Paper dispenser for optional delivery of saturated or dry paper

A dispenser, liquid technology, used in home appliances and other directions, can solve problems such as manual or motor drive, insufficient liquid coating, and inability to operate normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

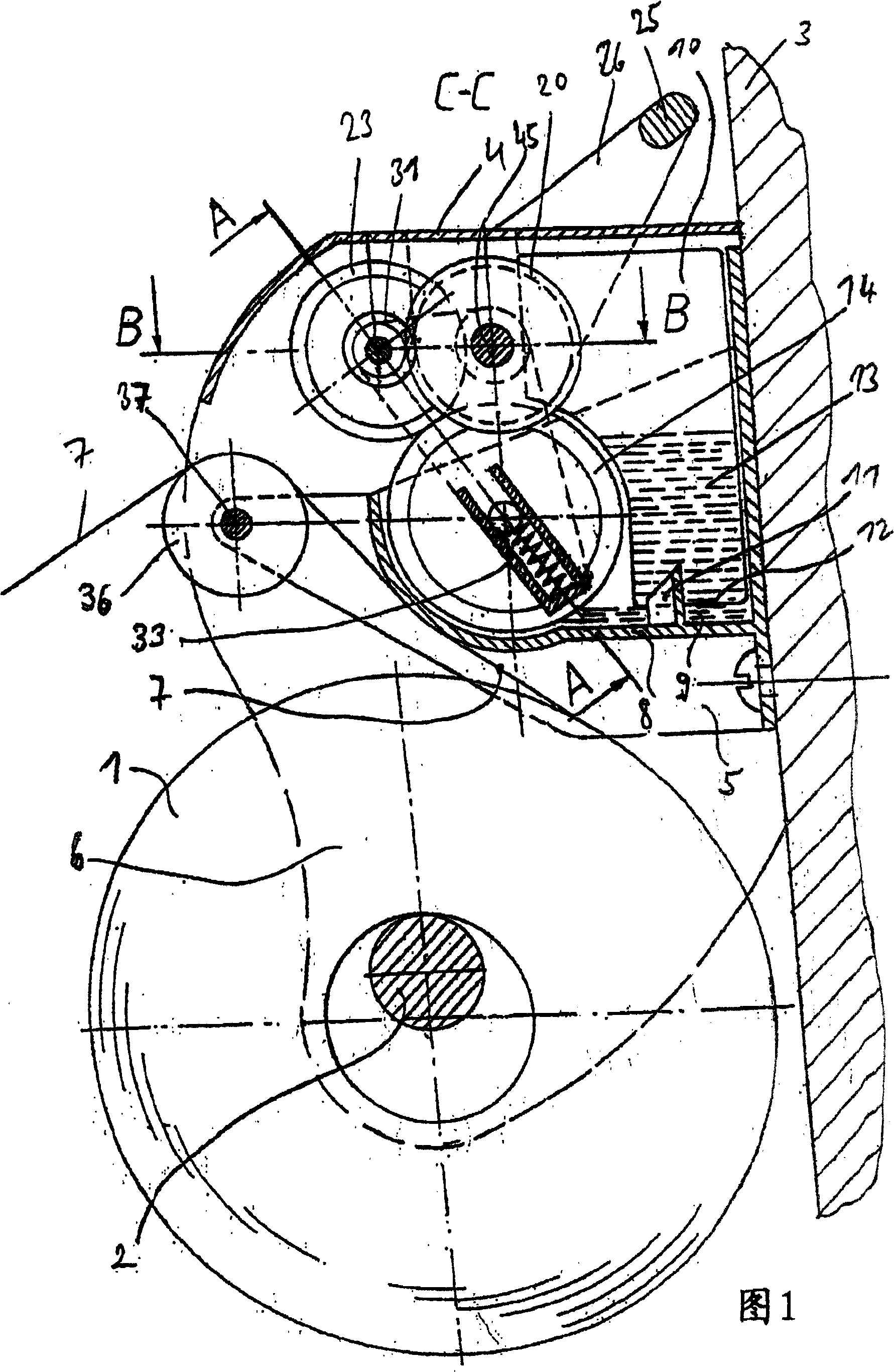

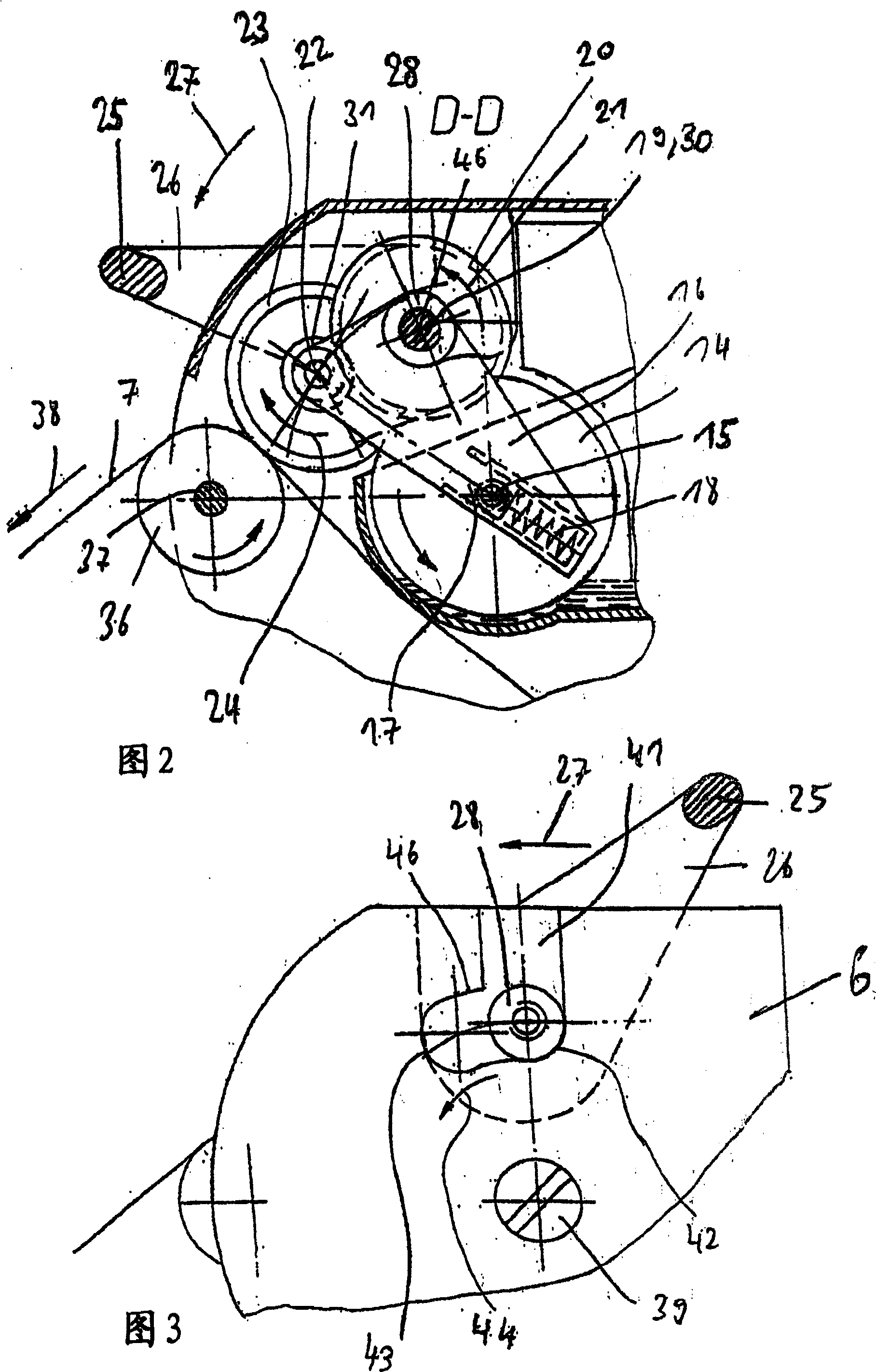

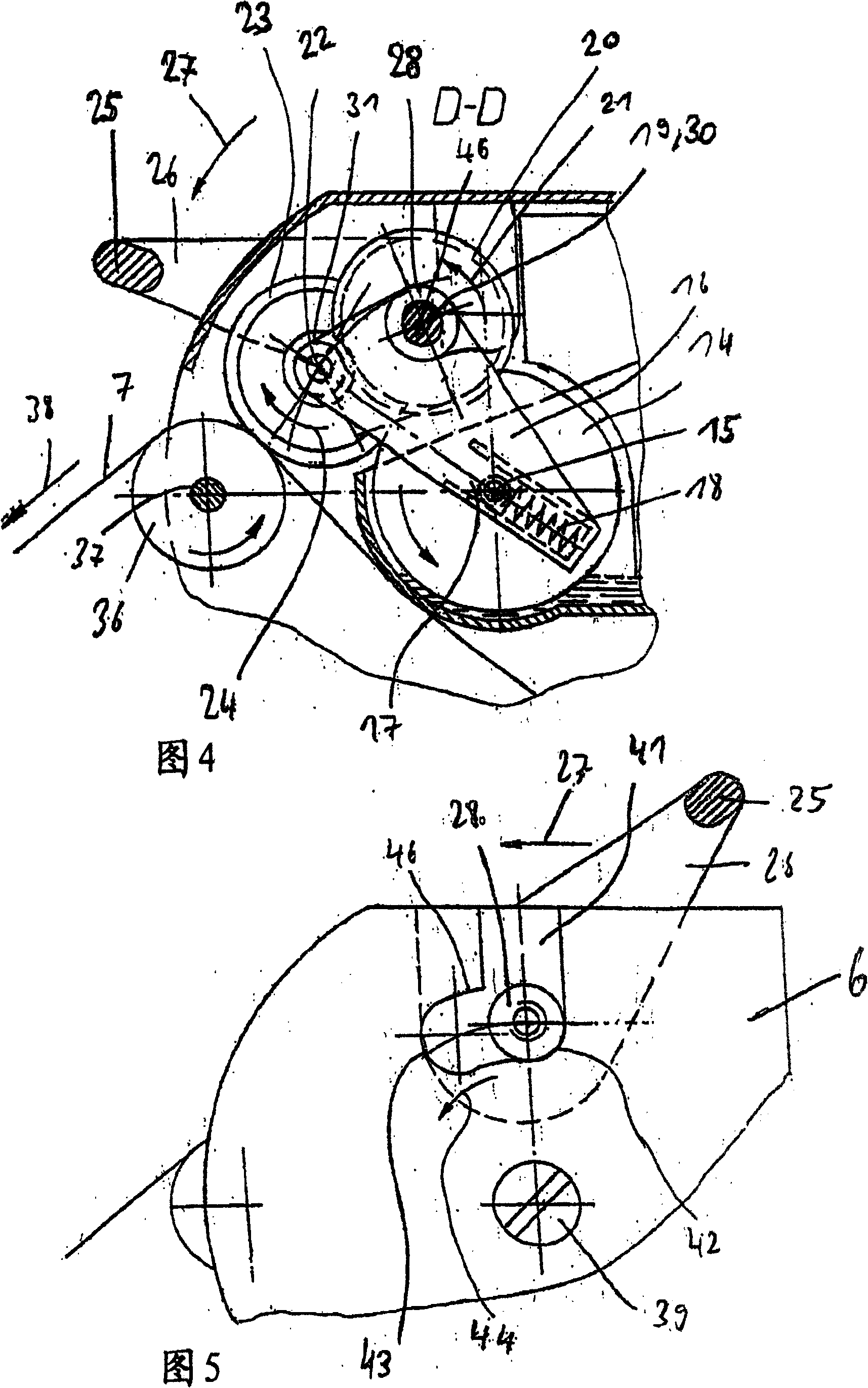

[0036] FIG. 1 generally shows a paper dispenser fastened to a wall 3 with a housing 5 .

[0037] On at least one side of the housing 5, a side wall 6 is arranged, on which a shaft 2 is fastened on one side. A paper roll is pushed from the side on the shaft 2 so that the paper strip 7 drawn from the paper roll 1 can be sent forward by the paper dispenser in the direction of the arrow 38 (see FIG. 2 ).

[0038] The housing 5 can be closed upwards by a cover 4 . A container 8 is inserted into the interior of the housing 5 , which is open upward on one side and has an otherwise surrounding closed side wall and has a closed bottom wall.

[0039] A can 10 (preferably made of plastic) is inserted into the interior of the container 8 from above and pressed with its bottom 12 onto a hollow tip 11 arranged on the bottom of the container 8 .

[0040] The sealing of the liquid in the tank 10 is thus released and the liquid flows via the hollow tip 11 into the interior of the container 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com