Auxiliary mechanism facilitating butt joint of building steel pipes

An auxiliary mechanism and steel pipe technology, which is applied in welding/cutting auxiliary equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of inconvenient welding, low cooling efficiency, time-consuming and laborious fixed welding, etc. The effect of welding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

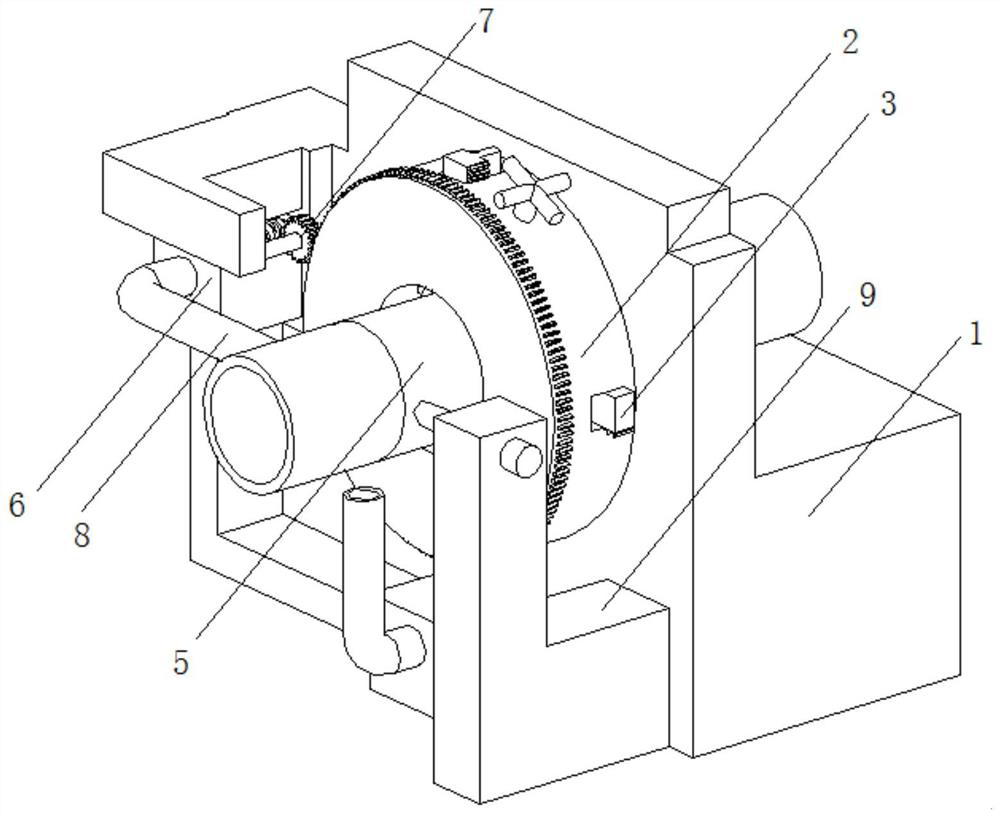

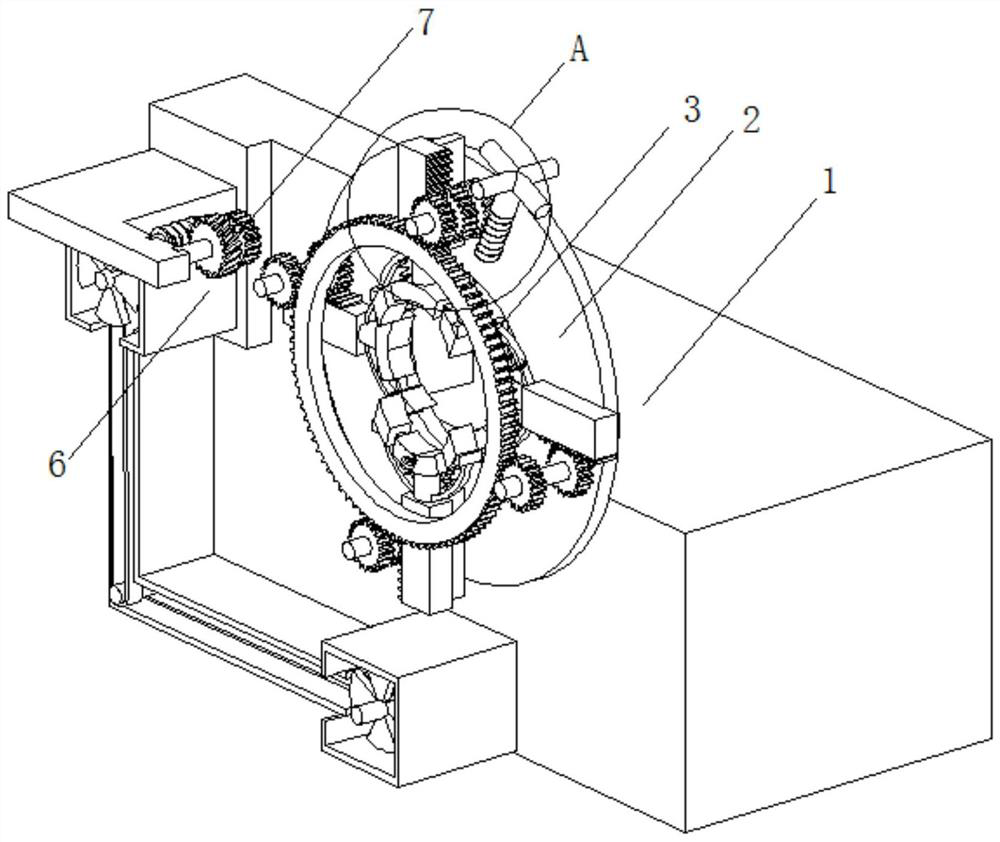

[0031] A aid for aid for building steel pipe docking, such as Figure 1 - Figure 5 As shown, including the pair of receivers, the internal rotation of the pair of recesses 1, and the inside of the rotary seat disk 2 is provided with a fixing mechanism 3, and the surface of the fixing mechanism 3 is provided with a steel pipe body 5, a front portion of the receiving station 1. The bolt is fixedly connected to the protective case 6, and the inner portion of the protective case 6 is provided with a rotating mechanism 7, and the front portion of the protective case 6 is in communication with a blower tube 8, and the front portion of the front portion of the guard box 6 is fixedly connected to the welding machine. Block 9.

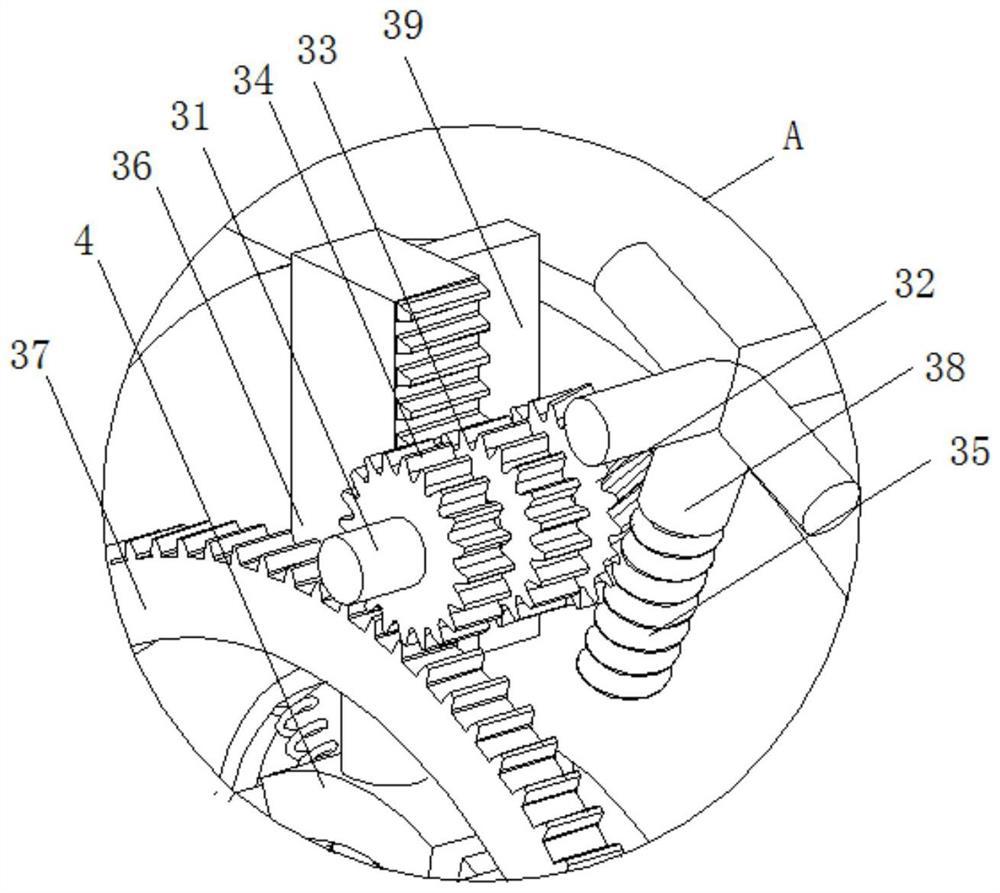

[0032] In the present embodiment, the fixing mechanism 3 includes a conversion post 31, both ends of the column 31, and the inner wall of the rotary seat disc 2, and the surface of the column 31 are welded to have a movable worm wheel 32, the meshing gear 33, and th...

Embodiment 2

[0043] like Figure 6-7 As shown, in the basis of the first embodiment, in the present embodiment, the rotating mechanism 7 includes a motor 71 and a secondary roller 74, and the surface of the motor 71 is fixedly connected to the surface of the panel 1, the output shaft card of the motor 71. In touch with the active roller 72, the front end of the active roller 72 is welded, and the surface welding of the secondary pass roller 74 is welded, and the interior of the interior of the interior of the discharge wheel 75 is engaged with the interior welding of the interior welding of the interior of the discharge wheel 76. The connecting shaft 77, the surface welding of the connecting shaft 77 has a rotating gear 78.

[0044] By providing the rotating mechanism 7, the interaction between the various structures between the rotation mechanism 7 is used to achieve the effect of rotating the welding while the fan 73 is reached, and the steel tube body 5 is rotated in the restriction of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com