecting connection parts 19 at both ends of the torsion beam 11 having U-shaped cross section and extending in the right and left directions of a vehicle body with trailing arms 10L, 10R on the left and right sides extending in the forward and backward directions of the vehicle body and swinging vertically. The connection part 19 is provided with a slit 20 which is formed on a longitudinal wall 17 of the torsion beam 11 and extends in the left and right directions and whose one end is opened and upper and lower flanges 17a overhanging in the forward and backward directions from upper and lower fringe parts of the slit 20. While the slit 20 is fitted into the trailing arms 10L, 10R, outer end fringes of an upper wall 16 and a lower wall and the upper and lower flanges 17a are welded on the trailing arms 10L, 10R. (C)2004,JPO.

Owner:HONDA MOTOR CO LTD +1

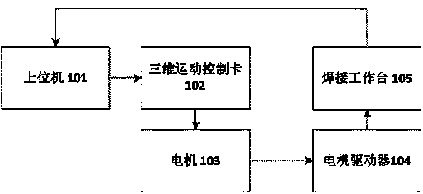

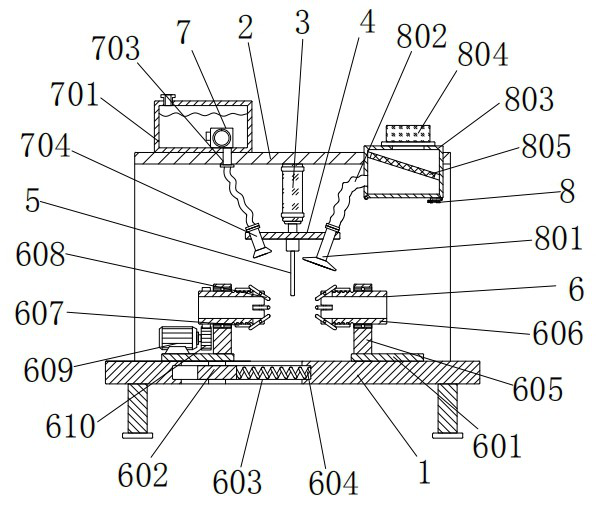

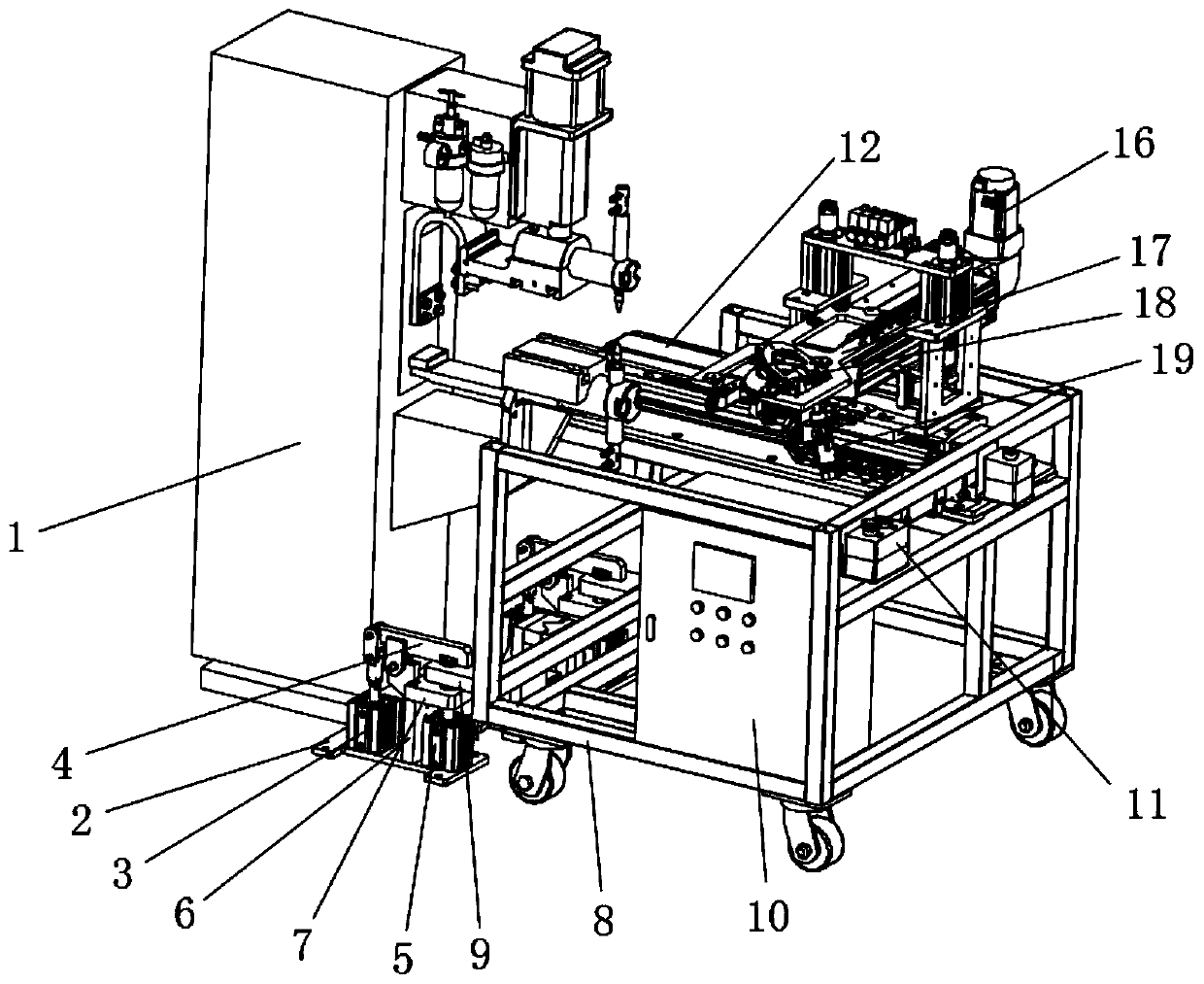

Motion control method suitable for automatic welding of complex curve device

InactiveCN104353926AImprove welding accuracyReduce complexityArc welding apparatusSpatial structureElectric machine

The invention discloses a motion control method suitable for automatic welding of a complex curve device. The motion control method comprises the following steps: a three-dimensional motion control card is plugged in a PCI bus interface of an upper computer, and is connected with an automatic welding bench through a motor; the three dimensional spatial structure of a to-be-welded device is simulated on the upper computer; a control instruction is sent to the three-dimensional motion control card according to the three dimensional spatial structure of the to-be-welded device; the three dimensional control card controls the working state of the motor according to the control instruction; the motor controls the welding bench to conduct linkage according to the predetermined motion of the three dimensional spatial structure of the to-be-welded device; the welding bench conducts automatic welding on the to-be-welded device, and feeds back current welding coordinate to the upper computer in a real-time manner. The motion control method is suitable for welding of a complex curve path, and has the advantages that the motion control method is low in cost, flexible to control, and high in work efficiency and automation degree.

Owner:JIEYANG SHUNXING STAINLESS STEEL IND +1

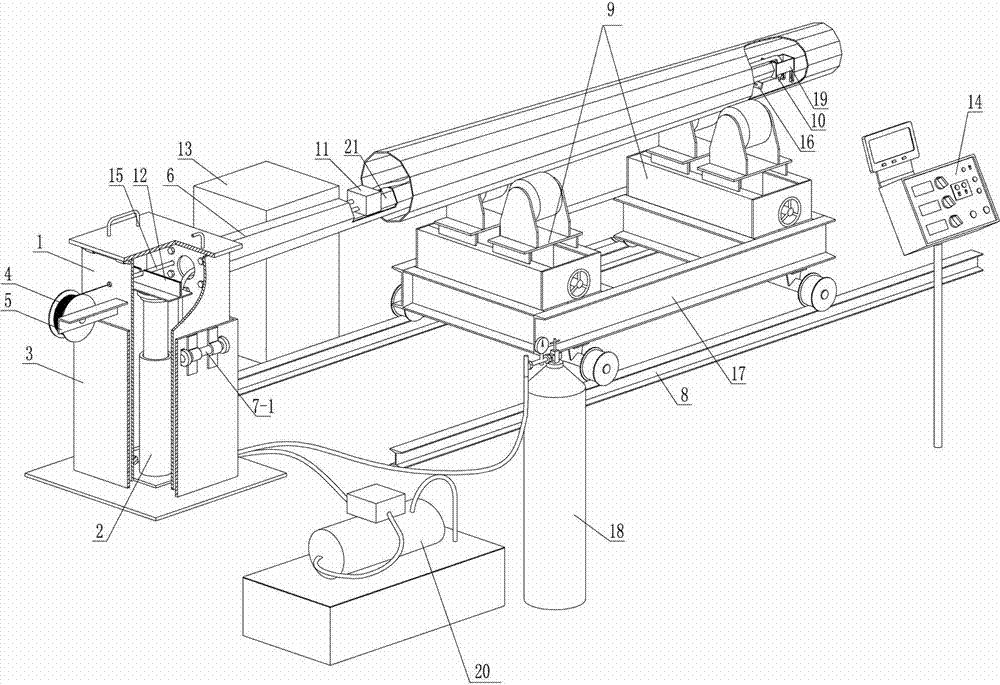

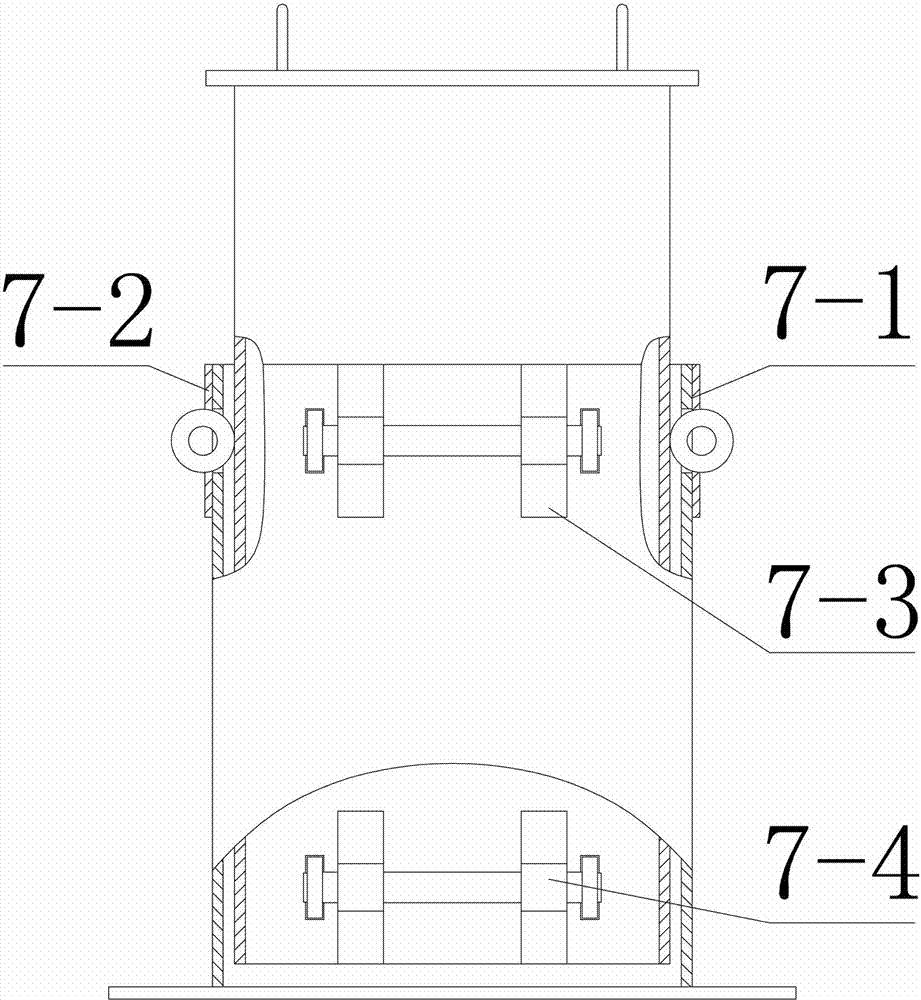

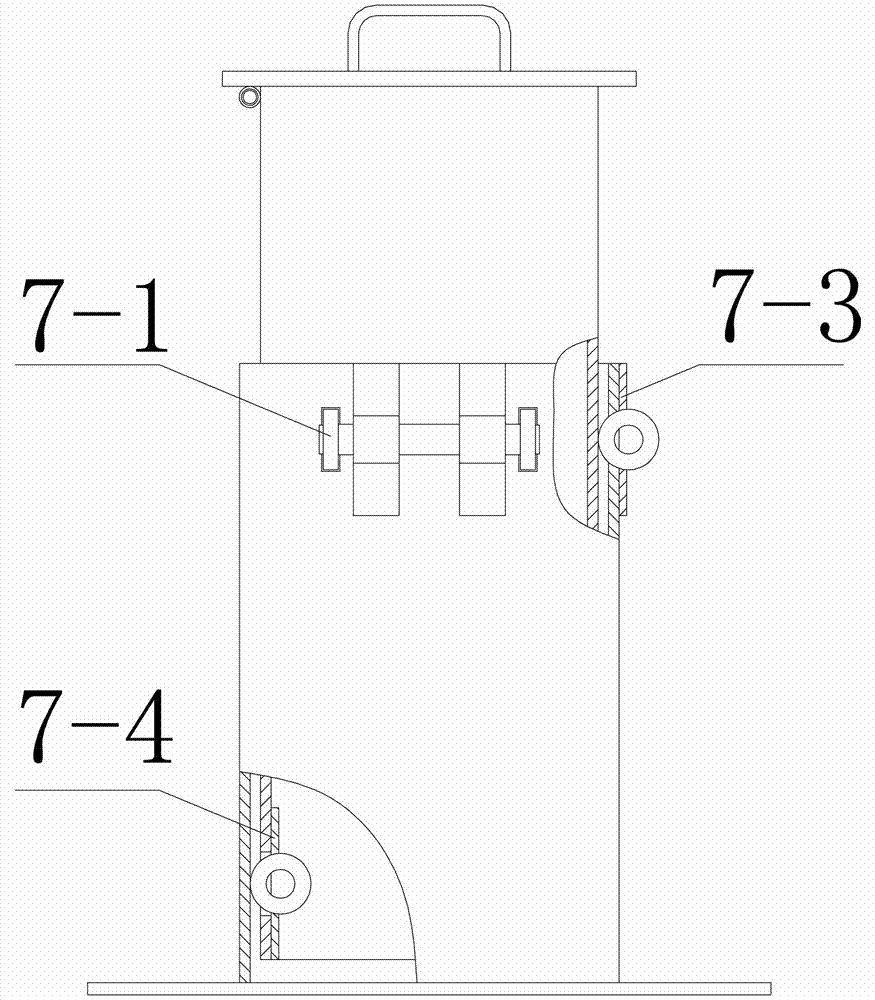

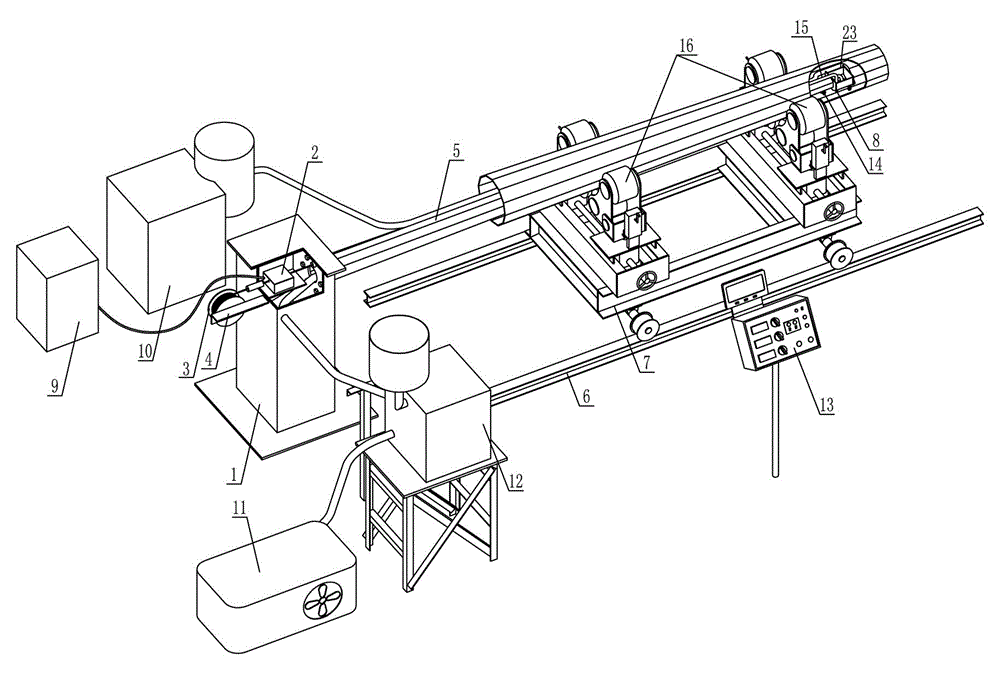

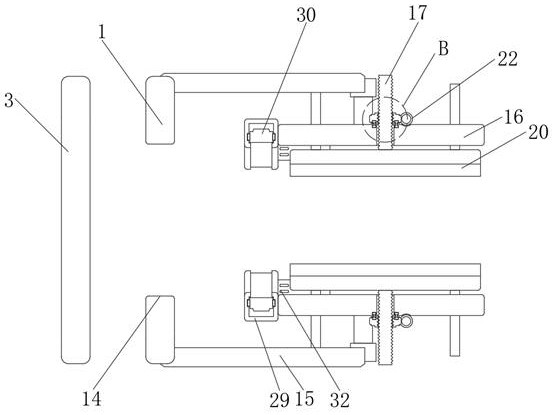

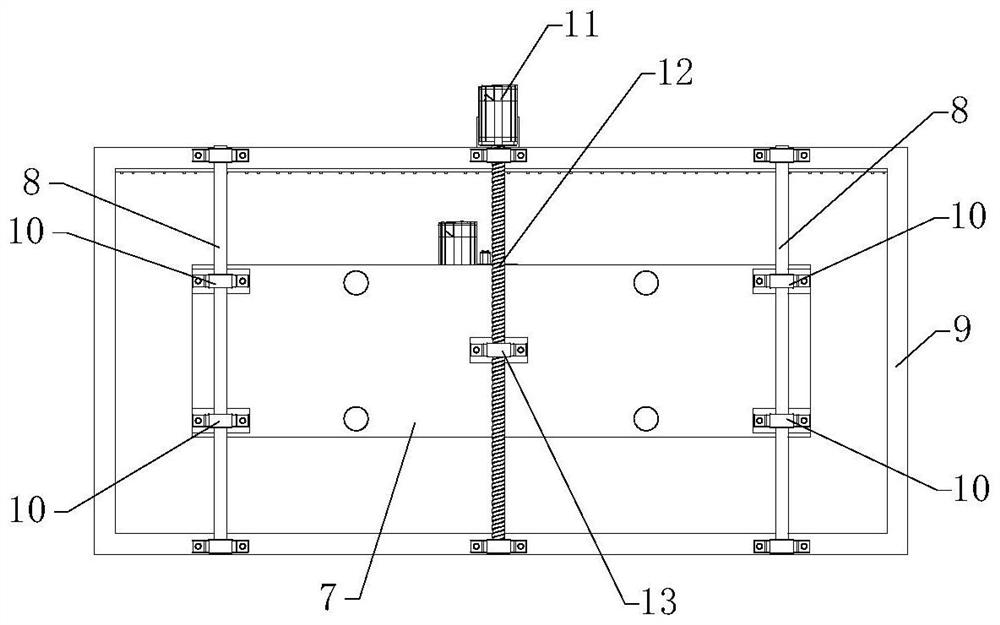

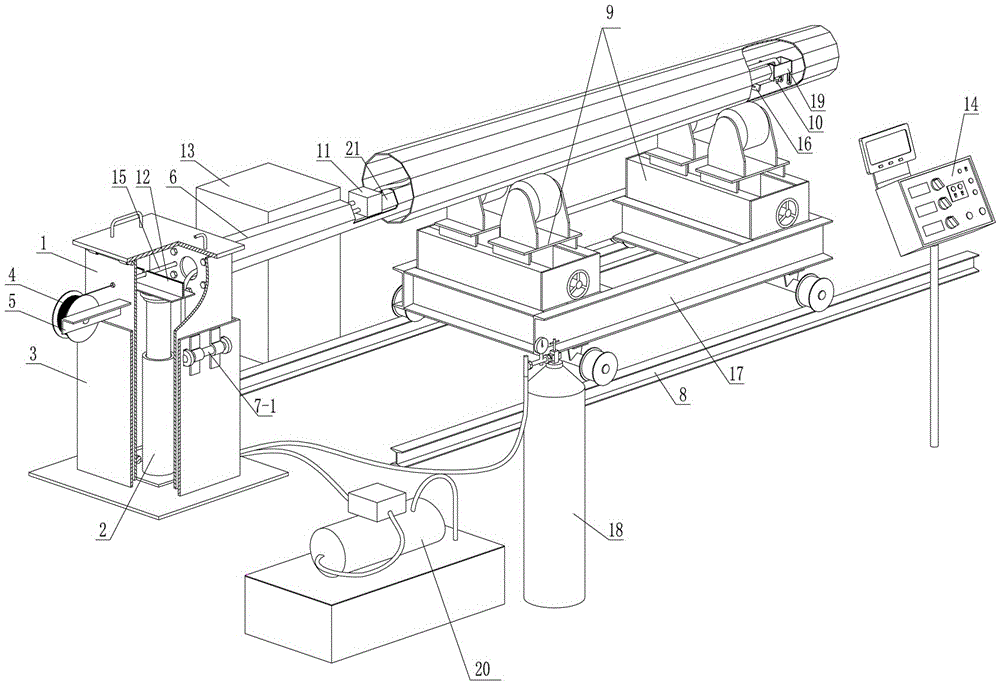

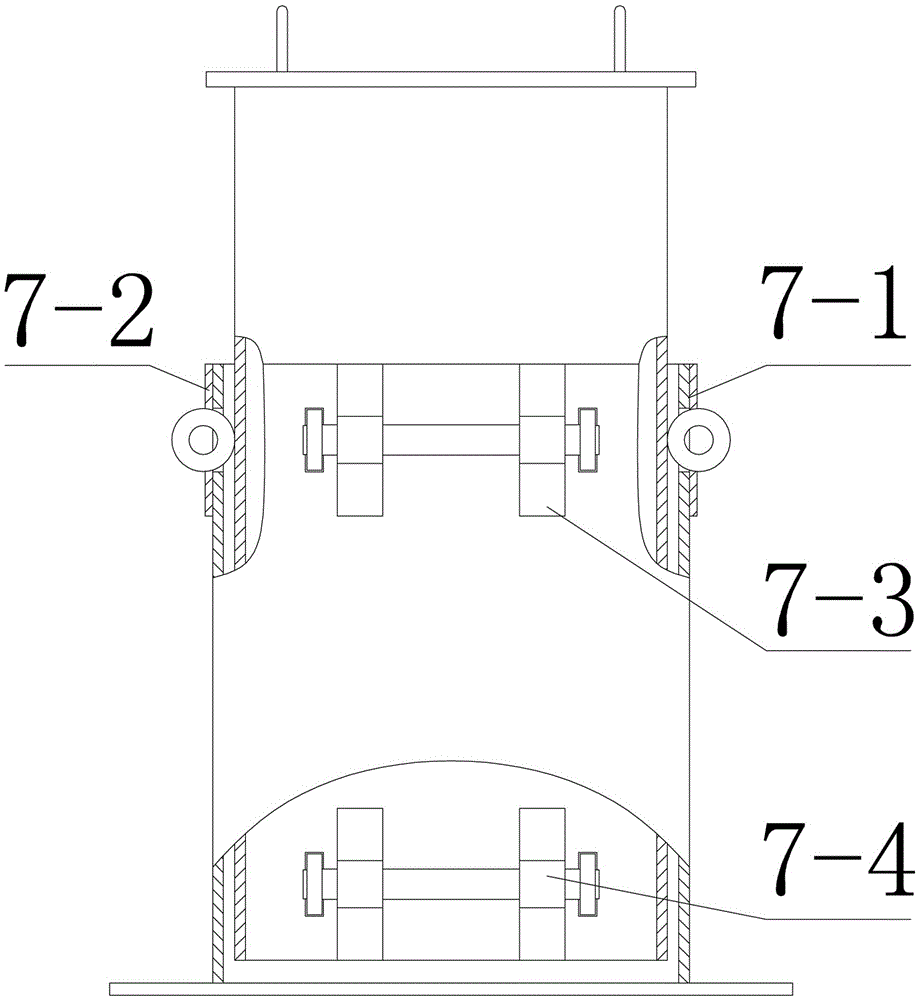

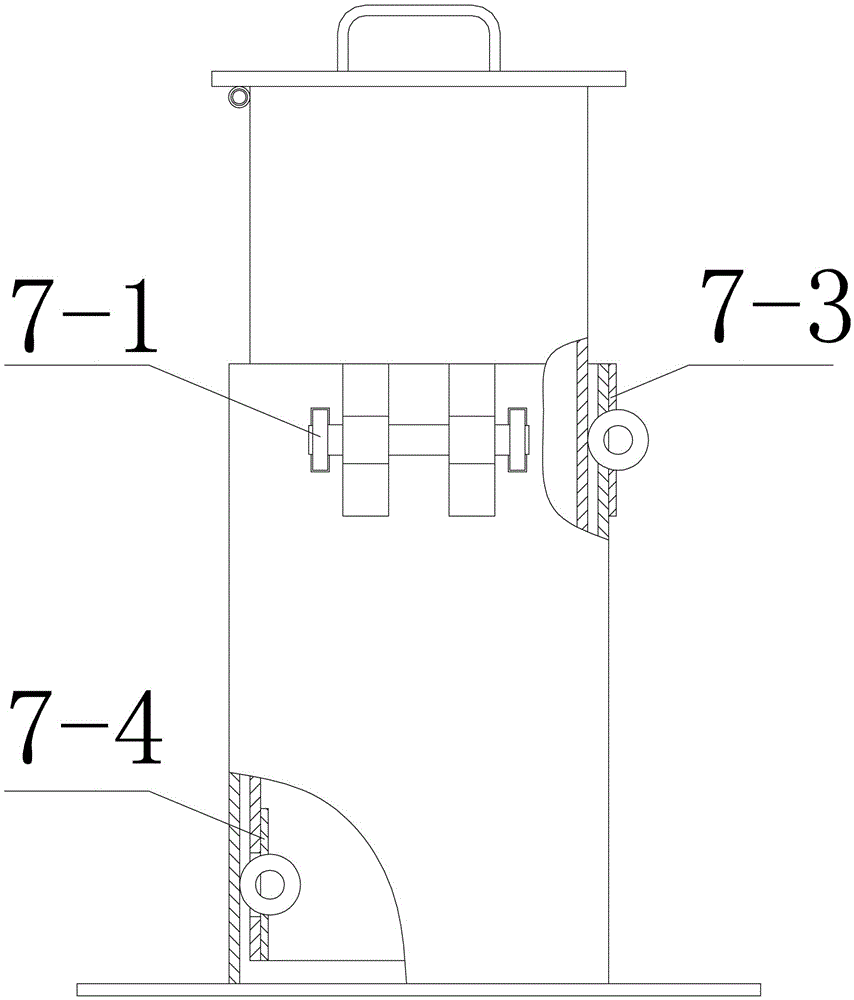

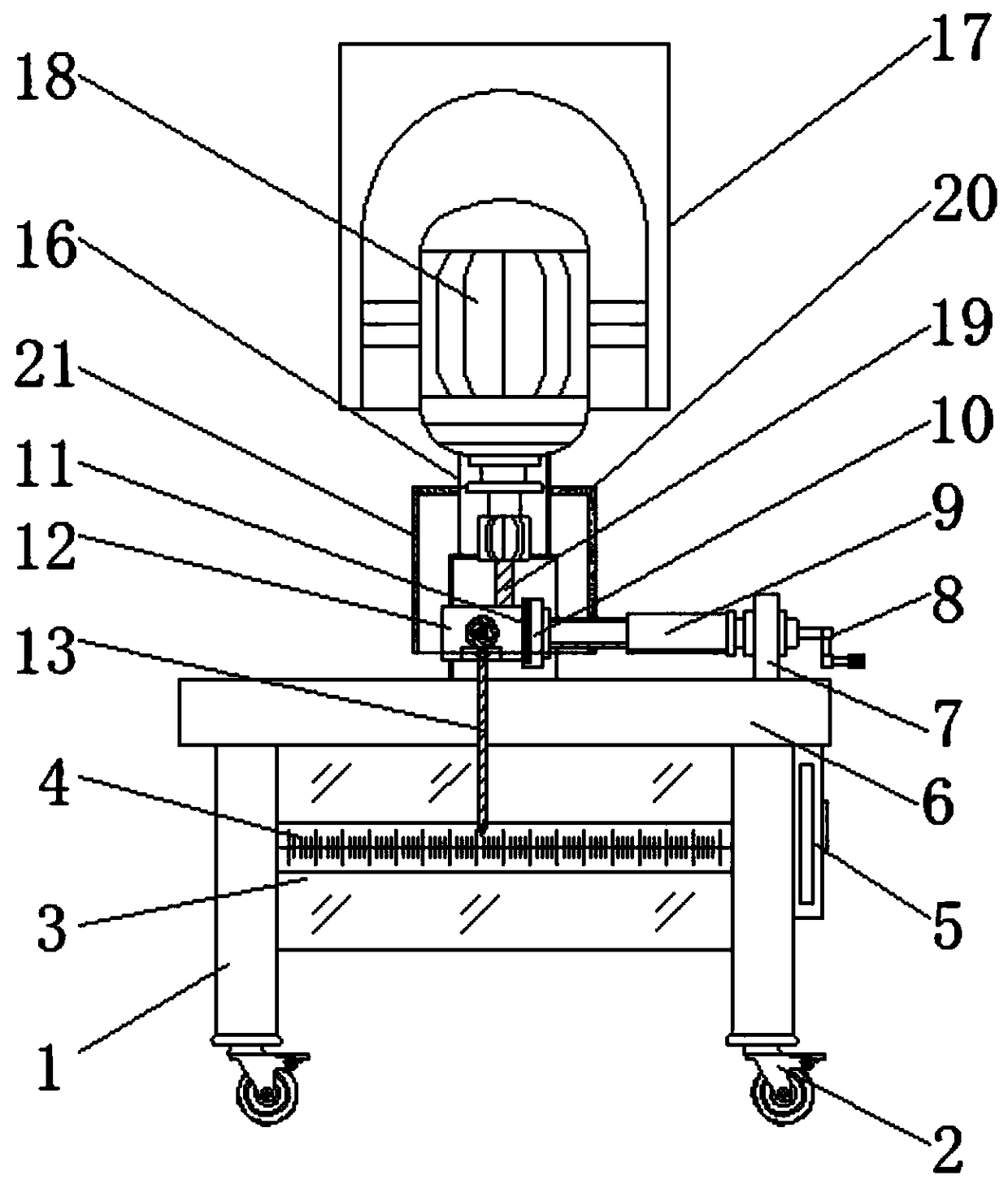

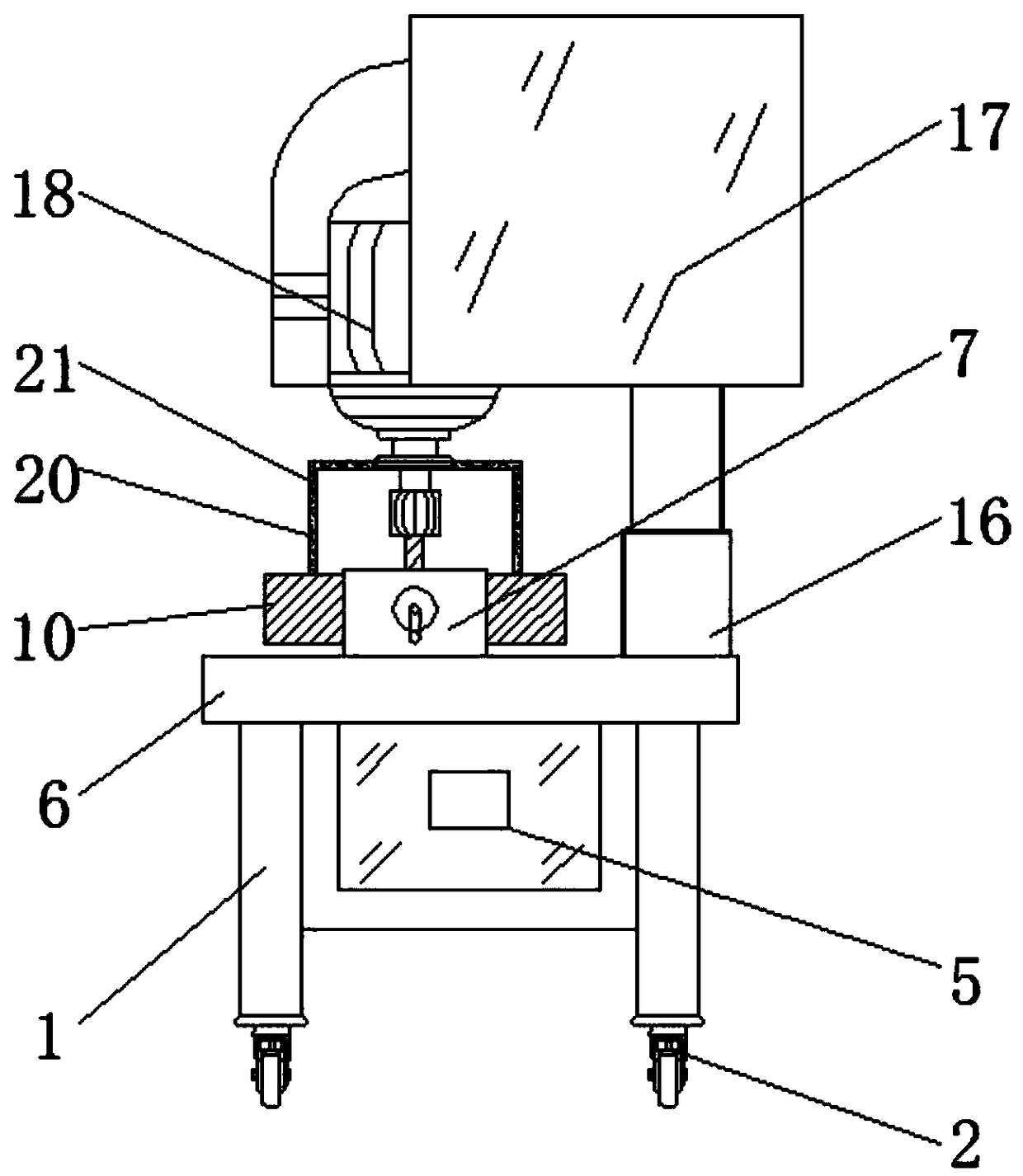

Automatic submerged arc welding device for longitudinal seams in steel tubes

InactiveCN104400198AIncrease stiffnessAvoid accumulationElectrode supporting devicesMetal working apparatusSteel tubeSubmerged arc welding

The invention relates to an automatic submerged arc welding device for longitudinal seams in steel tubes. The device comprises a machine head, an automatic wire feeder, a support arm, a running gear, a welding gun, a wire reel support, an air compressor, a flux conveyer, a welder, a flux recycling machine and a control box, wherein the automatic wire feeder is fixedly arranged in the machine head; the wire reel support is arranged on one side of the outside of the machine head; one end part of the support arm is fixedly arranged on the other side of the machine head; the other end part of the support arm is fixedly provided with a support wheel frame; the welding gun is arranged in the support wheel frame; the welder, the air compressor, the flux conveyer and the flux recycling machine are adjacent to the machine head respectively; the welder is connected with the welding gun through a wire; the flux conveyer is connected with the air compressor through a communicating tube; the control box is arranged on the outer side of the running gear. The automatic submerged arc welding device is simple in structure and convenient to operate, time and labor are saved, the labor intensity is reduced, a welding operator is not required to enter a steel tube to implement other welding methods, harmful gas is prevented from harming the operator, and the welding quality of welding lines is improved.

Owner:河北省景县宏远通讯有限公司

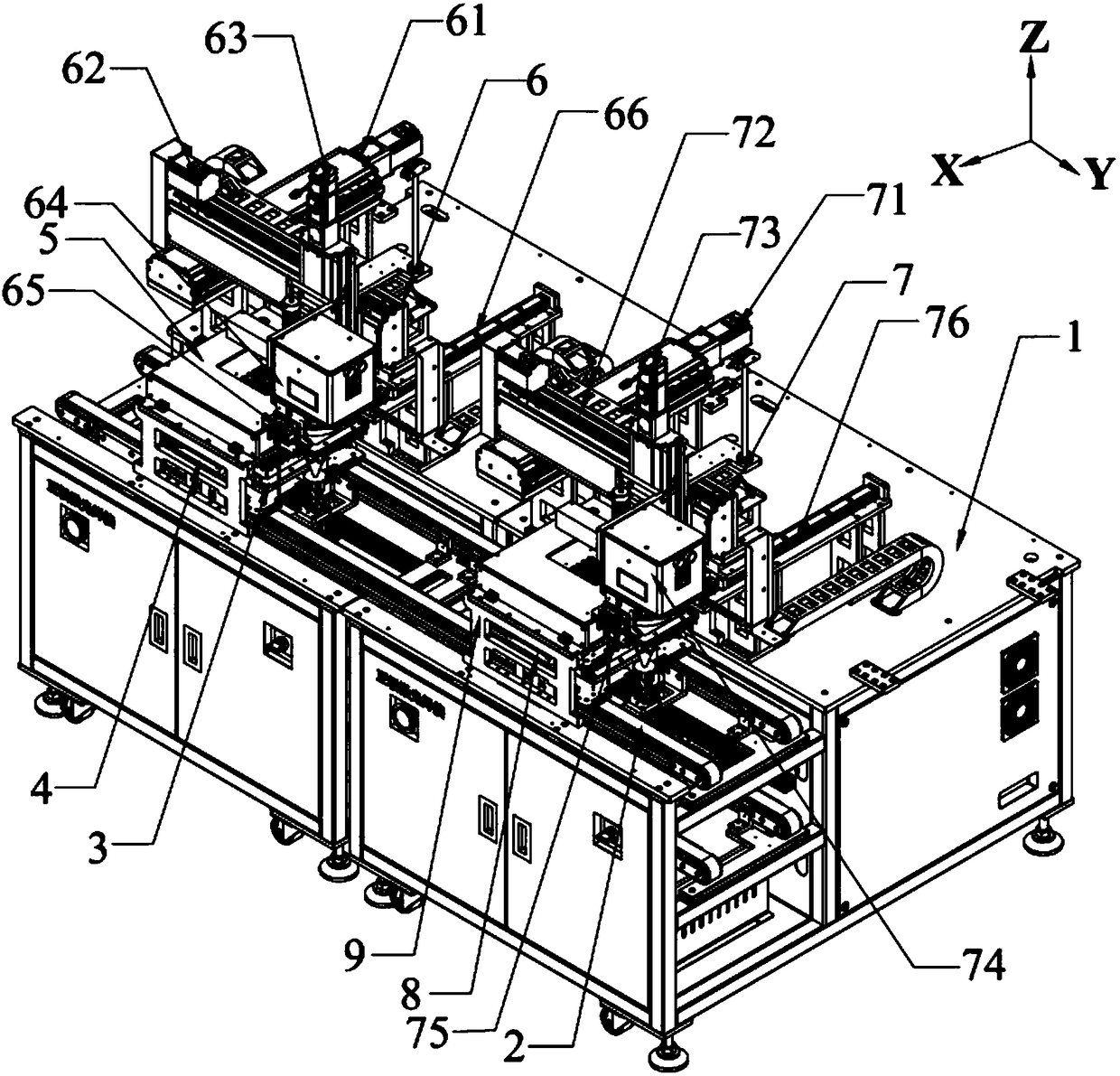

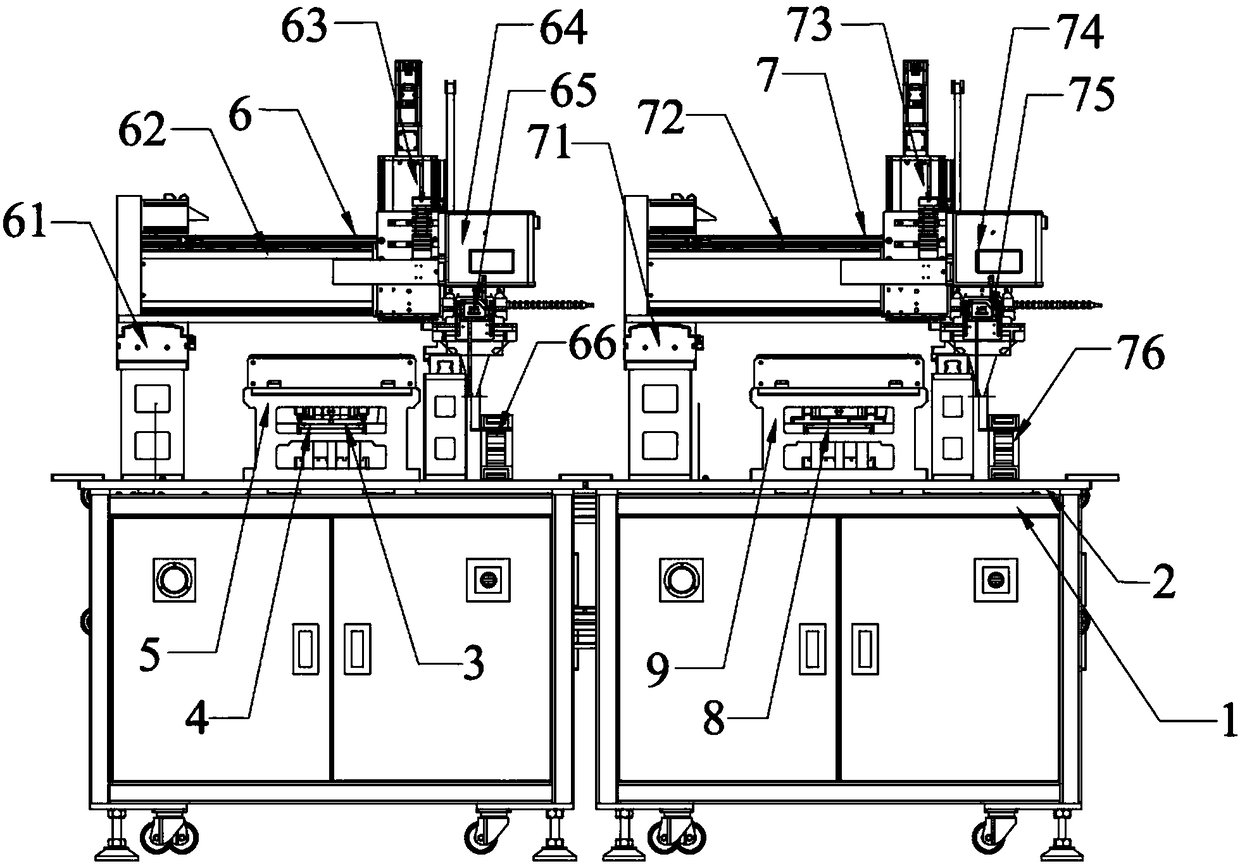

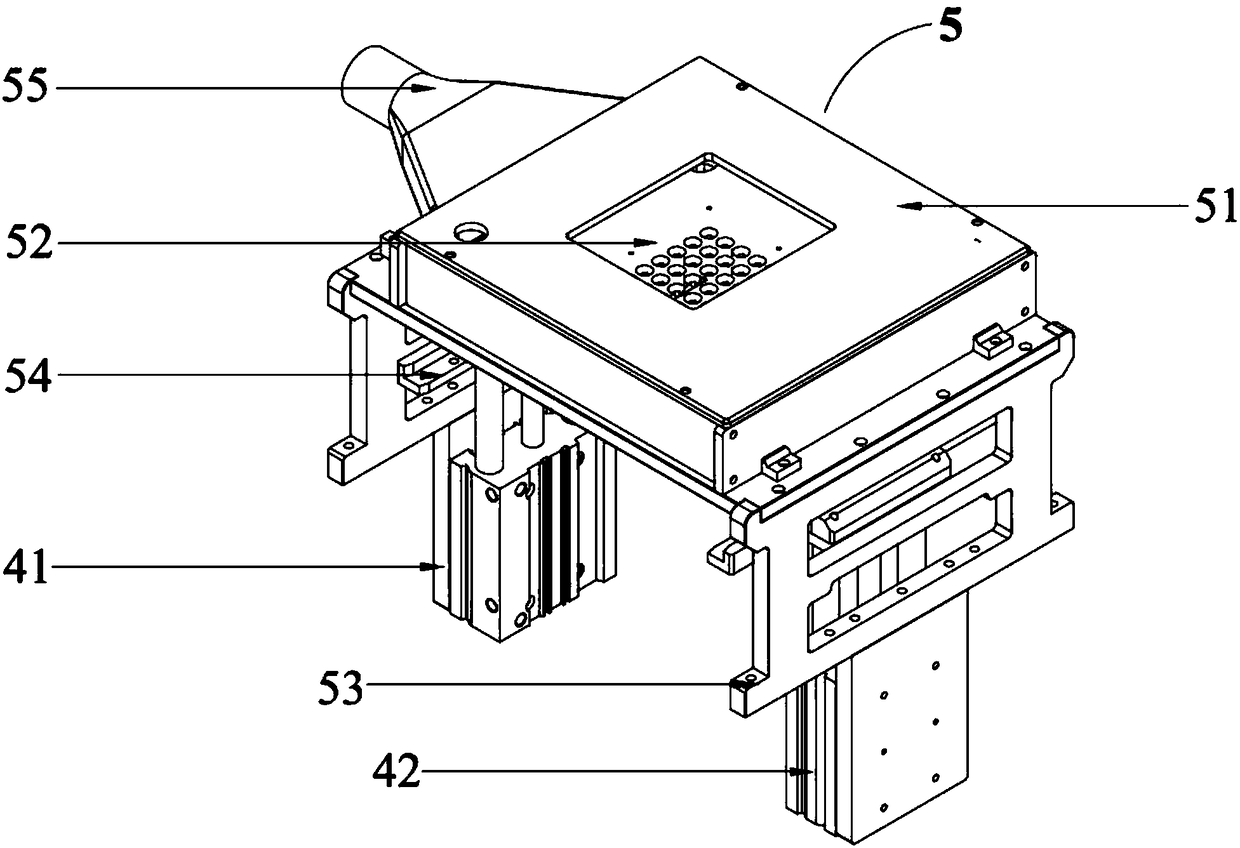

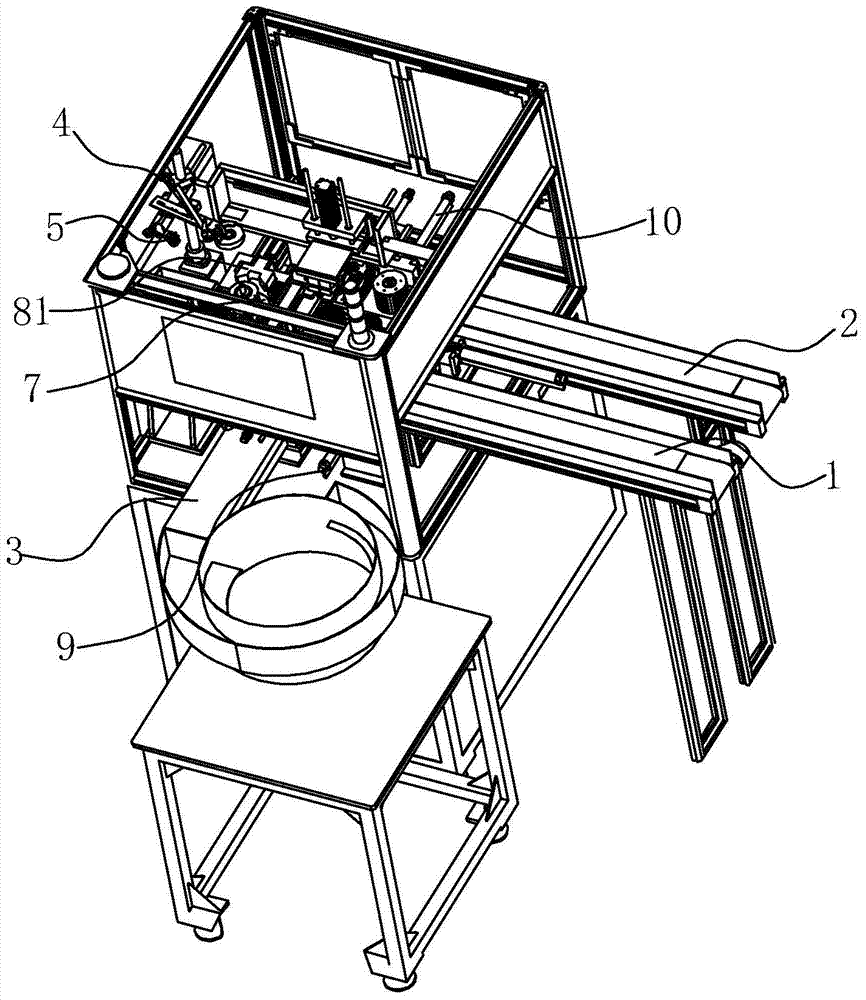

Laser spot welder for battery

PendingCN108145313APrecise positioningImprove welding efficiencyLaser beam welding apparatusEngineeringSpot welding

The invention discloses a laser spot welder for a battery. The laser spot welder comprises a machine frame, a conveying line, multiple carriers and at least one welding station, wherein the conveyingline is arranged on the machine frame, the multiple carriers are arranged on the conveying line and are used for carrying to-be-welded cell modules, and the welding stations are arranged on the machine frame; each welding station comprises a spot welding mechanism and a stopping part, wherein the spot welding mechanisms and the stopping parts are arranged on the machine frame; and when the carriers carrying the to-be-welded cell modules run within the motion stroke of the spot welding mechanisms, the stopping parts enable the carriers to keep in a static state, and the spot welding mechanismsperform welding actions on the to-be-welded cell modules. According to the laser spot welder for the battery, batch welding can be automatically carried out on positive poles of the to-be-welded cellmodules, so that the problem that in the prior art, the welding efficiency is low is solved, and the welding efficiency is improved.

Owner:HUIZHOU DESAY AUTOMATION TECH

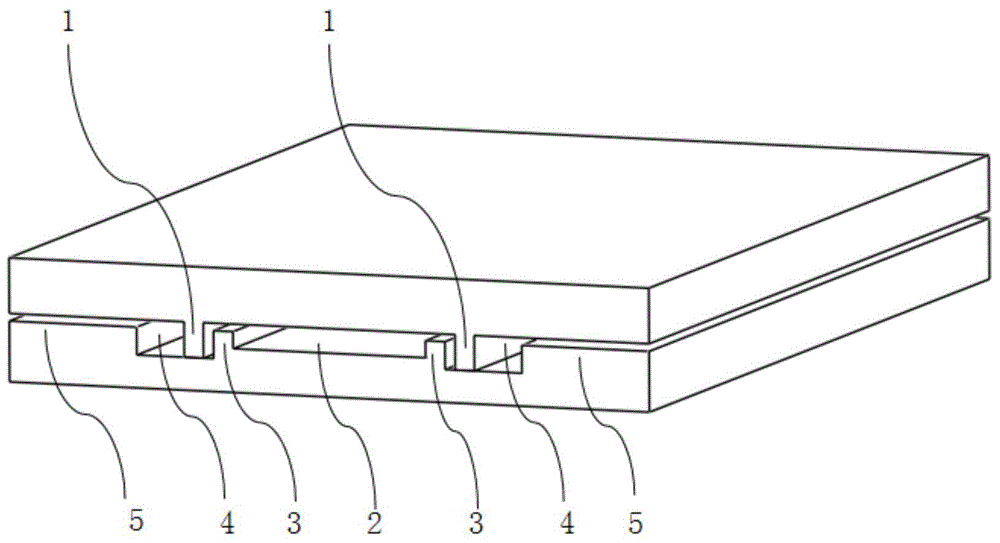

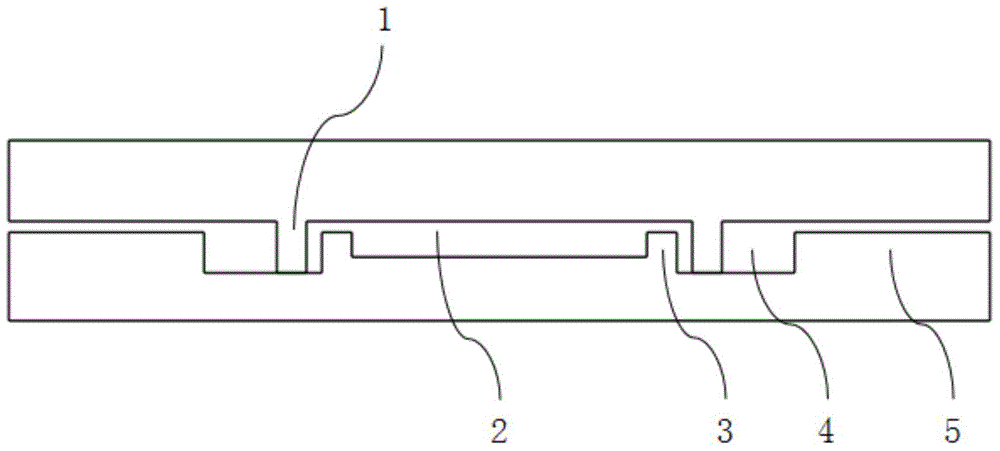

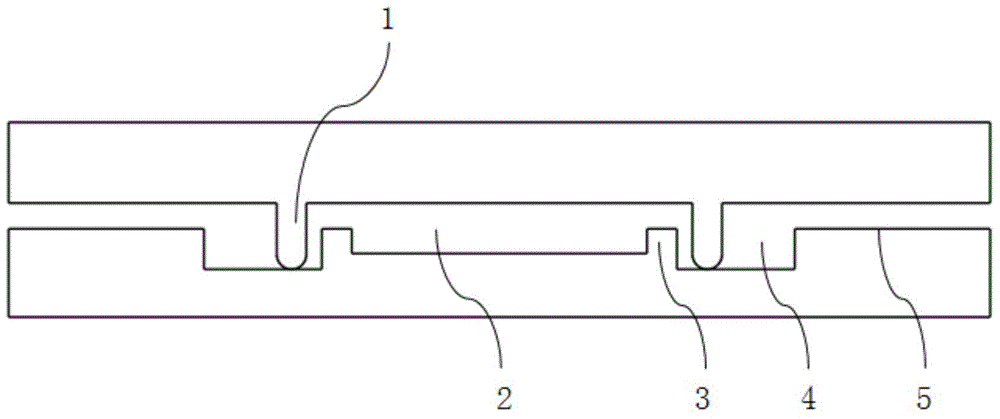

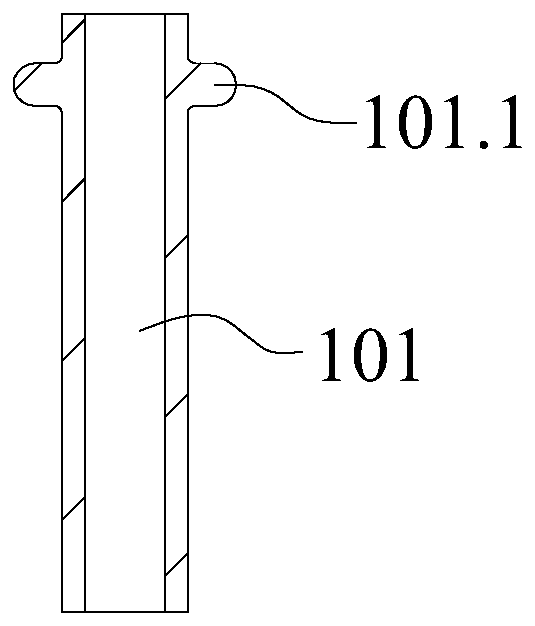

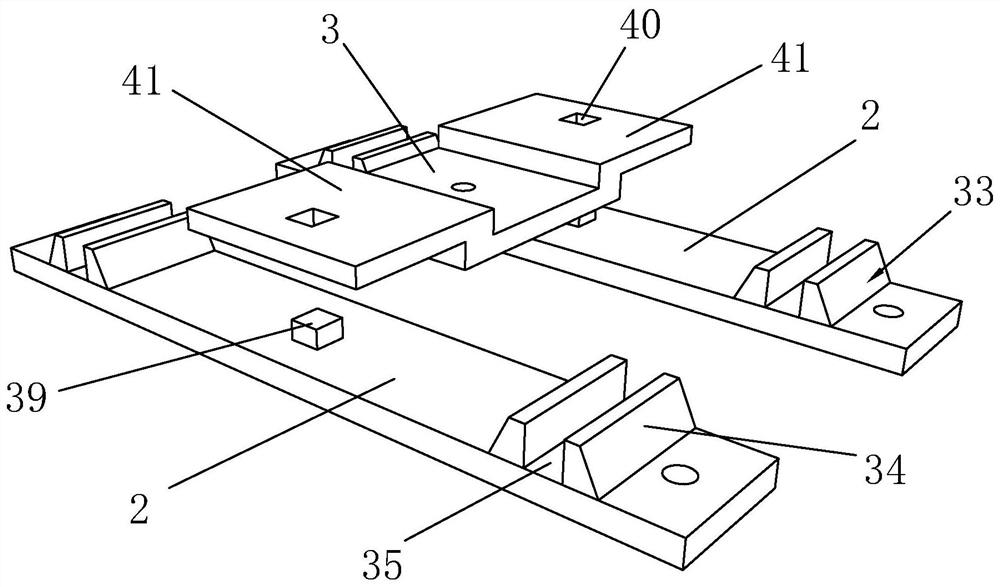

Joint structure used for flow casting control and weld stopping control of POCT chip product ultrasonic welding

InactiveCN104960195AImprove accuracyImprove welding accuracyDomestic articlesUltrasonic weldingStructure of the Earth

The invention provides a joint structure used for flow casting control and weld stopping control of POCT chip product ultrasonic welding. The joint structure is characterized in that a micro channel, weld ponds, weld stopping platforms and flow blocking platforms are formed in a substrate; energy-oriented ridges are formed in a cover plate; the cover plate is installed on the substrate, and the alignment and location between the cover plate and the substrate are achieved through the cooperation between the energy-oriented ridges and the weld ponds; in the ultrasonic welding process, molten polymers are stored in the weld ponds, the polymers are prevented from overflowing, and the melting and flow casting control of the polymers is achieved; a large amount of welding energy is absorbed through the weld stopping platforms, the fusion welding operation of the energy-oriented ridges is stopped, and the weld stopping control is achieved. By means of the joint structure, the problems that in the ultrasonic welding process of a POCT chip, the micro channel is prone to being blocked, and the control accuracy of the channel height is poor are solved, and the joint structure has the advantages of being simple in structure, convenient to align and high in welding strength.

Owner:DALIAN UNIV OF TECH

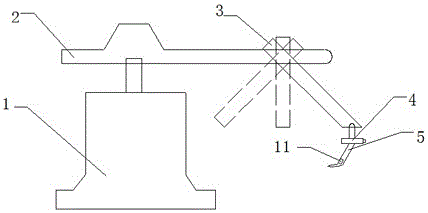

Robot-based automatic welding apparatus especially for steel grating plate and working method thereof

ActiveCN104985301AImprove welding accuracyGuaranteed stabilityArc welding apparatusWelding/soldering/cutting articlesGratingAutomatic control

Disclosed in the invention is a robot-based automatic welding apparatus especially for a steel grating plate. The robot-based automatic welding apparatus comprises a fixed seat, a horizontal shaft, a first joint shaft, a second joint shaft, a welding gun, and a control device. The fixed seat is fixed on the ground by foundation bolts; the horizontal shaft is fixed on the fixed seat by a positioning pin; and the horizontal shaft, the first joint shaft, the second joint shaft, and the welding gun are connected with the control unit by a circuit. According to the automatic welding apparatus, a position sensor is installed on an arm of a robot and is controlled by an automatic control system to localize a welding point accurately and thus cooperation with the welding gun is realized, thereby substantially improving the welding accuracy of the welding device, effectively guaranteeing the stability and consistency of the welding quality, effectively avoiding insufficient welding and solder skips and thus realizing precise welding. In addition, the invention also relates to a working method of the automatic welding apparatus.

Owner:SUZHOU WST ROBOT AUTOMATION CO LTD

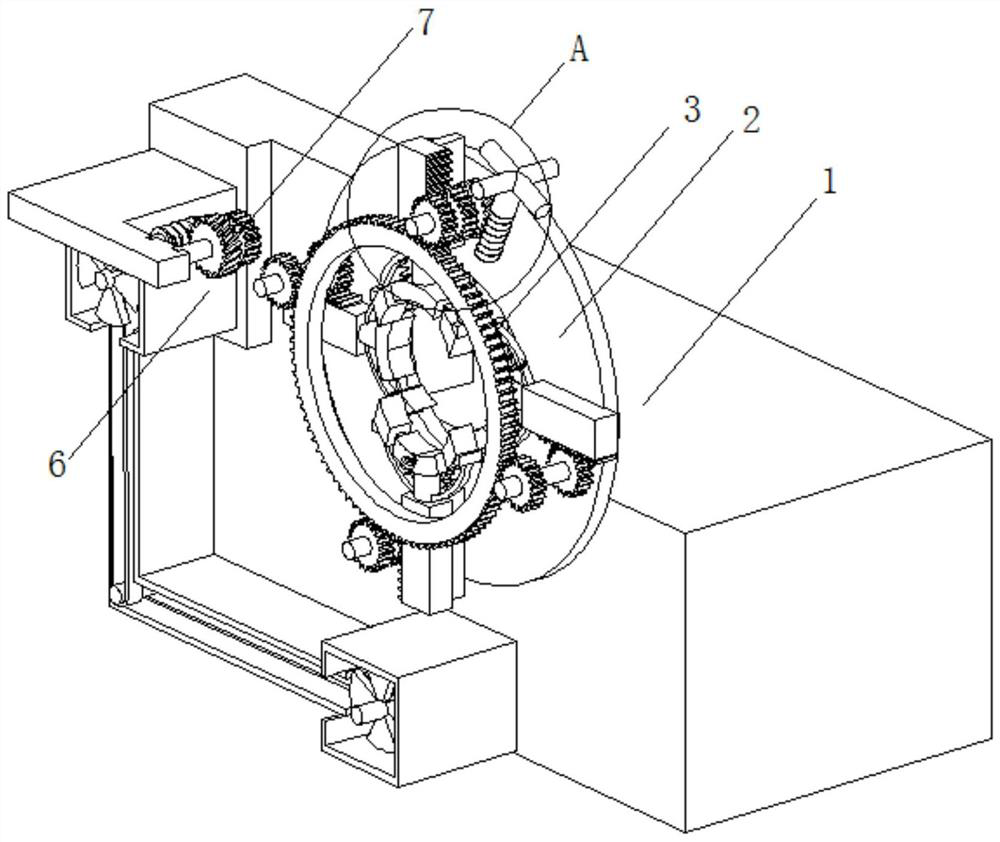

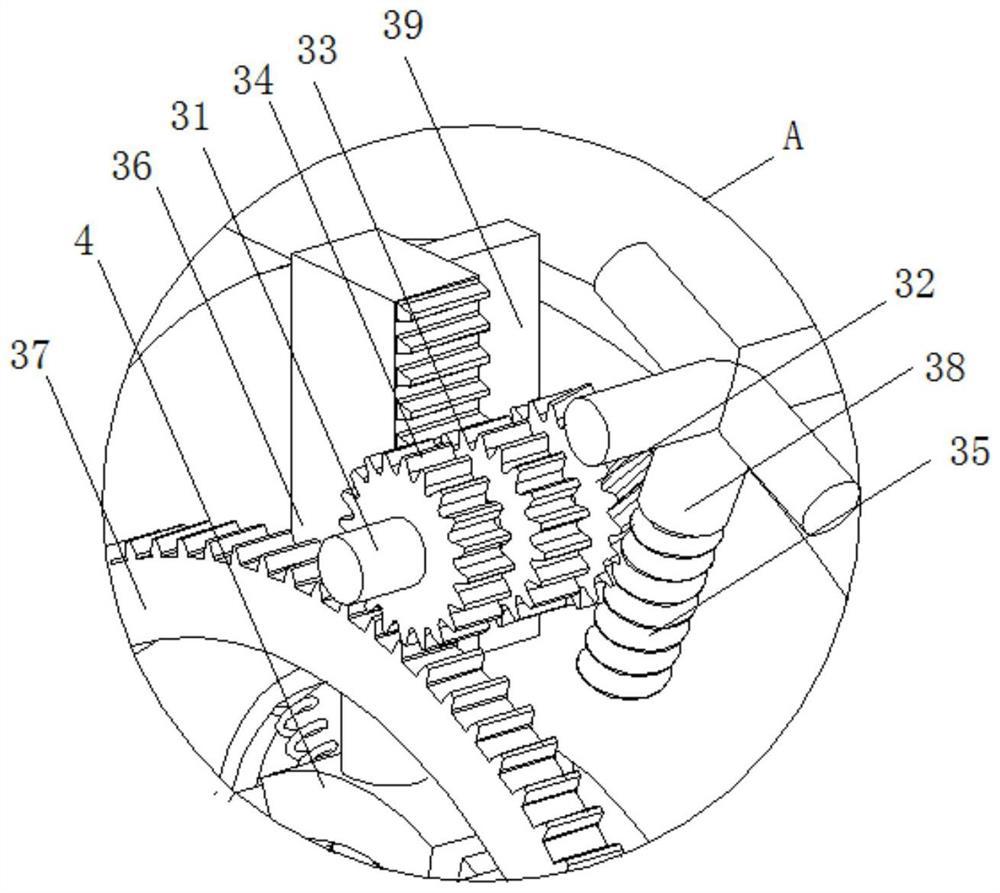

Auxiliary mechanism facilitating butt joint of building steel pipes

PendingCN113211002AAchieve clamping and fixing effectAvoid the problem of manual welding inconvenienceWelding/cutting auxillary devicesAuxillary welding devicesButt jointConstruction engineering

The invention relates to the technical field of steel pipe butt joint, and discloses an auxiliary mechanism facilitating butt joint of building steel pipes. The auxiliary mechanism comprises a butt joint table, the interior of the butt joint table is rotatably connected with a rotating seat disc, the interior of the rotating seat disc is provided with a fixing mechanism, and the surface of the fixing mechanism is provided with steel pipe bodies; and the front portion of the butt joint table is fixedly connected with a protection box through bolts, a rotating mechanism is arranged in the protection box, and the front portion of the protection box communicates with an air blowing pipe. According to the auxiliary mechanism facilitating butt joint of the building steel pipes, the effect of synchronously clamping and fixing the steel pipe bodies with different sizes in four directions is achieved through mutual operation of all structures in the fixing mechanism and the rotating mechanism, so that time and labor are saved, the effect that the steel pipe bodies are rotationally welded under the limitation of the inner structure of the rotating seat disc while air cooling is conducted is achieved, the problem that traditional manual surrounding welding is inconvenient is further avoided, and therefore the effect of assisting butt joint of the steel pipes is achieved.

Owner:牟丹

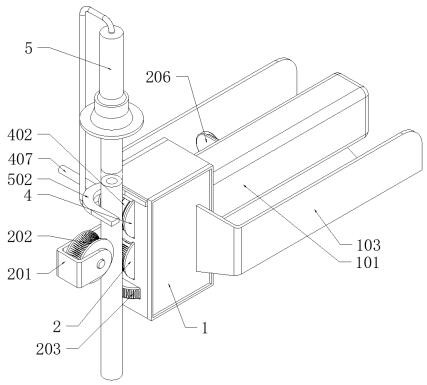

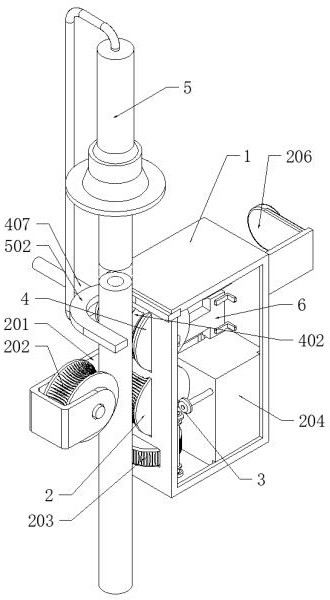

Handheld electric welding gun with automatic welding rod supply structure

ActiveCN114083093ARealize the rotary driveUniform coverageElectrode supporting devicesWelding protection meansDrive wheelHand held

The invention discloses a handheld electric welding gun with an automatic welding rod supply structure, and belongs to the field of electric welding. According to the invention, a first driving wheel and a clamping wheel are rotationally connected to a shell and a connecting plate correspondingly; a welding rod clamped in the middle of the first driving wheel can be conveyed through rotation of the first driving wheel, feeding operation can be automatically completed when the device is used for welding operation, the situation that the distance between a welding point and a human hand is too far is avoided, the welding difficulty is reduced, and the welding accuracy is improved; and a second driving wheel is rotationally connected to the inner end wall of the left side of the shell, rotation driving of the welding rod can be achieved, the welding rod can synchronously stir molten iron molten at the welding position during welding operation, the molten iron can cover the welding position more evenly, and the welding effect during welding is improved conveniently.

Owner:南通诺澳电子有限公司

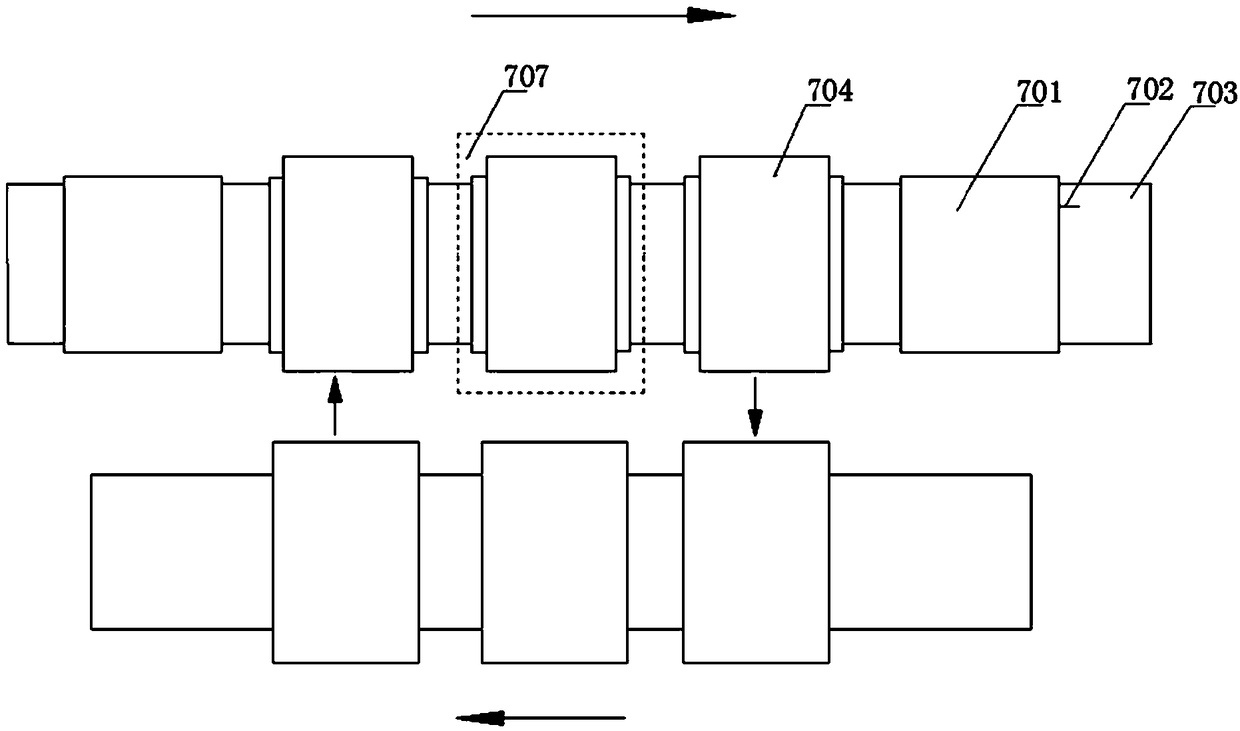

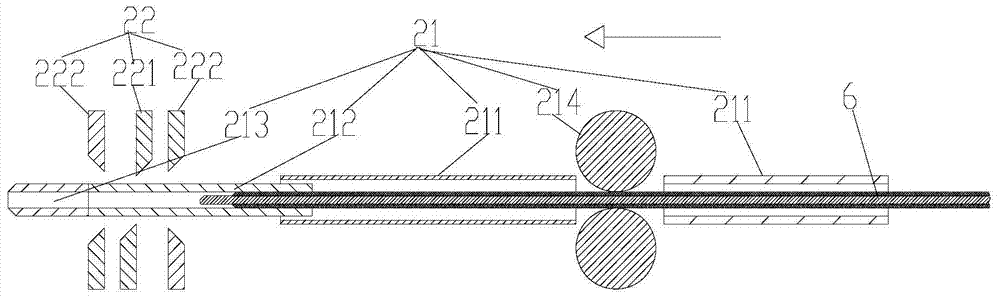

Welding strip pulling compressing device and method and series welding machine

PendingCN109277734AReduce processing timeImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention provides a welding strip pulling compressing device and method and a series welding machine. The welding strip pulling compressing device comprises a guiding welding strip device, a first pulling device, a second pulling device, a conveyor line and a welding strip positioning device, wherein the second pulling device is arranged at the rear side of the first pulling device; a batterypiece is put on the conveyor line; and the guiding welding strip device is arranged between the first pulling device and the second pulling device. The welding strip pulling compressing method comprises the steps that the first pulling device pulls a welding strip to the guiding welding strip device; the second pulling device pulls the welding strip to the battery piece; and the welding strip andthe battery piece are compressed together by the welding strip positioning device. The series welding machine uses the welding strip pulling compressing device and also comprises a battery piece feeding device, a welding strip feeding device and a welding device. The invention can comprehensively improve the welding operation efficiency and quality.

Owner:WUXI AUTOWELL TECH

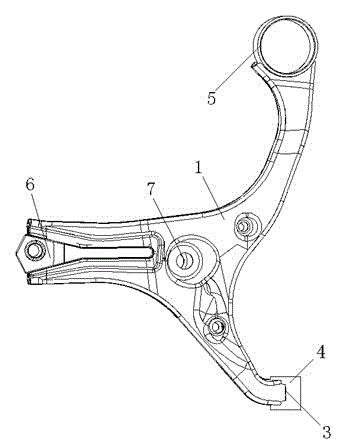

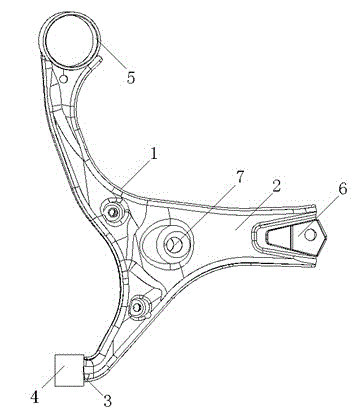

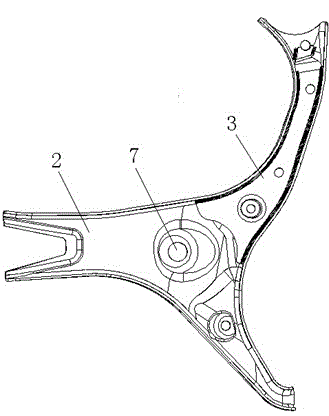

Automobile lower suspension arm assembly

InactiveCN104057796AImprove welding accuracyImprove connection strengthPivoted suspension armsMechanical engineeringAutomotive engineering

The invention discloses an automobile lower suspension arm assembly and belongs to the field of automobile parts. The automobile lower suspension arm assembly is mainly composed of a lower suspension arm main body assembly and a shaft pin lining sleeve, a front shaft sleeve and a ball pin bracket which are arranged on the lower suspension arm main body assembly, and is characterized in that the lower suspension arm main body assembly is composed of an upper plate, a lower plate and a reinforcing plate; the upper plate and the lower plate both have U-shaped structures; the two sides of the upper plate and the lower plate are connected through welding; the reinforcing plate is arranged in the lower plate; positioning holes are correspondingly formed in the upper plate, the lower plate and the reinforcing plate. According to the invention, the two sides of the upper plate and the lower plate are welded and the reinforcing plate is arranged on the lower plate, so that the connecting strength of the automobile lower suspension arm assembly is increased, the welding precision of the upper plate and the lower plate is increased, the firmness and strength of the automobile lower suspension arm assembly are greatly increased, and the automobile lower suspension arm assembly is difficult to deform and crack after long-term use and has the characteristics of simple processing, convenience in implementation, low production cost, and the like.

Owner:程龙凤

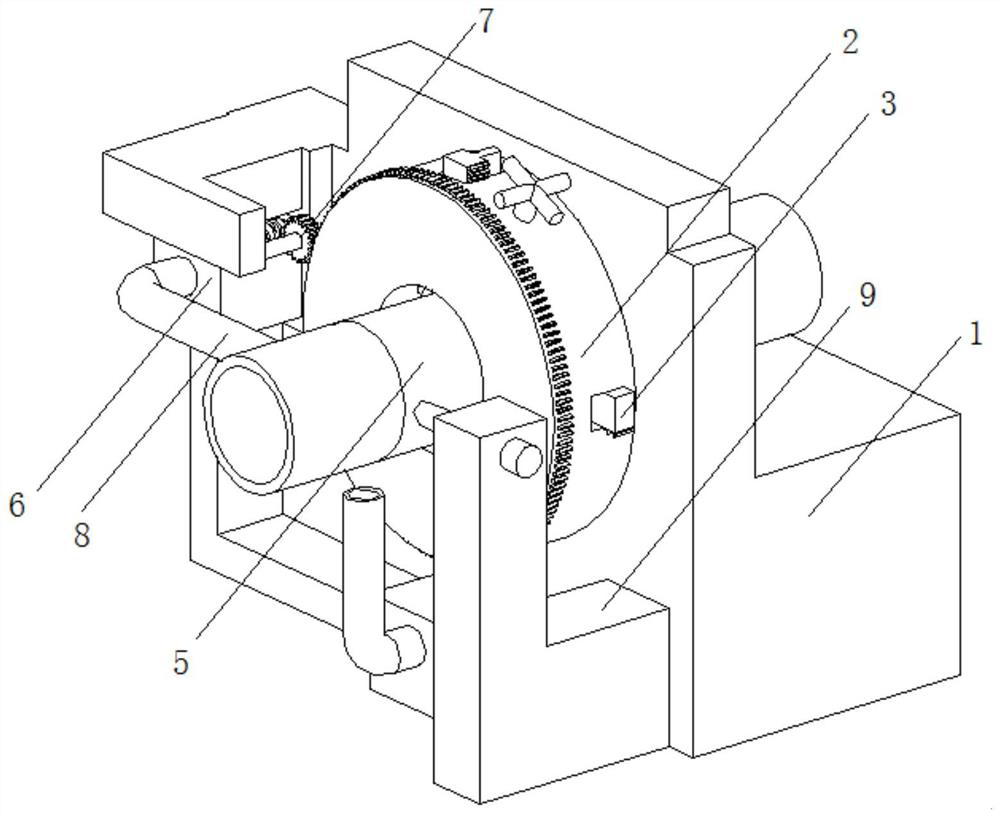

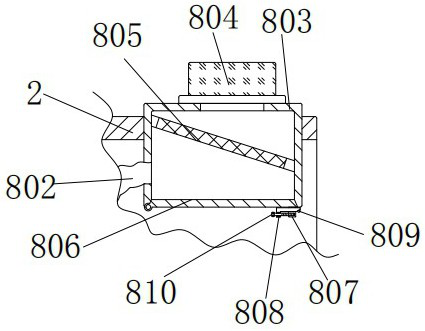

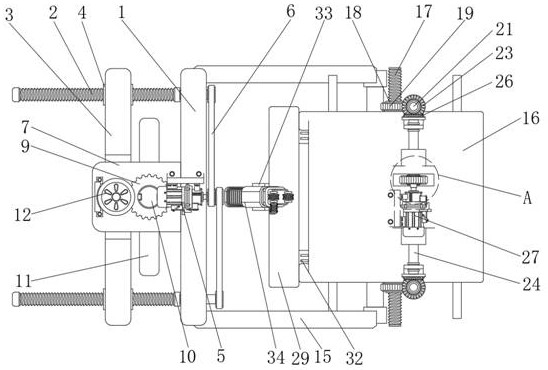

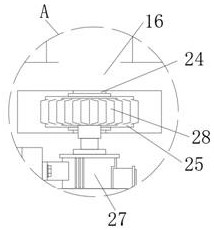

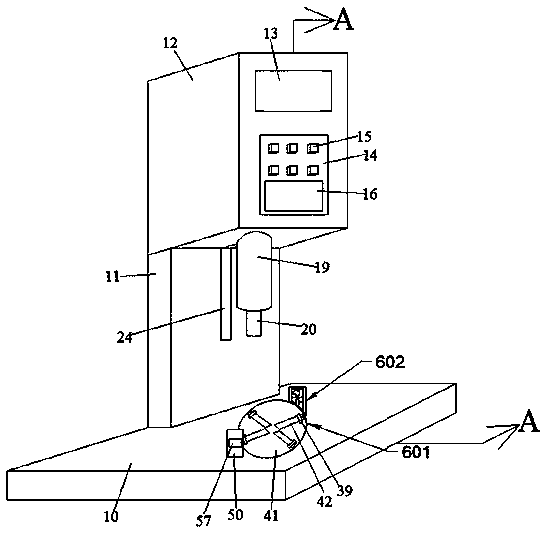

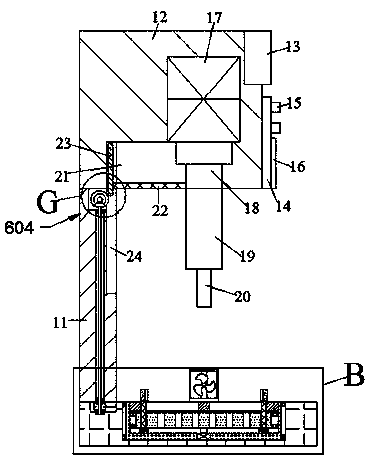

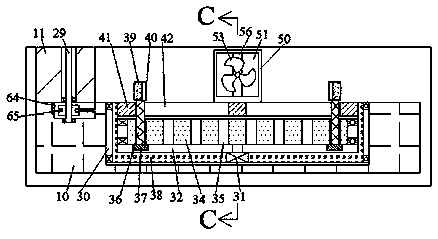

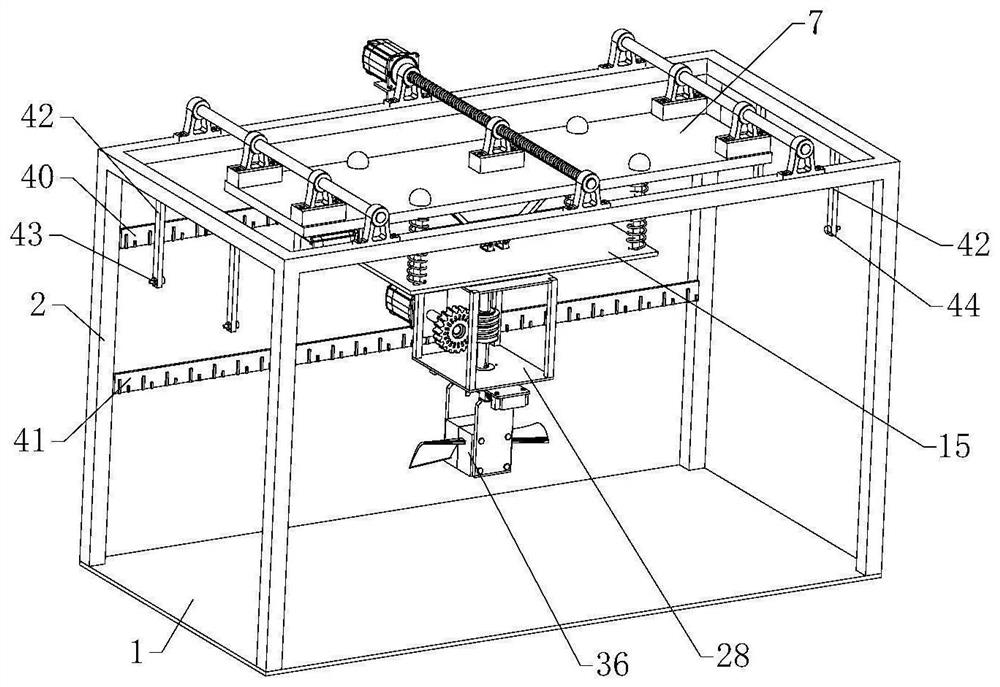

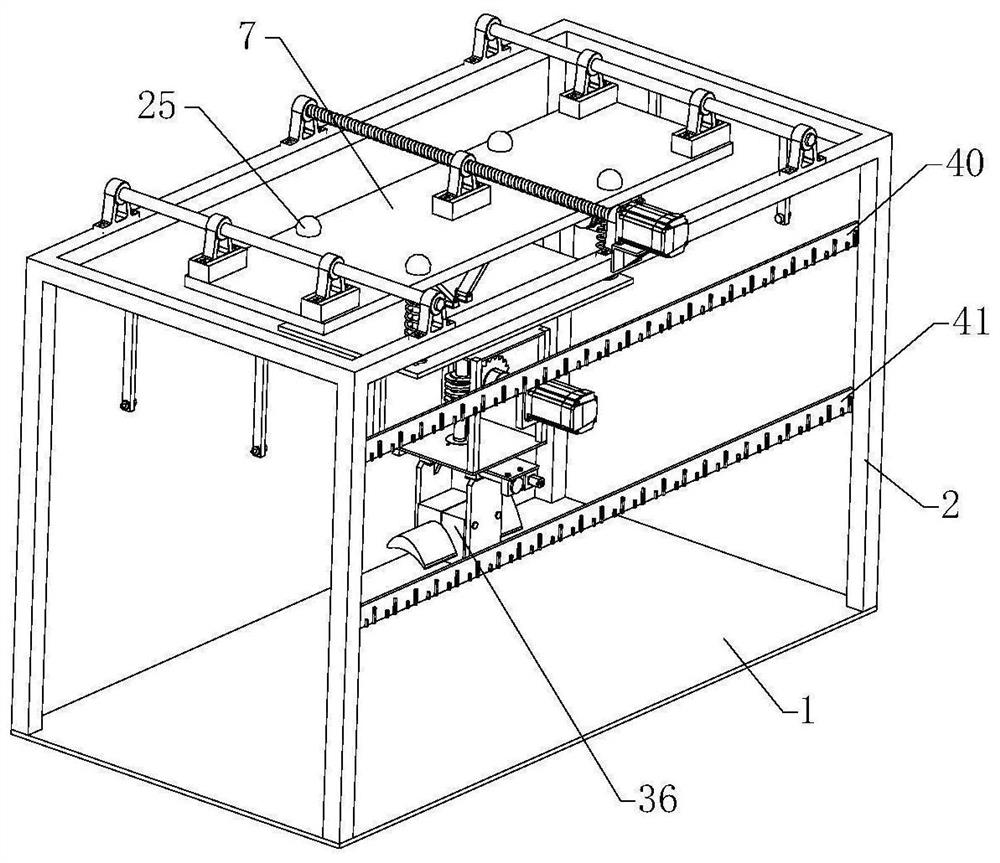

Intelligent welding equipment and intelligent welding method for metal materials

InactiveCN113146083ARealize automatic adjustmentImprove welding accuracyWelding/cutting auxillary devicesAuxillary welding devicesGear wheelMetallic materials

The invention discloses intelligent welding equipment for metal materials. The intelligent welding equipment comprises a bottom table, a rack is fixedly connected to the top of the bottom table, a welding gun is installed in the center of the bottom of a transverse plate, and a clamping assembly is arranged at the top of the bottom table. According to the intelligent welding equipment for the metal materials, through threaded connection of lantern rings and annular distribution of clamping rods, sleeves on the two sides can clamp and fix a metal pipe, automatic adjustment can be achieved, the welding accuracy is greatly improved, annular welding can be achieved through meshing connection of gears, through arrangement of a water pump and a spray head, spraying cooling can be conducted on the welding position after welding is completed, then the cooling efficiency is greatly improved, meanwhile, a motor is used in cooperation, the cooling effect is improved, through the arrangement of a filter screen and an exhaust fan, waste gas and dust generated during welding can be adsorbed, collected and purified, then environmental pollution is avoided, and through clamping connection of a curved rod and a clamping rod, dust in a square box can be cleaned conveniently.

Owner:杨洋

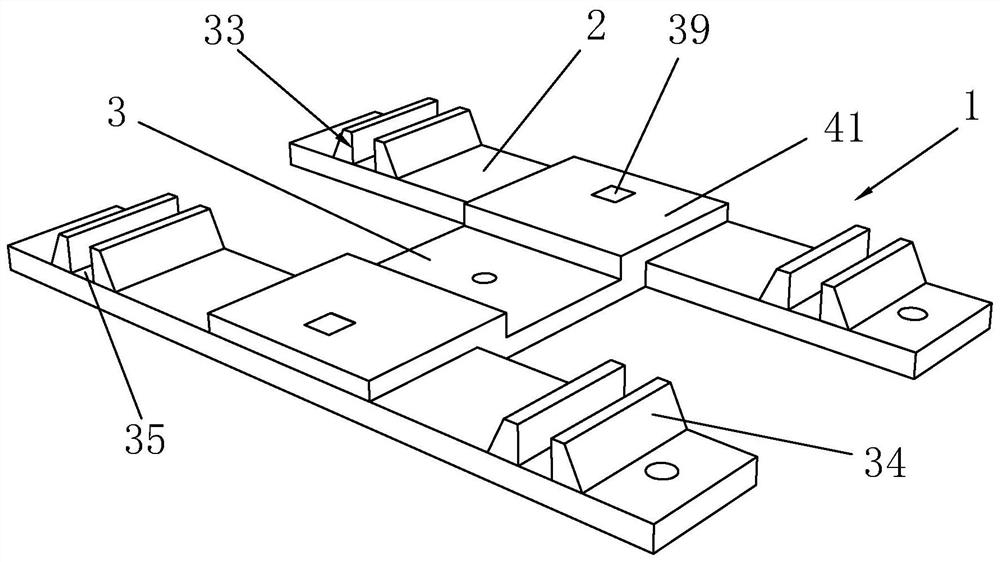

Automobile seat framework welding device with positioning structure

ActiveCN112518195AAvoid clamping instabilityEffective positioningWelding/cutting auxillary devicesAuxillary welding devicesCar seatGear drive

The invention discloses an automobile seat framework welding device with a positioning structure. The automobile seat framework welding device comprises a supporting main plate, a first servo motor, abelt pulley transmission mechanism, a second servo motor, a third servo motor and a fourth servo motor; first screw rods are symmetrically inserted into the front end and the rear end of the left side of the supporting main plate; and the outer sides of the two sets of first screw rods are sleeved with clamping plates, first threaded sleeves are symmetrically embedded in the front sides and the rear sides of the interiors of the clamping plates, and the first servo motor is fixedly installed in the middle of the top of the supporting main plate. According to the automobile seat framework welding device, a sliding semi-ring is arranged to annularly slide in a fixed sleeve rail, a welding conveying head is arranged to be fixedly connected with the sliding semi-ring through a connecting base, and through meshing of teeth, a fourth gear drives the sliding semi-ring to rotate around the circle center position of the fixed sleeve rail when rotating, so that annular welding work is effectively conducted on the welding position between a steel pipe and a beam plate, and the comprehensiveness of welding operation conducted on a framework through the device is effectively guaranteed.

Owner:NINGBO POLYTECHNIC

Ultrasonic plastic welder for automobile fitting processing

The invention discloses an ultrasonic plastic welder for automobile fitting processing. The ultrasonic plastic welder for automobile fitting processing comprises a base, wherein a clamping device is arranged in the base; the clamping device can clamp automobile fitting to be subjected to plastic welding; the outer side of the clamping device is equipped with a cooling device; after the fittings are subjected to plastic welding, the cooling device can keep integrity of the appearance of a welded part; and a one-way rotating device is arranged at the left side of the clamping device. The clamping device can clamp the automobile fittings to be subjected to plastic welding, so that stability of workpieces in a welding process is guaranteed, welding accuracy is improved, and the welded part canrotatebly adjust a welding position; and after the ultrasonic welder accomplishes welding, an air-cooling device can be driven to work along with ascending of a plastic welding head, so that comprehensive uniform cooling can be instantly performed on the workpiece, and therefore, stability of workpiece forming is improved.

Owner:温州创荣超声波电子设备有限公司

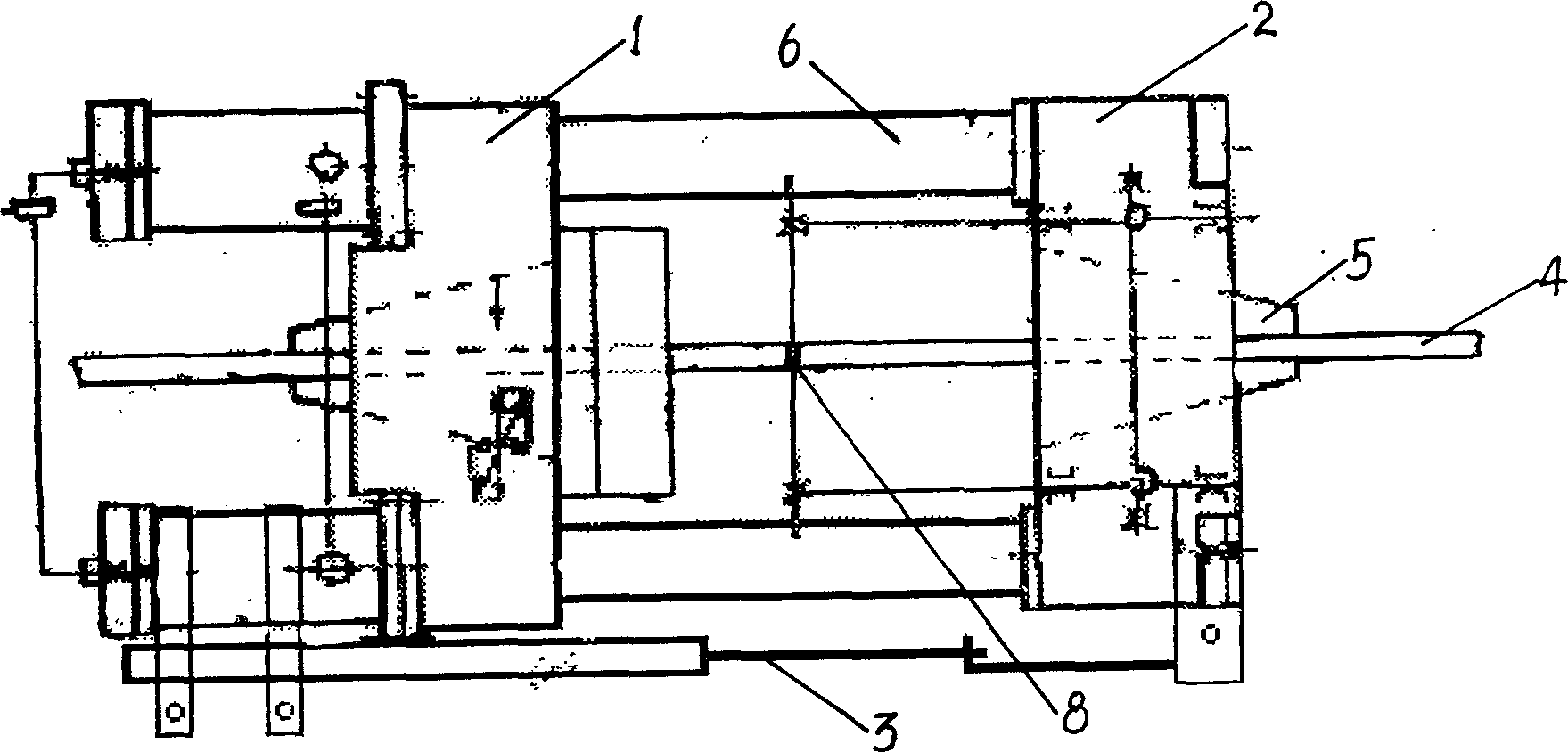

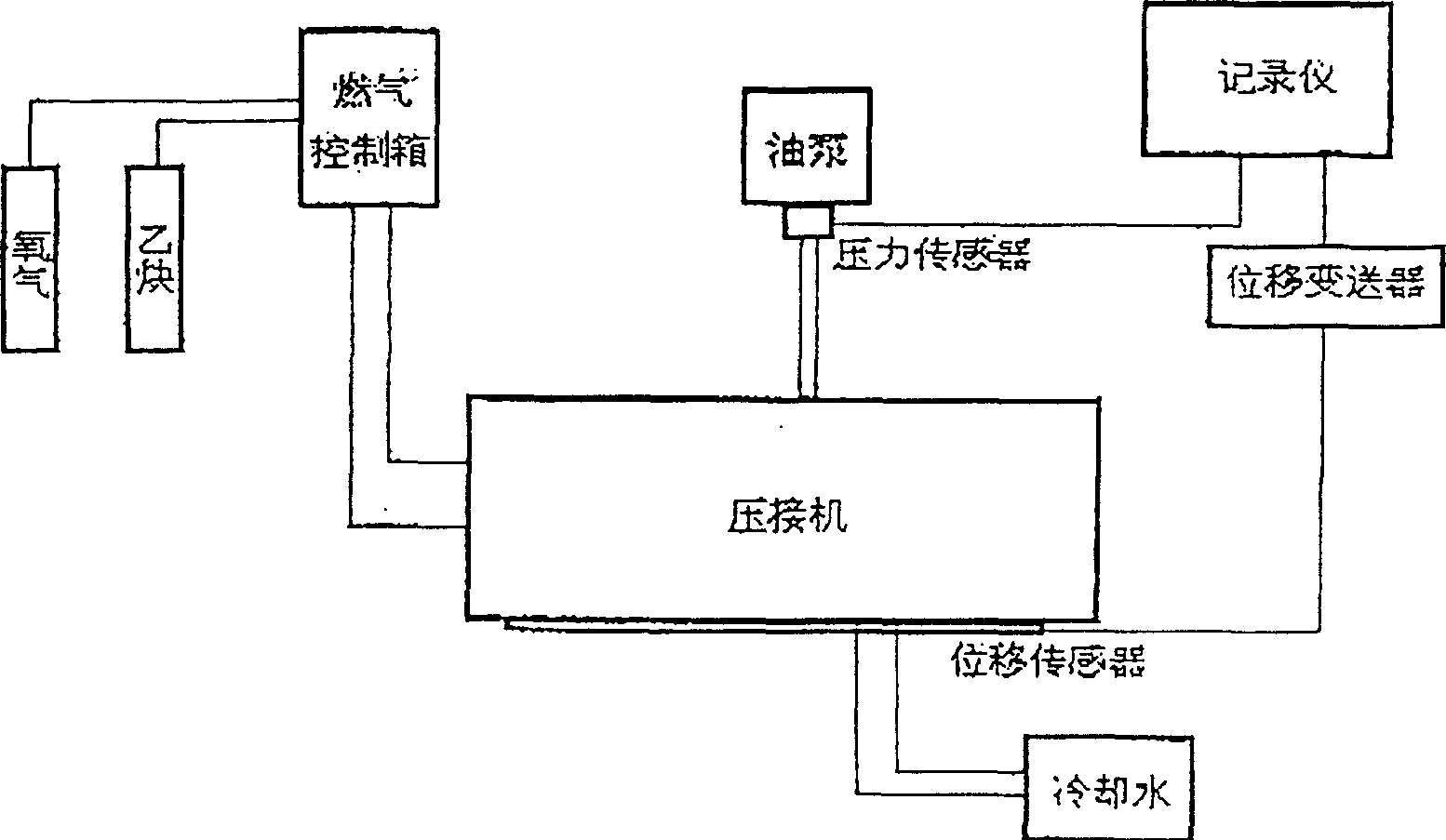

Control method of mobile steel rail pneumatic welding machine and its used equipment

InactiveCN1718355AIncrease the level of automationGood reproducibilityWelding/cutting auxillary devicesArc welding apparatusButt weldingTransducer

A control method for butt-welding steel rails by movable pneumatic welding machine features that the shift sensor, shift transducer and recorder are used for monitoring the relative expansive shift, compression shift and end forge shift of steel rail, the pressure sensor and recorder are used for monitoring the welding pressure and welding end forge force, and the monitored data is used to control the pressure decrement and end forge. Its apparatus is also disclosed.

Owner:攀枝花钢铁有限责任公司钢铁研究院

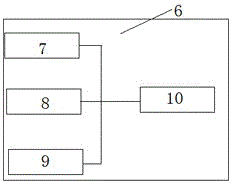

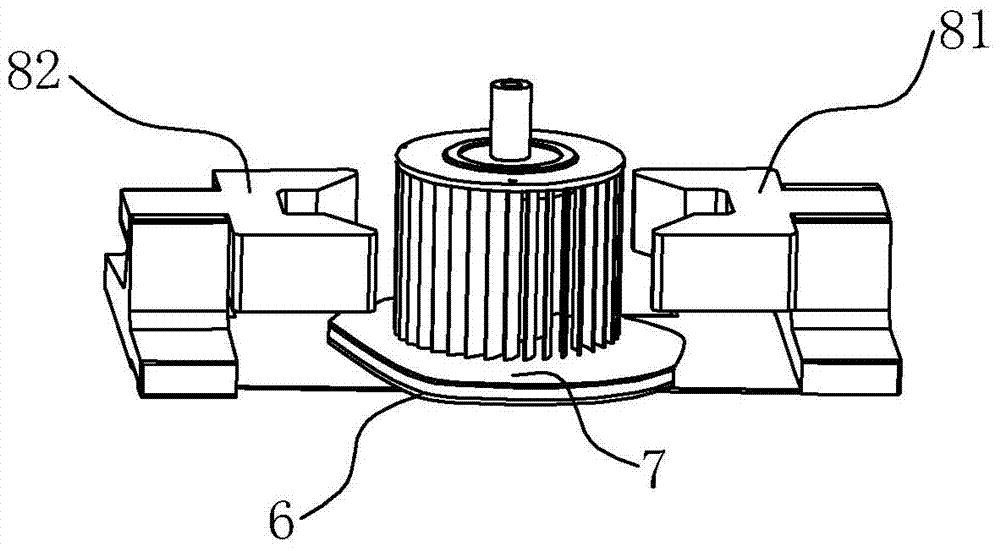

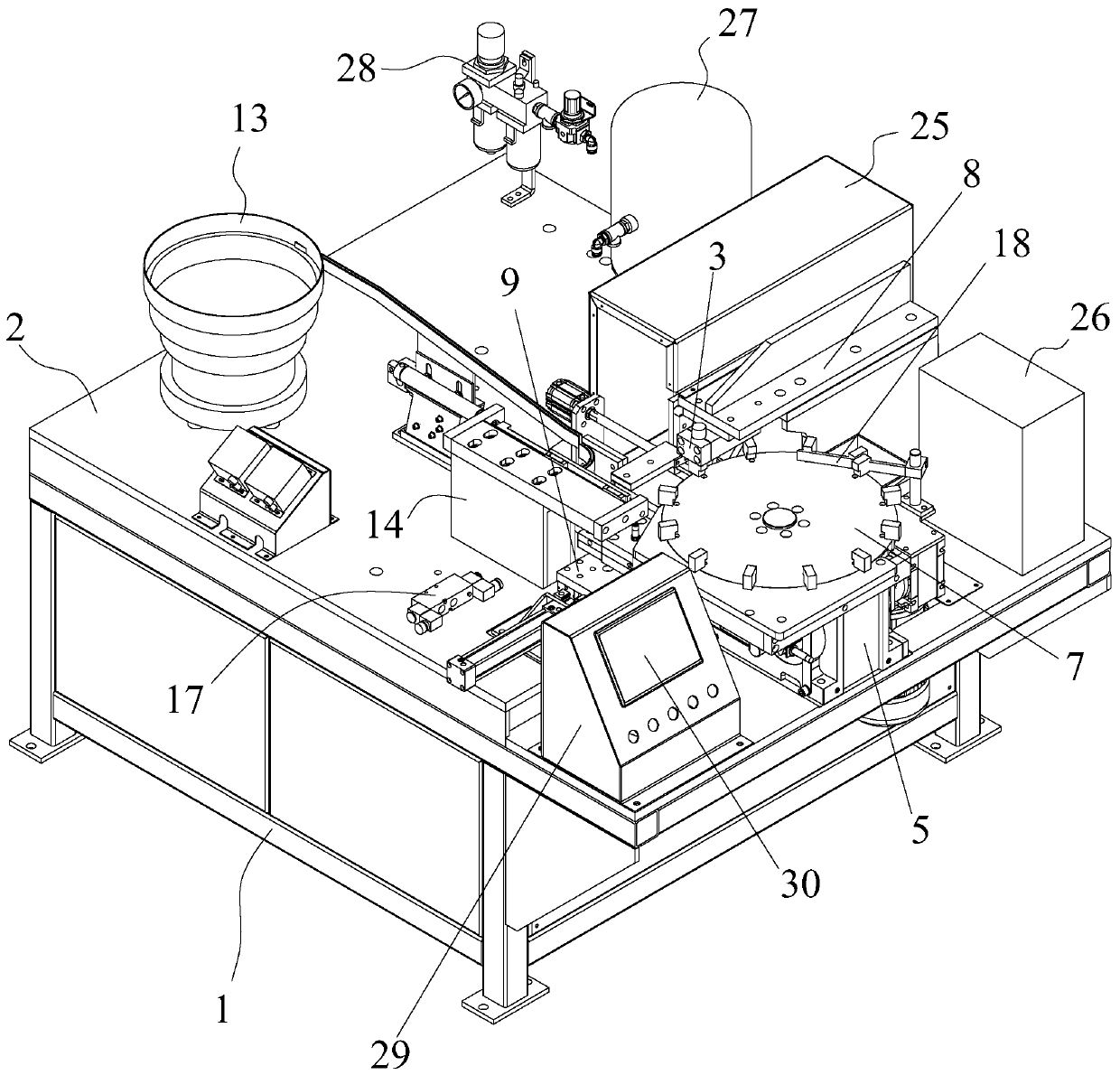

Correcting and positioning device for through-flow blade processing equipment

InactiveCN104325422APrecise correction positioningImprove welding accuracyWork holdersCMOSPulp and paper industry

The invention relates to a correcting and positioning device for through-flow blade processing equipment. The correcting and positioning device is respectively connected with a first linear conveying rail, a second linear conveying rail and a third linear conveying rail of an input component, and comprises an air cylinder clamping jaw, CMOS image collecting equipment, a positioning flat plate, a rotating positioning disc, a first positioning clamping jaw and a second positioning clamping jaw, wherein the air cylinder clamping jaw can swing, the CMOS image collecting equipment is connected with a controller, the positioning flat plate can rotate, the first positioning clamping jaw and the second positioning clamping jaw can move, the air cylinder clamping jaw and the CMOS image collecting equipment are respectively arranged above the rotating positioning disc, the rotating positioning disc is arranged on the positioning flat plate, an opening of the first positioning clamping jaw is in opposite arrangement to an opening of the second positioning clamping jaw, and the positioning flat plate is arranged in the middle position between the two openings. The CMOS image collecting equipment collects the surface information of a component arranged on the rotating positioning disc and sends the surface information to the controller for storage, and then, the angle of a subsequent component arranged on the rotating positioning disc is regulated to be respectively identical to the angle of a former component stored in the controller, so that the fast and precise correcting and positioning of a through-flow blade is realized.

Owner:NINGBO FATO AUTOMATION TECH

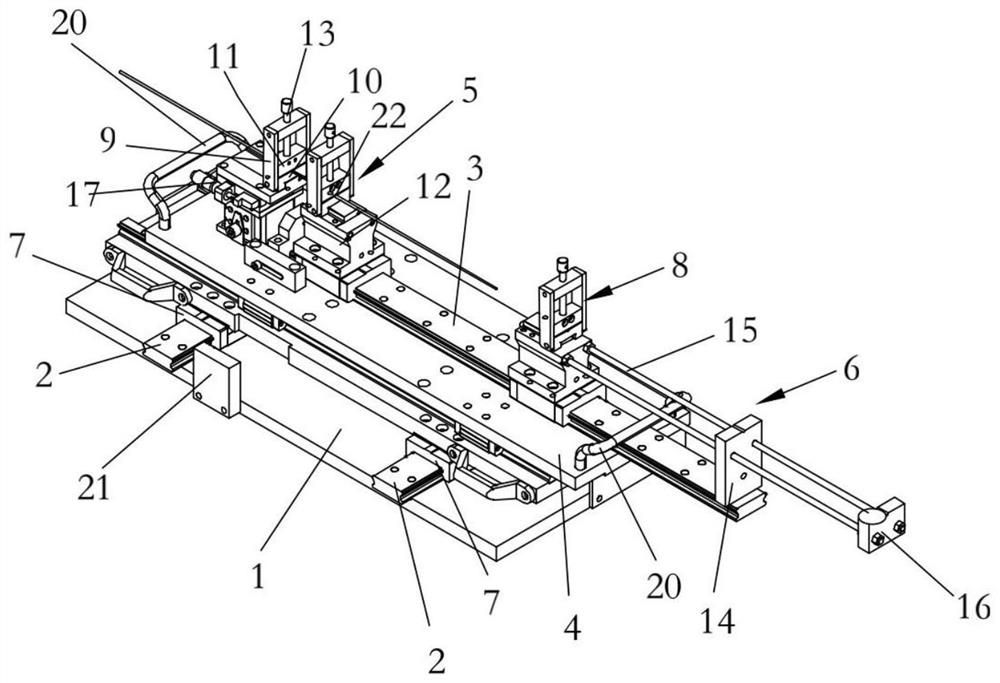

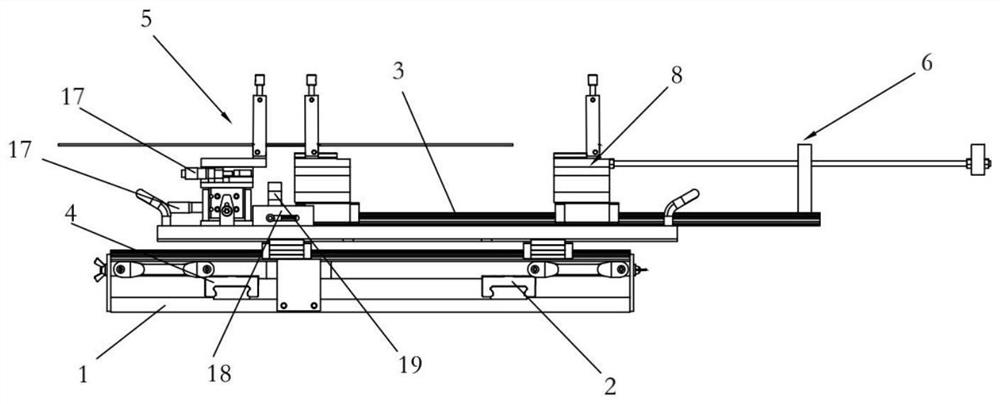

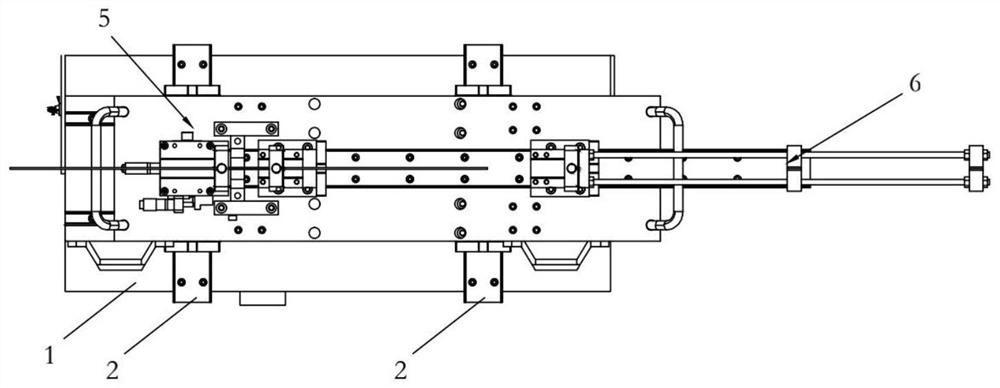

Fixing tool for steam turbine blade

ActiveCN112809277AEasy to adjust laterSolve the problem of poor assembly and welding consistencyWelding/cutting auxillary devicesAuxillary welding devicesSteam turbine bladeEngineering

The invention relates to the technical field of steam turbine blade machining, in particular to a fixing tool for a steam turbine blade. The fixing tool comprises a rack erected on a base, a translation adjusting mechanism which is arranged on the rack and used for executing the translation adjusting procedure of the blade to be machined, a lifting mechanism which is arranged at the working end of the translation adjusting mechanism and used for executing the lifting adjusting procedure of the blade to be machined, a horizontal overturning mechanism which is arranged at the working end of the lifting mechanism and used for executing the horizontal overturning procedure of the blade to be machined, and a positioning mechanism which is arranged at the working end of the horizontal turnover mechanism, located below the horizontal turnover mechanism and used for positioning the blade to be machined. And according to the technical scheme disclosed by the invention, the problem that the assembling and welding consistency is poor due to the fact that the tool position of a stator blade is manually adjusted is solved. The fixing tool can automatically adjust the horizontal position, the height and the horizontal inclination of the stator blade so as to automatically adjust the position of a tool, so that assembling and welding are consistent, and the assembling and welding precision is improved.

Owner:德阳六合能源材料有限公司

Automatic welding device

PendingCN111014913AGuaranteed coaxialityAvoid human errorWelding accessoriesAutomatic controlEngineering

The invention discloses an automatic welding device which comprises a rack, the rack is provided with a welding mechanism, the welding mechanism comprises an upper welding head tool and a lower welding head tool, the upper welding head tool is provided with an upper welding head, the lower welding head tool is provided with a lower welding head, and the upper welding head and the lower welding head are connected to the positive electrode and the negative electrode of a weldment transformer respectively; the workpiece feeding mechanism is used for conveying the workpieces to be welded to the position under the upper welding head one by one; the weldment feeding mechanism is used for conveying weldments to be positioned above the lower welding head one by one; the driving mechanism is used for driving the lower welding head to move towards the upper welding head until the welding piece is in contact conduction with the workpiece to generate a welding arc so as to realize welding fixation; and the controller is electrically connected with the welding mechanism, the workpiece feeding mechanism, the weldment feeding mechanism and the driving mechanism, and automatic control over the welding process is achieved. The welding device is high in welding precision, high in efficiency and low in cost.

Owner:NINGBO XINZHOU RESISTANCE WELDER

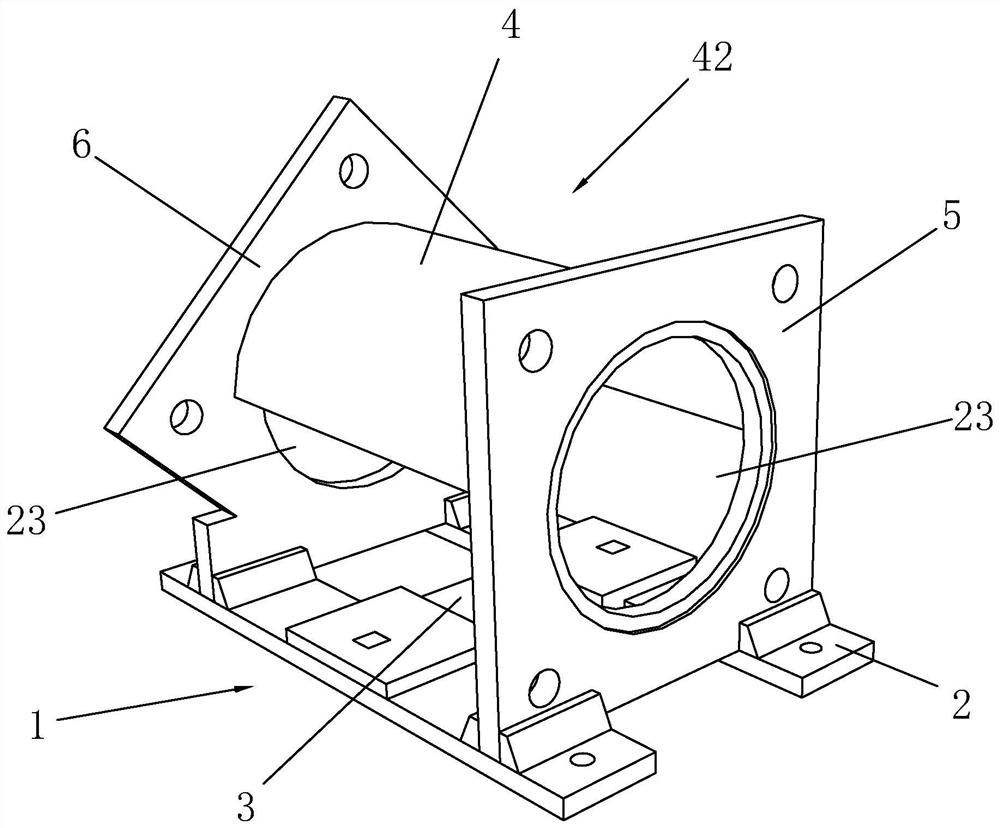

Method for manufacturing motor mounting bracket

ActiveCN112372170AImprove the strength of its own structureImprove installation stabilityWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryStructural engineering

The invention discloses a method for manufacturing a motor mounting bracket. The method comprises the following steps of: 1) preparing a support bottom plate; 2) preparing a bracket; 3) assembling andfixing the bracket; 4) assembling and fixing the support bottom plate; and 5) assembling and fixing the support bottom plate and the bracket. The motor mounting bracket is firm and reliable in structure, and the stability of a motor after being mounted is effectively improved; the whole motor mounting bracket is assembled by the support bottom plate and the bracket, and auxiliary positioning welding is carried out for welding of all parts of the bracket by adopting an auxiliary device, so that accurate positioning adjustment between an arc-shaped plate and end plates at two sides is effectively guaranteed, and the actual welding accuracy and quality are improved; all components of the support bottom plate are accurately positioned through blocks and grooves and then welded and fixed in amatched manner, so that the structural strength of the support bottom plate is guaranteed; and finally the bracket and the support bottom plate are combined and welded, so that the structural stability of the whole motor mounting bracket is effectively ensured, and the use performance of the motor mounting bracket is better.

Owner:嵊州市龙凯机械加工厂

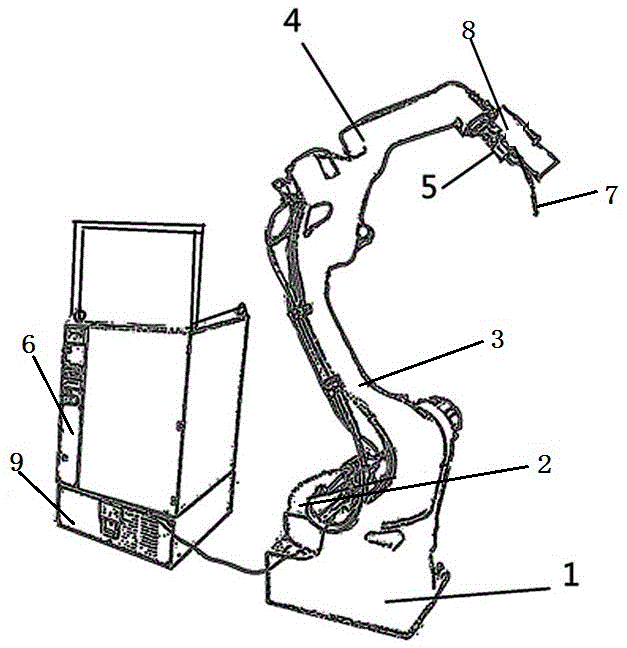

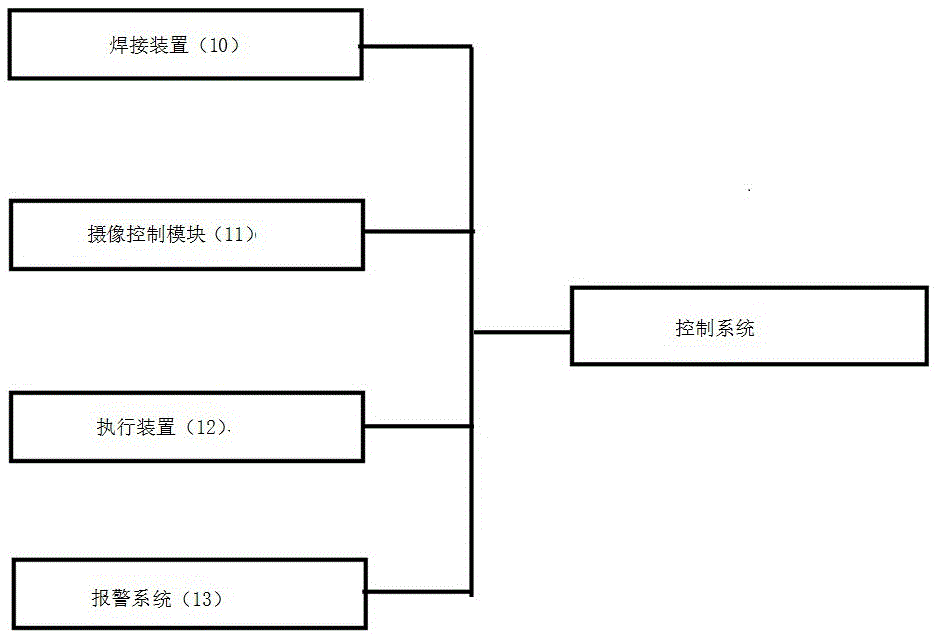

High-precision robot automatic welding device special for grid plate and working method thereof

ActiveCN106514077AImprove welding precisionImprove welding efficiencyProgramme-controlled manipulatorWelding/cutting auxillary devicesRotational axisEngineering

The invention discloses a high-precision robot automatic welding device special for a grid plate. The high-precision robot automatic welding device special for the grid plate comprises a fixed base, a rotating shaft, a lower arm, an upper arm, a wrist joint and an electric control box, wherein the rotating shaft is arranged on the fixed base; the lower arm is connected with the rotating shaft through a positioning pin; the upper arm is connected with the lower arm through a positioning pin; the wrist joint is connected with the upper arm through a positioning pin, and a welding gun and a camera device are arranged at one end of the wrist joint; cameras are arranged in the camera device; the rotating shaft, the lower arm, the upper arm, the wrist joint and the camera device are all electrically connected with an electric control box. According to the high-precision robot automatic welding device special for the grid plate, the camera device is arranged in the automatic welding device; the grid plate which is required to be welded is shot through three groups of cameras; the images shot by the cameras are subjected to data processing and analyzing through a control system in a control device; the type of the grid plate which is required to be welded, a position which is required to be welded and the welding quality are known precisely, so that the welding precision of the automatic welding device is greatly improved.

Owner:SUZHOU WST ROBOT AUTOMATION CO LTD

Weld joint real-time tracking device based on laser vision

PendingCN114378490AEasy to moveGuaranteed accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

The invention provides a real-time welding seam tracking device based on laser vision. The real-time welding seam tracking device comprises a welding equipment body, and a bearing structure is arranged on the side face of the welding equipment body; a moving structure is arranged on the top side of the bearing structure; the other side of the bearing structure is slidably connected with a clamping structure; a positioning structure is connected between the clamping structure and the bearing structure; a fixing structure is arranged on the top side of the clamping structure; the bottom side of the welding equipment body is fixedly connected with a cleaning structure; a to-be-welded steel plate can be horizontally placed through the bearing structure, the welding accuracy is guaranteed, the steel plate with the large area can be conveniently moved through the moving structure, the welding sides of the two fixed steel plates can be kept parallel through the clamping structure, the width of a welding seam can be adjusted through the fixing structure, and the welding efficiency is improved. The welding seam between the steel plates can be accurately adjusted through the positioning structure, and dust at the welding position can be cleaned through the cleaning structure.

Owner:米开罗那(上海)工业智能科技股份有限公司

Automatic gas shielded welding device for longitudinal seam in steel pipe cavity

InactiveCN104493337BEasy to liftIncrease stiffnessWelding/cutting auxillary devicesAuxillary welding devicesUltimate tensile strengthMechanical engineering

The invention relates to an automatic gas shielded welding device of a longitudinal gap in a steel pipe cavity. The device comprises a machine head, a support arm, a walking device, a welding machine, a welding gun, a control box and a support wheel frame, wherein the machine head consists of an outer machine head and an inner machine head; one end of the support arm is fixed at the other side of the inner machine head; the support wheel frame is fixed at the other end of the support arm; an oscillator and a fixture fixed at one side of the oscillator are fixed in the support wheel frame; the welding gun is fixed in the middle of the fixture; a welding gun observing probe is fixed below the end of the support arm; and an automatic wire feeding machine is fixed in a mounting groove hole in the support arm. The device is simple in structure and convenient for operation, can largely improve the welding efficiency and reduce the labor intensity, needs no welding workers to enter steel pipes for welding to prevent harmful gas from harming the workers, and improves the product quality.

Owner:河北省景县宏远通讯有限公司

Wire feeding and welding device and method

InactiveCN103894763AFlexible and efficient weldingImprove welding accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining process

The invention relates to the technical field of welding, and provides a wire feeding and welding device which comprises a welding system used for welding a wire on a workpiece. The welding system is provided with a conveying device used for conveying the wire to a welding machining site, and the conveying device is provided with a wire machining system used for peeling and cutting off the wire. The wire machining system used for peeling and cutting off the wire is mounted on the conveying device of the welding system, manual feeding and discharging in the machining process are not needed, the wire conveying device is used for feeding the wire and directly conveying the machined wire to a to-be-welding machining site for welding, welding can be carried out flexibly and efficiently in a narrow space, and welding accuracy is high.

Owner:O NET COMM SHENZHEN

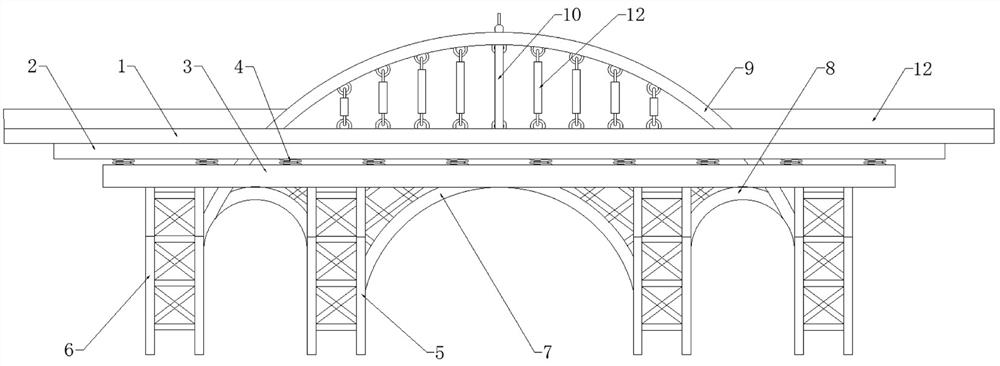

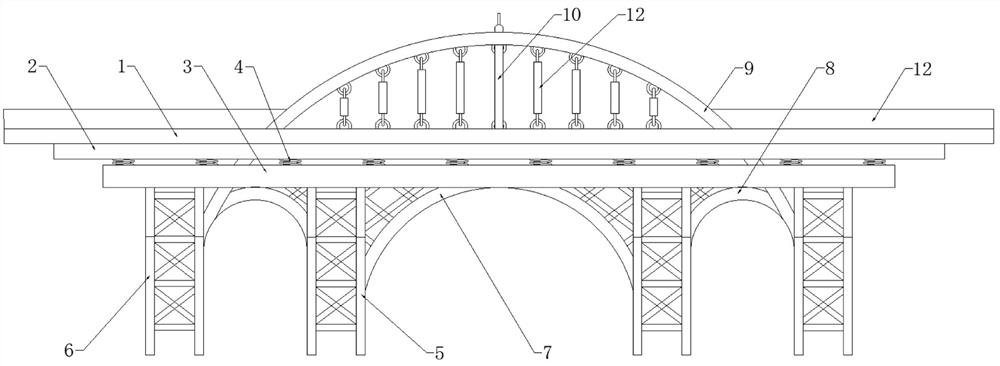

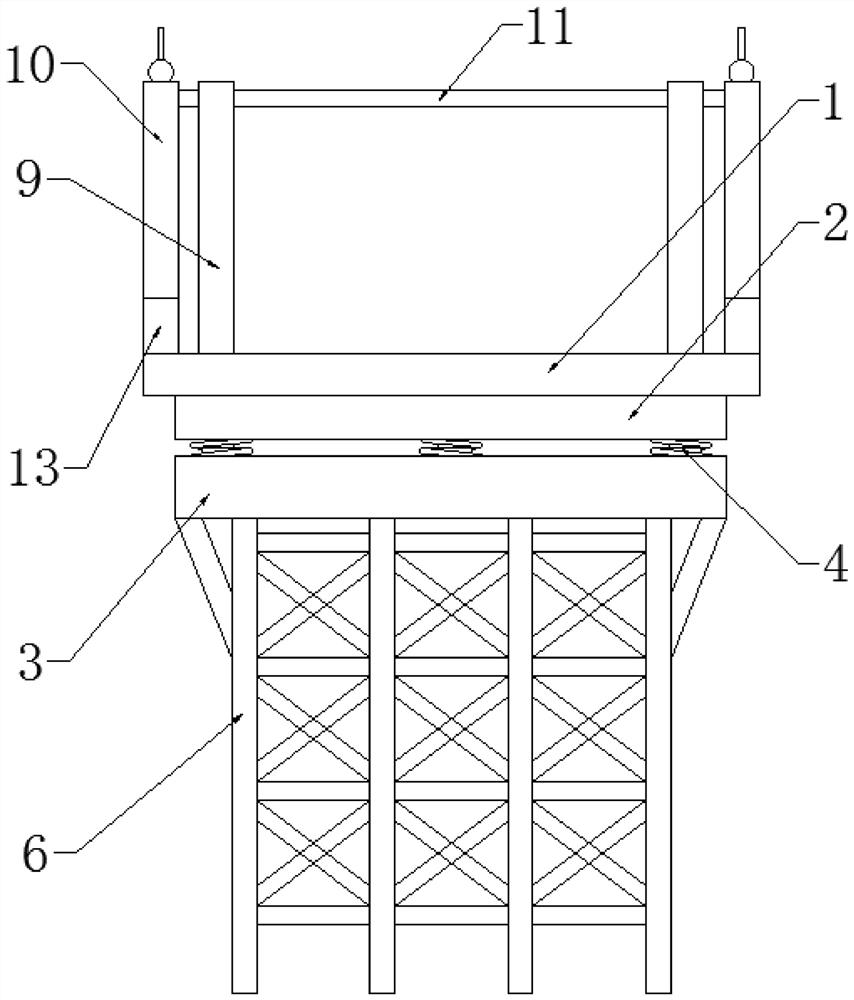

Bridge steel structure and welding method thereof

ActiveCN112252160ALong maintenance periodSolve the problems of difficult adjustment and poor welding effectArc welding apparatusBridge structural detailsBridge deckEngineering

The invention discloses a bridge steel structure and a welding method thereof. The bridge steel structure comprises a bridge deck slab; a fixing plate is fixedly installed at the bottom end of the bridge deck slab; a bridge deck base is arranged on the side, away from the bridge deck slab, of the fixing plate; and damping structures are connected to the bridge deck base and the fixing plate and evenly distributed between the bridge deck base and the fixing plate; main piers are fixedly installed on the side, away from the fixing plate, of the bridge deck base and are symmetrically distributedwith the central axis of the bridge deck base as the symmetry axis. The bridge steel structure is novel in structure, simple in structure, good in damping effect, small in jolt and noise, high in stability, high in welding accuracy, high in adjustability and good in welding effect.

Owner:河南六建重工有限公司

Positioning jig for welding gun

PendingCN114669945APrevent movementImprove welding accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSlide plate

The invention relates to the technical field of positioning jigs, in particular to a positioning jig for a welding gun, the positioning jig comprises a bottom plate, a transverse sliding rail, a longitudinal sliding rail, a sliding plate, a limiting mechanism and adjusting assemblies, the limiting mechanism comprises a plurality of limiting assemblies, and each limiting assembly comprises a support, a first clamping piece, a second clamping piece, an adjusting seat and a lifting screw. During welding, the sliding plate can move along the transverse sliding rail, the limiting assemblies can move along the longitudinal sliding rail, a user can adjust the front-back position and the left-right position of the multiple limiting assemblies according to requirements, and after a welded object is inserted into the clamping cavity, the first clamping piece is moved downwards, and the welded object is clamped and then welded; and a welded object can be effectively prevented from moving during welding, and the welding accuracy is improved.

Owner:东莞市元昌机床有限公司

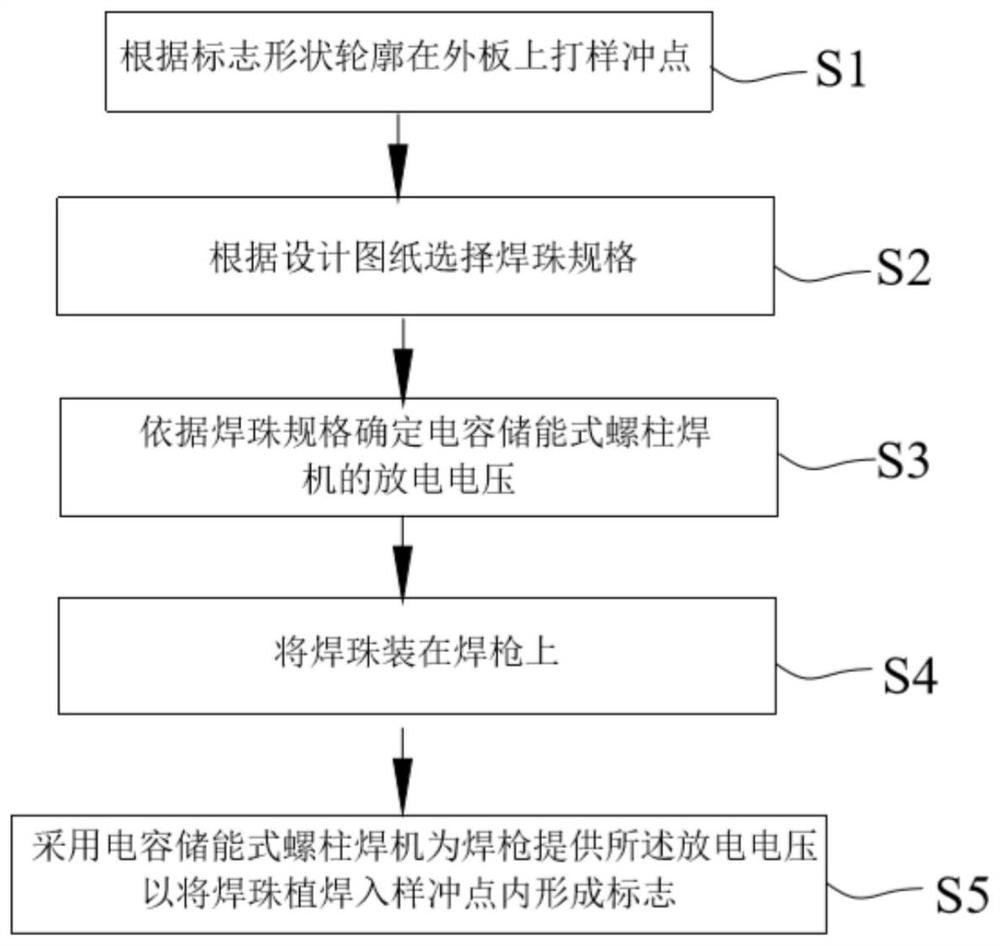

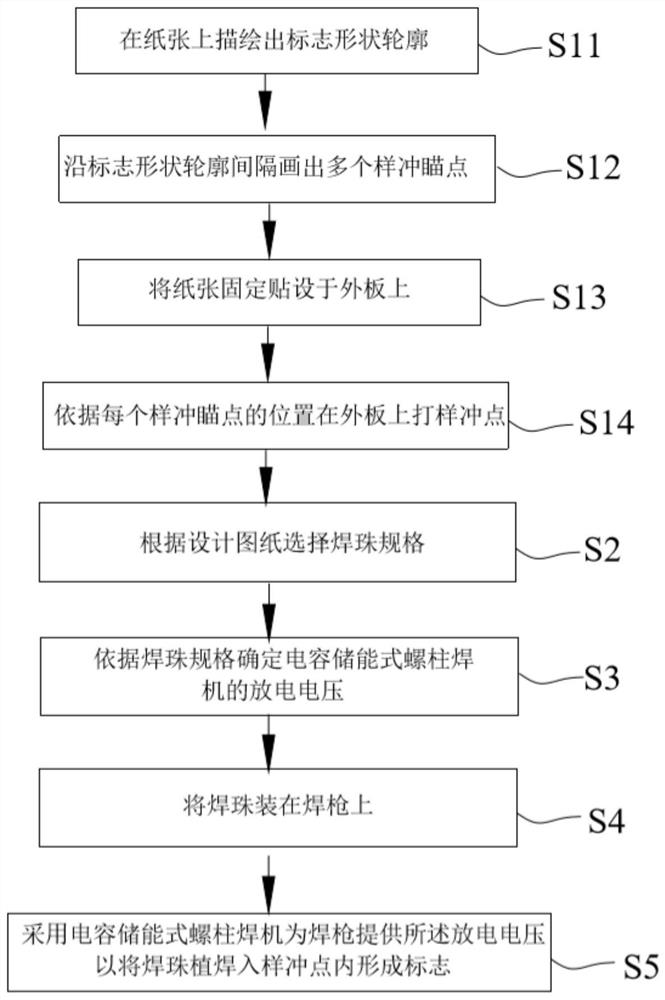

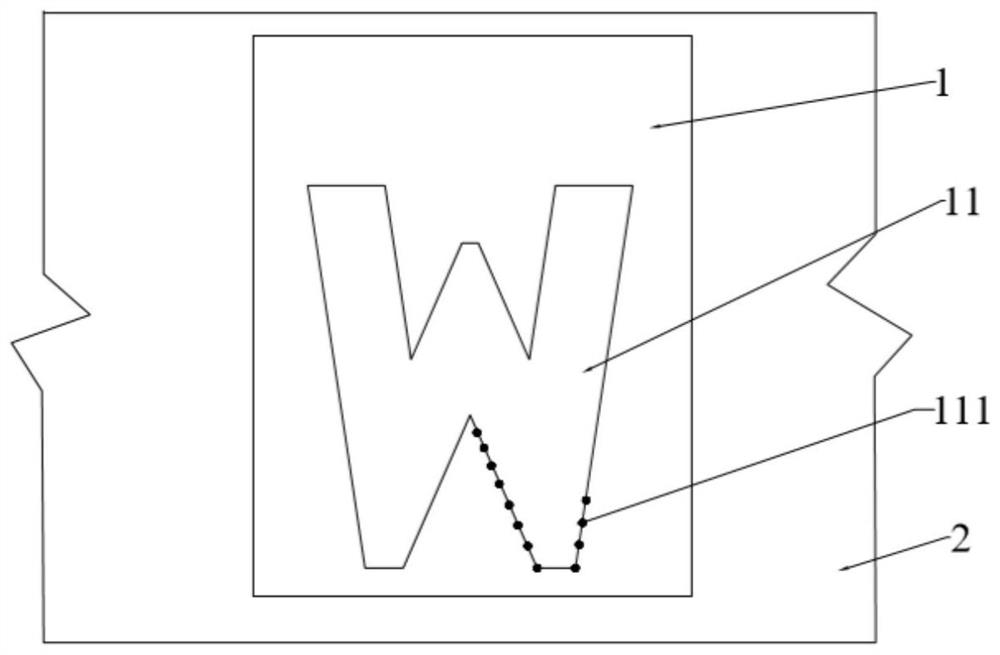

Planking mark stud welding process

The invention discloses a planking mark stud welding process, and relates to the technical field of ship planking mark manufacturing. The planking mark stud welding process comprises the following steps that S1, sample punching pin point punching is conducted on a planking according to the shape and contour of a mark; S2, welding bead specifications are selected according to a design drawing; S3, the discharge voltage of a capacitive energy storage type stud welding machine is determined according to the welding bead specifications; S4, welding beads are mounted on a welding gun; and S5, the capacitive energy storage type stud welding machine is adopted to provide the discharge voltage for the welding gun, so that the welding beads are subjected to stud welding into sample punching pin points to form the mark. According to the process, the defects caused by existing CO2 semi-automatic welding or manual arc welding are overcome, the welding precision is improved, and the appearance of the mark is more uniform and attractive.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

High efficiency welding machine

InactiveCN109382595AImprove stabilityImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesIndustrial engineeringPulley

The invention discloses a high efficiency welding machine which comprises support legs, a graduation line, a push plate, clamping devices, a motor and a square-shaped frame. Pulley wheels are mountedon bottom ends of the support legs, a box body is arranged between the support legs, an outer surface of the box body is provided with the graduation line, a horizontal support plate is fixed on top ends of the support legs, a right end of a power source box is provided with a fixed plate, a rocking handle is mounted on one side of the fixed plate while a first telescoping rod is mounted on the other side of the fixed plate, the clamping devices are mounted on an inner surface of the push plate, a concaved plate is arranged between the clamping devices, the concaved plate is mounted on the horizontal support plate via a second sliding groove, a third telescoping rod is fixed on the horizontal support plate, a work box is mounted on a top end of the third telescoping rod, the motor is arranged in the work box, and a welding gun head is mounted on a bottom end of the motor. The convenient type welding machine is great in welding stability, high in welding efficiency and precision, low inpollution and great in convenience of use.

Owner:TIANJIN SHIJI JINQING WELDING MATERIAL

Wax mold welding device used for precision casting and welding method of wax mold welding device

PendingCN112453321AHigh precisionImprove welding accuracyFoundry moulding apparatusPrecision castingThreaded rod

The invention discloses a wax mold welding device used for precision casting. The device comprises a working box with an opening formed in the upper end, two clamping mechanisms are arranged in the working box, each clamping mechanism comprises a clamping box, and the clamping boxes are slidably connected between a partition plate and the inner side wall of the working box; and horizontally-arranged threaded rods are rotatably connected to the inner side walls of the clamping boxes, two sections of threads with opposite rotating directions are arranged on each threaded rod, clamping sleeves are connected to the two sections of threads of each threaded rod in a threaded sleeving manner, connecting blocks are fixedly connected to the side walls, close to the center of the working box, of thetwo clamping sleeves of each threaded rod, and the connecting blocks penetrate through the side walls of the clamping boxes in a sliding manner and are fixedly connected with movable plates. By arranging the clamping mechanisms, it can be simultaneously guaranteed that wax molds on the two sides are always located in the middles of the clamping boxes after being clamped, and then the welding precision is higher; and through the arrangement of an adjusting mechanism, simultaneous and multi-directional heating can be achieved through multiple spray heads, and the welding efficiency is greatly improved.

Owner:和县华林精密铸造有限公司

XY-axis multi-point automatic butt-welding device for half cover of automobile exhaust pipe

PendingCN111360385ASolve welding efficiencySolve welding precisionWelding/cutting auxillary devicesAuxillary welding devicesButt weldingEngineering

The invention discloses an XY-axis multi-point automatic butt-welding device for a half cover of an automobile exhaust pipe. The XY-axis multi-point automatic butt-welding device comprises a butt-welding machine and an XY-axis loading vehicle, wherein a quick positioning mechanism is arranged between the butt-welding machine and the XY-axis loading vehicle; and the Y-axis loading vehicle is provided with a part cavity clamping mechanism and an XY-axis module. The part cavity clamping mechanism is driven to move and correspond to the butt welding machine through the movement of the XY-axis module for welding. The XY-axis multi-point automatic butt-welding device has a novel structure, can be quickly connected to multiple loading vehicles, can also perform multi-point precise welding, and issuitable for popularization.

Owner:佛山市顺德区赛恩特实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com