Handheld electric welding gun with automatic welding rod supply structure

An automatic supply, hand-held technology, applied in the direction of welding rod characteristics, manufacturing tools, welding equipment, etc., can solve the problems of electrode deviation, unfavorable welding accuracy, welding work efficiency, high welding operation technical requirements, etc., to reduce welding difficulty , improve convenience, improve the effect of welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

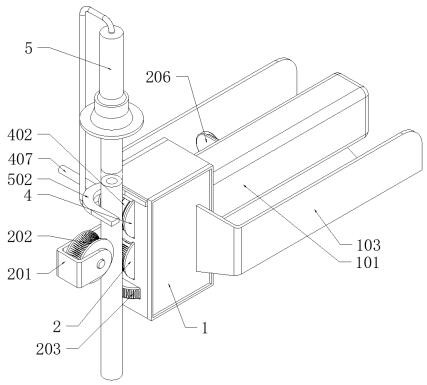

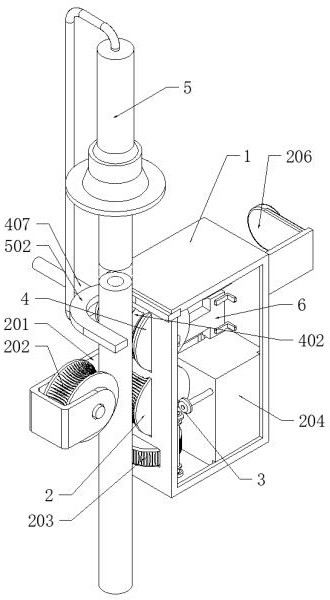

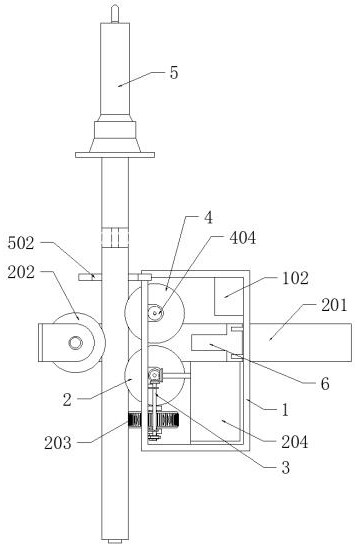

[0048] see figure 1 and Figure 4 , a hand-held electric welding gun with an automatic electrode supply structure, including a housing 1, a handle 101 is fixedly welded on the outer end wall on the right side of the housing 1, a power supply module 102 is fixedly installed on the inner end wall of the housing 1, the housing 1 A protective cover 103 sleeved on the outer side of the handle 101 is fixedly installed on the outer end wall of the handle 101, and the cross section of the protective cover 103 is set as a V-shaped structure. 103 for shielding to avoid electric sparks splashing on the hands of the operator. By setting the protective cover 103 on the outside of the handle 101, it can effectively shield and protect the hands of the operator when holding the handle 101, which effectively improves the operator's hand. The use safety of the device, at the same time, by setting the cross section of the protective cover 103 into a V-shaped structure, it can provide enough gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com