XY-axis multi-point automatic butt-welding device for half cover of automobile exhaust pipe

An automobile exhaust and automatic technology, which is applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of low welding efficiency and precision, and achieve the effect of improving welding quality, improving the flexibility of equipment, and improving the flexibility of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

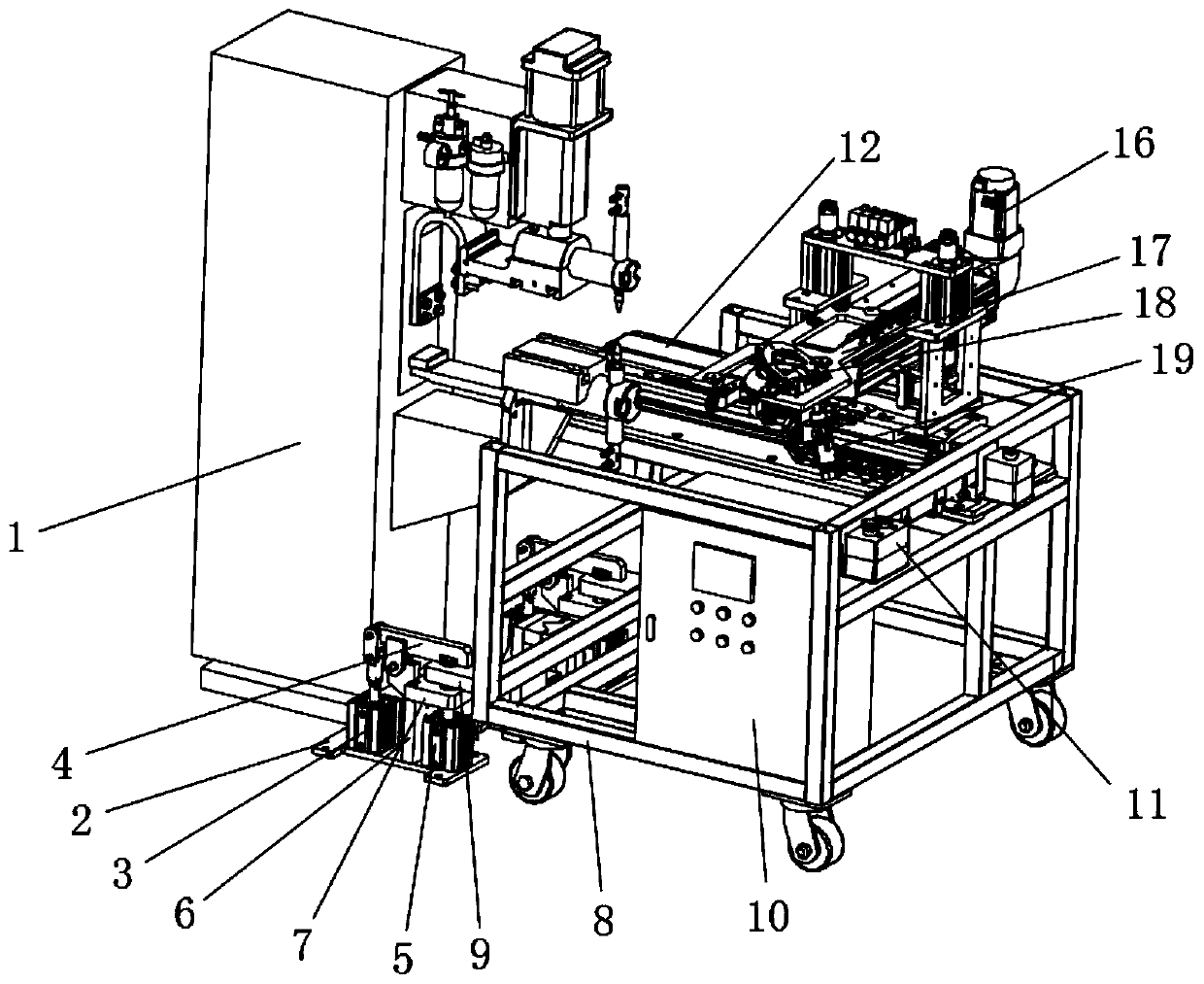

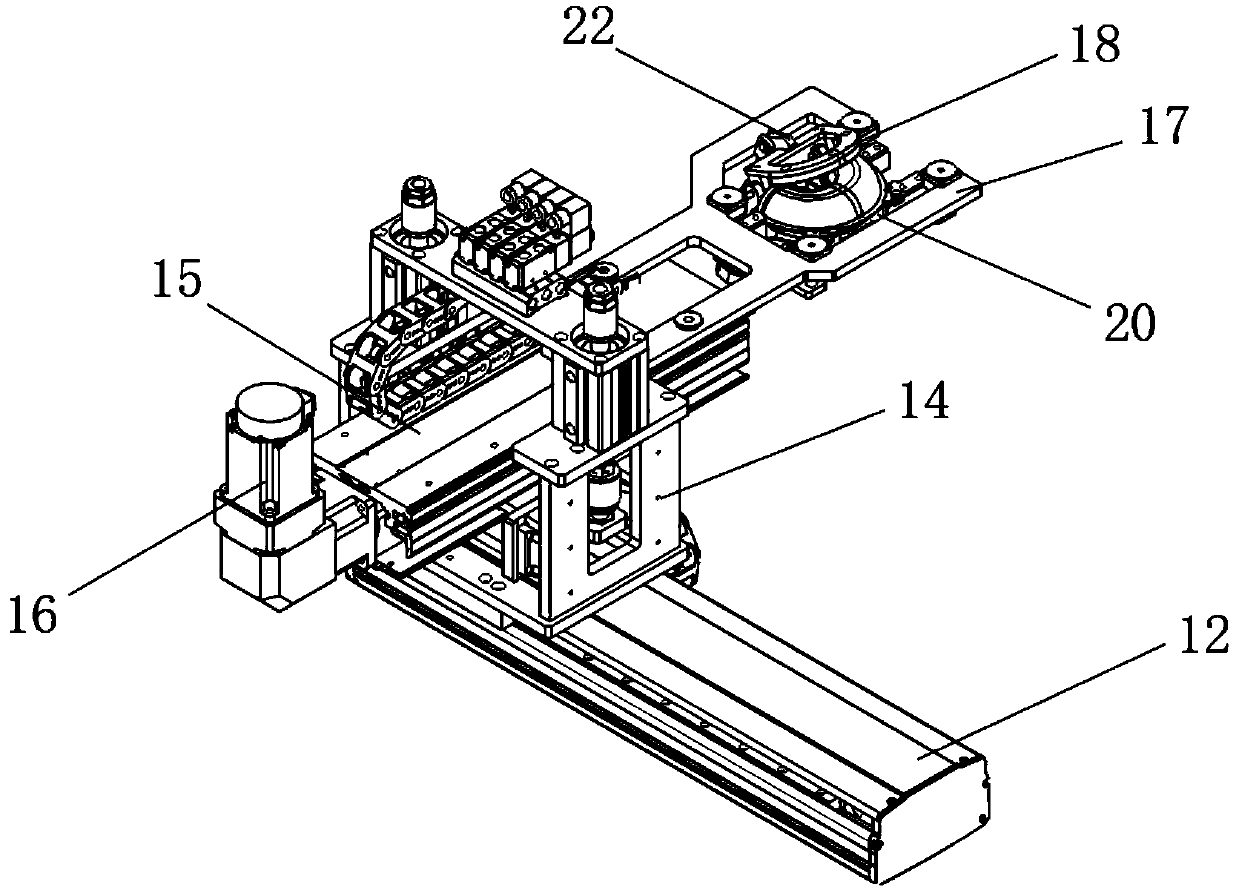

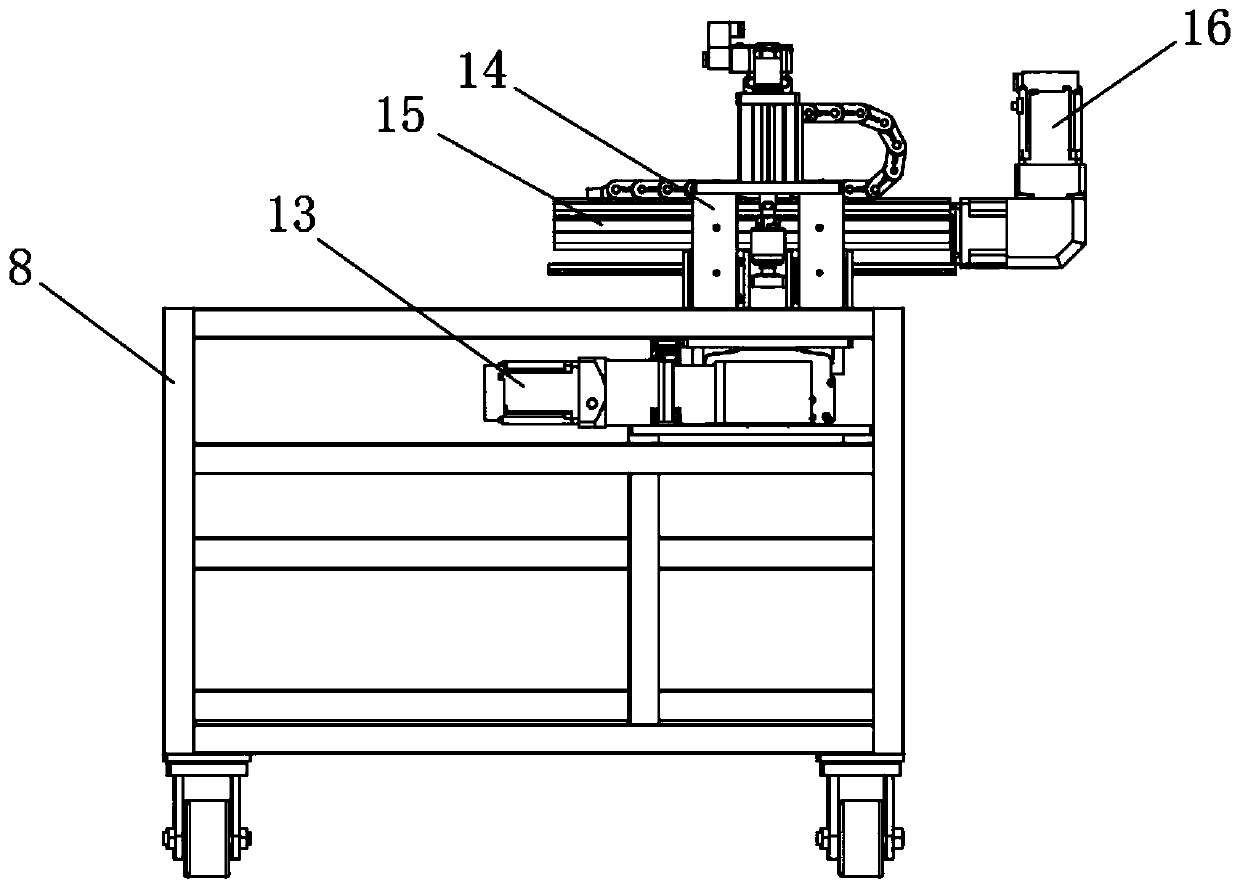

[0030] refer to Figure 1-7 , an automobile exhaust pipe half cover XY axis multi-point automatic butt welding device, comprising a butt welder 1 and an XY axis loading vehicle 8, characterized in that, the butt welding machine 1 and the XY axis loading vehicle 8 are provided with There is a fast positioning mechanism, and the Y-axis loading vehicle 8 is provided with a part cavity clamping mechanism and an XY axis module, and the movement of the XY axis module drives the part cavity clamping mechanism to move and weld correspondingly with the butt welder.

[0031] The quick positioning mechanism includes a bottom plate 2 installed at the bottom of the butt welding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com