Automatic submerged arc welding device for longitudinal seams in steel tubes

A technology of automatic submerged arc welding and internal longitudinal seam, which is applied in the direction of arc welding equipment, electrode support device, electrode characteristics, etc., can solve the problems of time-consuming and laborious, low production efficiency, and difficult to guarantee welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

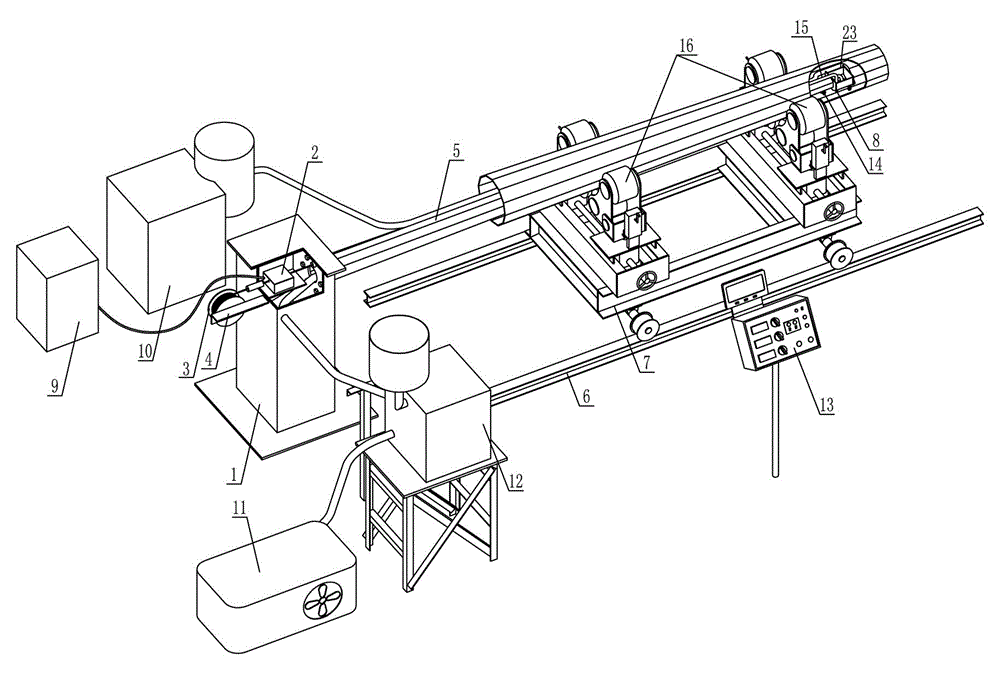

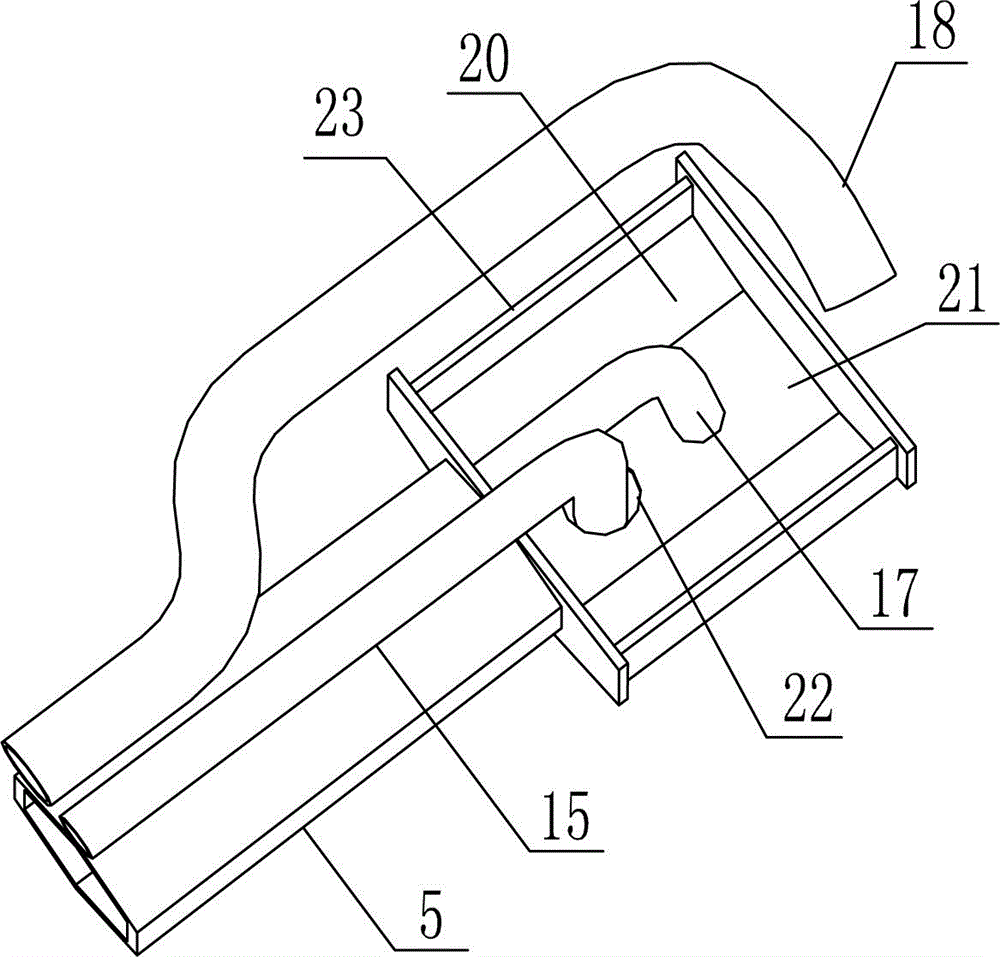

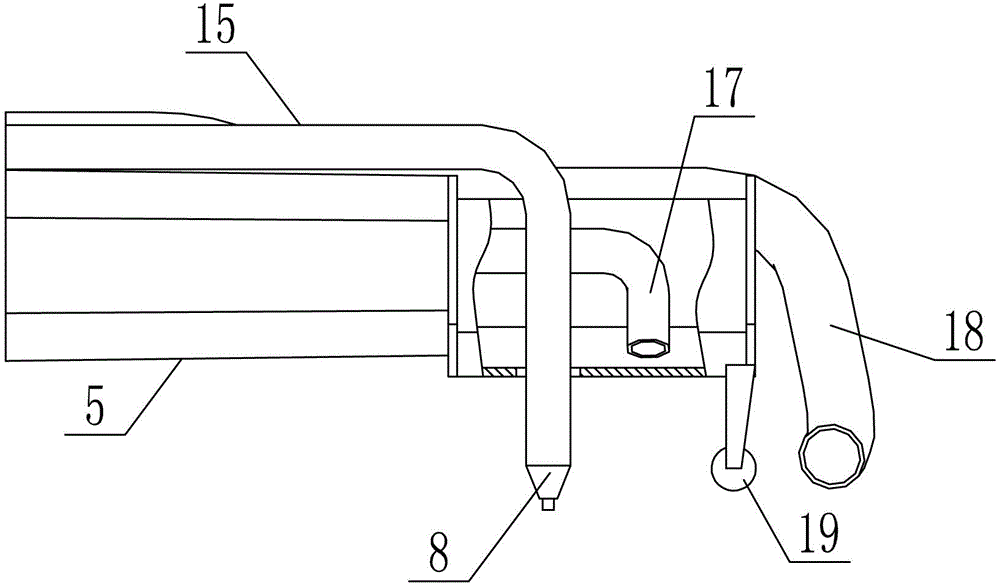

[0020] as attached figure 1 As shown, the present invention includes a machine head 1, an automatic wire feeder 2, a support arm 5, a traveling device 7, a welding torch 8, a wire reel support 4, an air compressor 11, a flux conveyor 12, a welding machine 9, and a flux recycling machine 10 And a control box 13; the machine head 1 is a box type, the automatic wire feeder 2 is fixedly arranged in the machine head 1, and the model of the automatic wire feeder 2 is MZ-1-1000. The wire reel support 4 is fixedly arranged on one side outside the machine head 1, and the wire reel 3 is fixedly arranged on one side of the wire reel support 4; one end of the support arm 5 is fixedly arranged on the other side of the machine head 1. On the other side, the support arm 5 is a hexagonal prism-shaped conical tube, which greatly enhances the rigidity of the support arm 5; the other end of the support arm 5 is fixedly provided with a support wheel frame, and the support roller frame includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com