Bridge steel structure and welding method thereof

A bridge steel and stable structure technology, applied to bridges, bridge parts, welding equipment, etc., can solve the problems of difficult adjustment of welding methods, low welding accuracy, poor welding effect, etc., achieve strong adjustability and improve welding accuracy degree, good welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

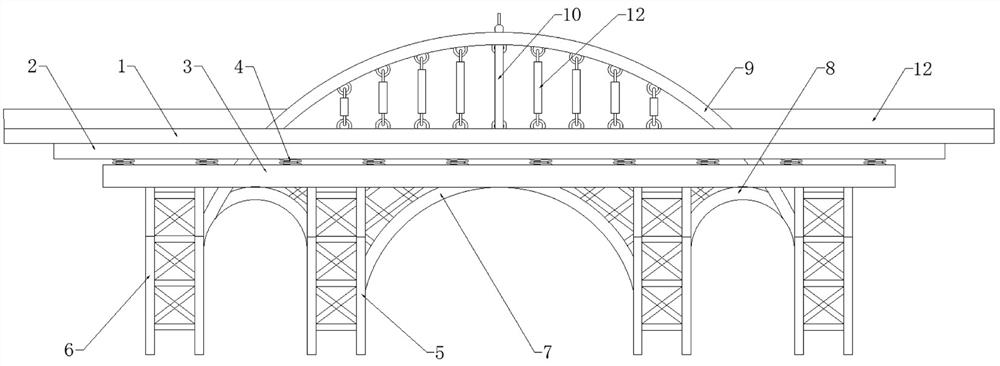

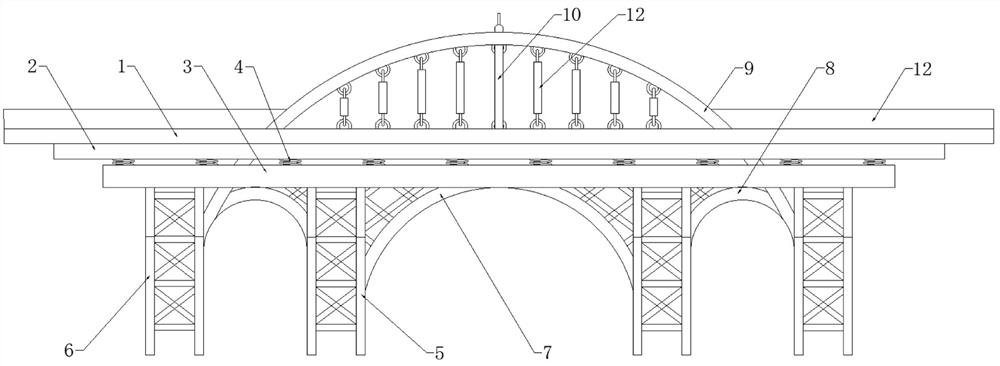

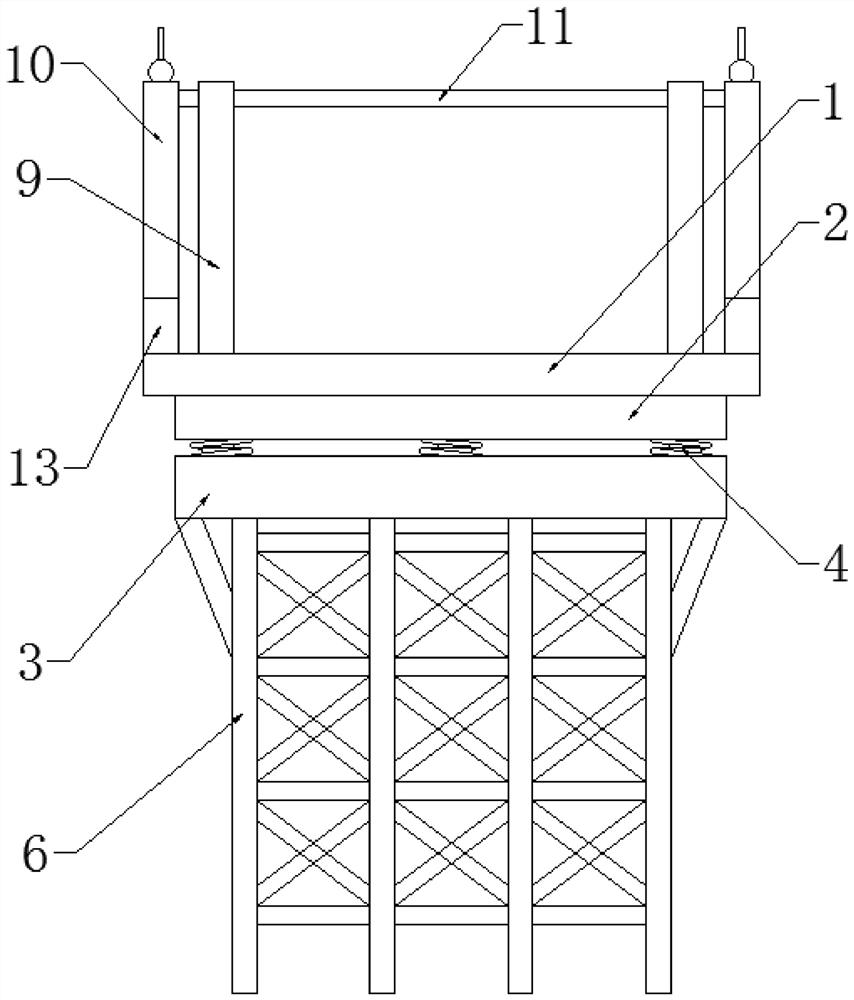

[0041] refer to Figure 1-7 , a bridge steel structure, including a bridge deck, the bottom of the bridge deck is fixedly installed with a fixed plate, the side of the fixed plate away from the bridge deck is provided with a bridge deck base, and the bridge deck base is connected to the fixed plate with a shock-absorbing The shock-absorbing structure is evenly distributed between the bridge deck base and the fixed plate. The side of the bridge deck base away from the fixed plate is fixedly installed with the main pier. The main pier is symmetrical with the central axis of the bridge deck base as the axis of symmetry. distribution, the two main piers are fixedly connected with a main arc-shaped tunnel, and the side of the main pier away from the main arc-shaped tunnel is equipped with auxiliary piers, and the auxiliary piers and the main piers are fixedly connected with an auxiliary arc-shaped tunnel, and the two auxiliary piers are fixedly connected There is a support frame, w...

Embodiment 2

[0062] On the basis of embodiment 1, the following adjustments are made to the specific steps before welding and the specific welding steps:

[0063] A welding method for a bridge steel structure, the specific steps before welding are as follows:

[0064] S1. Read the process documents carefully before assembly, and the direction of the steel plate, the position and size of the weld must be seen clearly. or arc receiving plate;

[0065] S2, steel plate is assembled:

[0066] S3. During the assembly process, the steel plate is welded and positioned, and the basic electrode with the electrode grade of 507 is used. The electrode should be placed in the insulation tube and used as it is taken out. The DC reverse connection method is used for welding;

[0067] S4. For tack welding during assembly, the welding length should be more than 50mm, the spacing should be less than 400mm, and the filling section should not exceed half of the weld cross section, and when cracks occur in ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com