Automobile lower suspension arm assembly

A technology for lower swing arms and assemblies of automobiles, which is applied in the field of auto parts and can solve problems such as affecting the normal driving of vehicles, cracks, and reduced shock absorption effects, and achieves the advantages of simple processing, increased firmness and strength, and improved welding accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

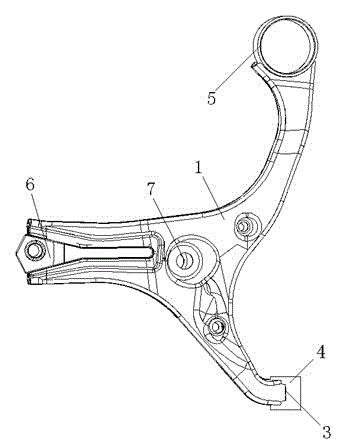

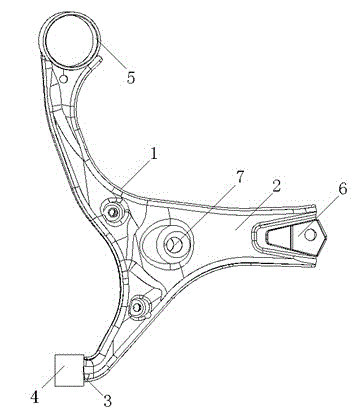

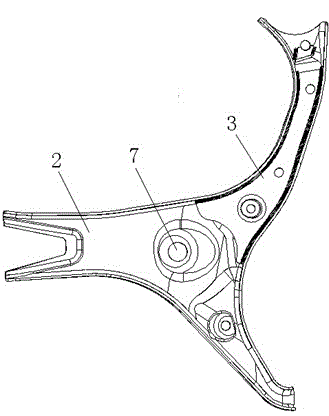

[0015] A lower swing arm assembly for automobiles, mainly comprising a lower swing arm main body assembly and a shaft pin bushing sleeve 4, a front bushing sleeve 5, and a ball stud bracket 6 arranged on the lower swing arm main body assembly, it is characterized in that the The main body assembly of the lower swing arm is composed of an upper plate 1, a lower plate 2 and a reinforcing plate 3, the upper plate 1 and the lower plate 2 are both arranged in a U-shaped structure, and the two sides of the upper plate 1 and the lower plate 2 are connected by welding , the connection gap between the upper plate 1 and the lower plate 2 is less than 1mm, and the uniform welding between the upper plate 1 and the lower plate 2 can improve the structural performance of the main body assembly of the lower swing arm, so that the lower swing arm assembly of the car is not easy to deform and crack , while the assembly method is simple, the processing efficiency is high, and the production cost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com