Patents

Literature

39results about How to "Reduce the minimum distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

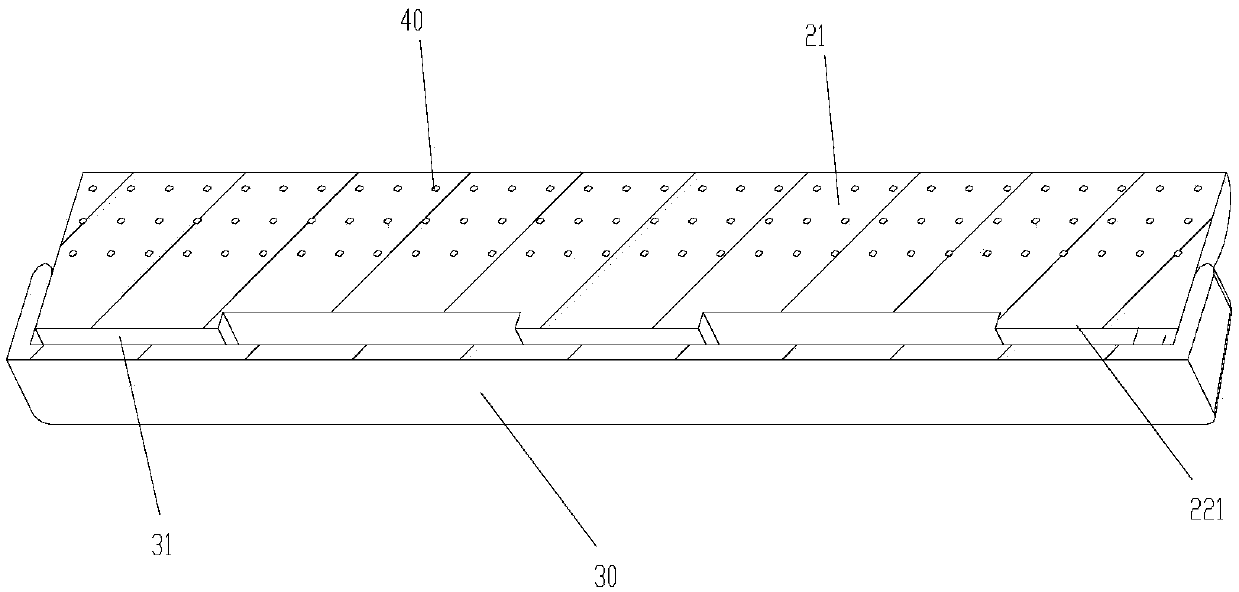

Planar antenna for mobile satellite applications

ActiveUS20100060535A1Satisfactory efficiencyLow-profileSimultaneous aerial operationsRadiating elements structural formsMicrostrip patch antennaGround plane

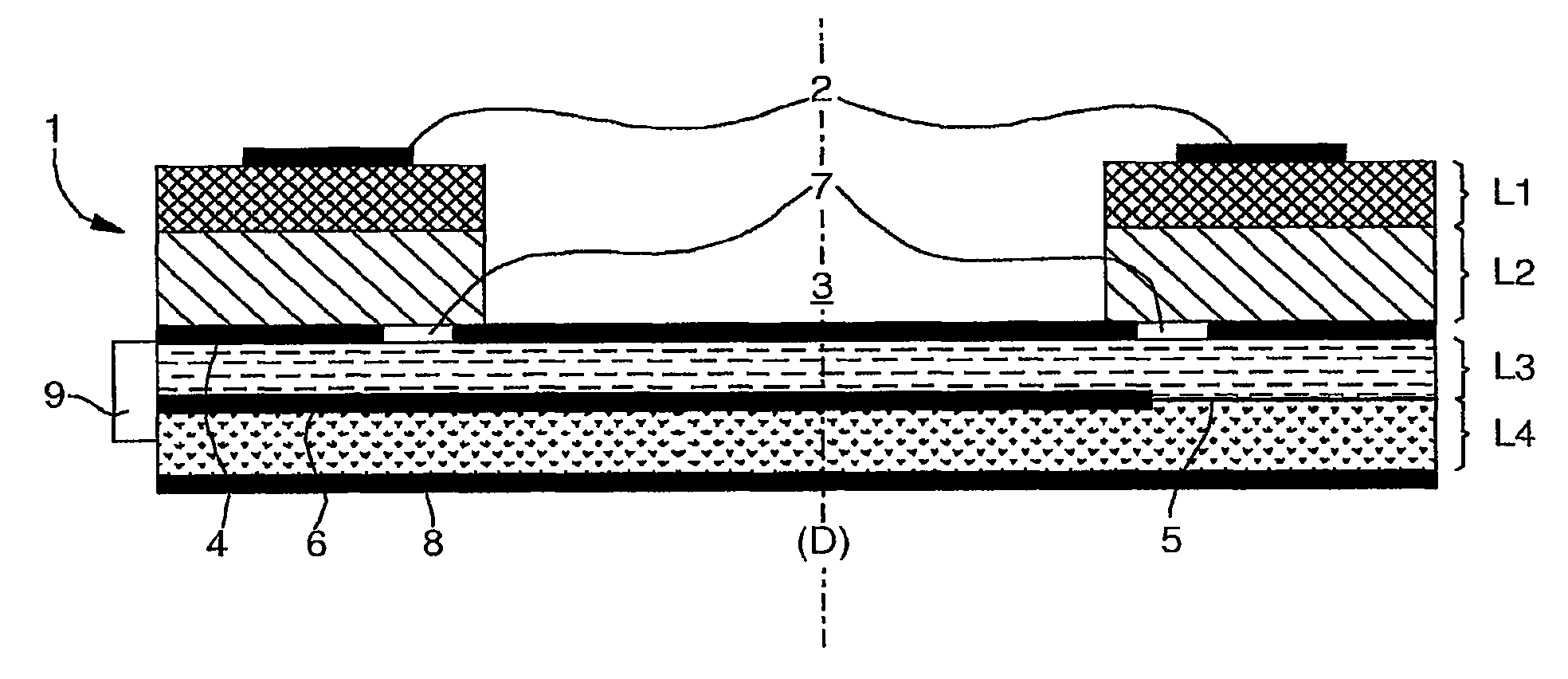

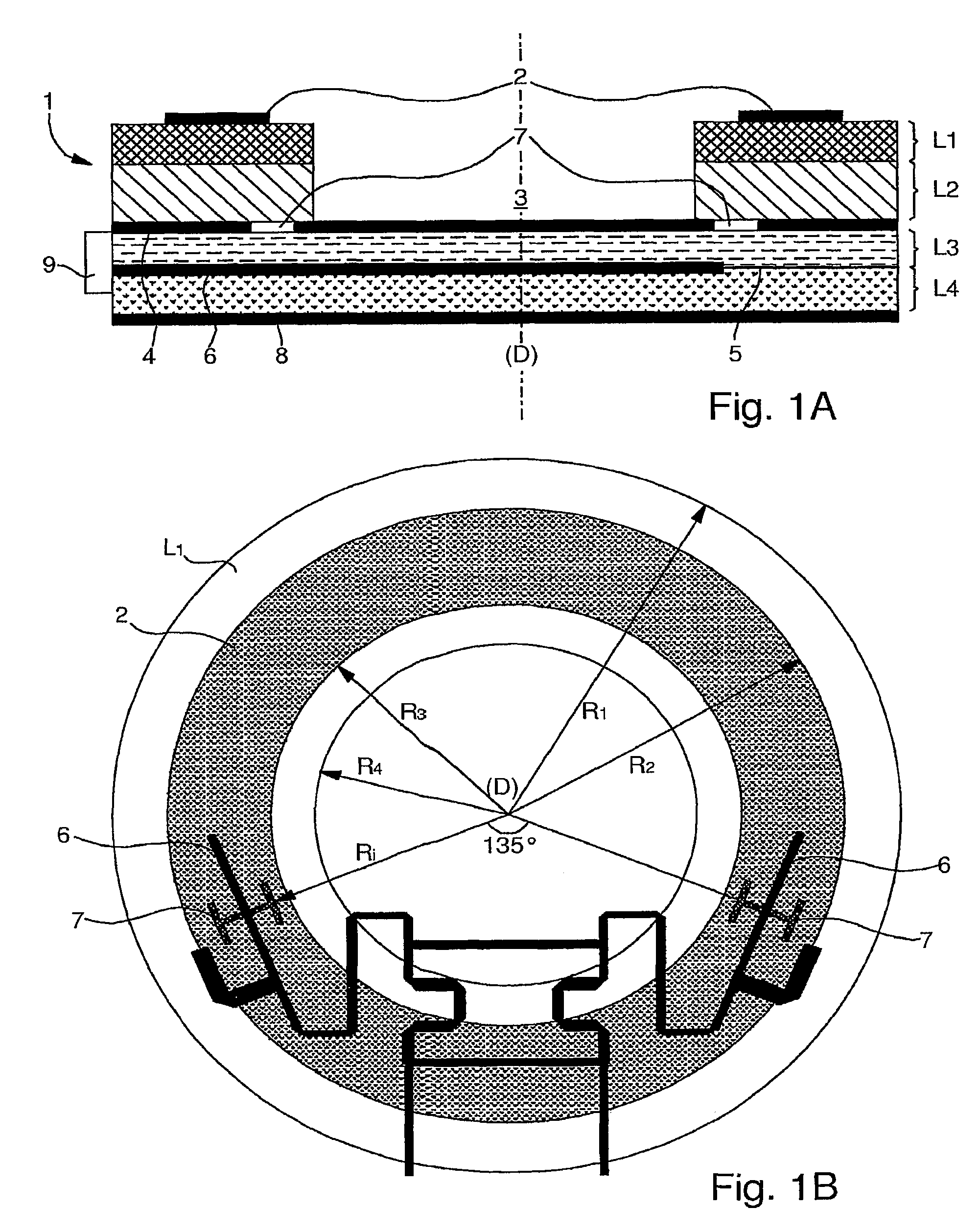

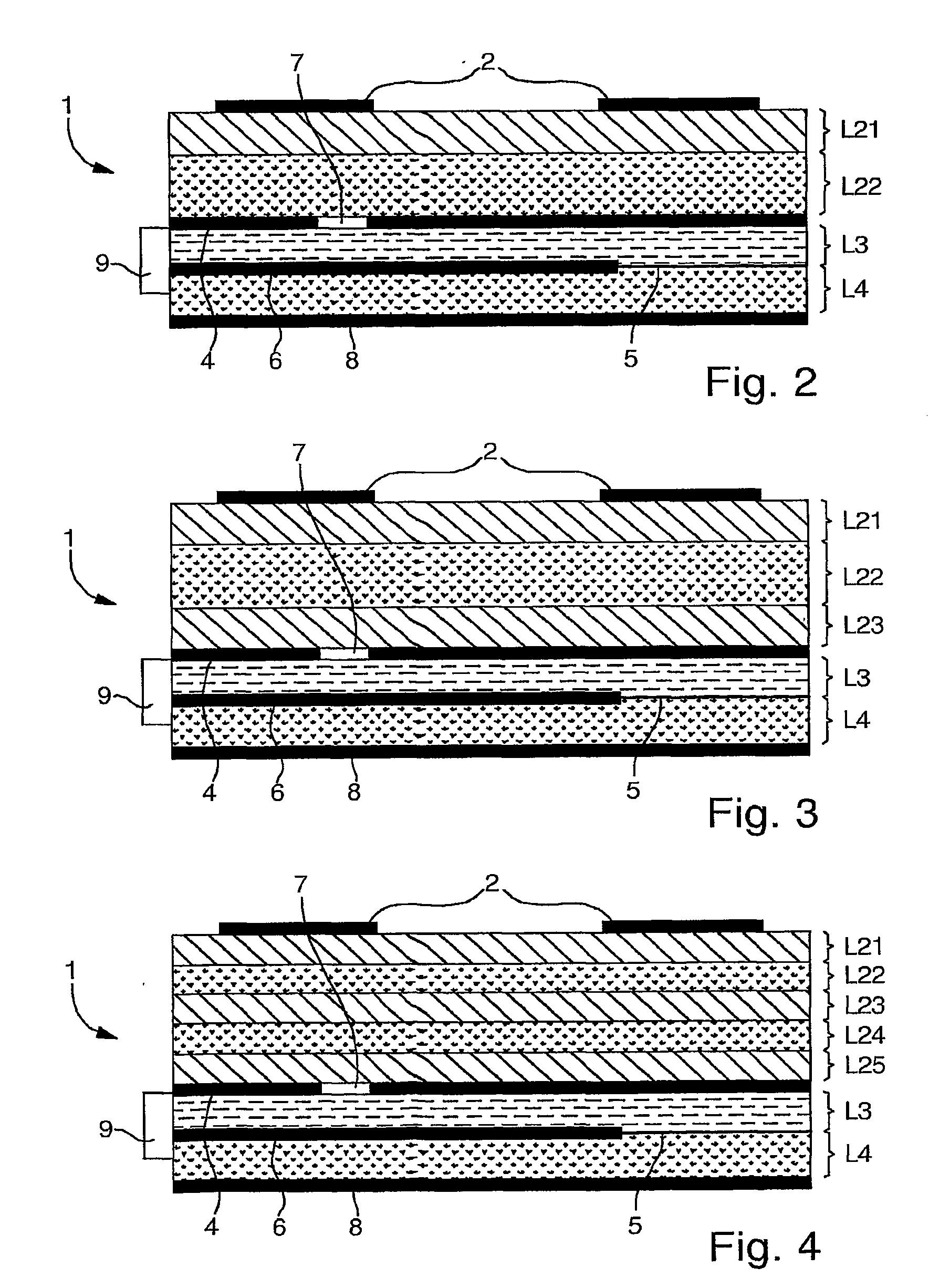

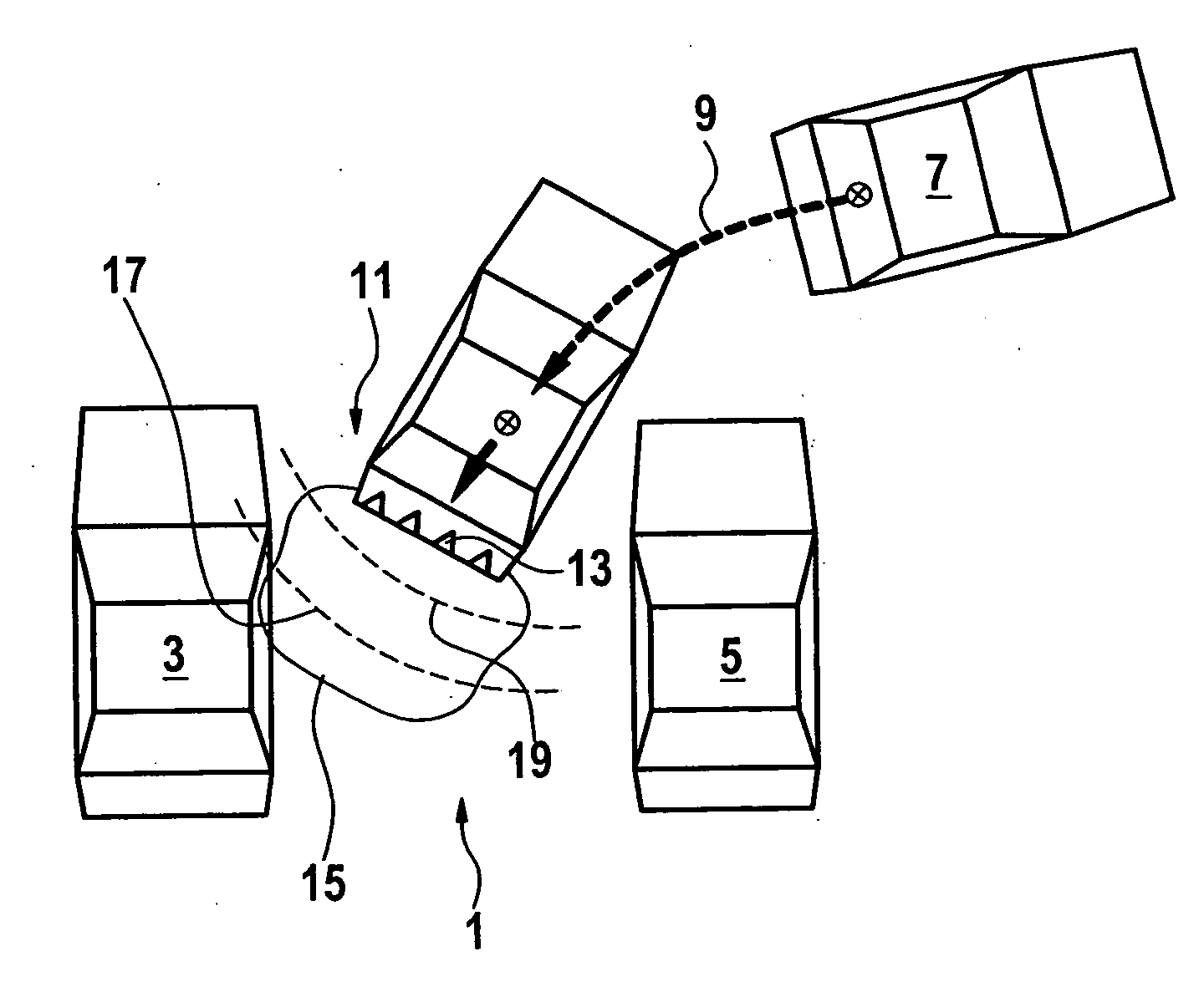

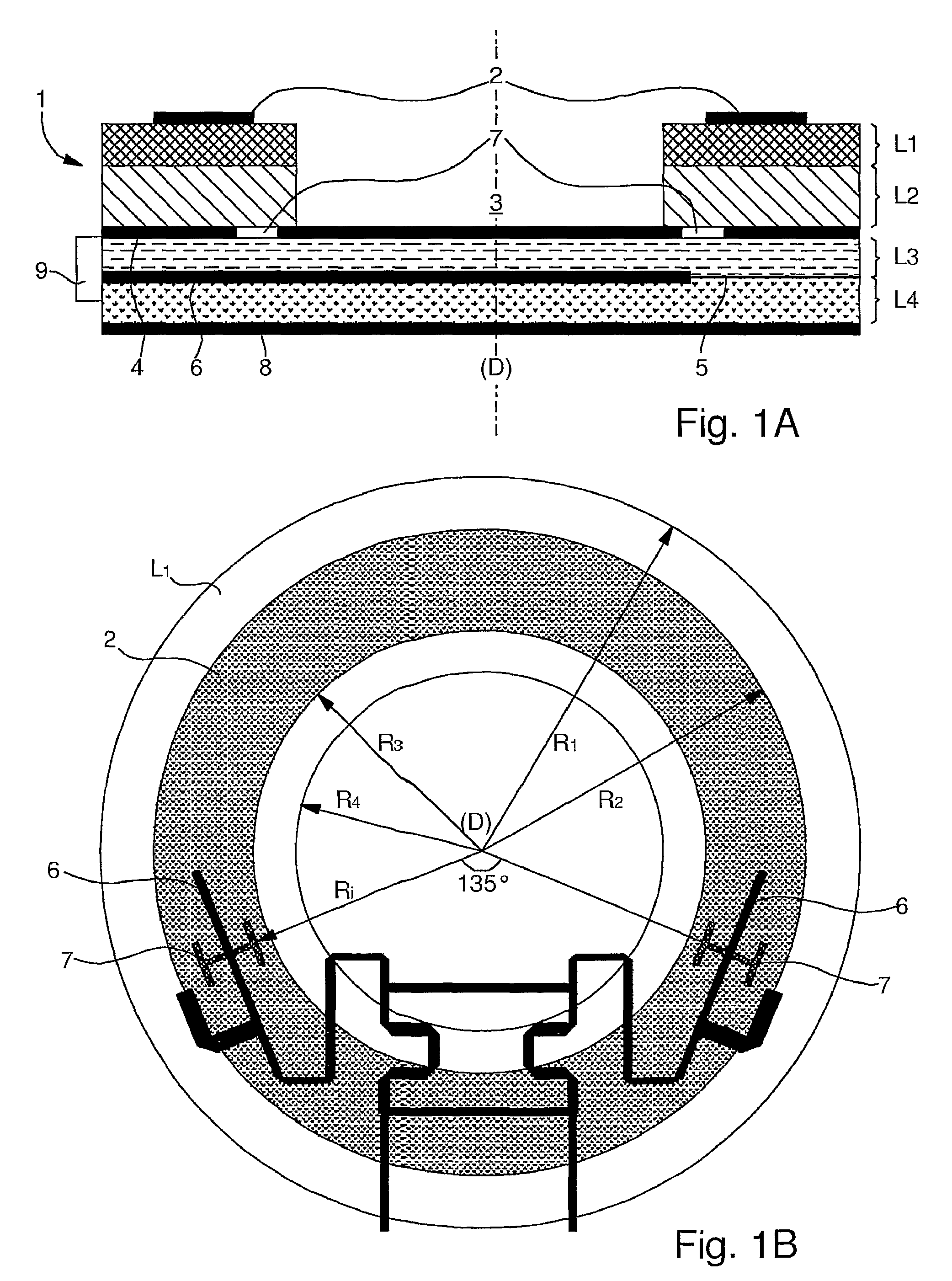

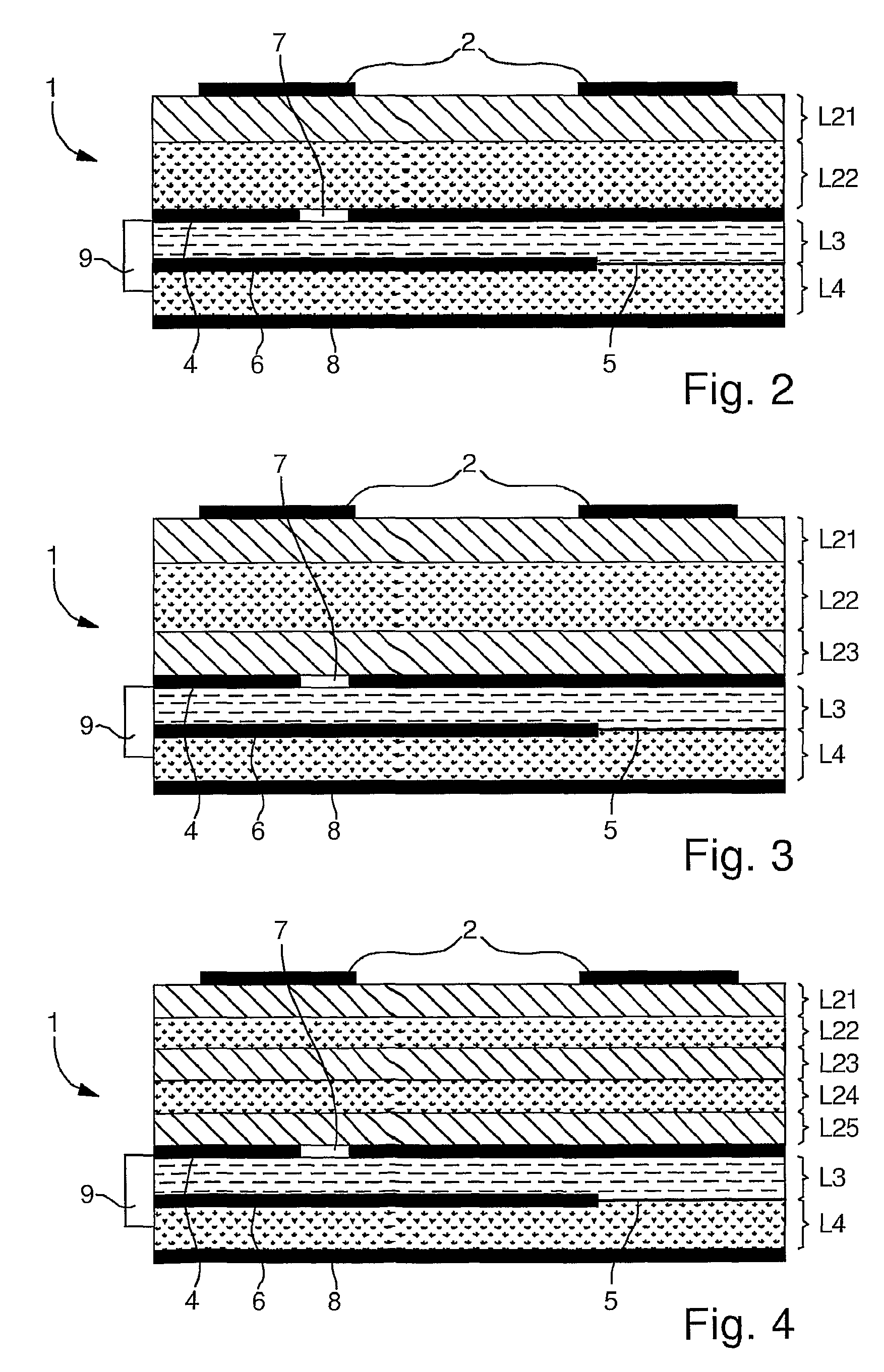

The invention relates to a microstrip patch antenna for mobile satellite communications comprising a first electrically conducting ground plane having at least one opening, at least one patch radiating element, at least one first dielectric layer, disposed between the first electrically conducting ground plane and the patch radiating element and more particularly between the at least one opening and the patch radiating element, at least one feed line for providing signal energy in a contactless manner to or from the patch radiating element through the opening and a second dielectric layer disposed between the feed line and the first electrically conducting ground plane wherein the antenna further comprises a second ground plane and a third dielectric layer disposed between the second ground plane and the feed line.

Owner:VIASAT INC

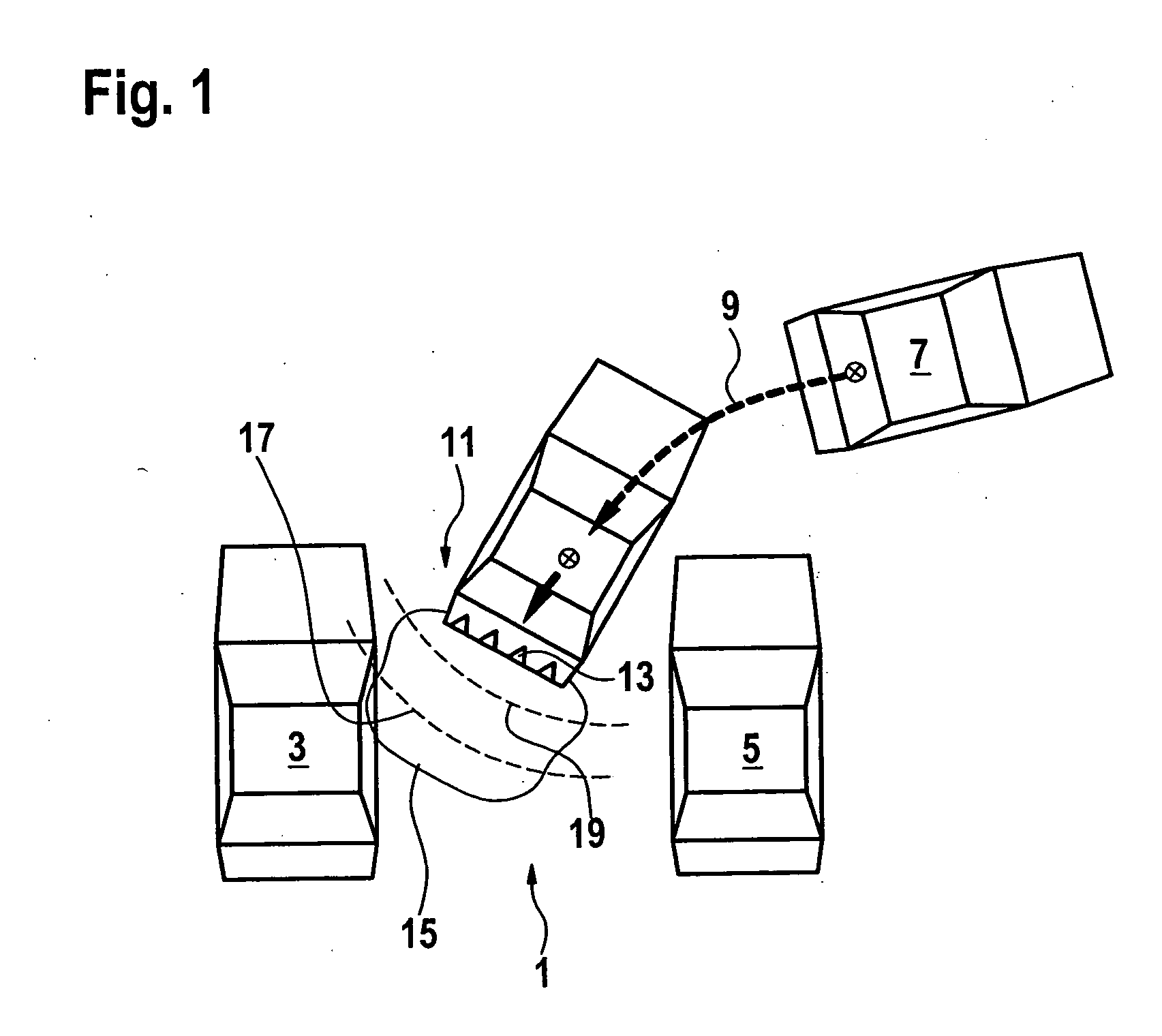

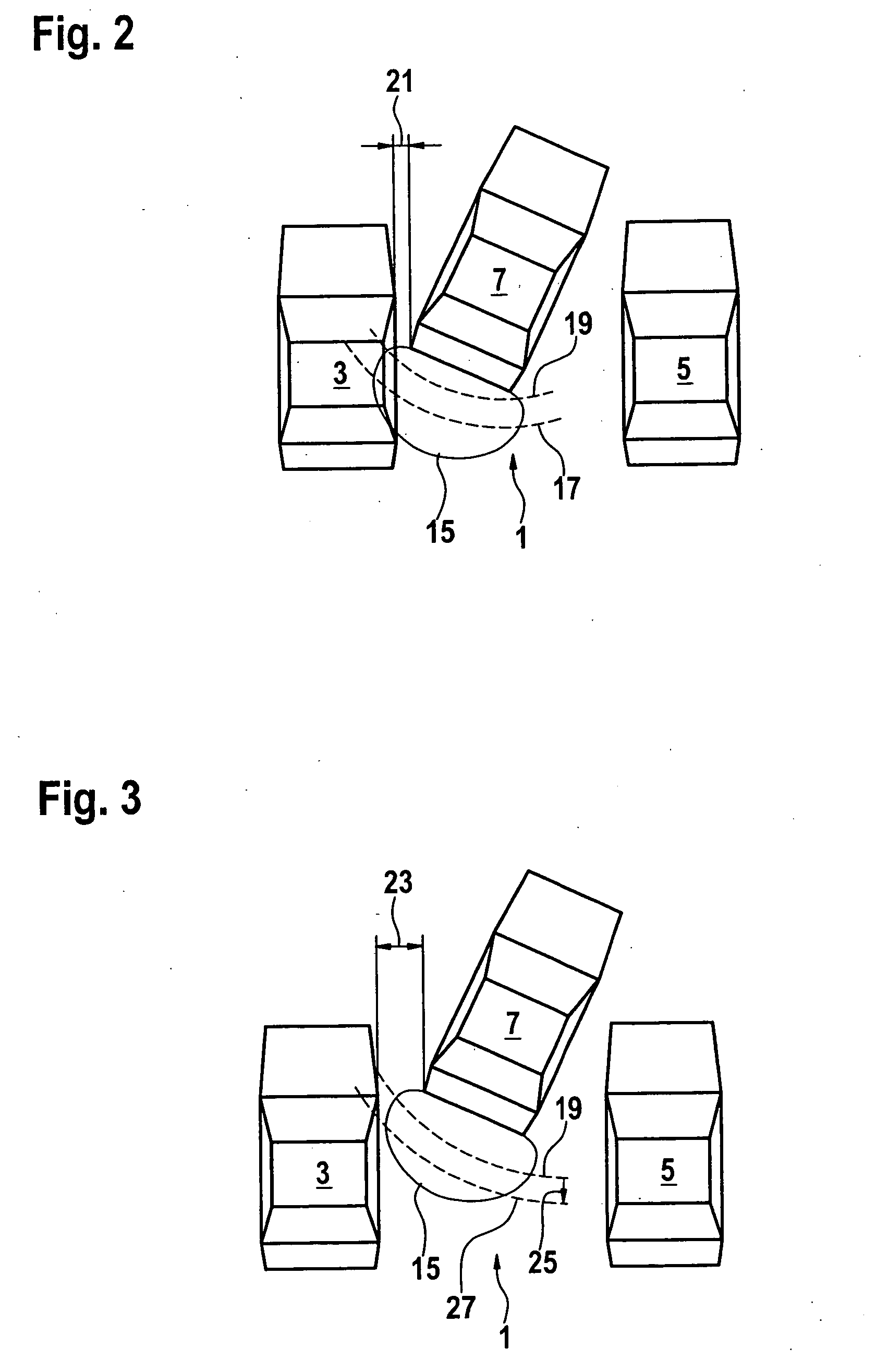

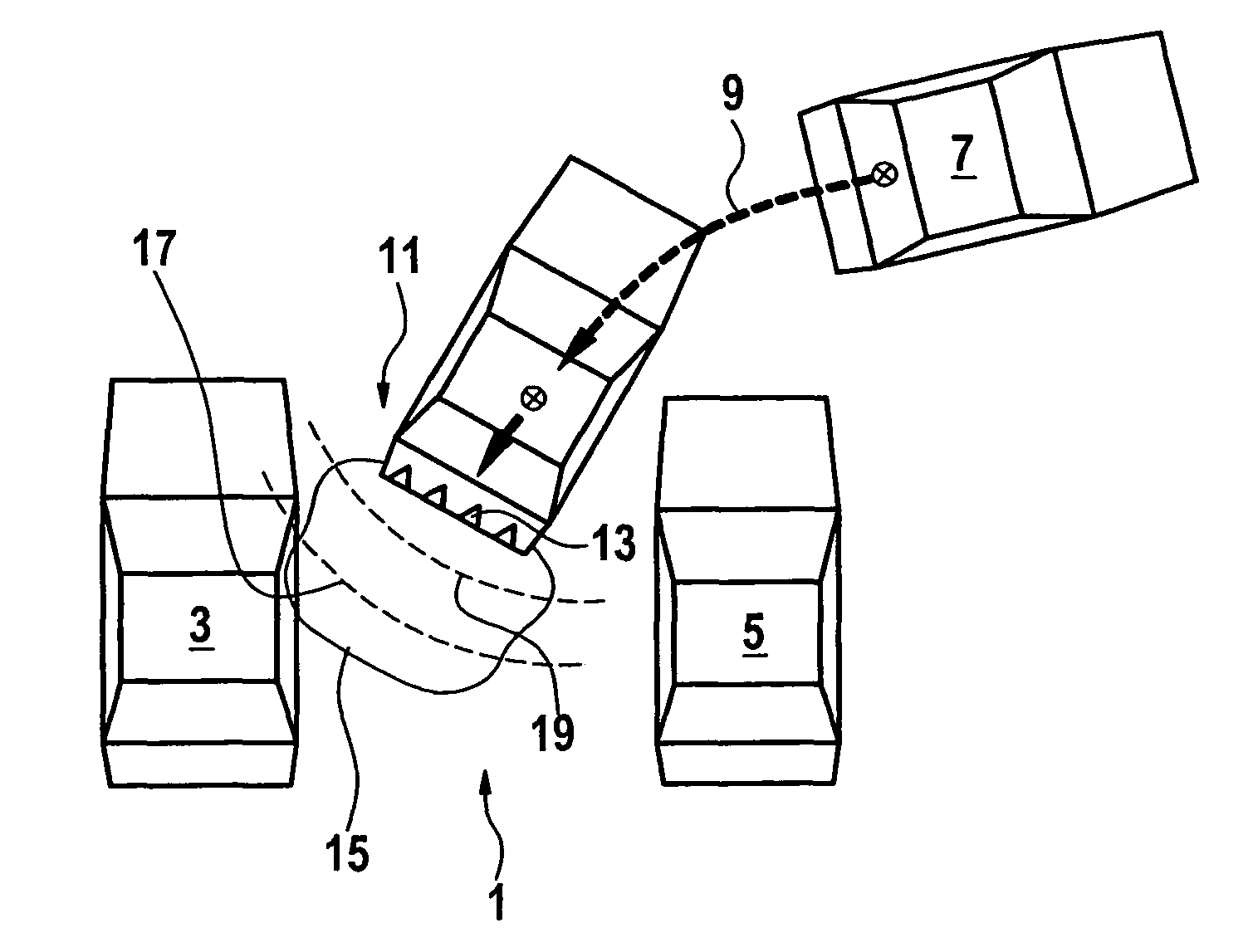

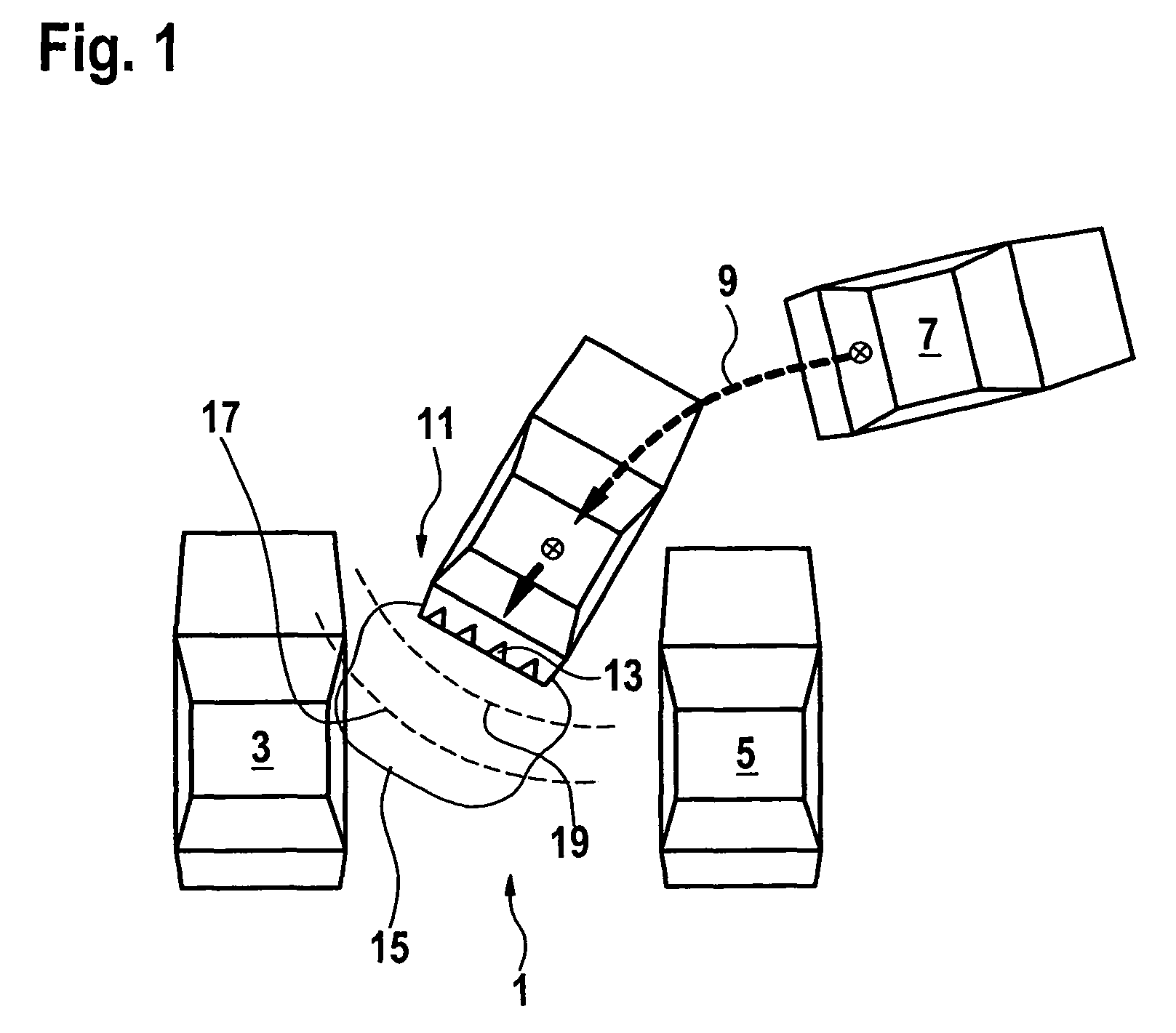

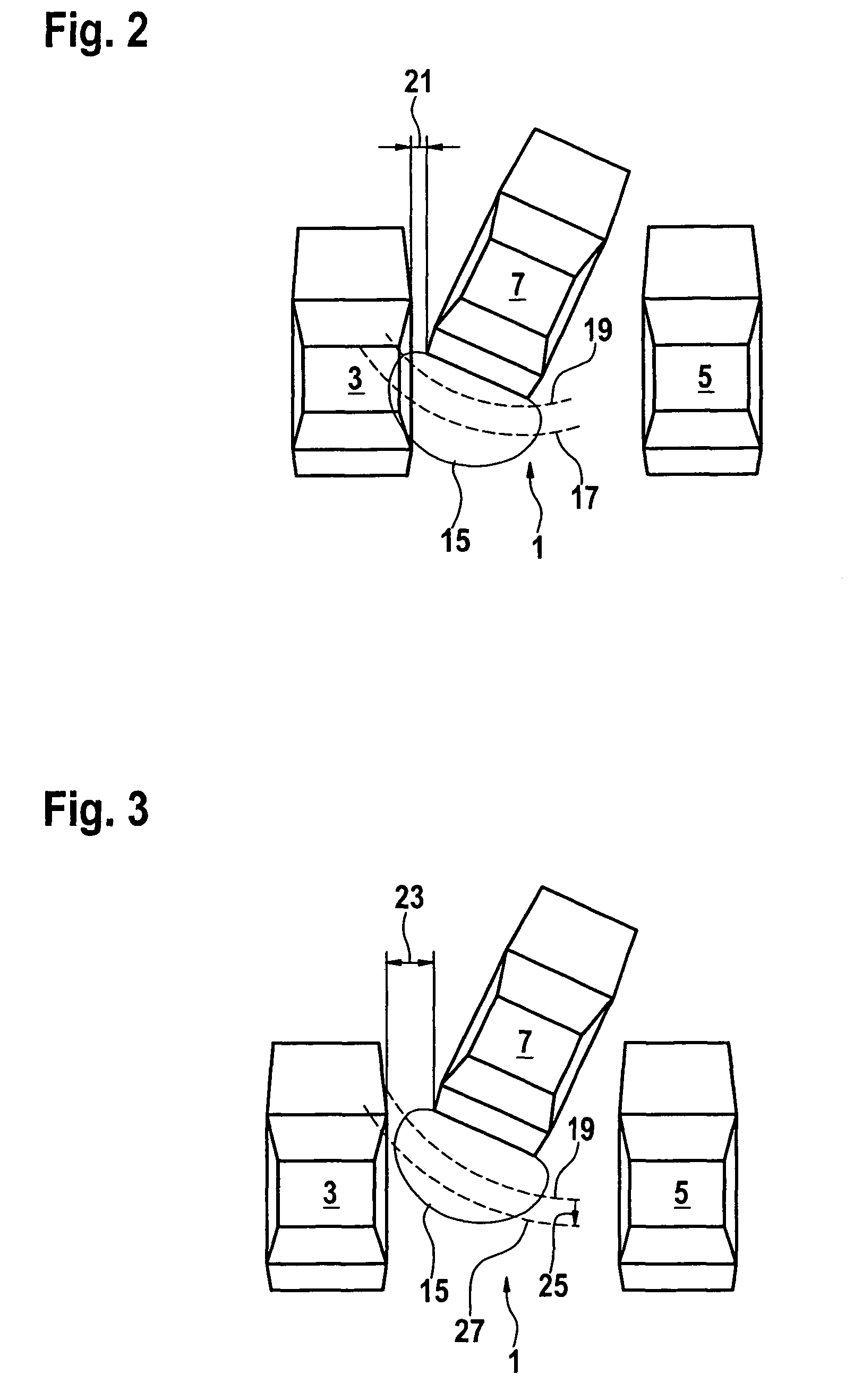

Method for warning a driver of a collision

ActiveUS20120013485A1Reduce the minimum distanceLarge minimum distanceIndication of parksing free spacesSteering partsDriver/operatorParking space

In a method for warning a driver of a vehicle about a collision with an object in the course a parking operation, the distance of the vehicle to at least one object in the environment of the vehicle is detected, and if a specified minimum distance is undershot, the driver is warned to stop the vehicle or the vehicle is stopped automatically. The specified minimum distance is varied as a function of the type of parking space and the executed parking maneuver.

Owner:ROBERT BOSCH GMBH

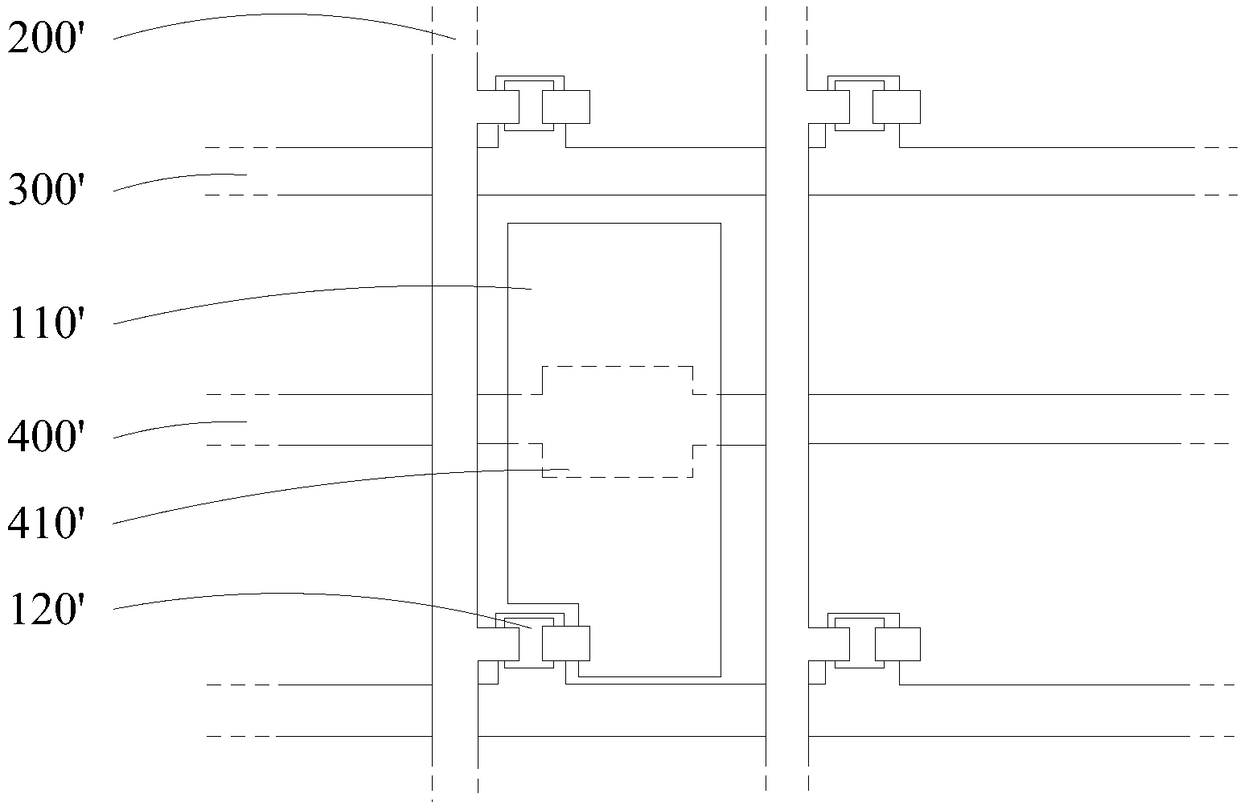

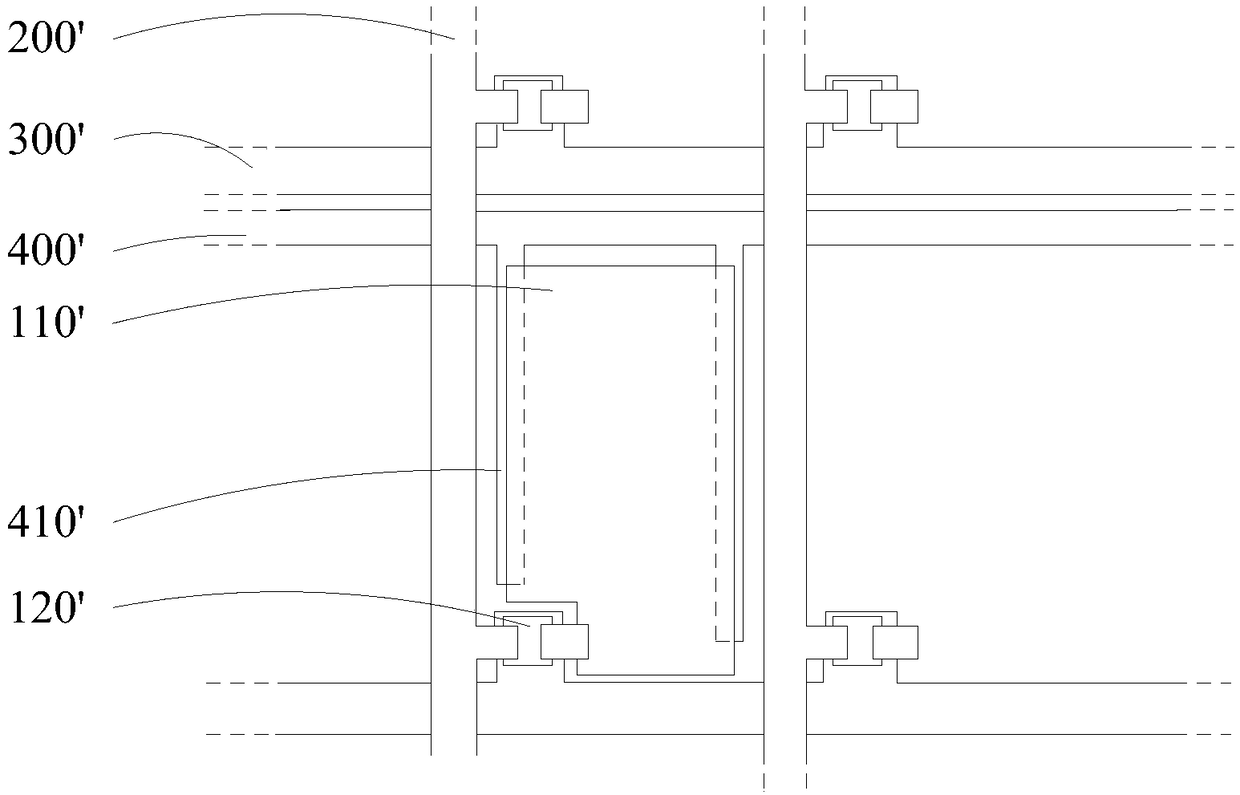

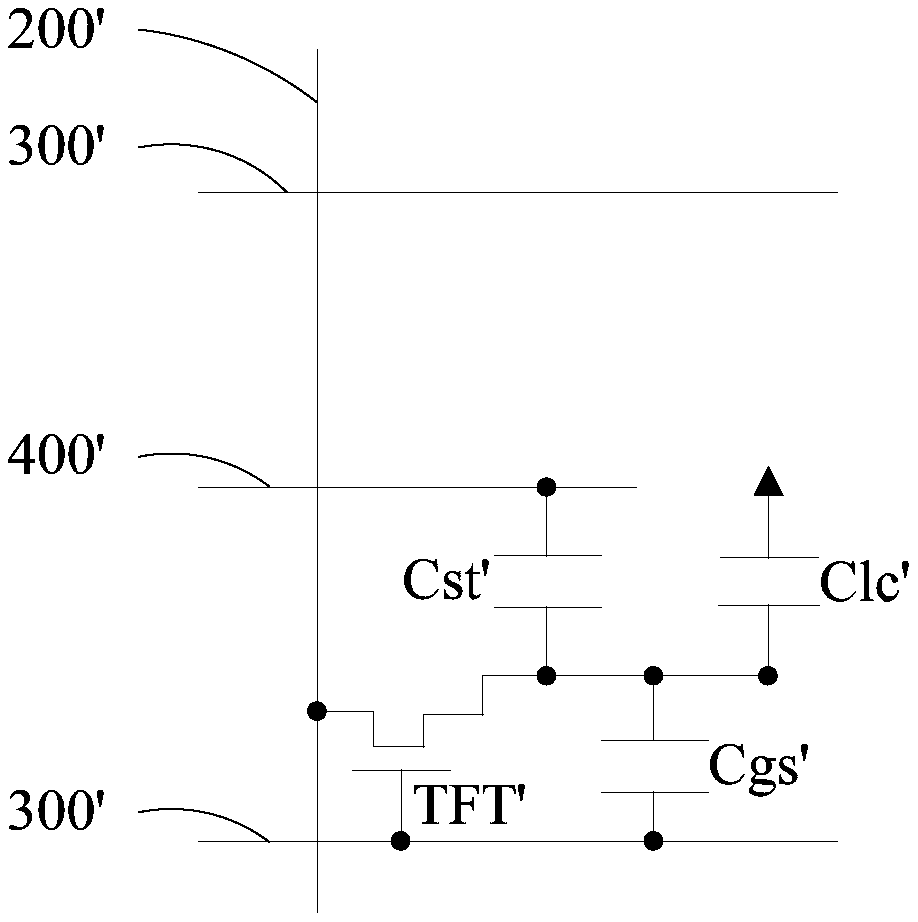

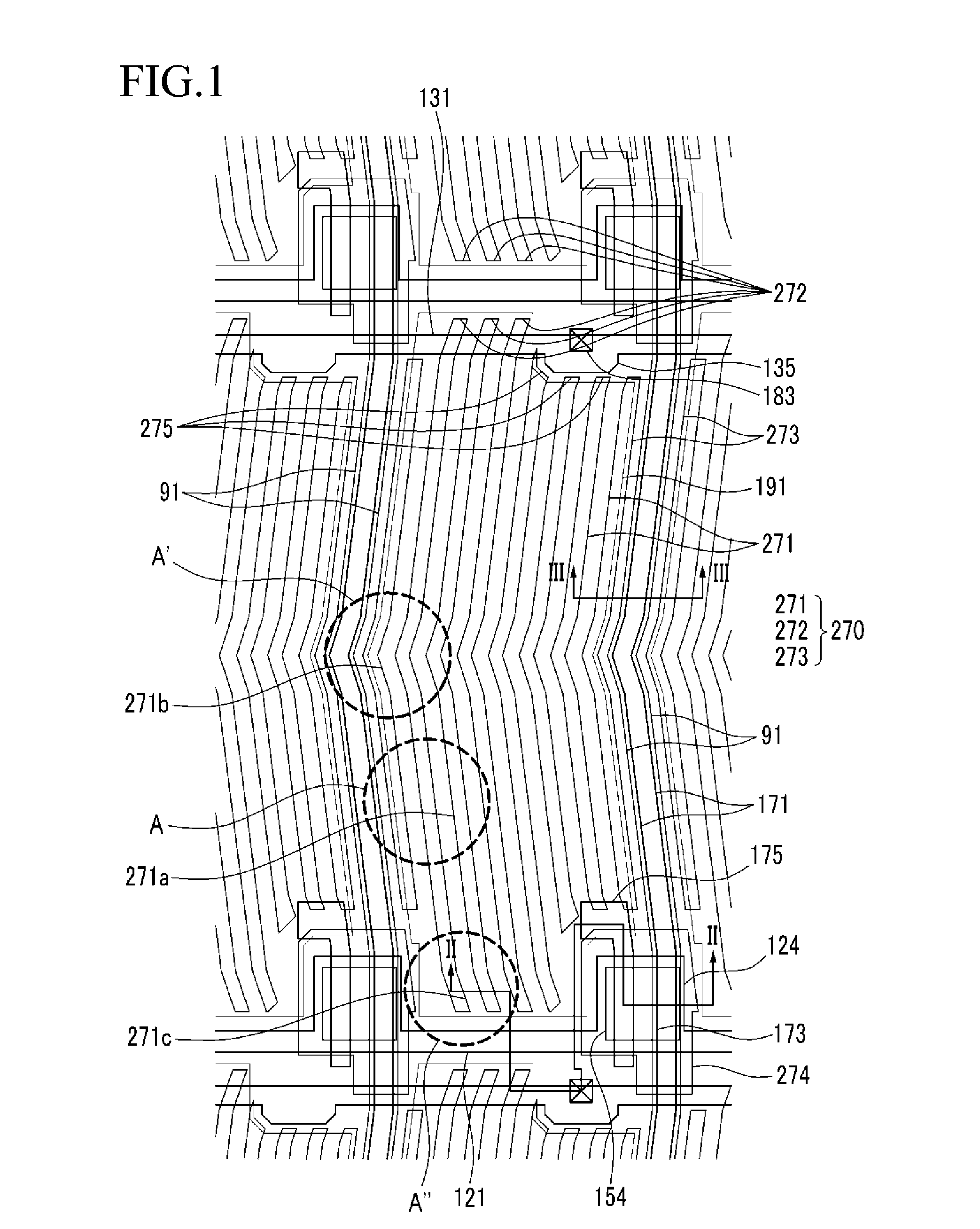

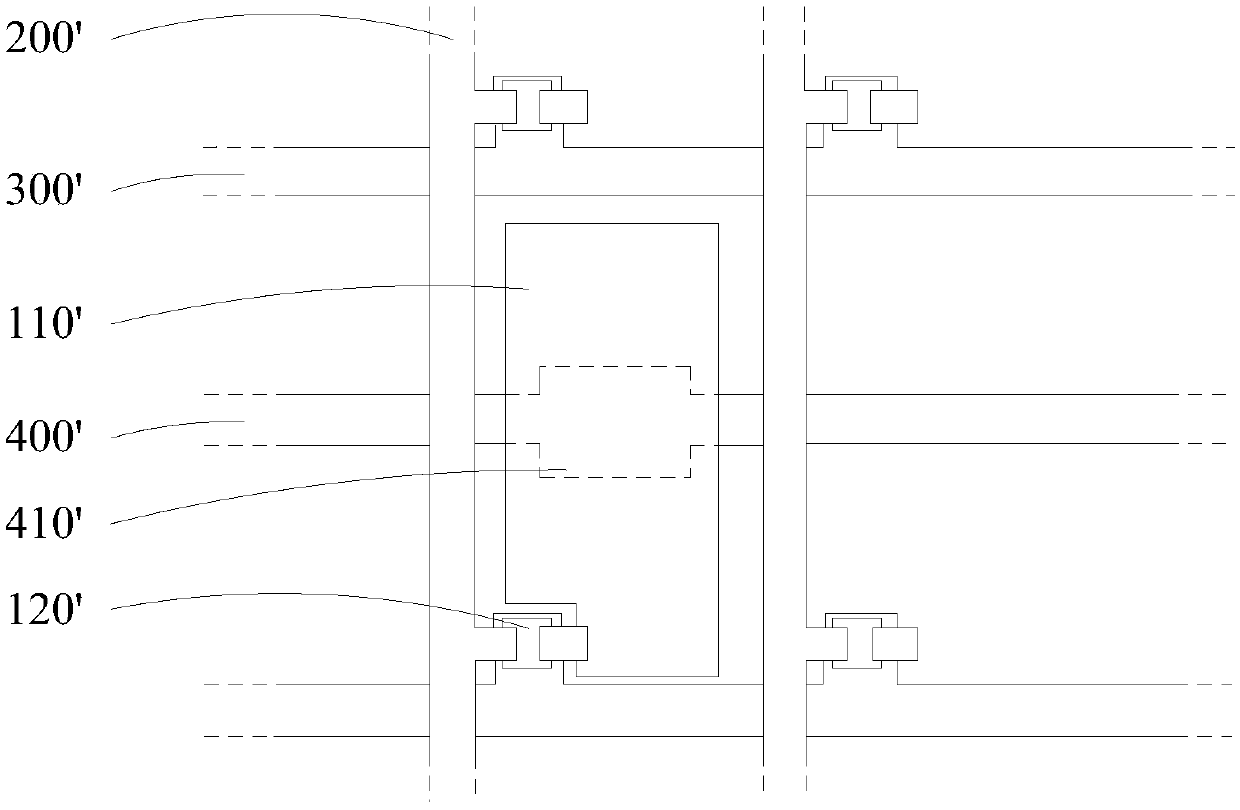

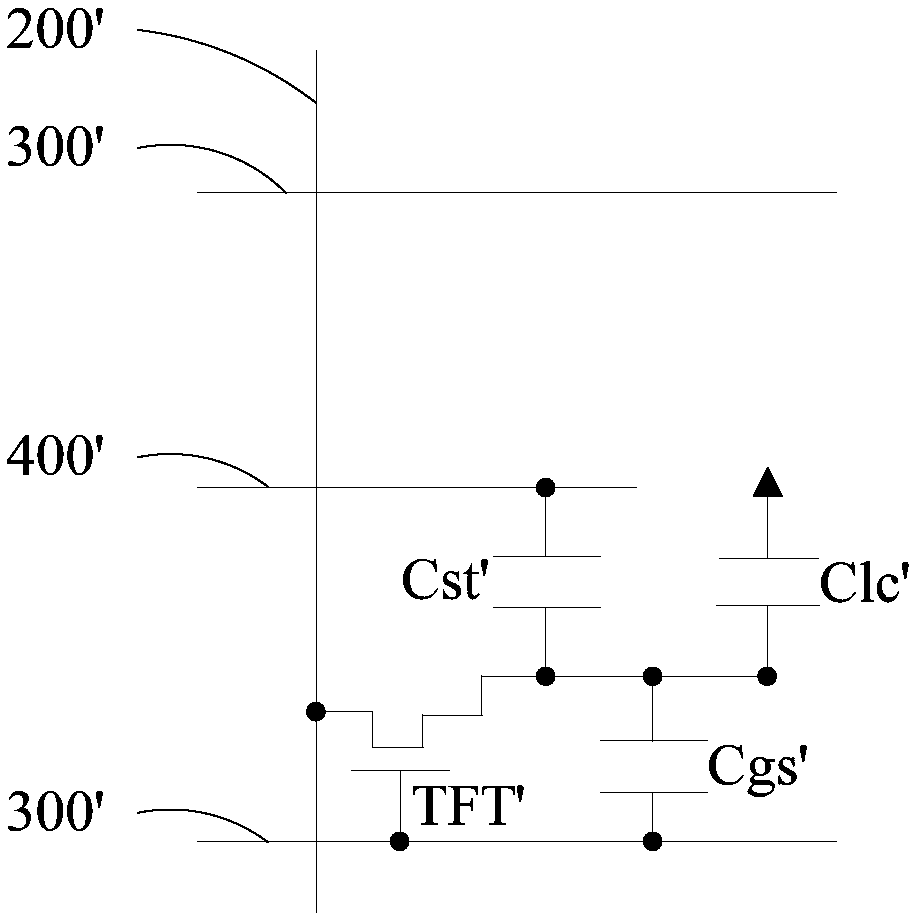

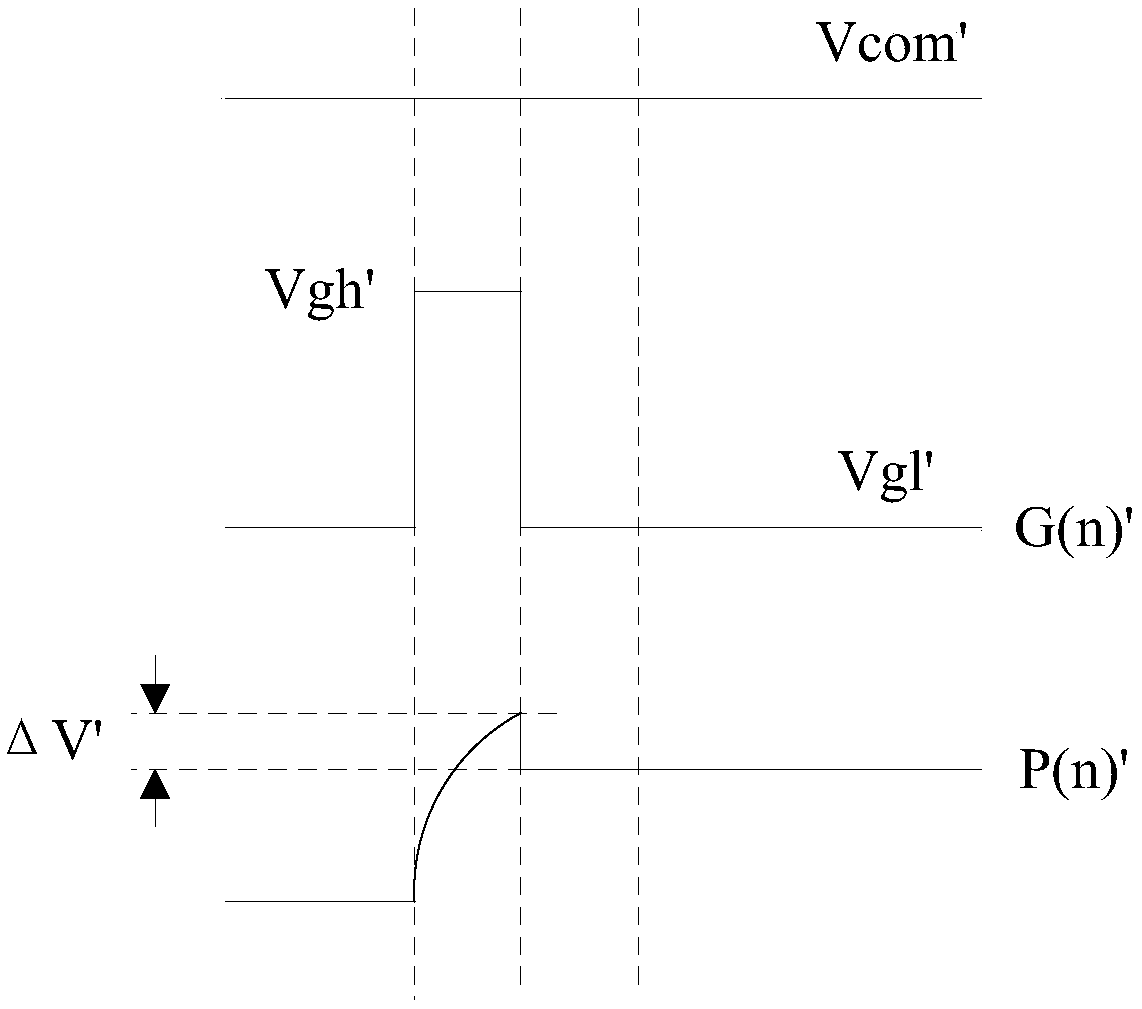

Display panel and display device

InactiveCN109116641APenetration constantLarge viewing angleStatic indicating devicesNon-linear opticsCapacitanceDisplay device

The invention discloses a display panel, comprising a plurality of data lines, scanning lines and common lines, and a plurality of first pixels and second pixels, wherein each common line comprises amain common electrode, a first branch common electrode and a second branch common electrode; the main common electrode, the first branch common electrode and the second branch common electrode of thesame common line are electrically connected, the main common electrodes and the scanning lines are distributed at intervals, and the first branch common electrodes and the second branch common electrodes are arranged adjacent to the data lines; the driving brightness of the first pixels is greater than the original brightness, each first pixel includes a first pixel electrode, and the first pixelelectrodes are partially overlapped with the first branch common electrodes to form a first storage capacitor; and the driving brightness of the second pixels is less than the original brightness, each second pixel includes a second pixel electrode, and the second pixel electrodes are partially overlapped with the second branch common electrodes to form a second storage capacitor. The invention also discloses a display device. According to the scheme of the invention, the flicker of the screen caused by backlash in the display panel can be reduced, and the display quality can be improved.

Owner:CHONGQING HKC OPTOELECTRONICS TECH CO LTD +1

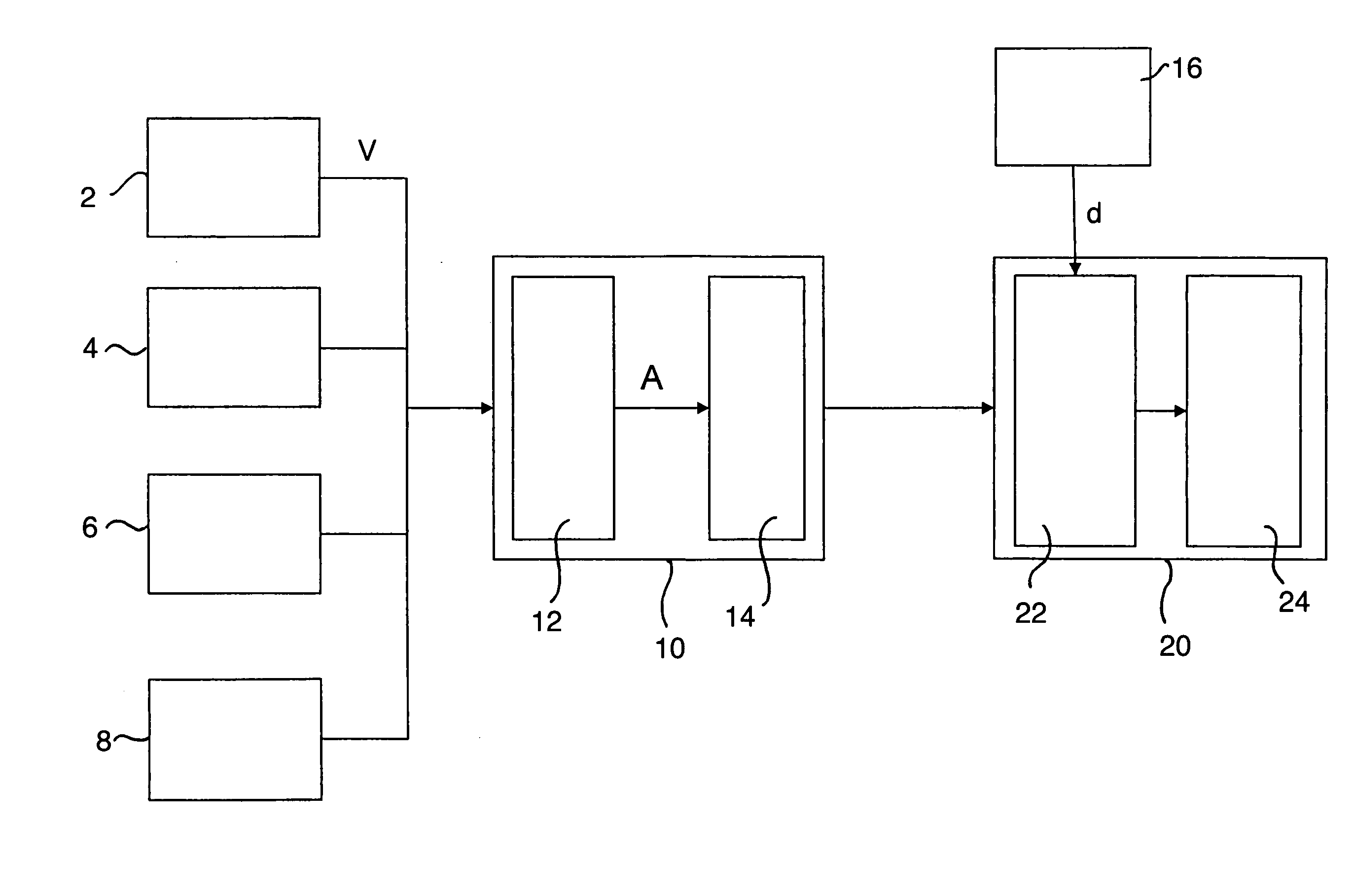

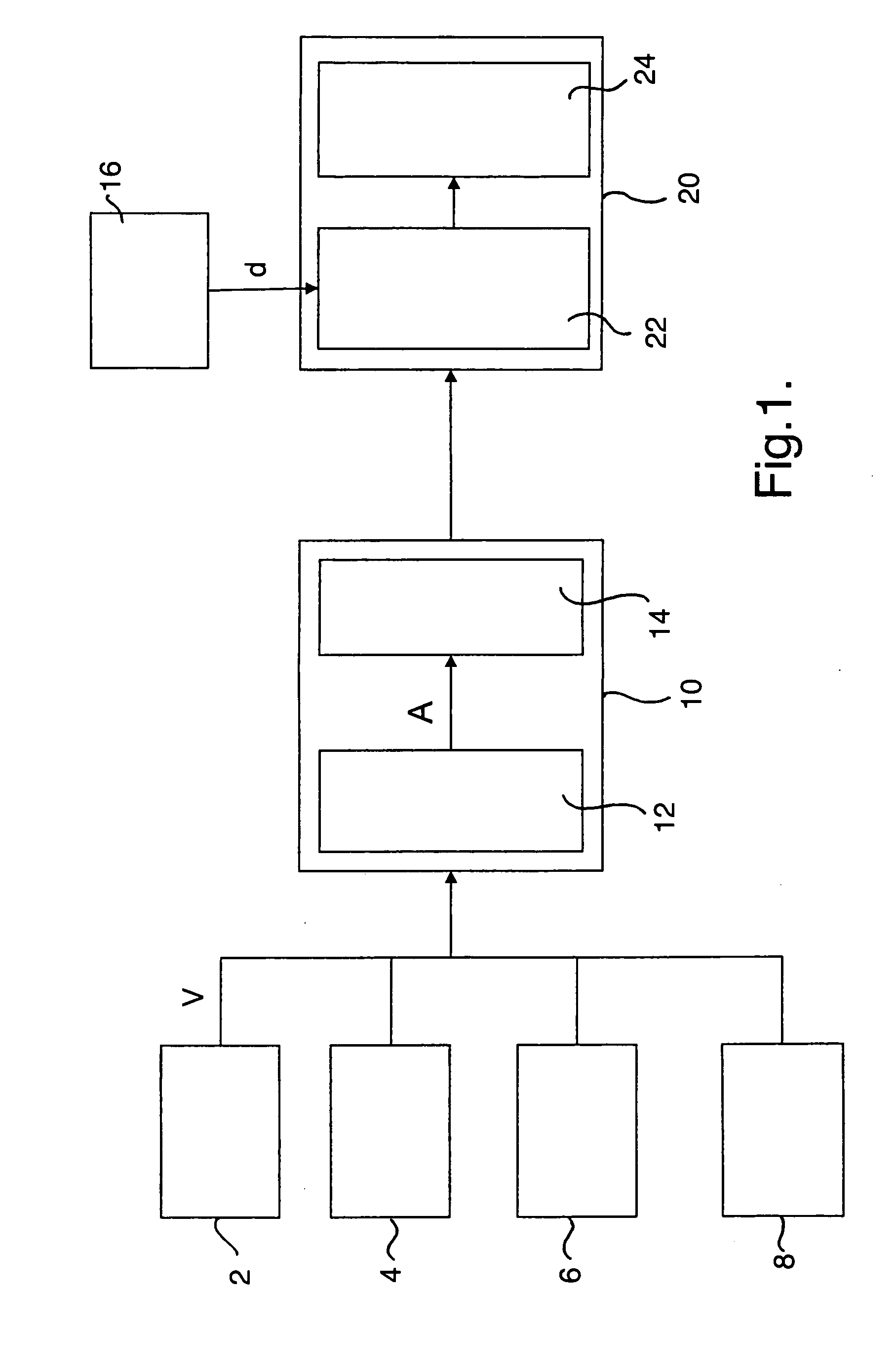

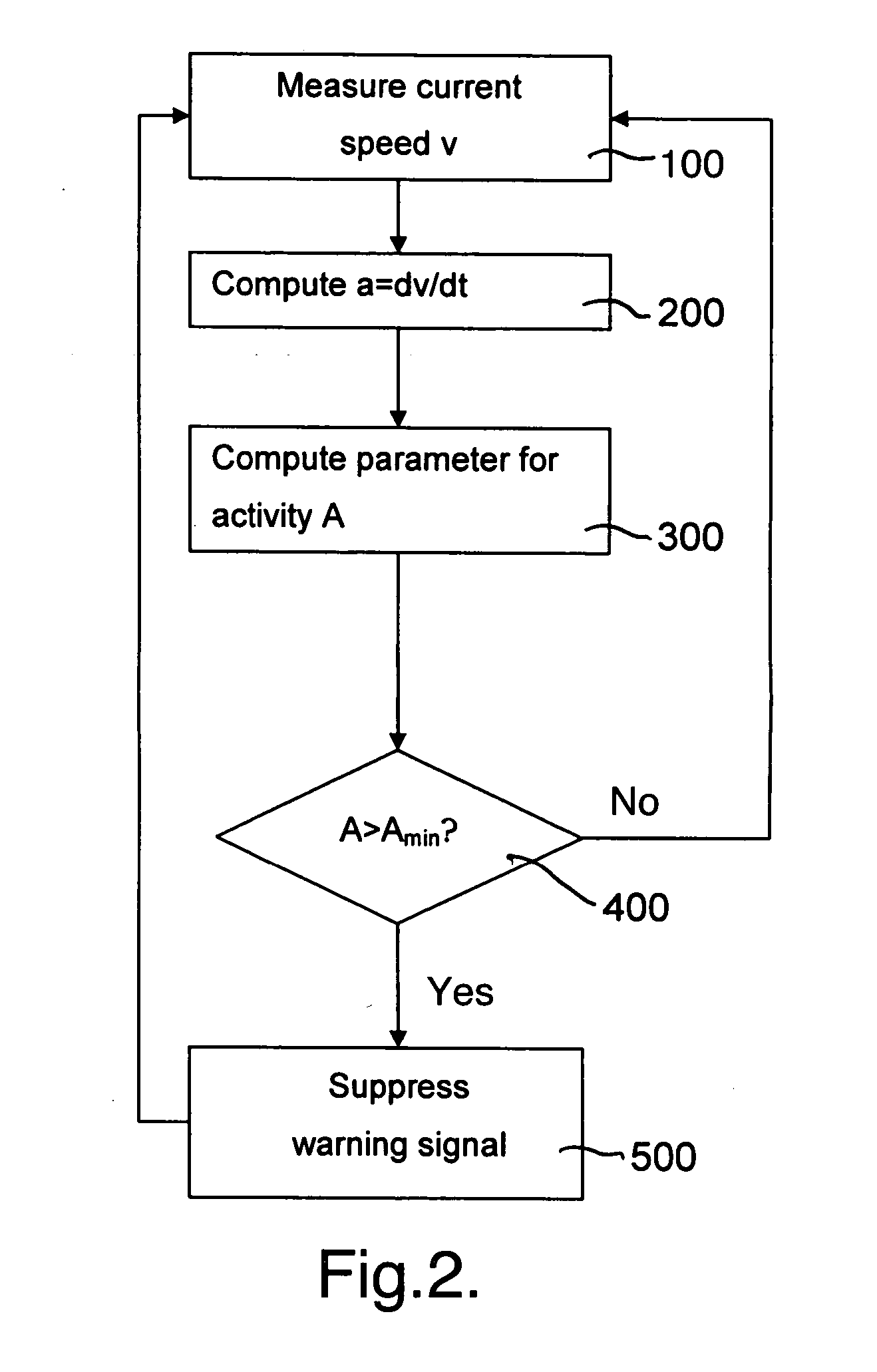

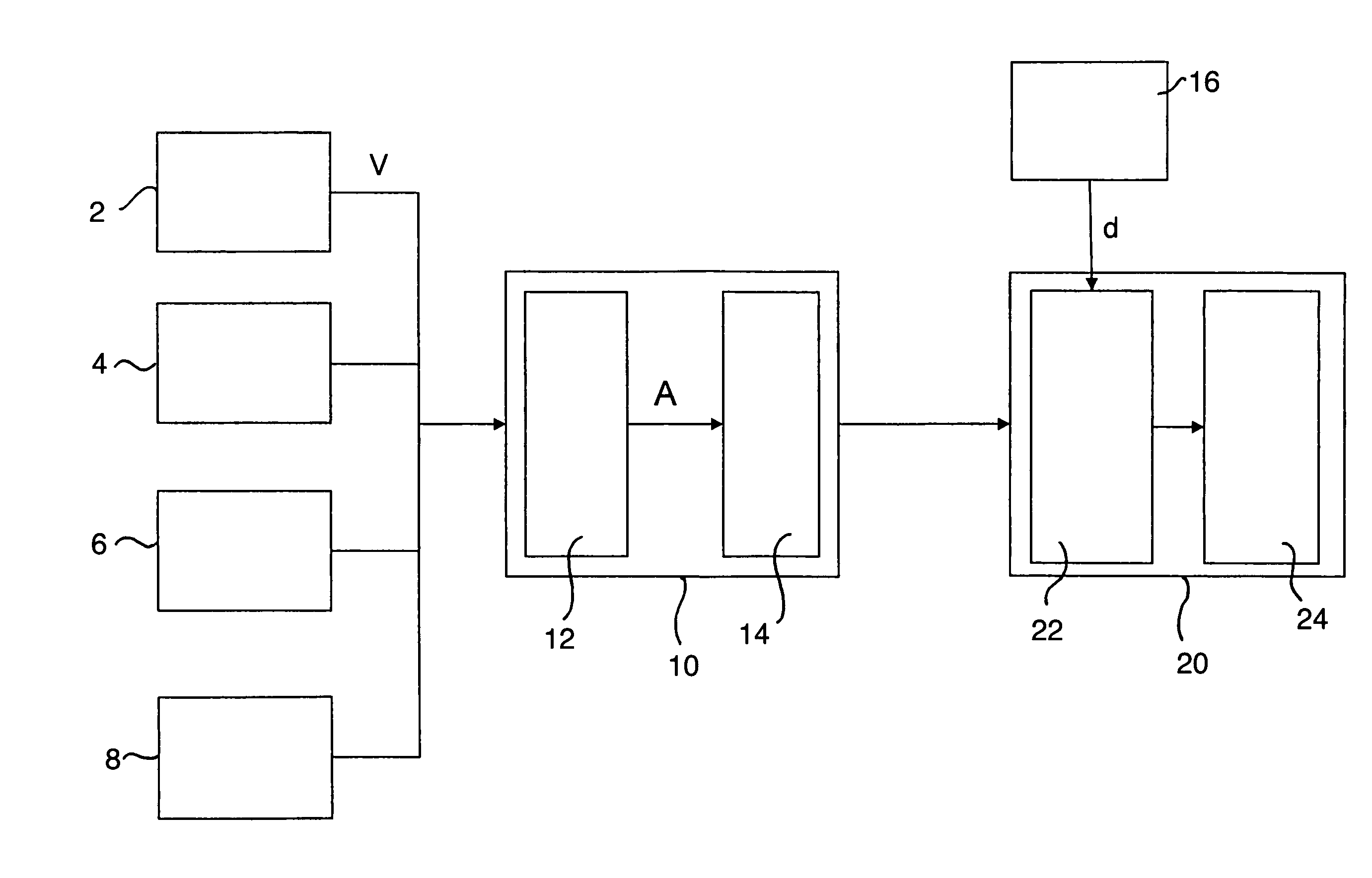

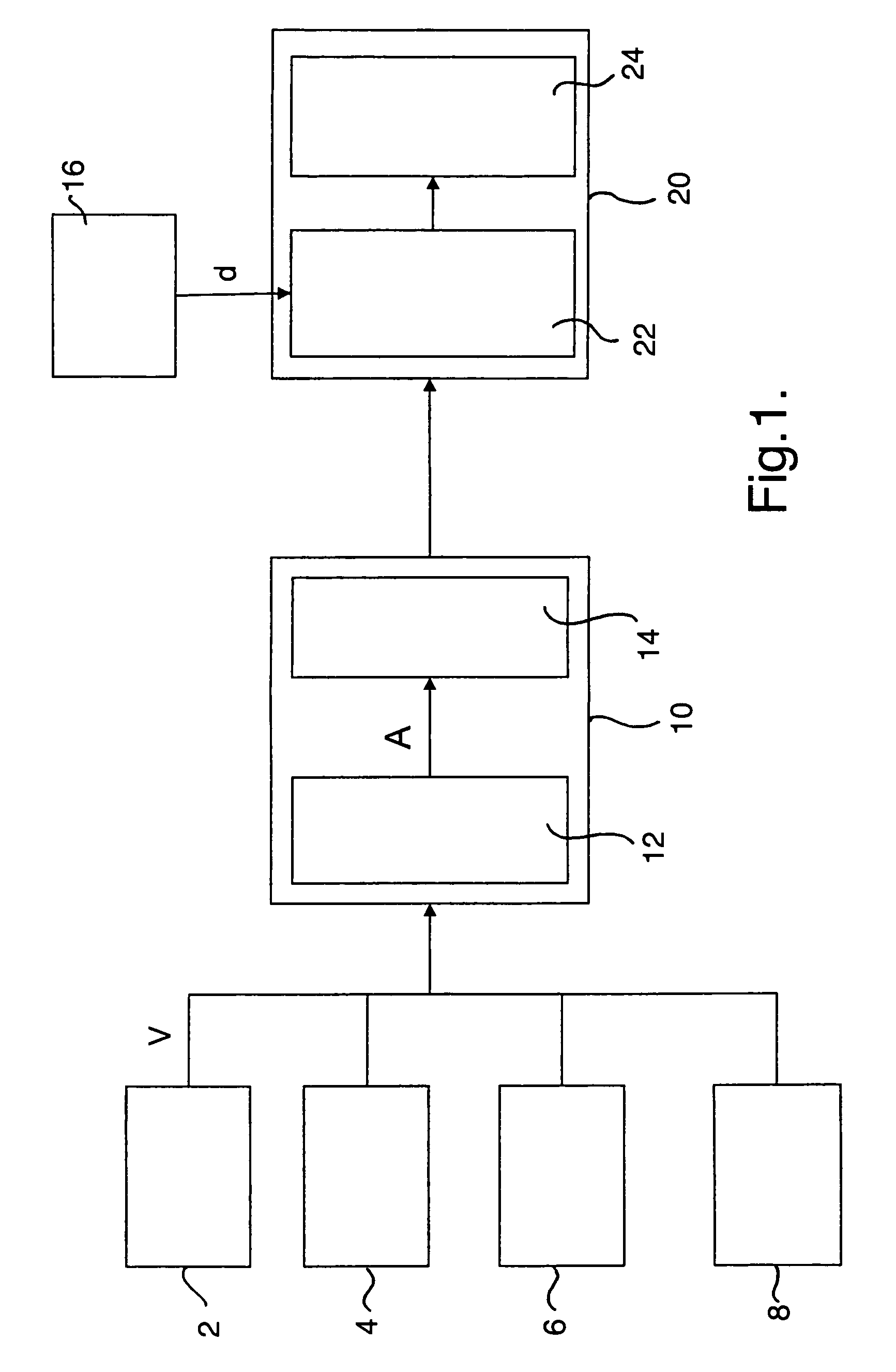

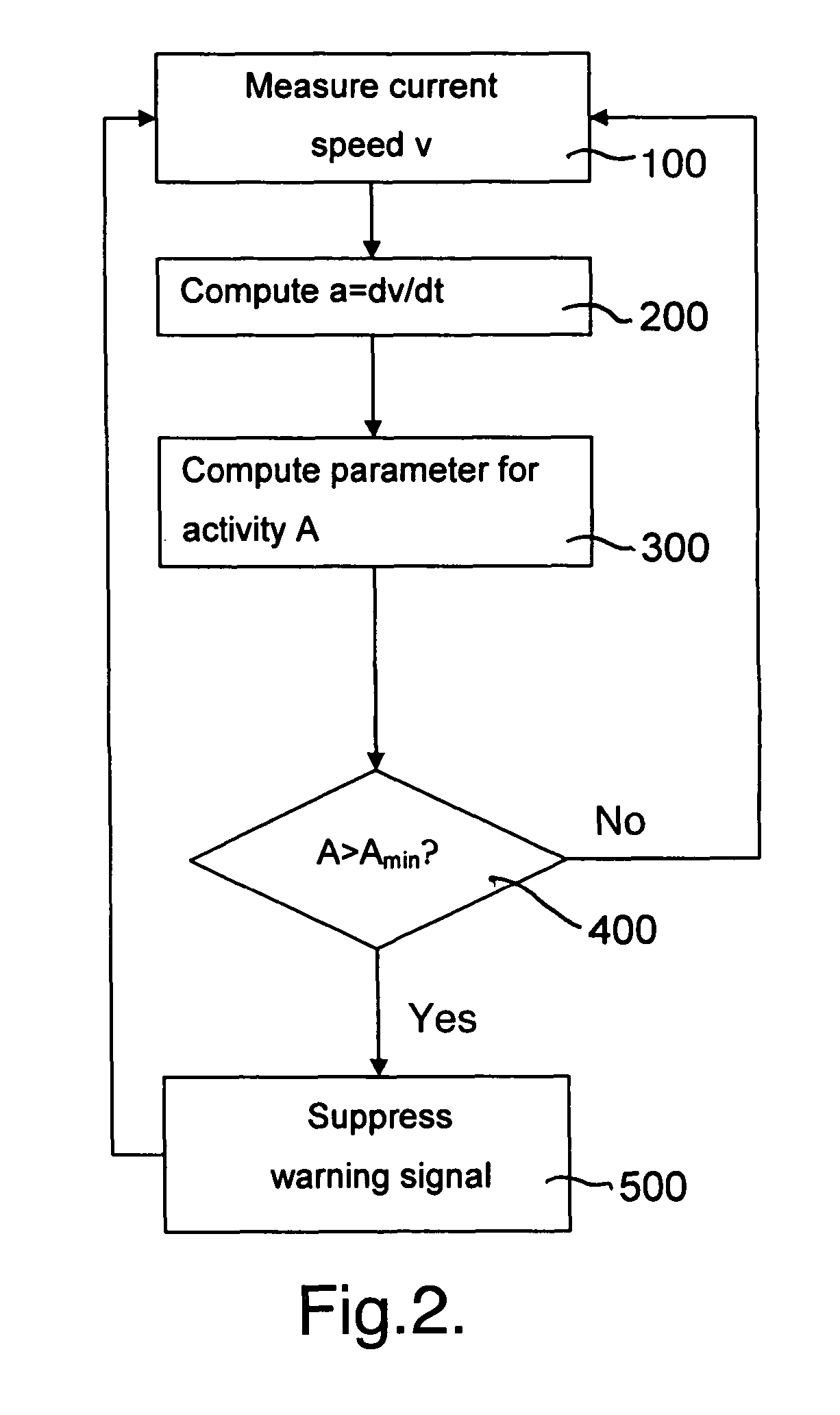

Method of controlling a driver assistance system and an associated apparatus

ActiveUS20070030157A1Easy to distinguishInhibit outputRoad vehicles traffic controlOptical signallingDriver/operatorEngineering

The present invention relates to a method of controlling a driver assistance system which can identify a danger situation with reference to a comparison of measured data with predetermined limit values and which can output a warning signal when it has identified a danger situation of this type. An additional control module is provided which determines an activity state of the driver in dependence on at least one input value which permits a conclusion on actions carried out by a driver and can suppress the outputting of the warning signal in dependence on this activity state.

Owner:APTIV TECH LTD

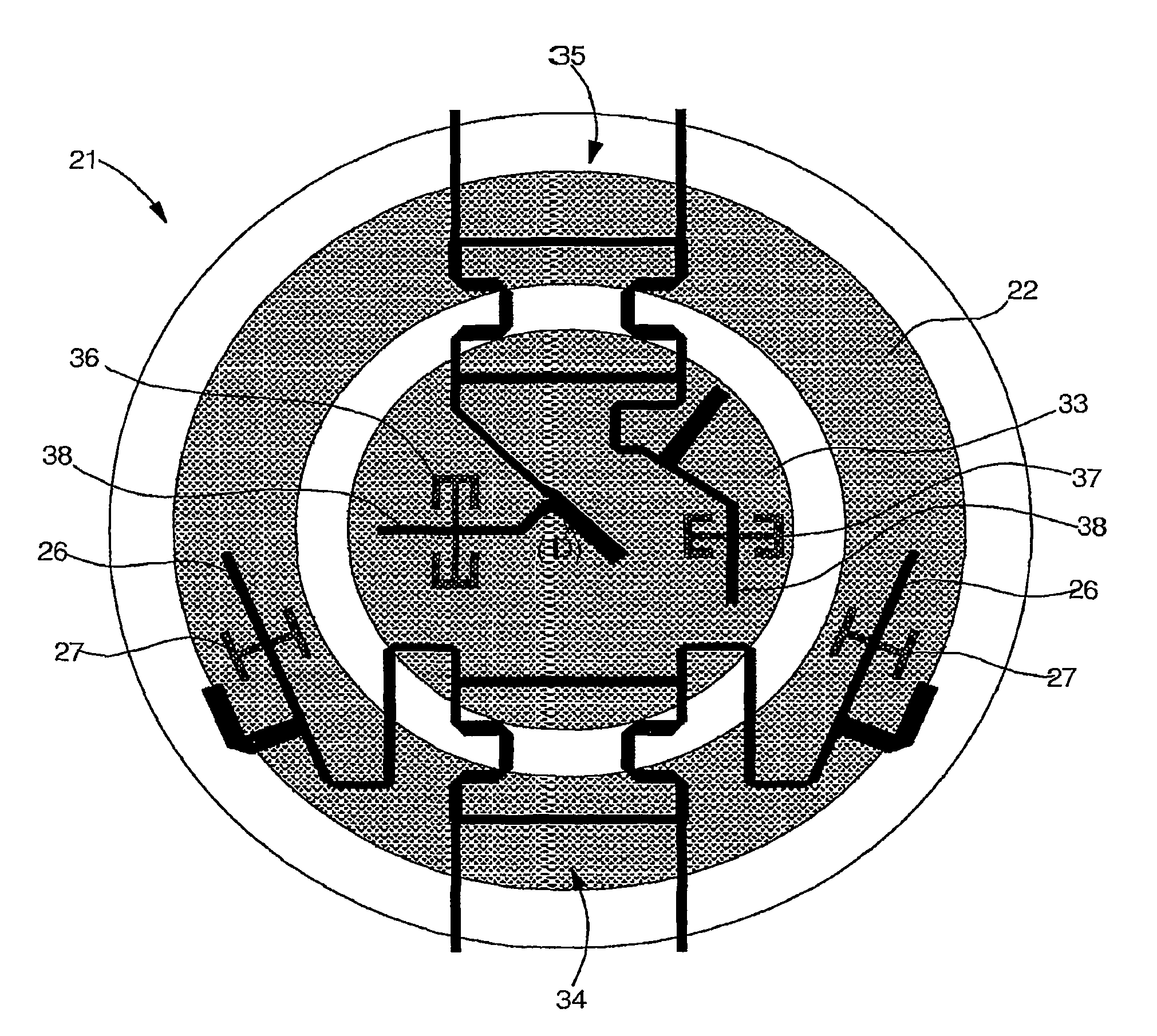

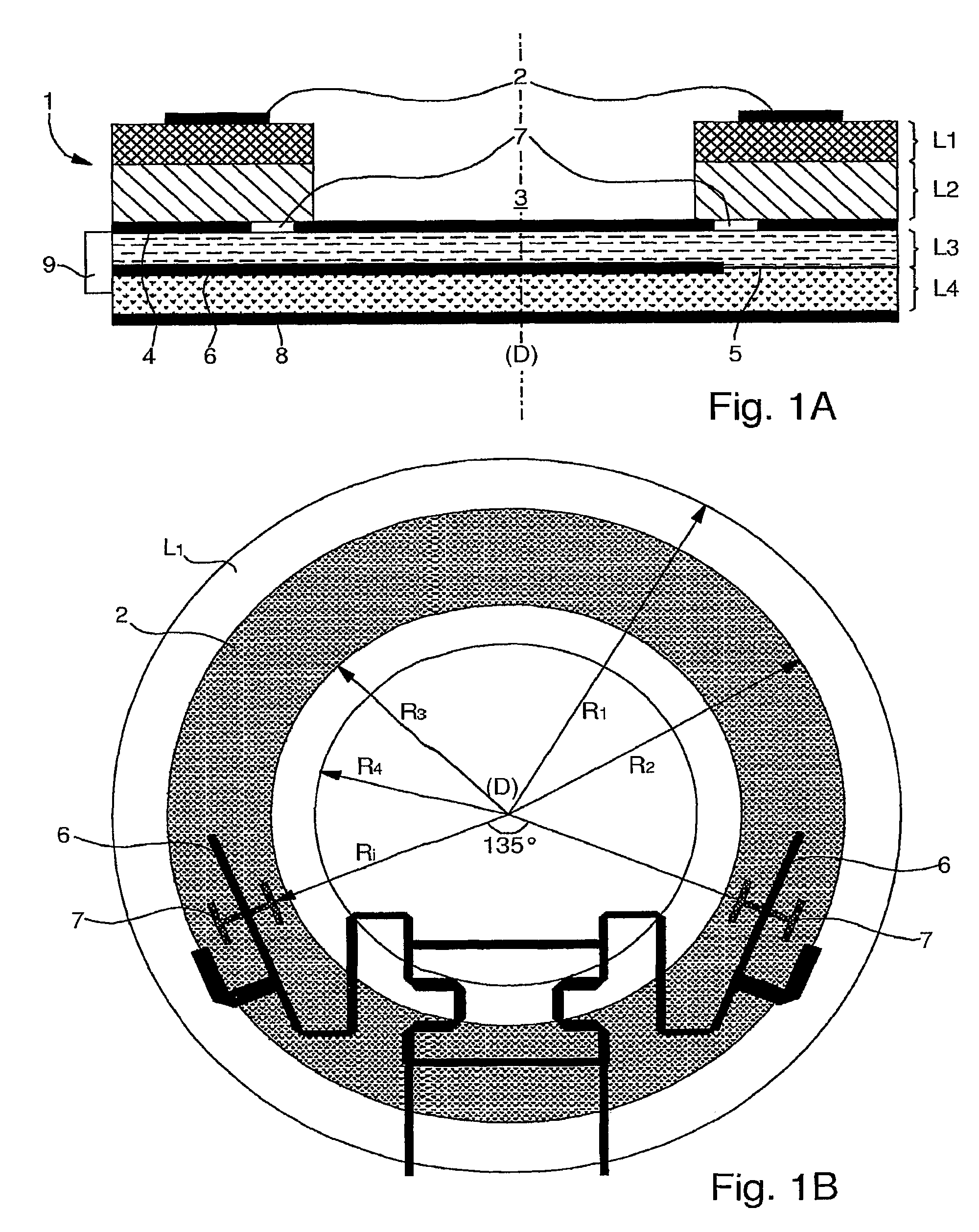

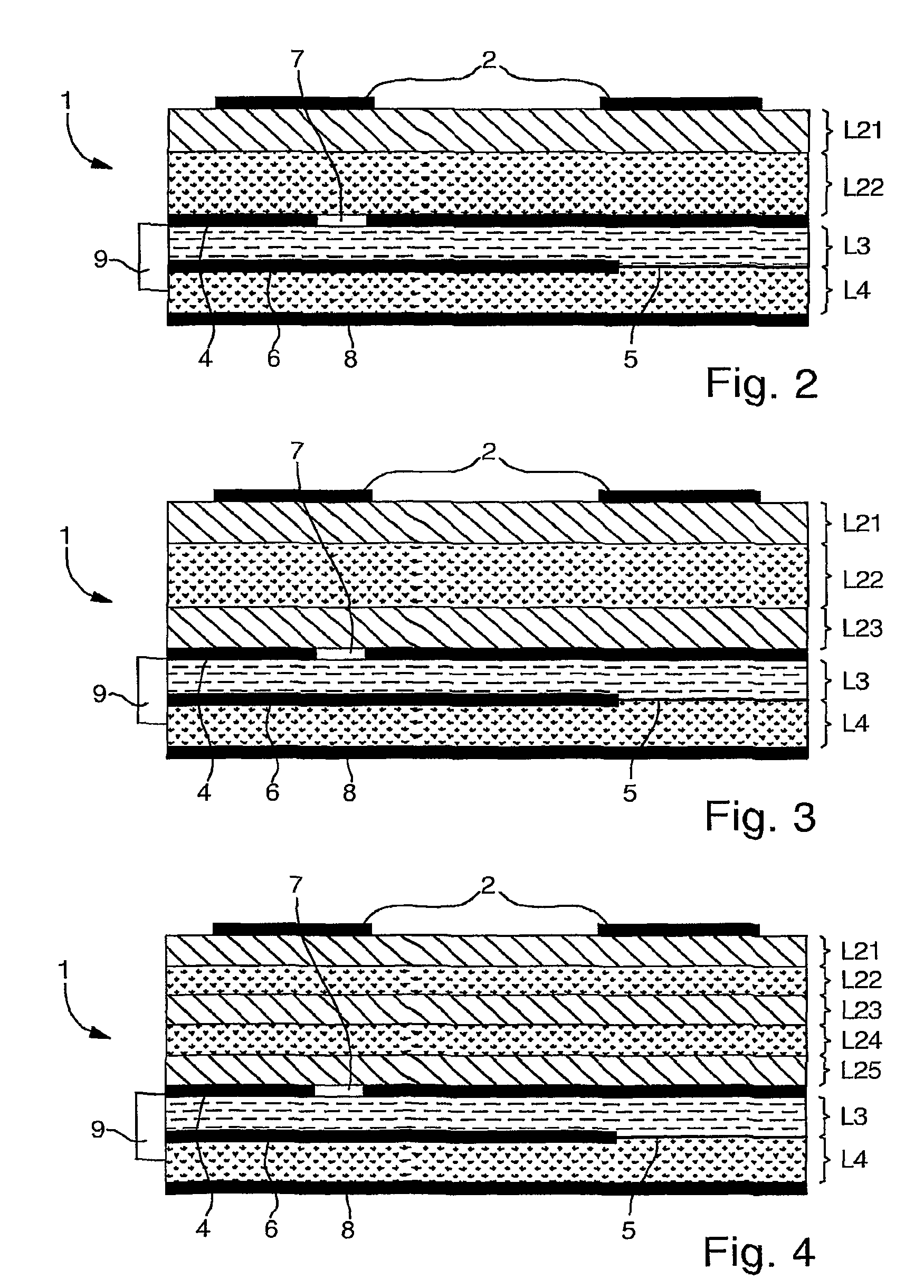

Planar Antenna for Mobile Satellite Applications

ActiveUS20080266178A1Satisfactory efficiencyReduce the minimum distanceSimultaneous aerial operationsRadiating elements structural formsPhysicsSatellite

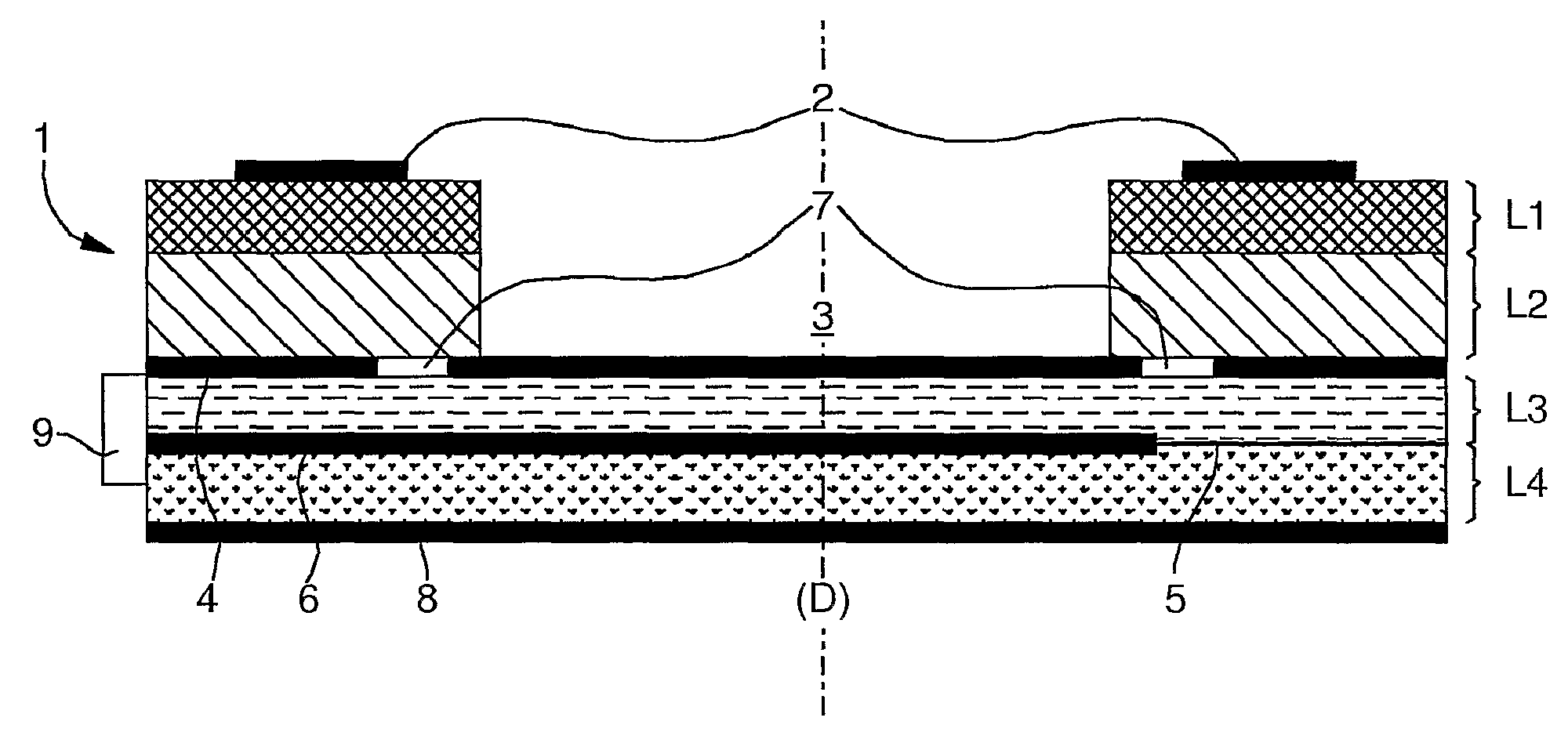

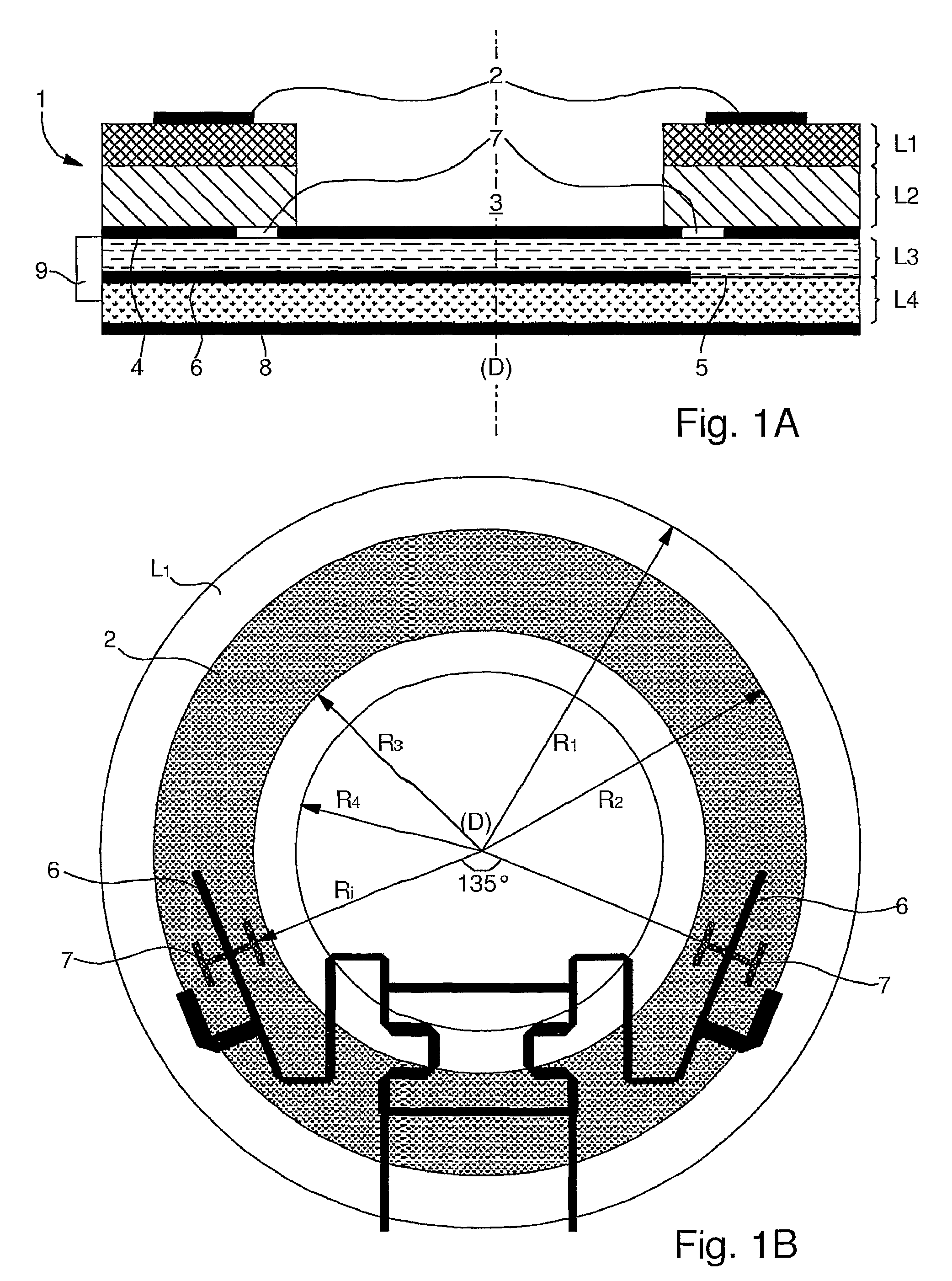

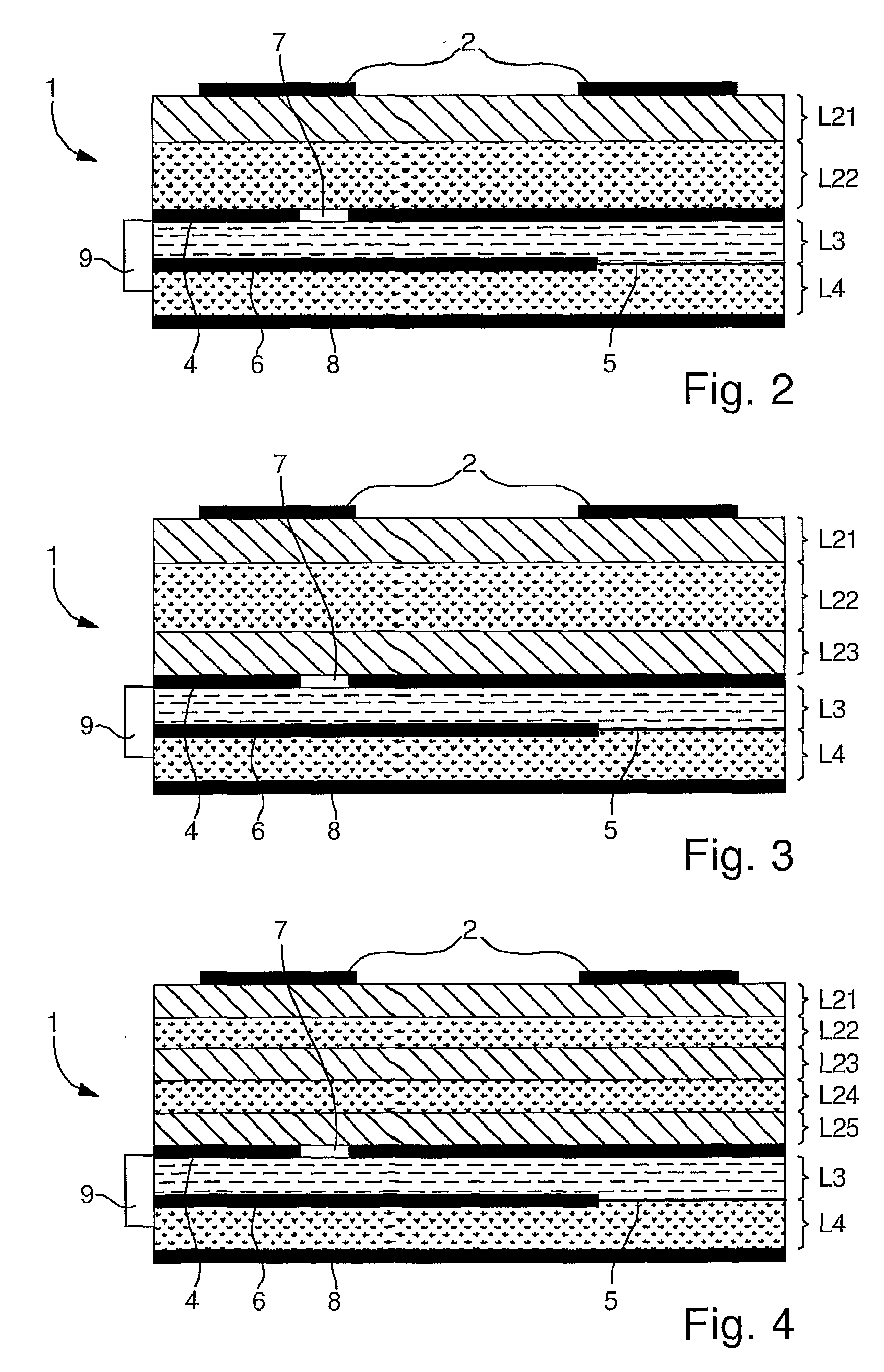

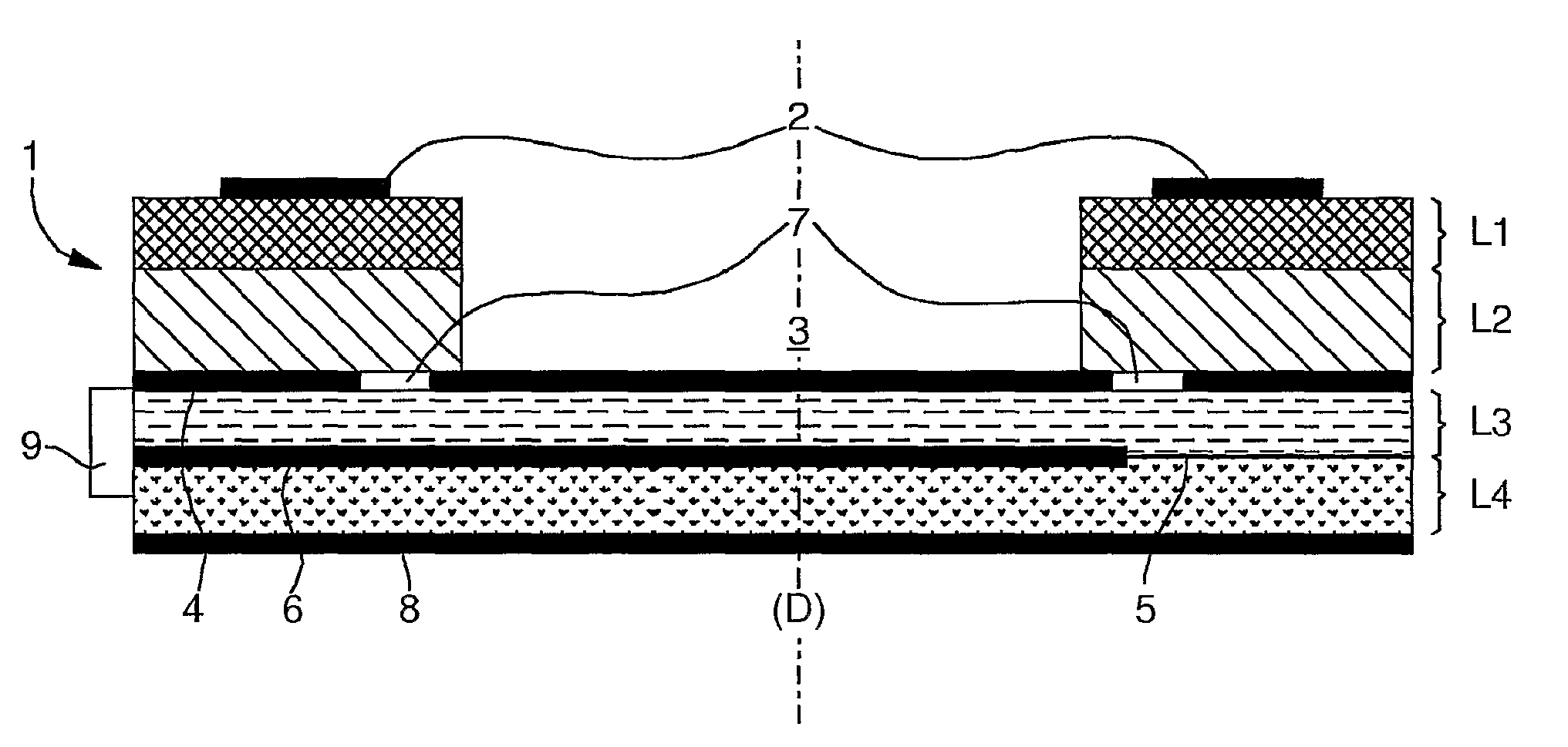

The invention relates to a microstrip patch antenna (1) for mobile satellite communications comprising a first electrically conducting ground plane (4) having at least one opening (7), at least one patch radiating element (2), at least one first dielectric layer (L2) disposed between the first electrically conducting ground plane and the patch radiating element and more particularly between the at least one opening and the patch radiating element, at least one feed line (6) for providing signal energy in a contactless manner to or from the patch radiating element through the opening and a second dielectric layer (L3) disposed between the feed line and the first electrically conducting ground plane wherein the antenna further comprises a second ground plane (8) and a third dielectric layer (L4) disposed between the second ground plane and the feed line.

Owner:VIASAT INC

Planar antenna for mobile satellite applications

ActiveUS7667650B2Satisfactory efficiencyReduce the minimum distanceSimultaneous aerial operationsRadiating elements structural formsMicrostrip patch antennaGround plane

The invention relates to a microstrip patch antenna (1) for mobile satellite communications comprising a first electrically conducting ground plane (4) having at least one opening (7), at least one patch radiating element (2), at least one first dielectric layer (L2) disposed between the first electrically conducting ground plane and the patch radiating element and more particularly between the at least one opening and the patch radiating element, at least one feed line (6) for providing signal energy in a contactless manner to or from the patch radiating element through the opening and a second dielectric layer (L3) disposed between the feed line and the first electrically conducting ground plane wherein the antenna further comprises a second ground plane (8) and a third dielectric layer (L4) disposed between the second ground plane and the feed line.

Owner:VIASAT INC

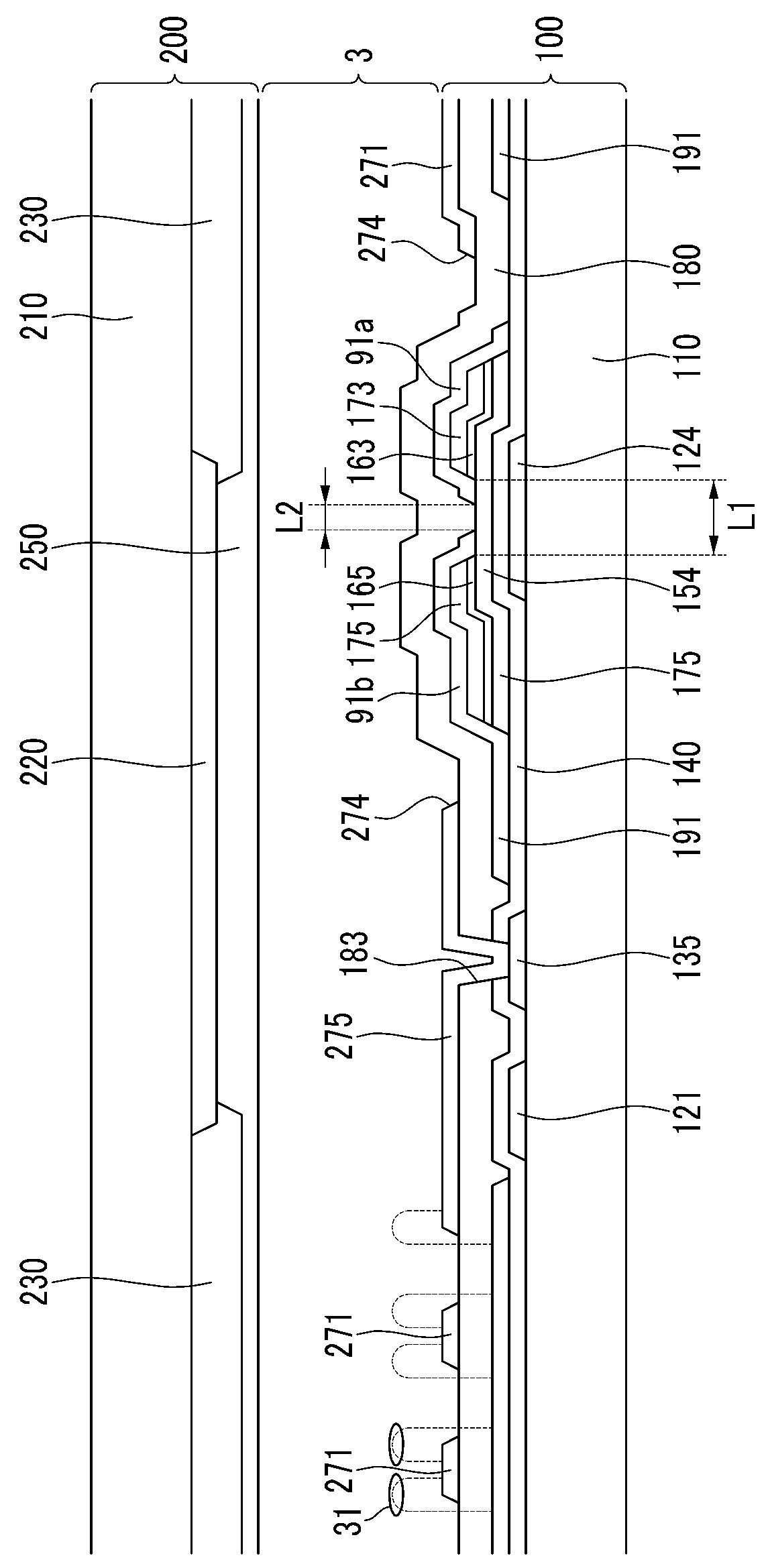

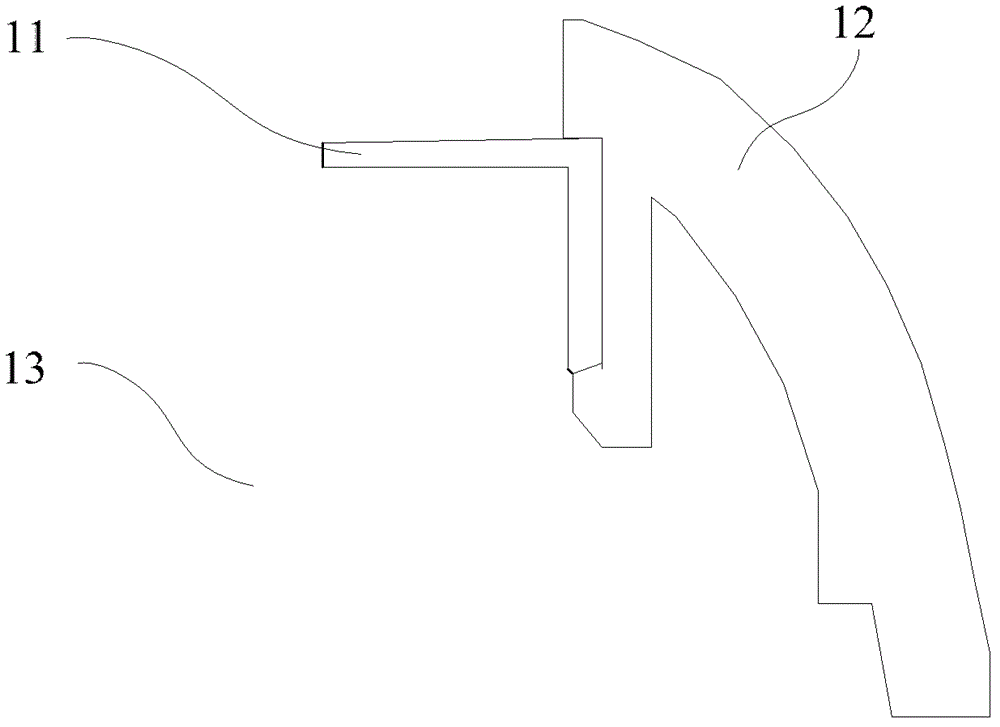

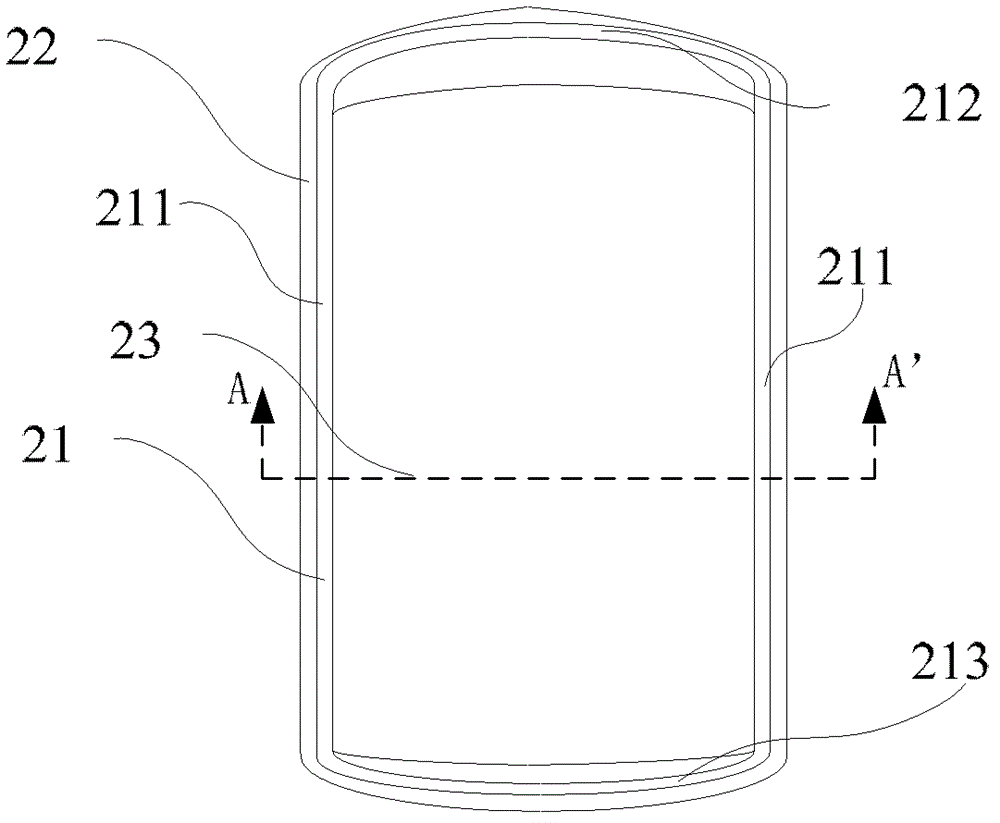

Washing machine inner tub and washing machine provided with same

ActiveCN107587310AAchieve washingAchieve dryingOther washing machinesTextiles and paperEngineeringMechanical engineering

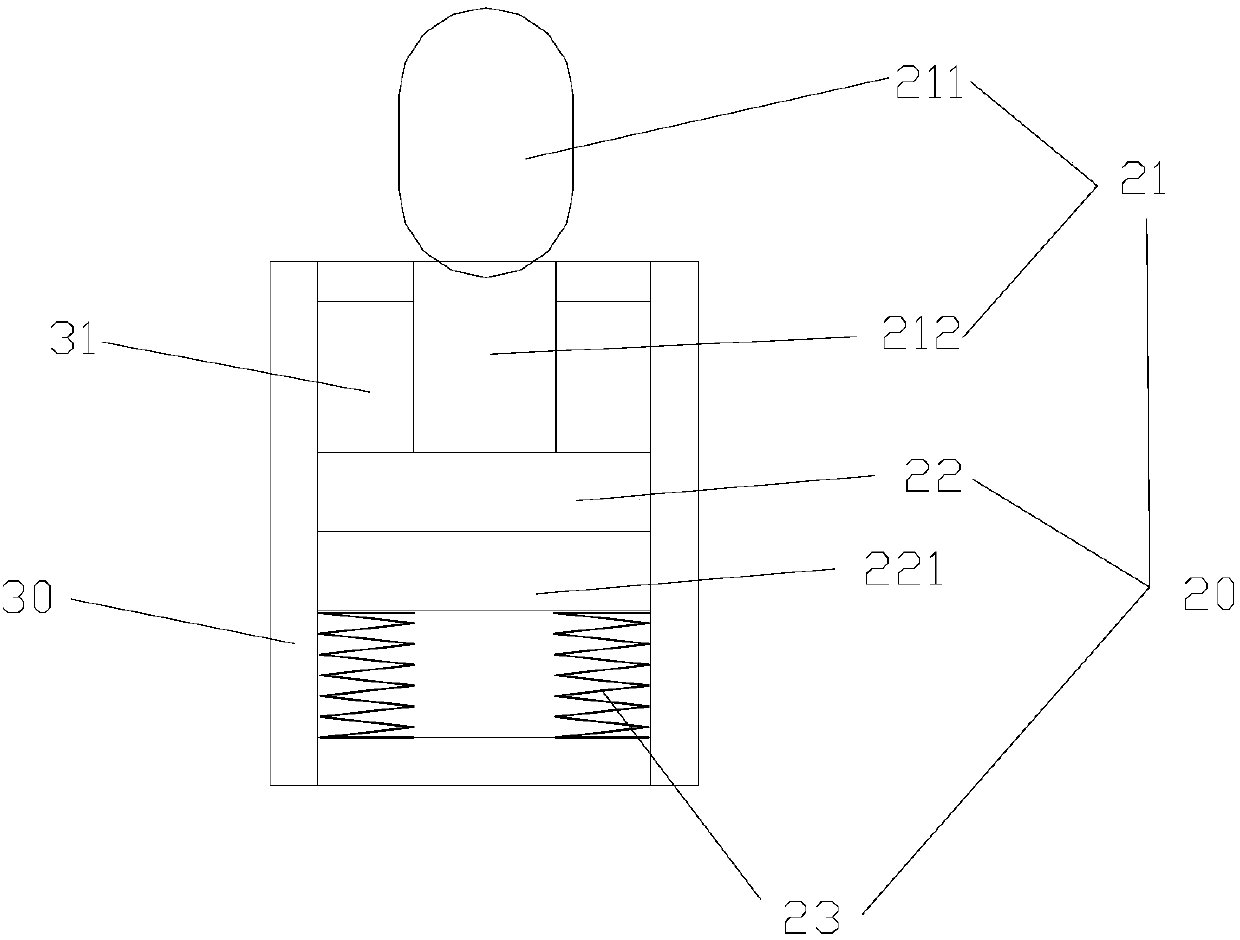

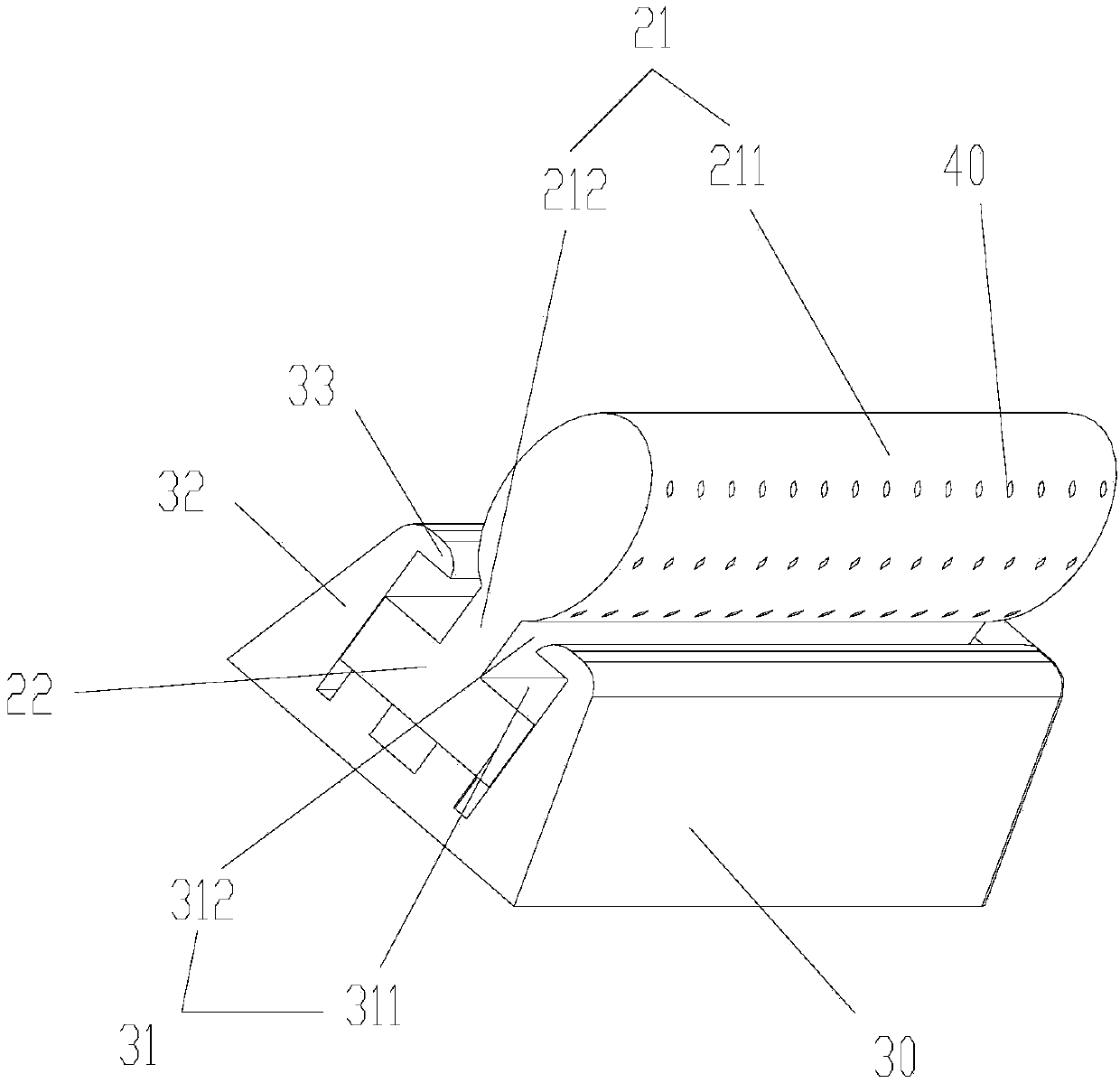

The invention provides a washing machine inner tub and a washing machine provided with the same. The washing machine inner tub comprises an inner tub body and also comprises a lifting rib assembly arranged on the inner wall of the inner tub body, wherein at least part of the lifting rib assembly is movably arranged in the radial direction of the inner tub body, and a predetermined dewatering distance L1 is reserved between the predetermined part of the lifting rib assembly and the middle axis of the inner tub body when the inner tub body is in a dewatering state. A predetermined drying distance L2 is reserved between the predetermined part of the lifting rib assembly and the middle axis of the inner tub body when the inner tub body is in a drying state, and the L1 is greater than the L2. By adopting the washing machine inner tub, the problem is solved by adopting the washing machine inner tub that clothes tightly adhere to the wall of the tub in the drying process of the tub washing machine in the prior art.

Owner:GREE ELECTRIC APPLIANCES INC

Method of controlling a driver assistance system and an associated apparatus

ActiveUS7710249B2Easy to distinguishInhibit outputRoad vehicles traffic controlOptical signallingEngineeringLimit value

The present invention relates to a method of controlling a driver assistance system which can identify a danger situation with reference to a comparison of measured data with predetermined limit values and which can output a warning signal when it has identified a danger situation of this type. An additional control module is provided which determines an activity state of the driver in dependence on at least one input value which permits a conclusion on actions carried out by a driver and can suppress the outputting of the warning signal in dependence on this activity state.

Owner:APTIV TECH LTD

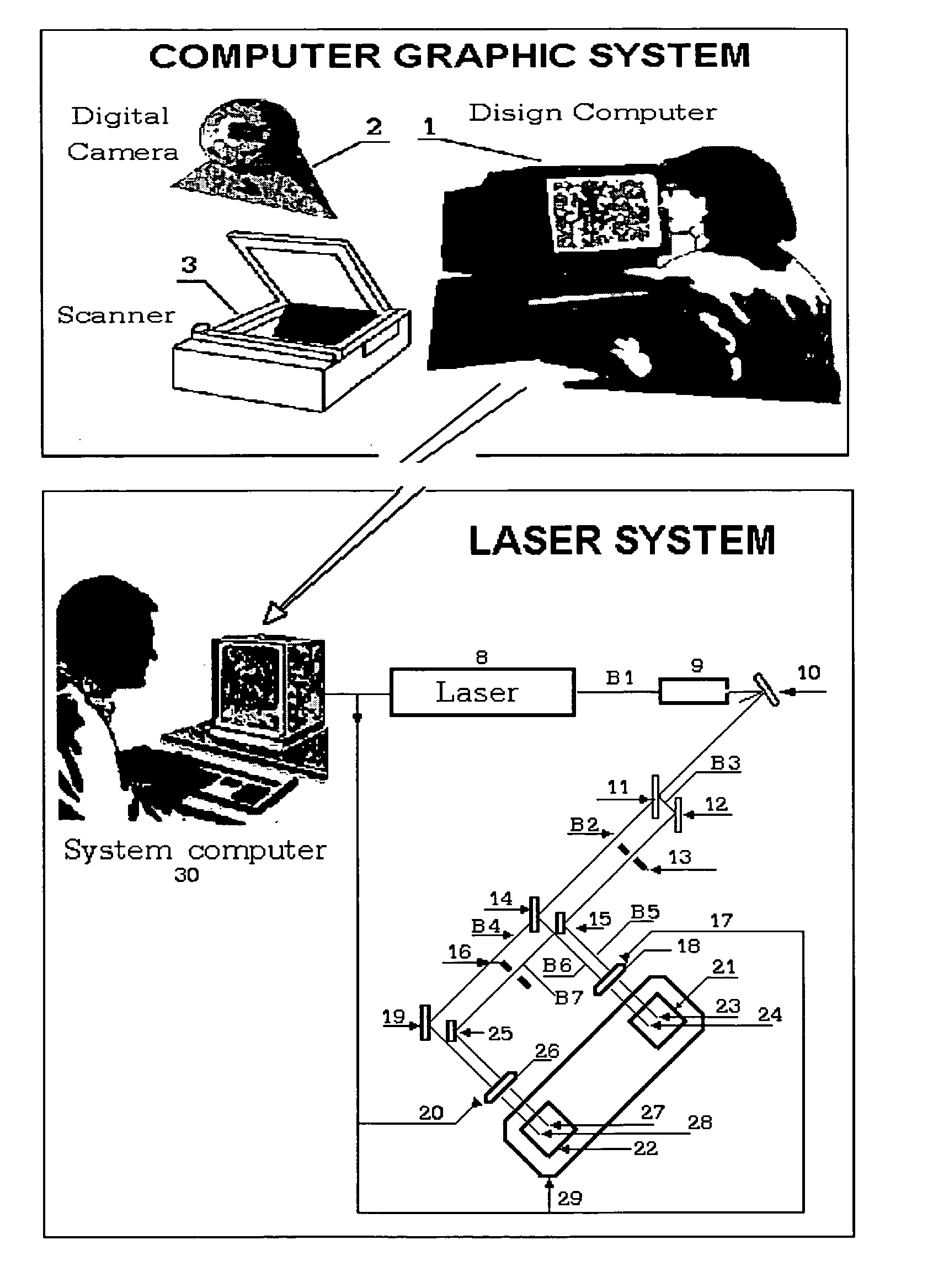

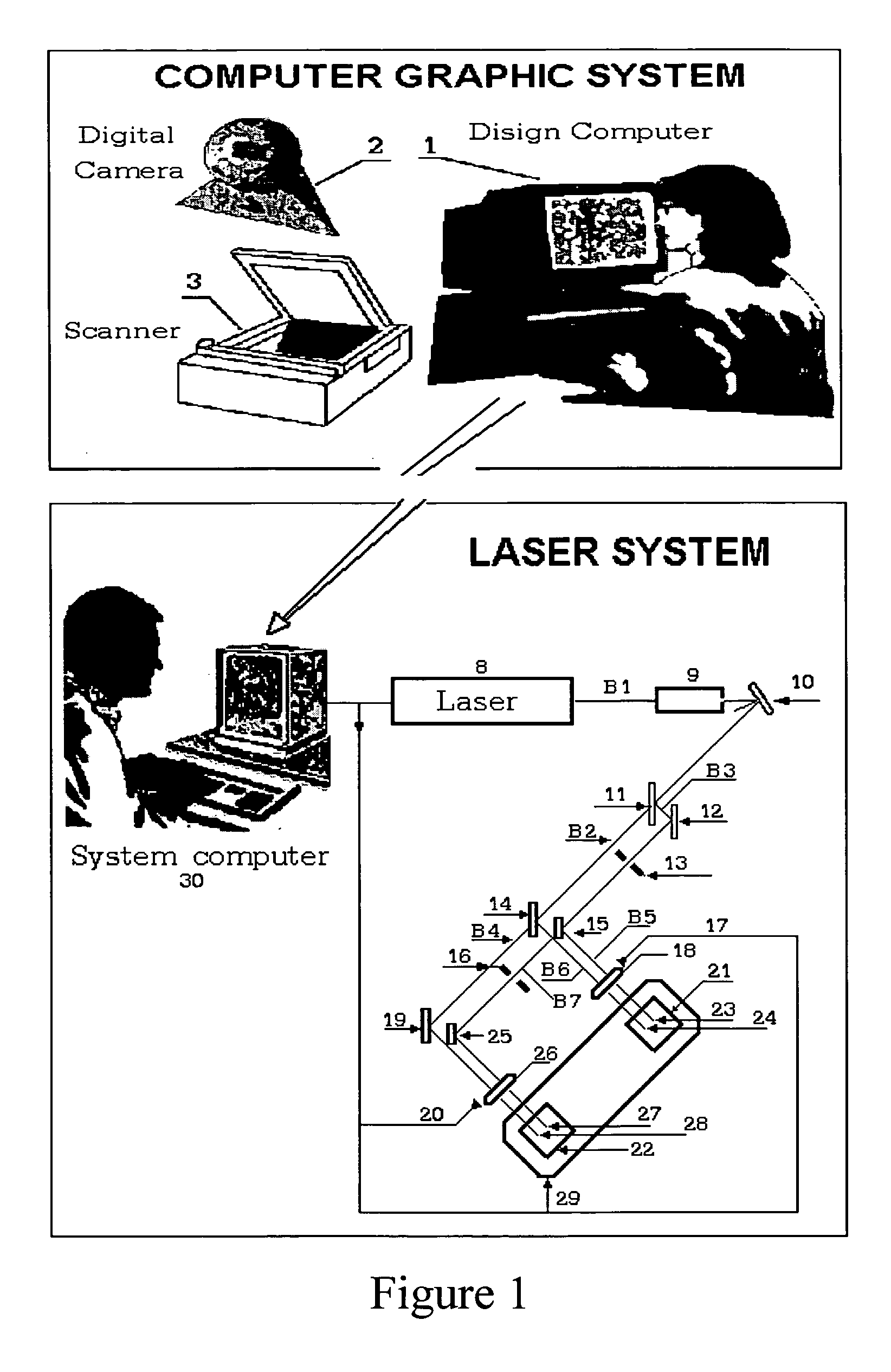

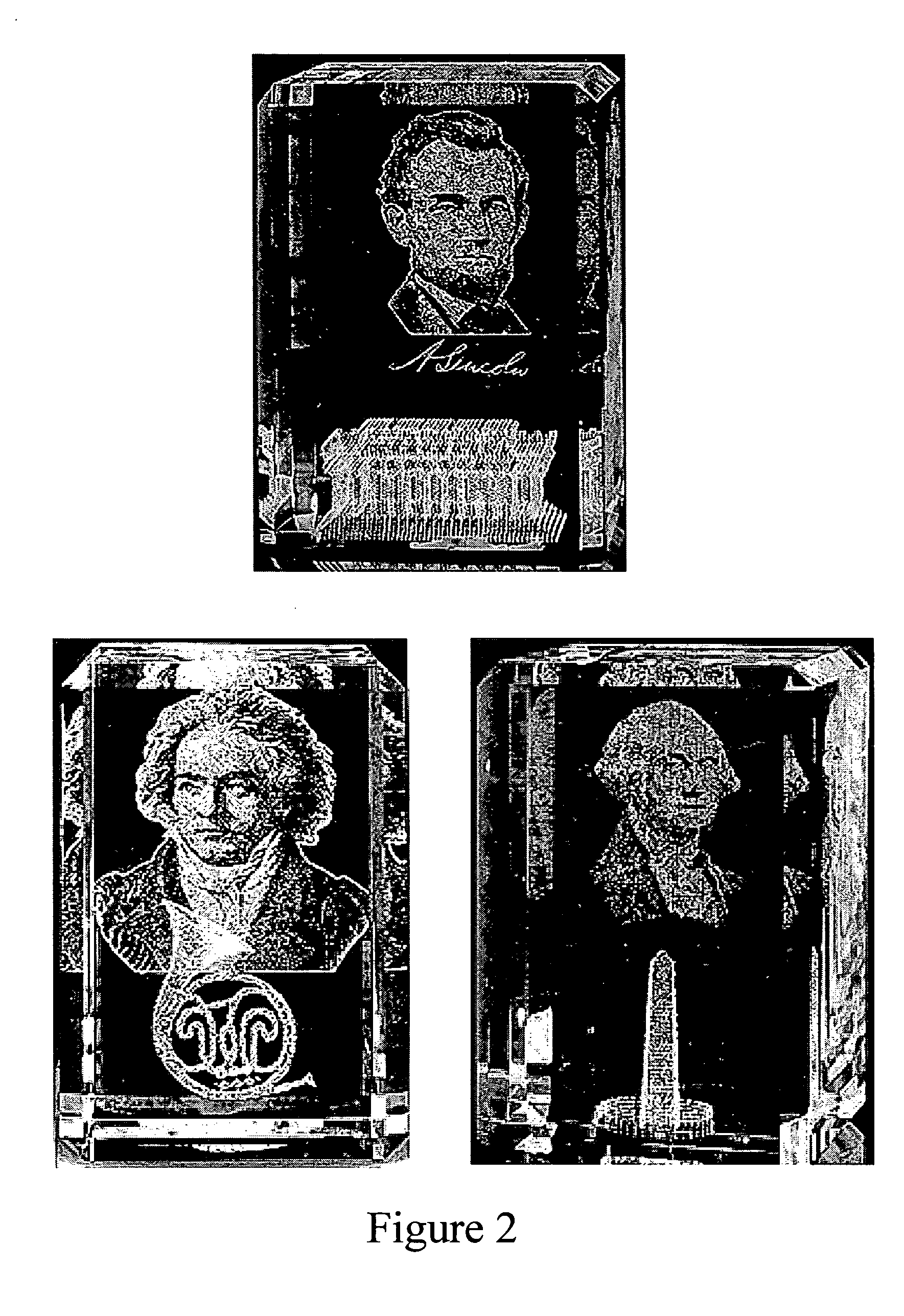

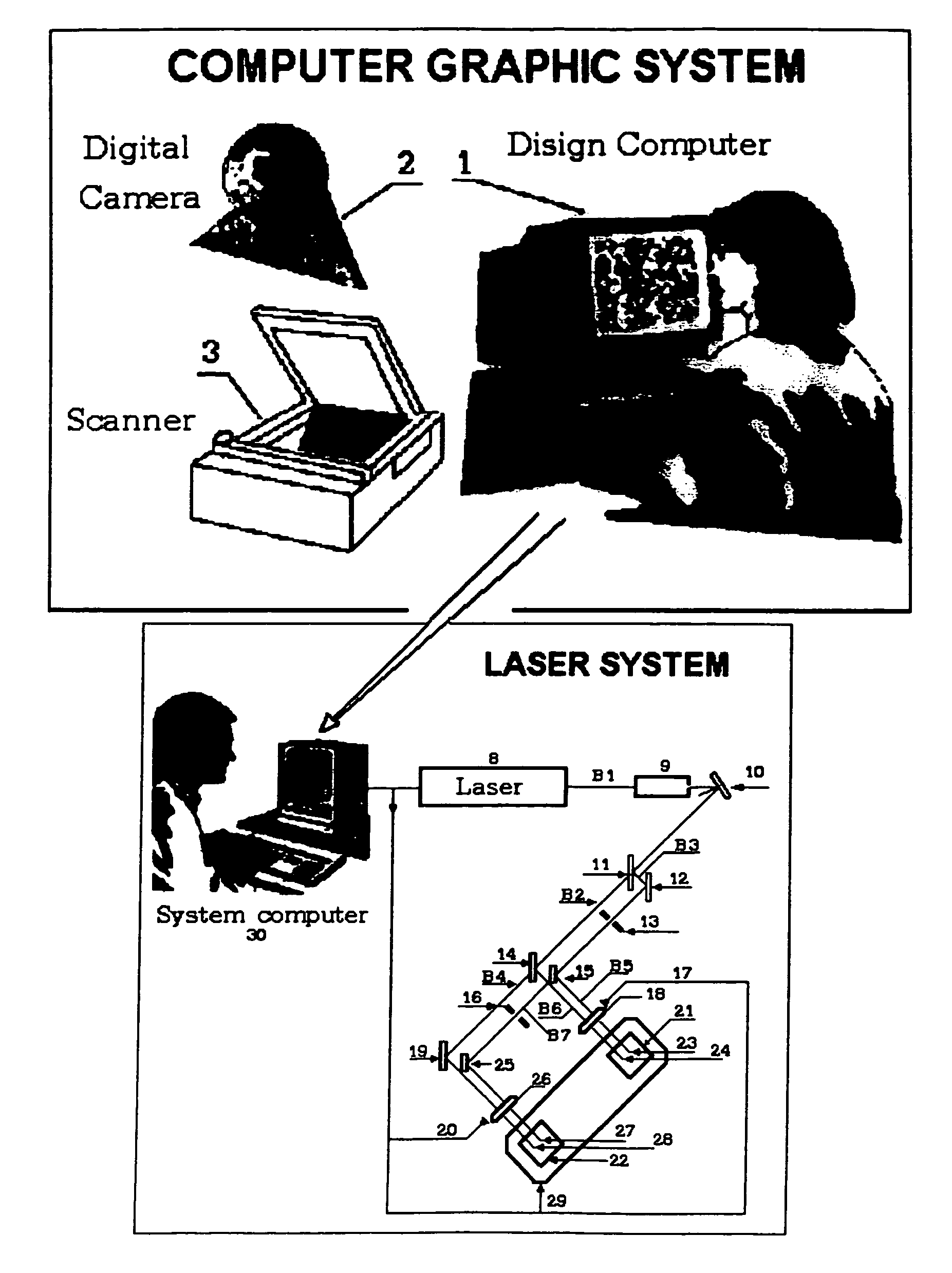

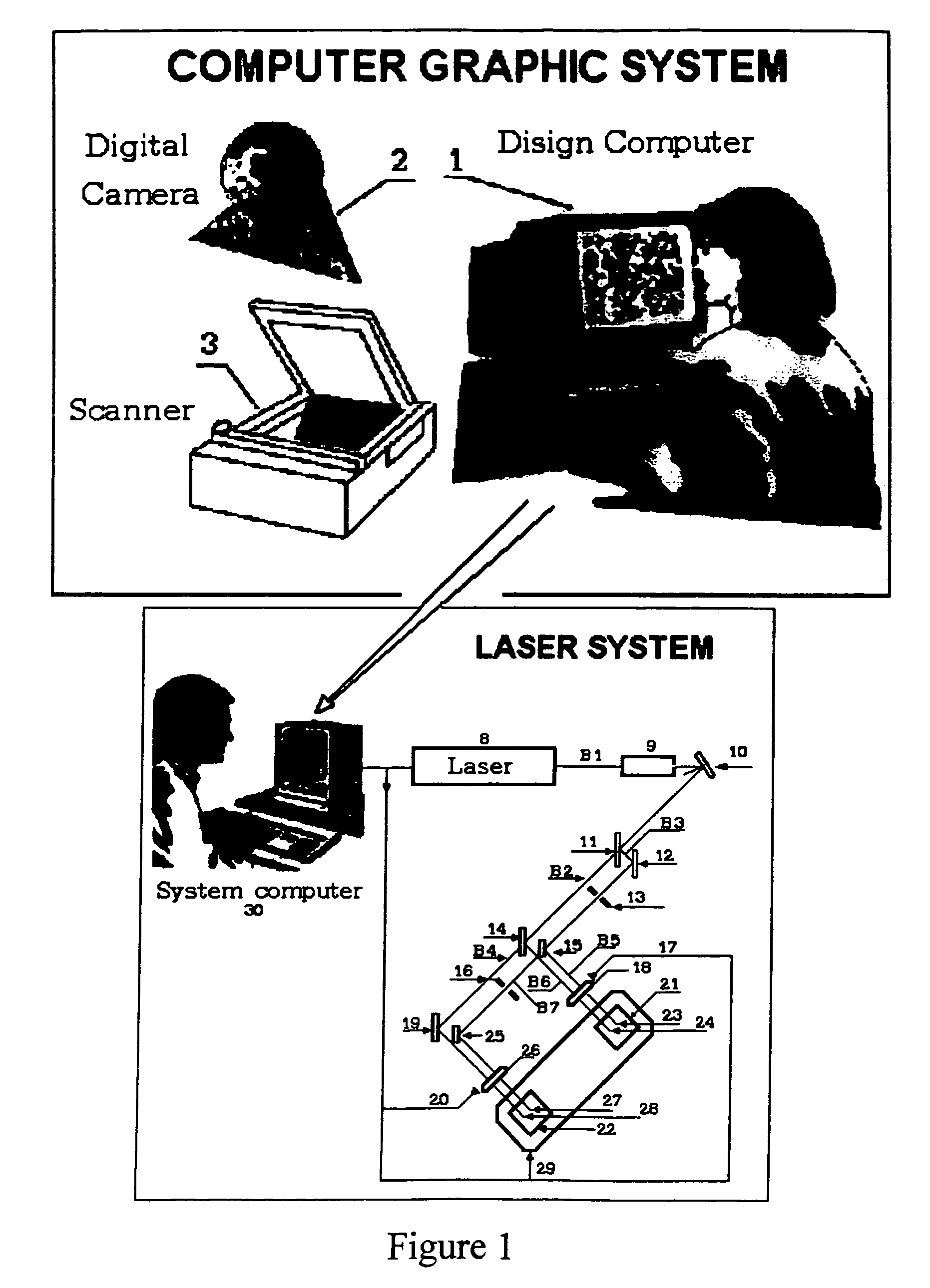

Laser-computer graphics system for generating portrait and 3-D sculpture reproductions inside optically transparent material

InactiveUS20050051522A1Improve contrastHigh resolutionBranding equipmentSolid-state devicesLaser lightReproduction

Embodiments of methods and laser-computer graphics systems for producing images such as portraits and 3-D sculptures formed from laser light created etch points inside an optically transparent material are disclosed. The produced image has a high resolution like a computer graphic image from which it is derived, little fluctuation in gray shades, and has no discernable point structure. In an embodiment, the image is comprised of auxiliary images of multiple layers of etch points, the points of each auxiliary layer and the respective layers spaced to prevent failure of the material. In a method and system, images are produced in multiple articles simultaneously using separate beams. An embodiment of the invention comprises a method and system for using two beams for generating etch points with improved optical characteristics, such etch points useful in generating a one layer image with high resolution. Another embodiment of the method comprises a method for creating iridescent etch points in material.

Owner:TROITSKI

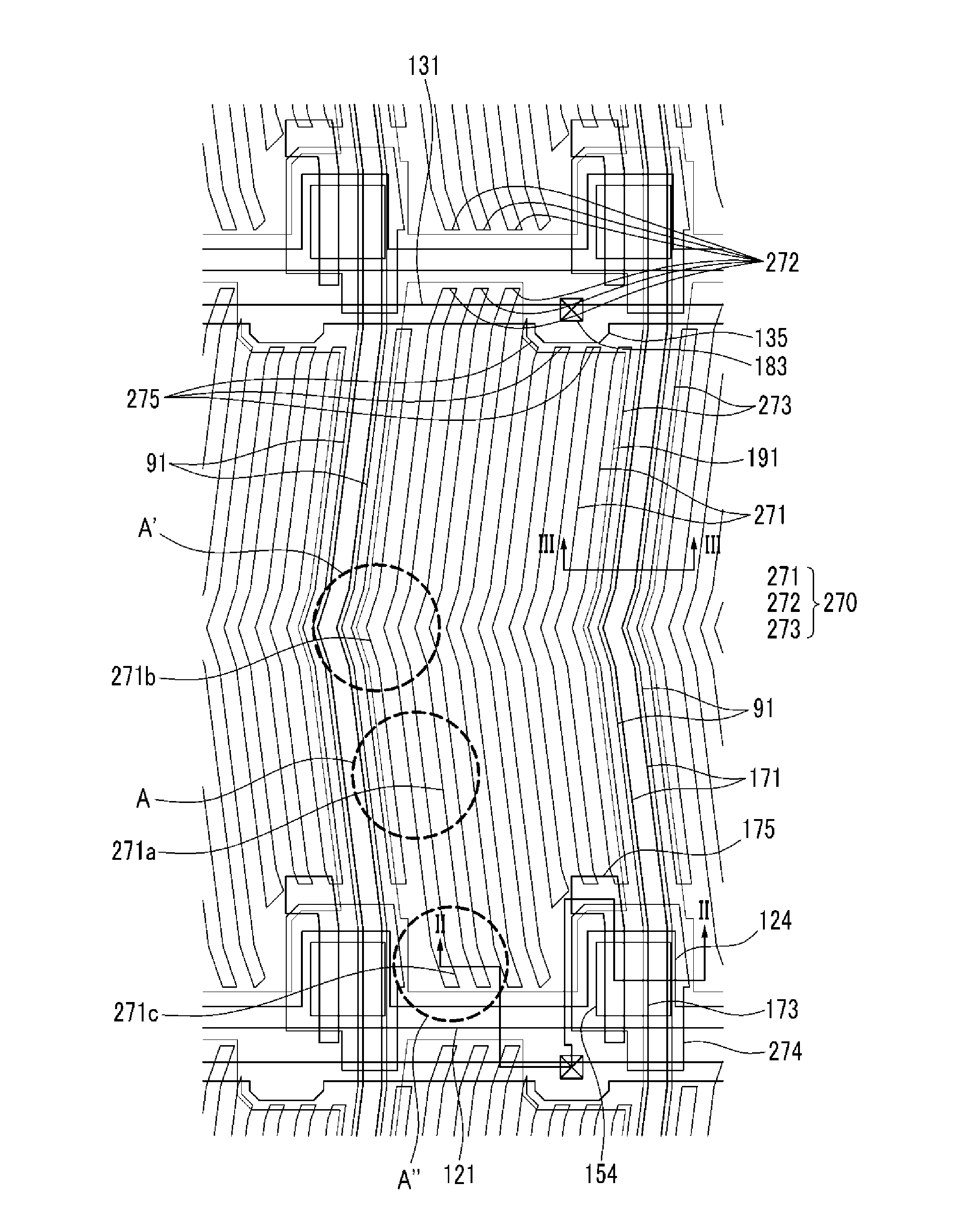

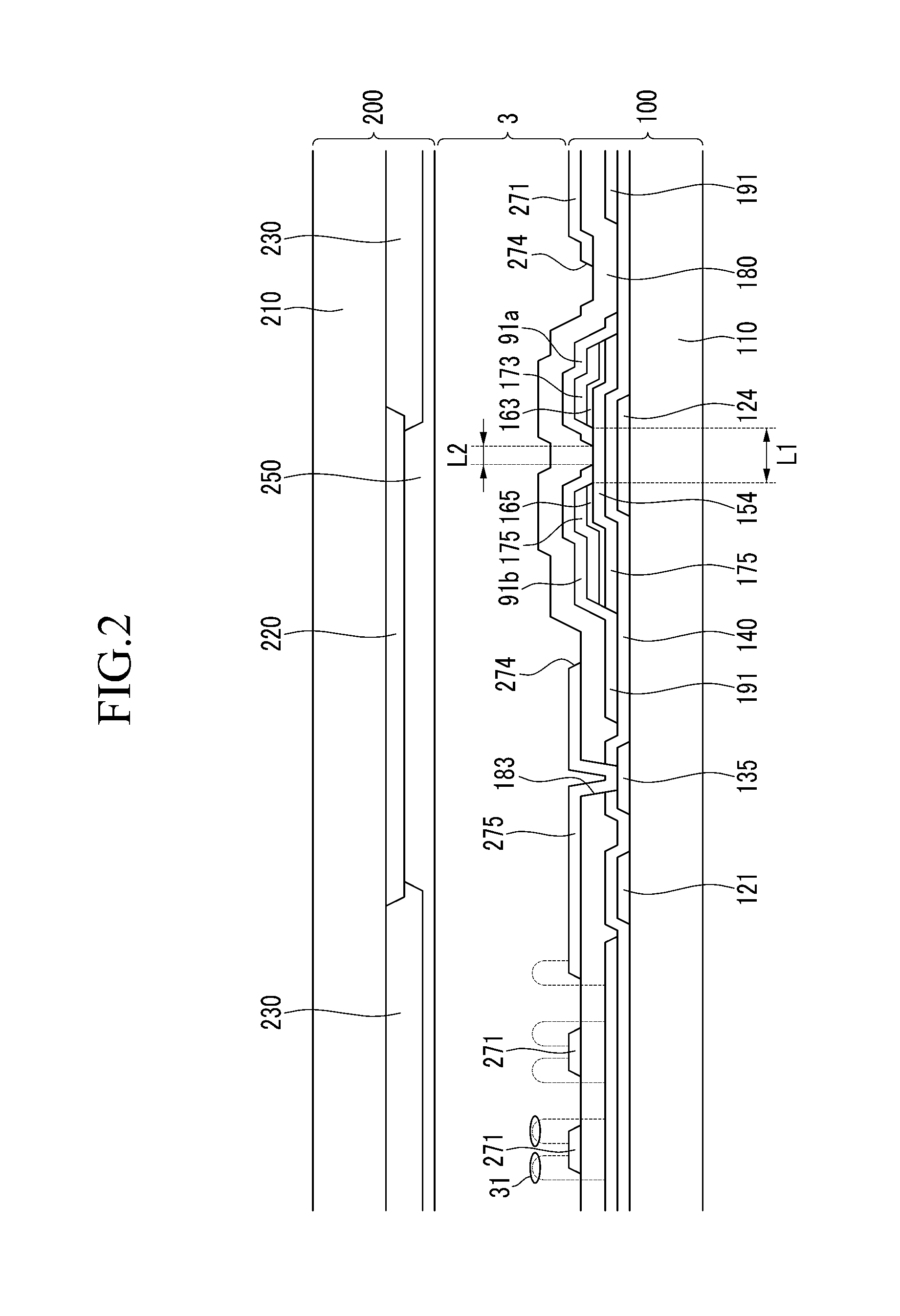

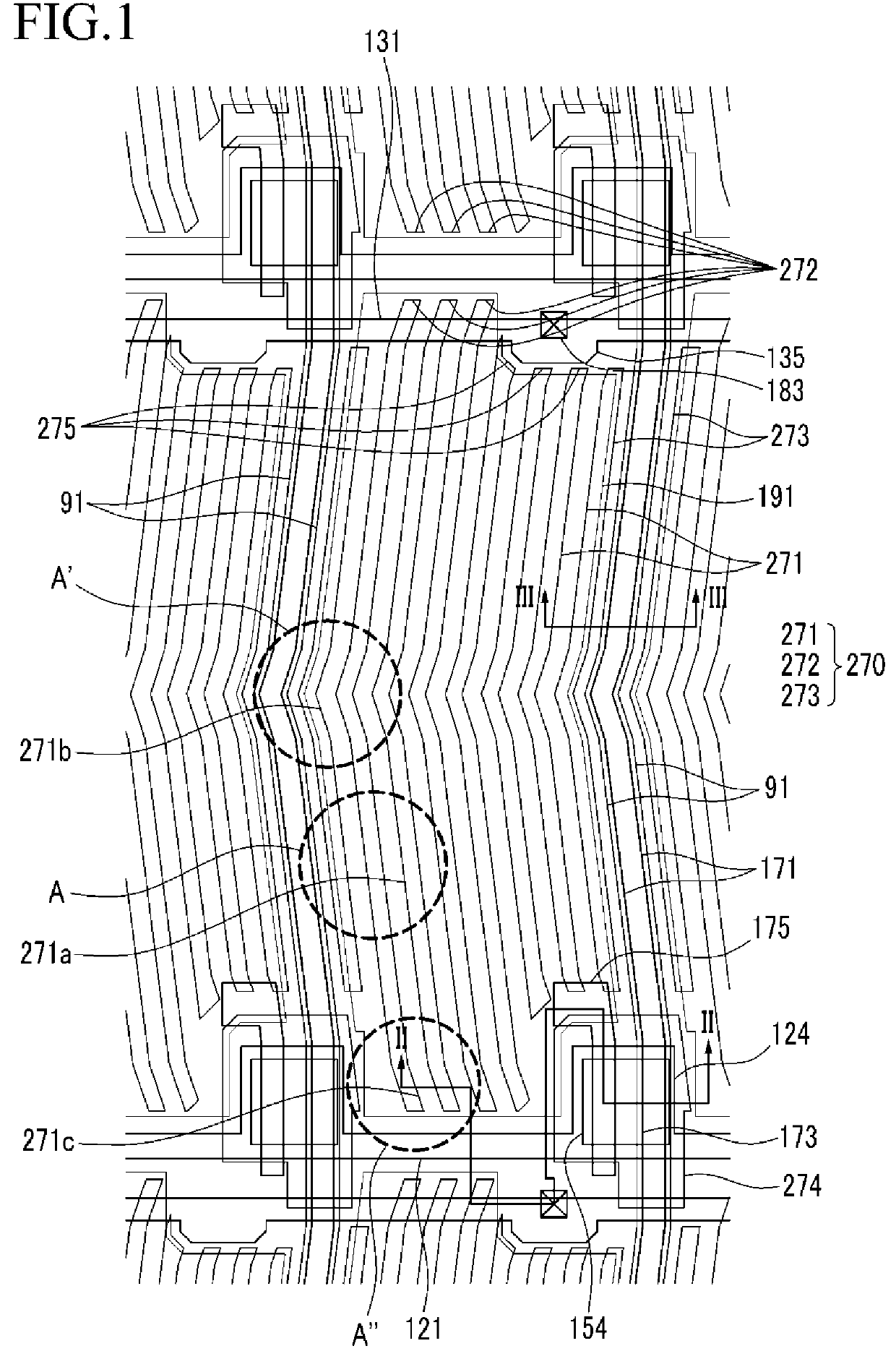

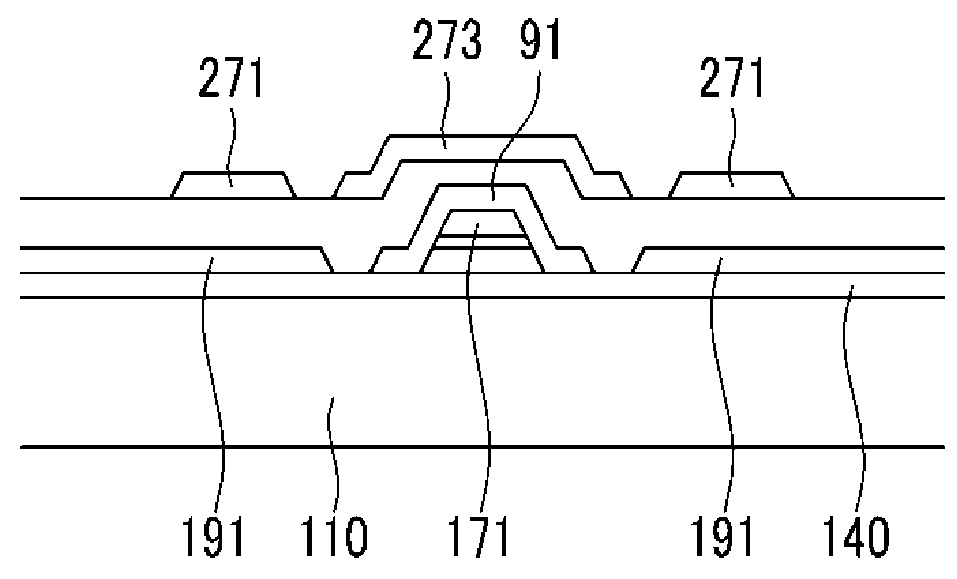

Liquid crystal display

ActiveUS20140125904A1Prevent oxidationLower resistanceStatic indicating devicesSolid-state devicesLiquid-crystal displaySemiconductor

A liquid crystal display includes: a substrate; a gate line and a data line disposed on the substrate; a semiconductor layer disposed on the substrate; first and second field generating electrodes disposed on the substrate; and a first protecting layer formed from the same layer as the first field generating electrode and covering at least a portion of the data line.

Owner:SAMSUNG DISPLAY CO LTD

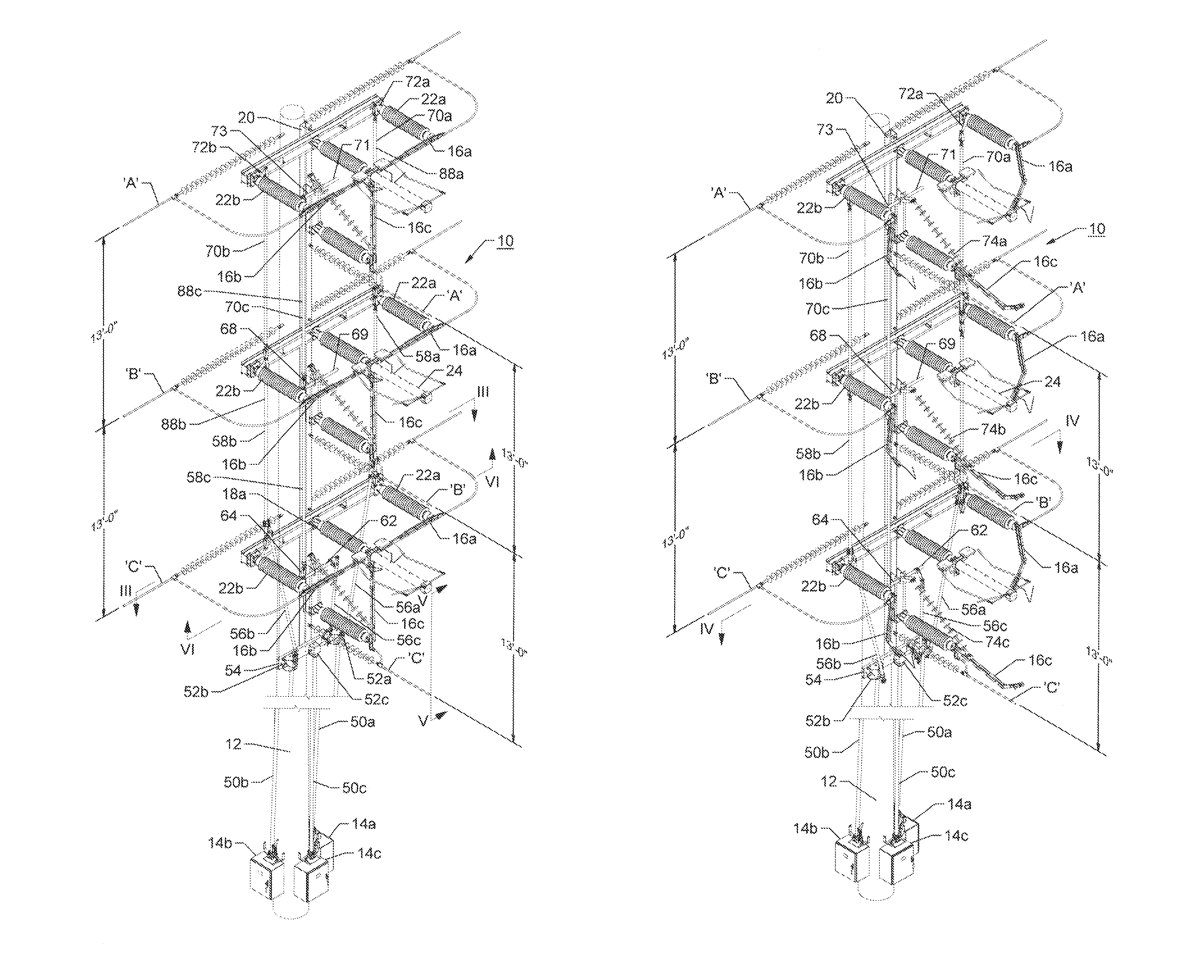

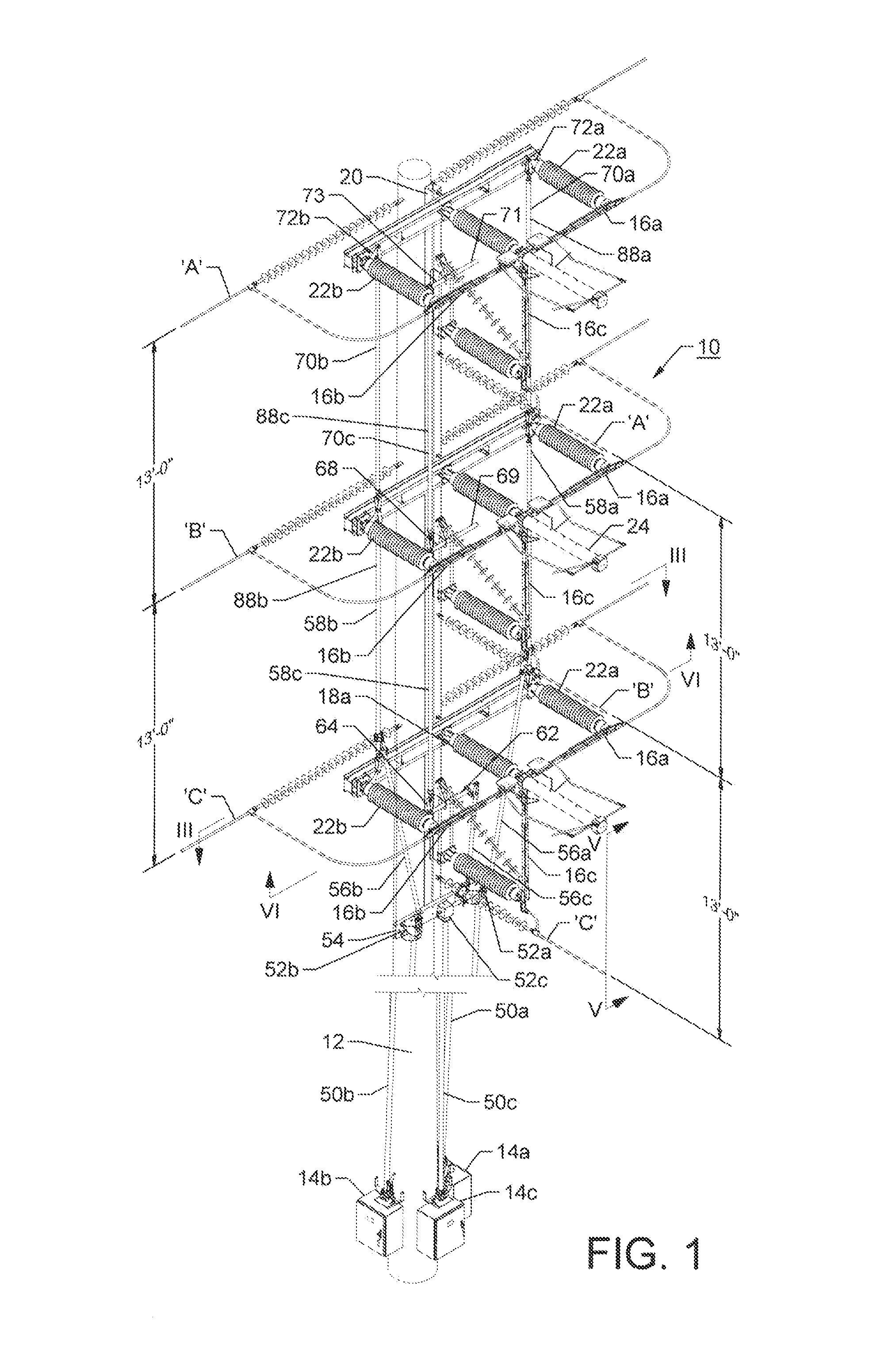

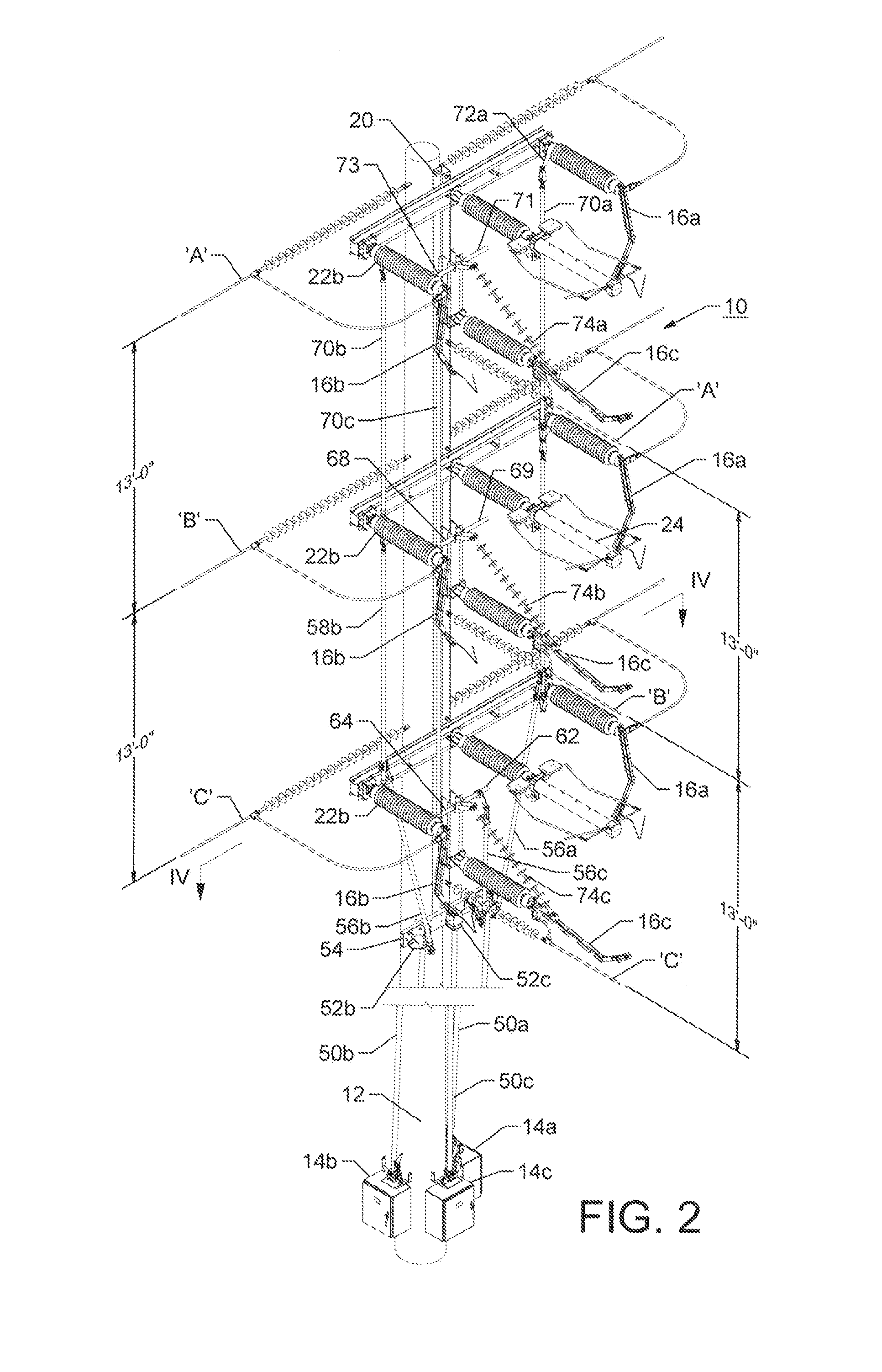

Unitized phase over phase two-way or three-way high voltage switch assembly with one vacuum interrupter per phase

ActiveUS9355797B1Reduce the minimum distanceLess electrical clearanceSwitches with movable electrical contactsHigh-tension/heavy-dress switchesElectric power transmissionElectricity

Switch gear for interconnecting a plurality of power transmission lines including a number of high voltage switches arranged in three phases for routing power in multiple directions. The switches are pre-mounted on a beam to form a three phase unit as a unitized assembly which is attached in the field to a vertical support structure. Each phase includes a vertical break switch and two side break switches for a three-way switch. For a two-way, each phase includes two side break switches. The vertical break switch and the two side break switches for each phase are operatively and electrically connected to a common electric power interrupter. The unitized assembly for each phase has the insulators and power interrupter arranged in cantilevered horizontal relationship with the beam which is attached to the vertical support structure. Operating links between phases are operatively connected in a push-pull relationship with the high voltage outdoor electric switches.

Owner:CLEAVELANDPRICE ENTERPRISES

Planar antenna for mobile satellite applications

ActiveUS8368596B2Satisfactory efficiencyReduce the minimum distanceSimultaneous aerial operationsRadiating elements structural formsMicrostrip patch antennaGround plane

The invention relates to a microstrip patch antenna for mobile satellite communications comprising a first electrically conducting ground plane having at least one opening, at least one patch radiating element, at least one first dielectric layer, disposed between the first electrically conducting ground plane and the patch radiating element and more particularly between the at least one opening and the patch radiating element, at least one feed line for providing signal energy in a contactless manner to or from the patch radiating element through the opening and a second dielectric layer disposed between the feed line and the first electrically conducting ground plane wherein the antenna further comprises a second ground plane and a third dielectric layer disposed between the second ground plane and the feed line.

Owner:VIASAT INC

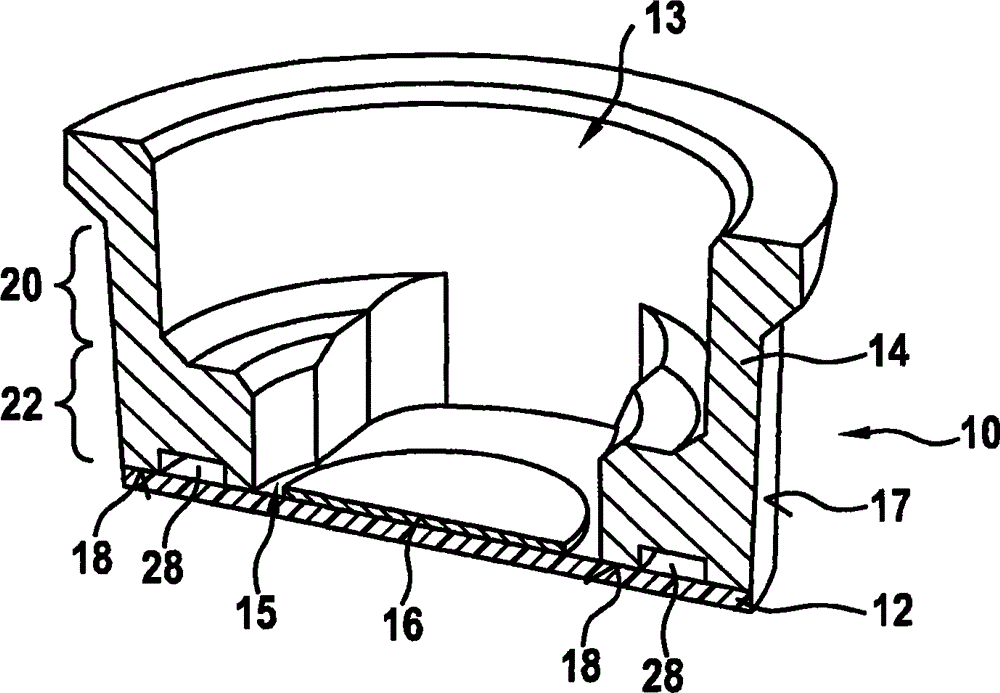

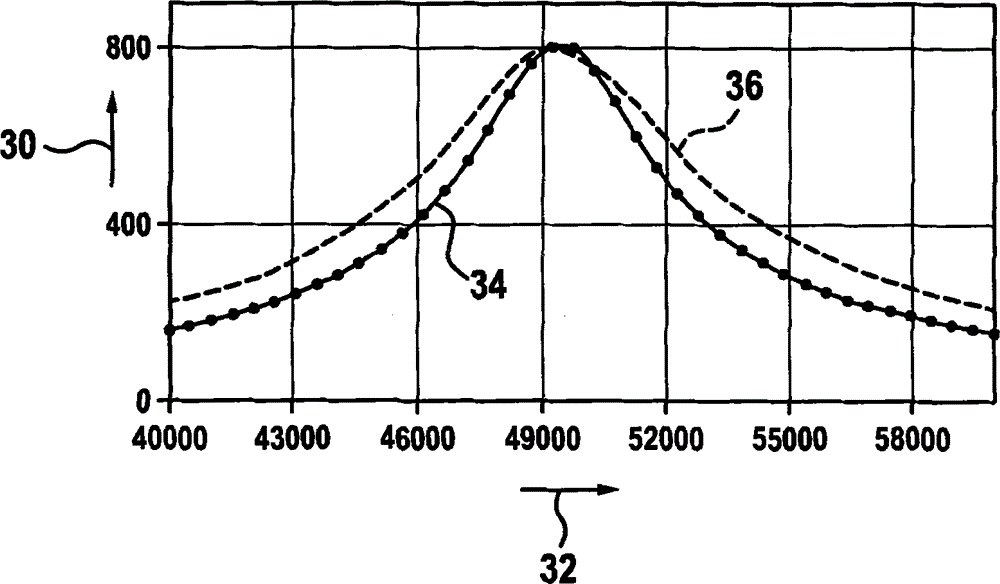

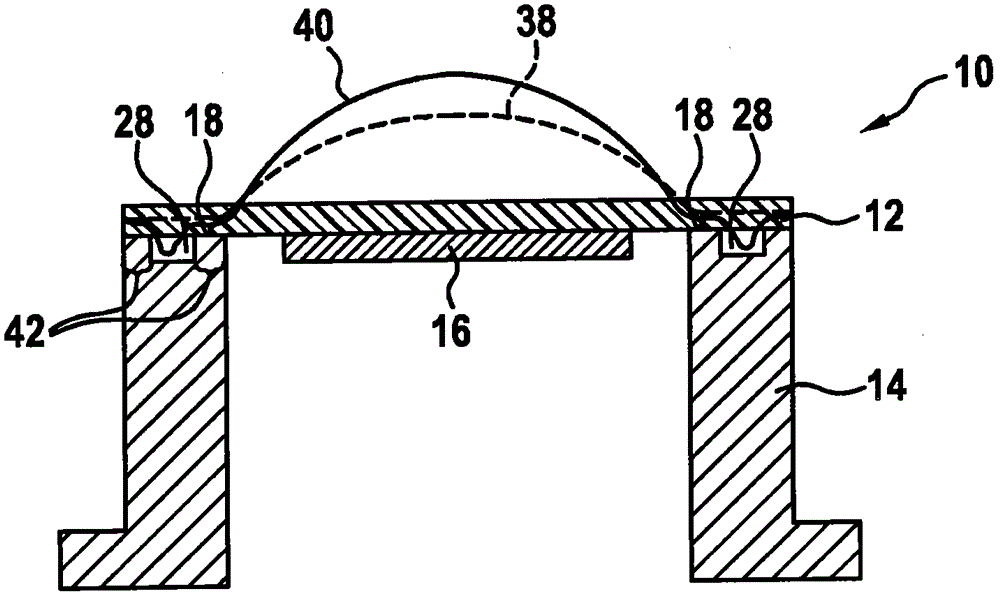

Acoustic sensor with a diaphragm made of a composite fiber material

ActiveCN104603870AEasy to manufactureBest working rangeSound producing devicesAcoustic wave reradiationEngineeringFibrous composites

The invention relates to an acoustic sensor (10) comprising a diaphragm (12) which can oscillate and which has a converter element (16) and comprising a sensor housing (14), wherein the diaphragm (12) is fabricated from a composite fibre material and is connected as a separate component to the sensor housing (14). The invention also relates to a use of the acoustic sensor (10) and to a method for manufacturing same.

Owner:ROBERT BOSCH GMBH

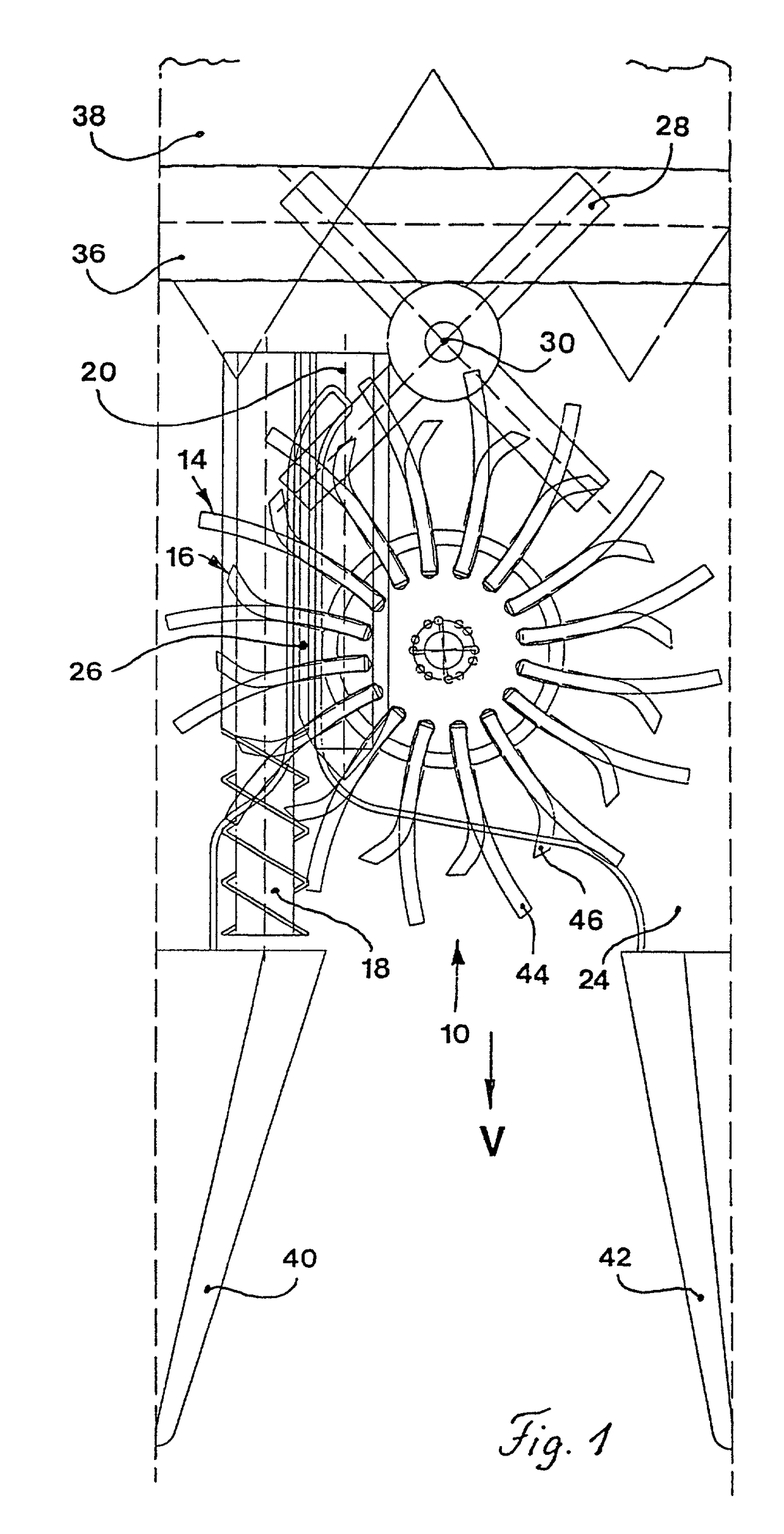

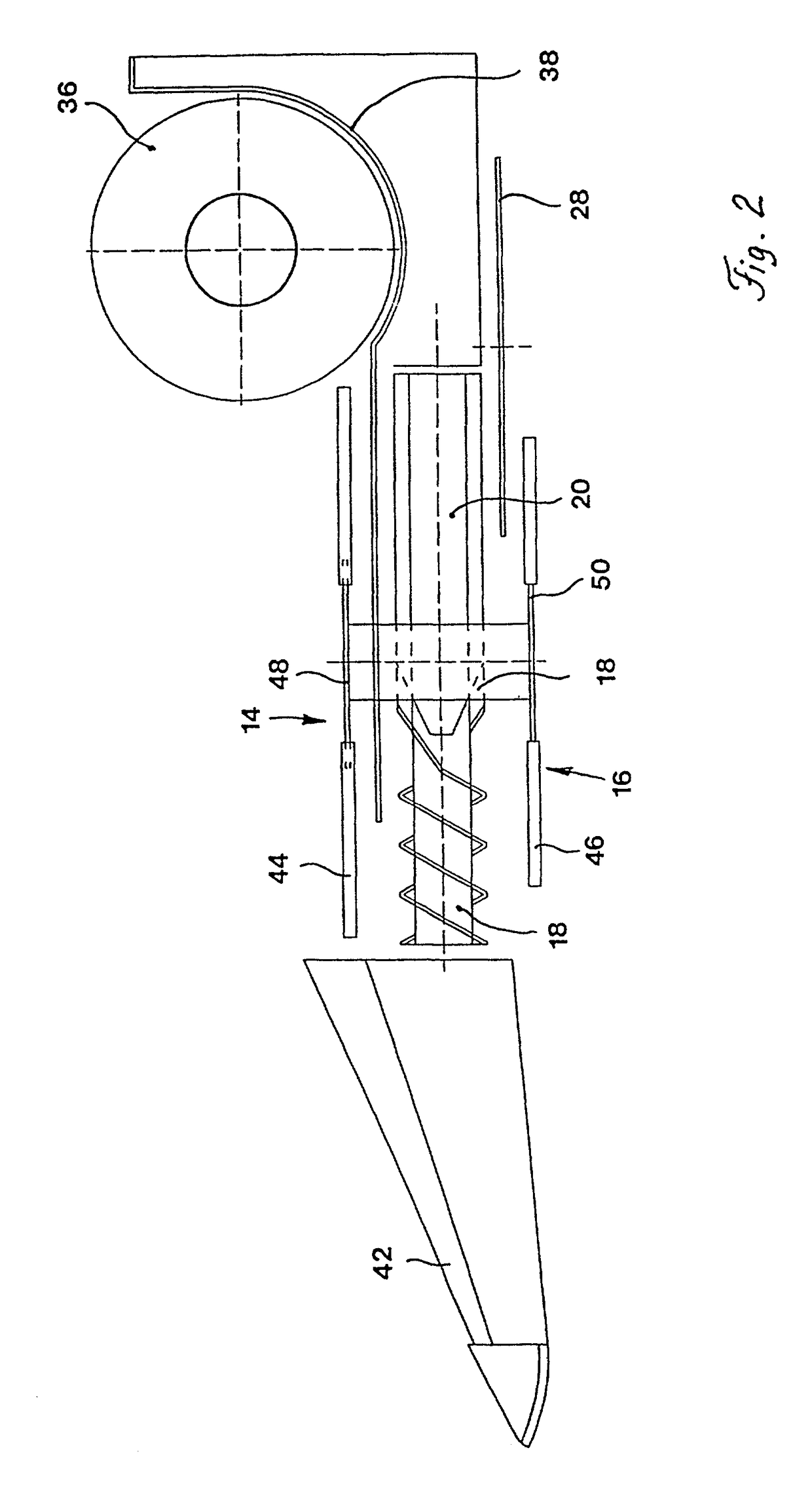

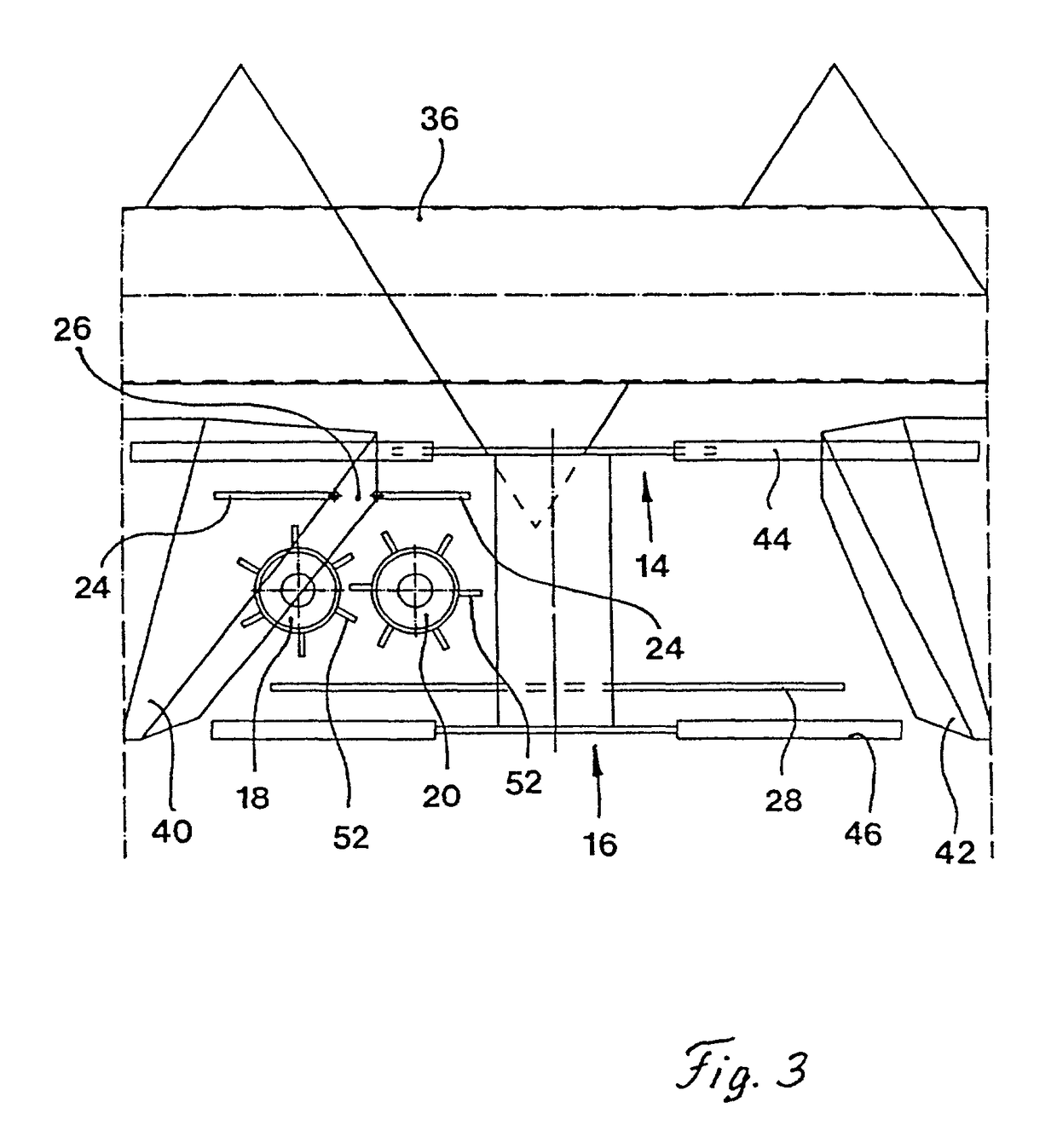

Row-insensitive feeding and picking device for an agricultural header

ActiveUS7905079B2Constant widthEvenly distributedHarvestersPortable power-driven toolsEffective lengthEngineering

A feeding and picking device having a rotating feeding device that is rotated about a vertical axis. The device is able to work in fields not planted in rows and is designed to grasp plant stalks and feed them into a picking device. The picking device comprises a snapping channel formed by snapping bars under which is located at least one snapping roll. The feeding device comprises a disc having fingers that overlap the snapping channel. The feeding device is therefore designed to transport the plant throughout the effective length of the picking device.

Owner:MASCHFAB KEMPER

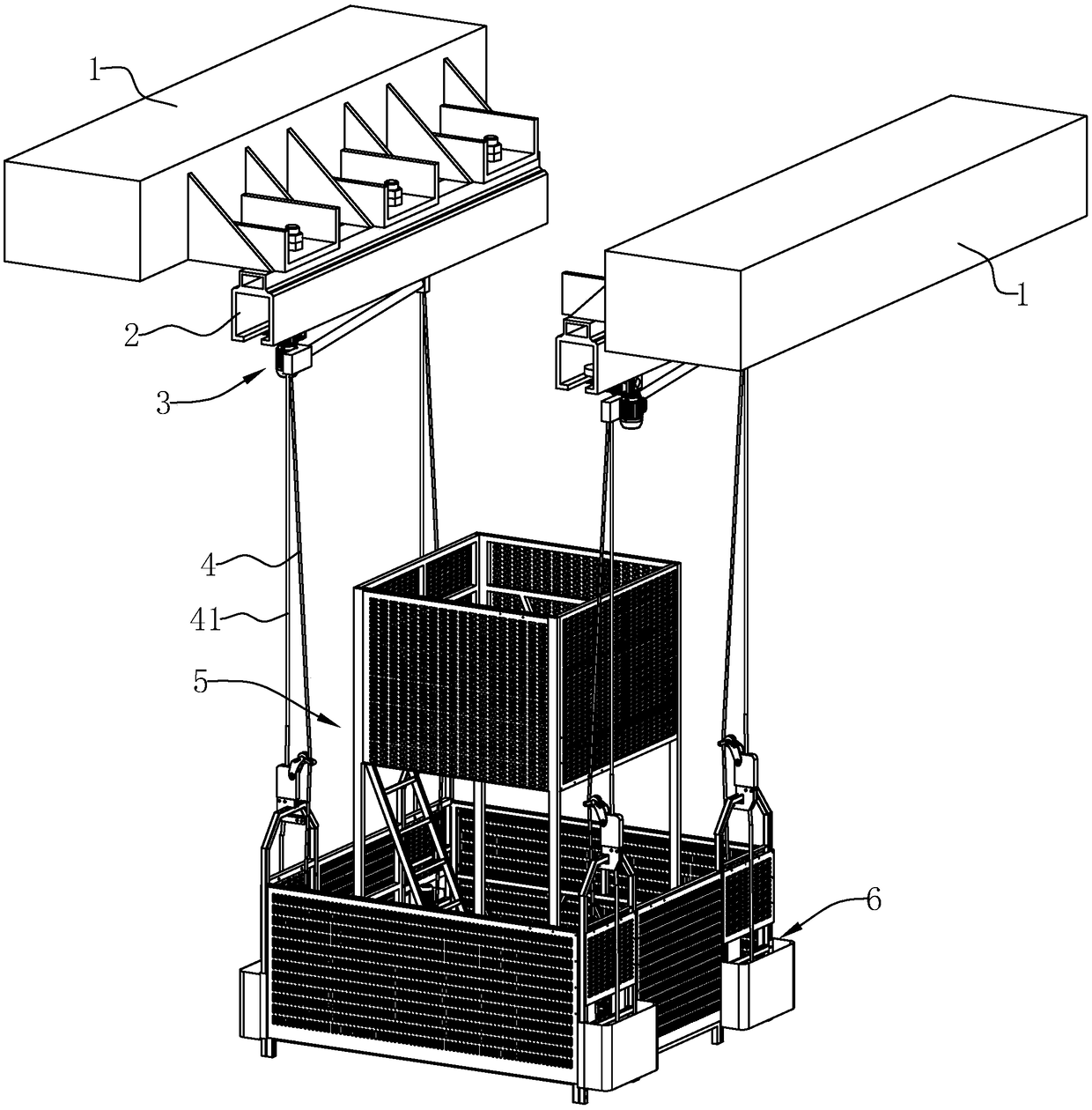

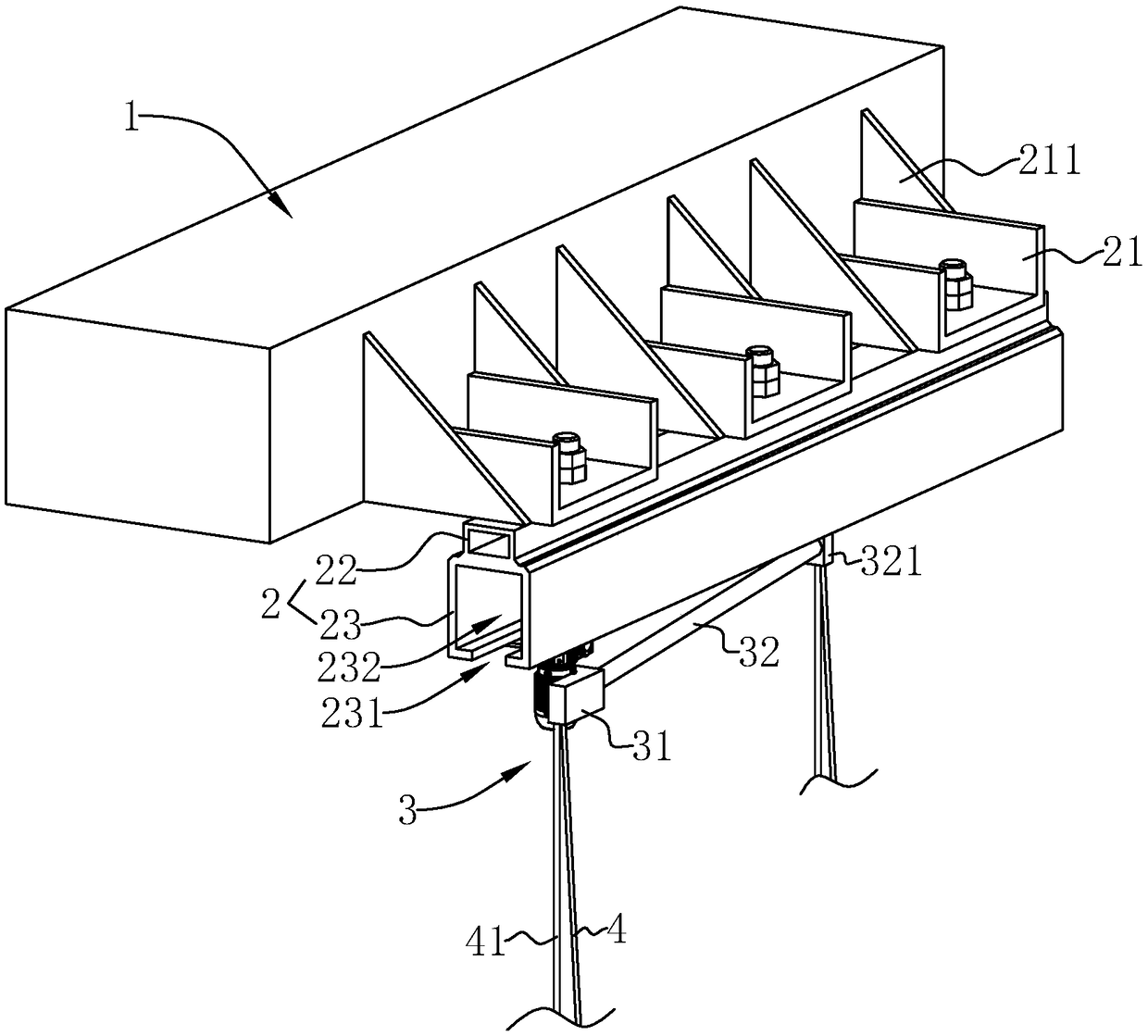

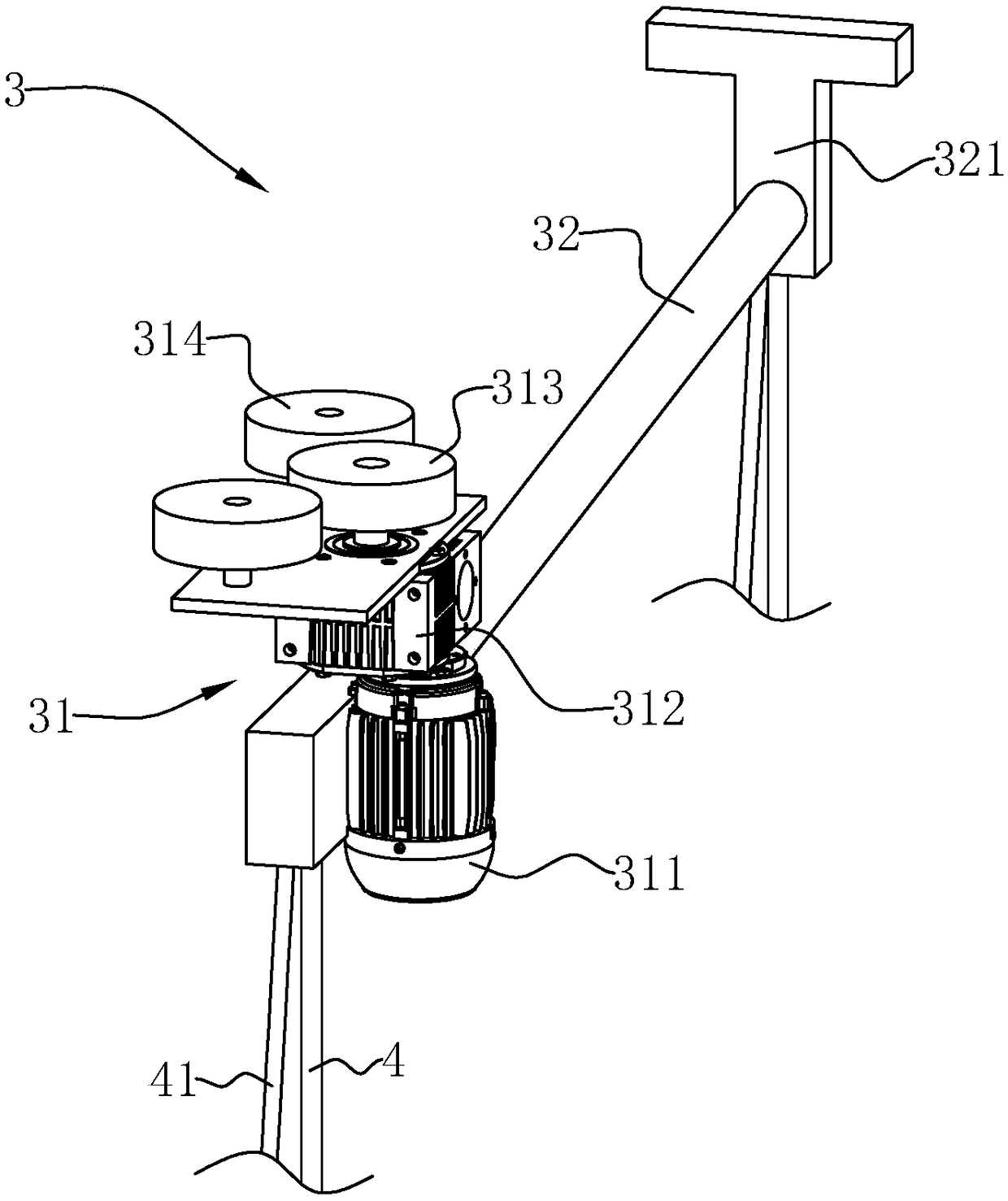

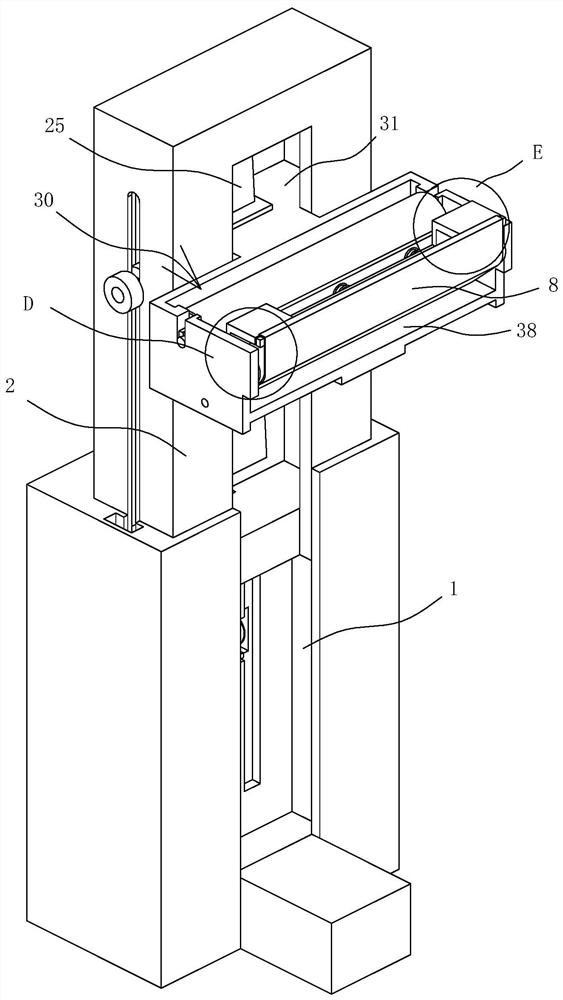

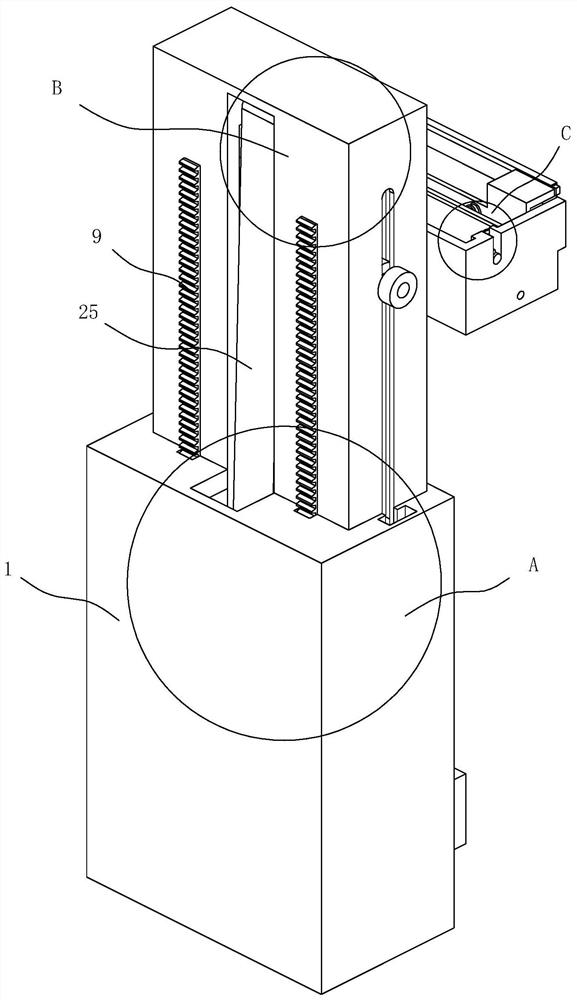

Rail-mounted working platform for building high-altitude suspension construction and capable of horizontally and vertically walking

InactiveCN109025234AImprove construction efficiencyAchieve horizontal movementBuilding support scaffoldsArchitectural engineeringHanging basket

The invention discloses a rail-mounted working platform for building high-altitude suspension construction and capable of horizontally and vertically walking, and relates to a building construction hanging basket; the technical scheme mainly comprises a guide rail fixed on one side of a girder, a horizontal moving device arranged on the guide rail in a slide mode, and a working platform hung belowthe horizontal moving device via steel wire ropes, wherein a lifting device used for winding the steel wire rope so as to rise and lower the working platform is fixed on the working platform. The rail-mounted working platform can vertically elevate, can horizontally move, and can improve the construction efficiency in the construction process.

Owner:BEIJING CONSTR ENG GRP CO LTD +2

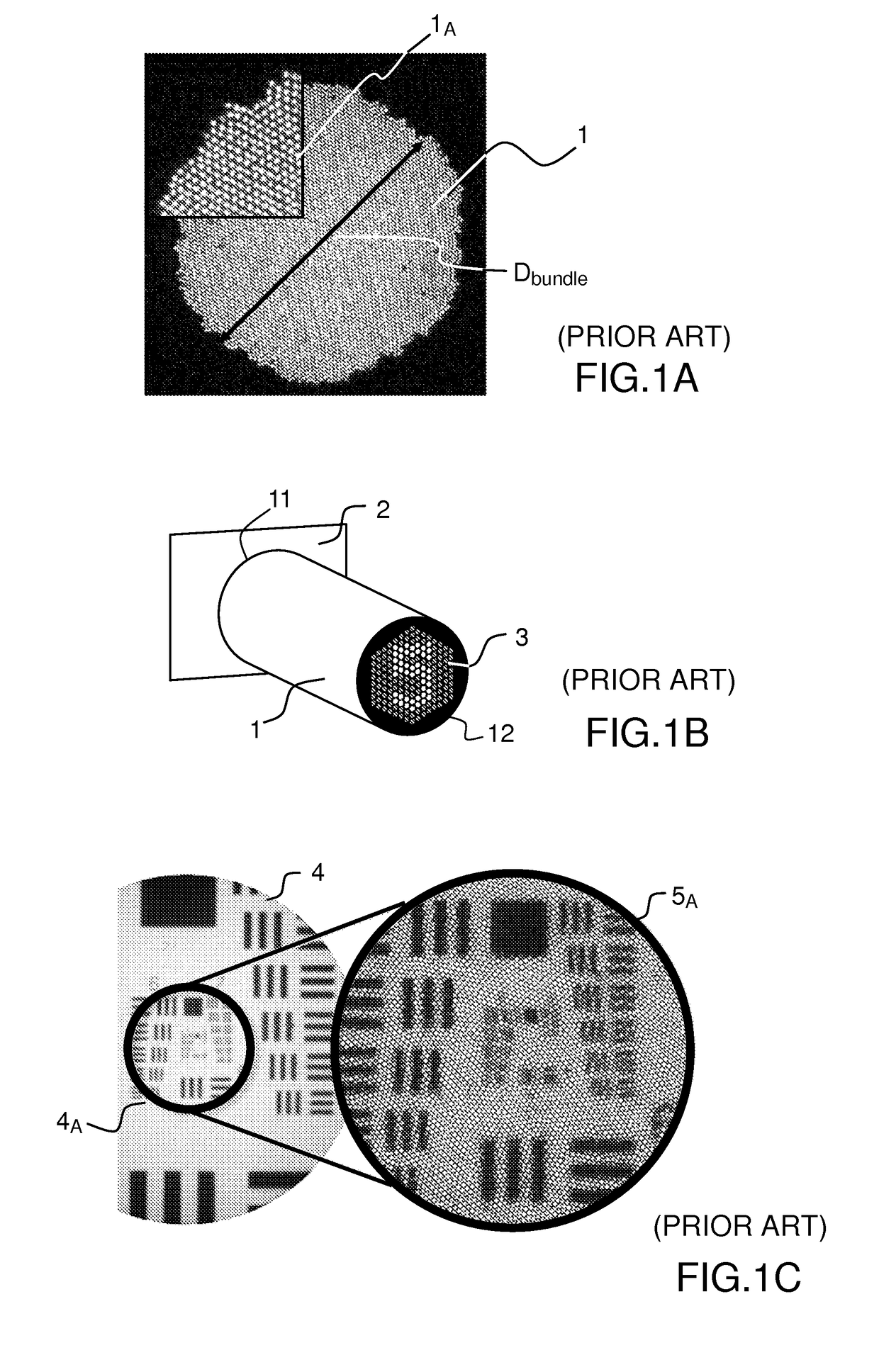

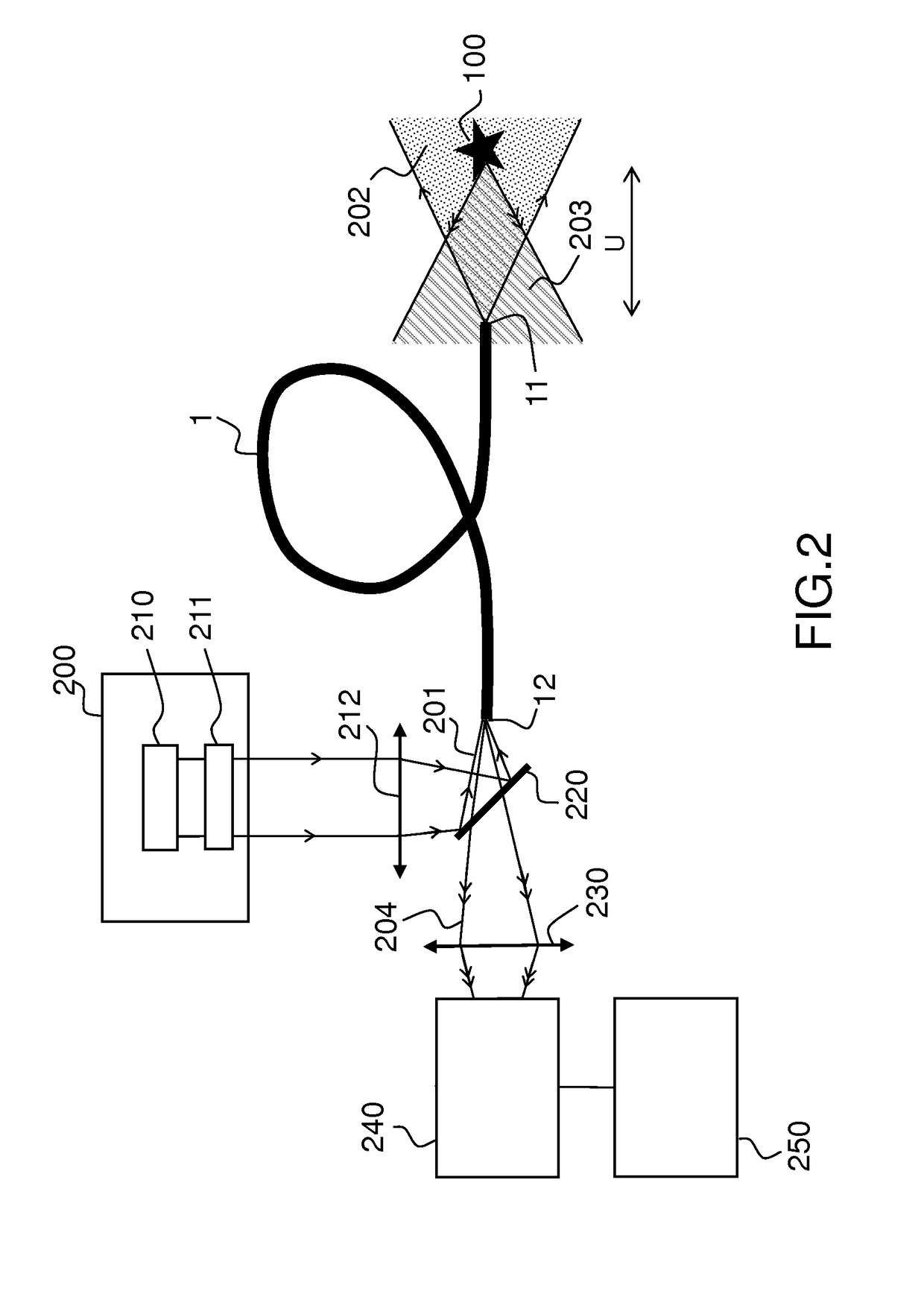

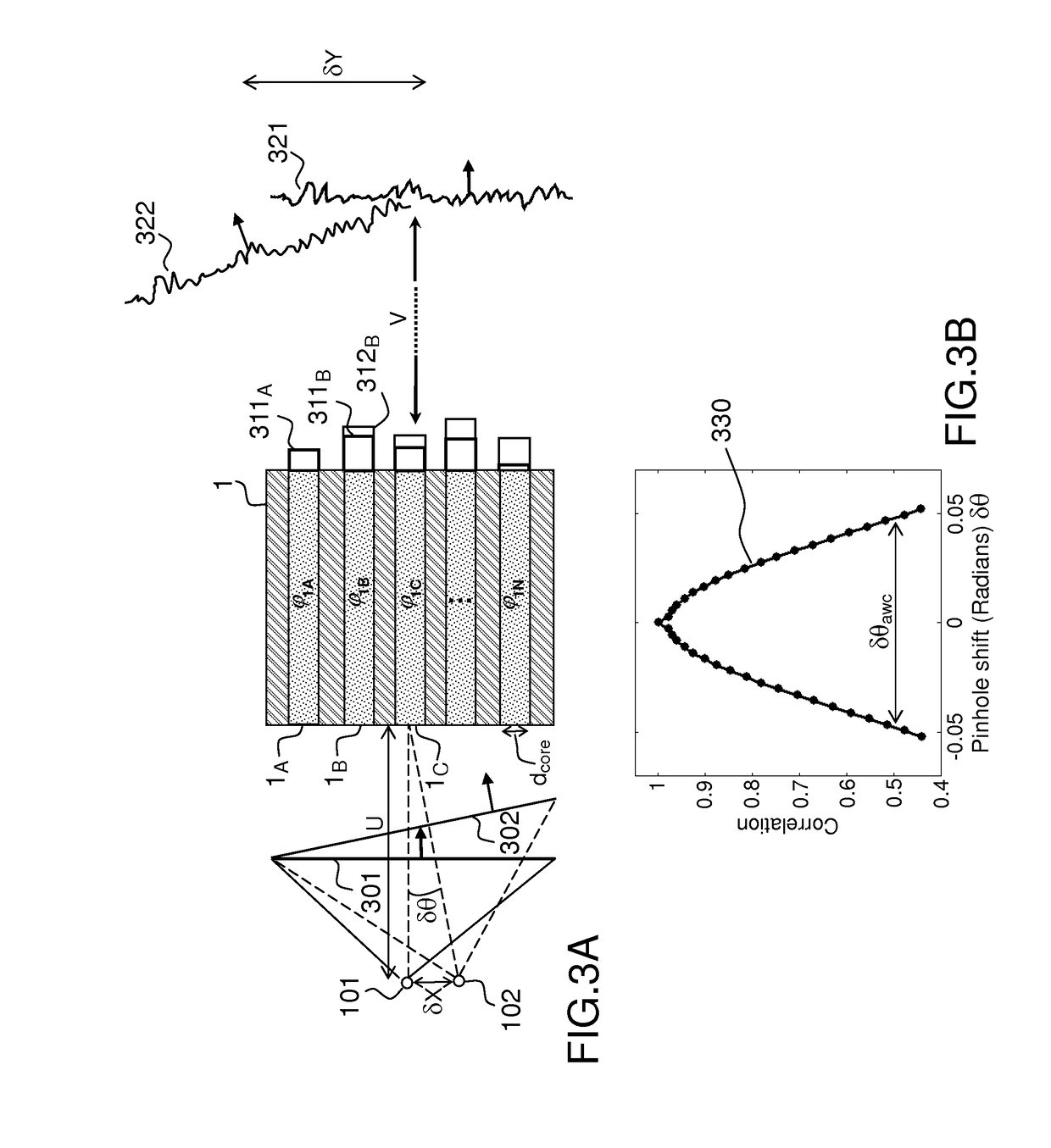

Systems and methods for high resolution imaging using a bundle of optical fibers

InactiveUS20190028641A1Increase the number ofHigh resolutionTelevision system detailsColor television detailsFiber bundleTwo dimensional detector

According to one aspect, the present description relates to a system for high resolution imaging of an object comprising a fiber bundle (1) comprising an array of optical fiber cores (A), said fiber bundle being adapted to receive a plurality of light beams issued from spatially incoherent point sources of an object; the system further comprises a two-dimensional detector (240) with a detection plane, located at a proximal end of the fiber bundle, adapted to receive speckle patterns, each speckle pattern resulting from the transmission of one of said light beams through at least a plurality of the fiber bundle cores, the ensemble of speckle patterns detected by the two-dimensional detector forming a multiple speckles image; and a processing unit (250) adapted to determine an image of the object from said multiple speckles image.

Owner:UNIV DE PROVENCE D AIX MARSEILLE I +3

Method for warning a driver of a collision

ActiveUS8823550B2Reduce the minimum distanceSufficient distanceDigital data processing detailsIndication of parksing free spacesDriver/operatorParking space

In a method for warning a driver of a vehicle about a collision with an object in the course a parking operation, the distance of the vehicle to at least one object in the environment of the vehicle is detected, and if a specified minimum distance is undershot, the driver is warned to stop the vehicle or the vehicle is stopped automatically. The specified minimum distance is varied as a function of the type of parking space and the executed parking maneuver.

Owner:ROBERT BOSCH GMBH

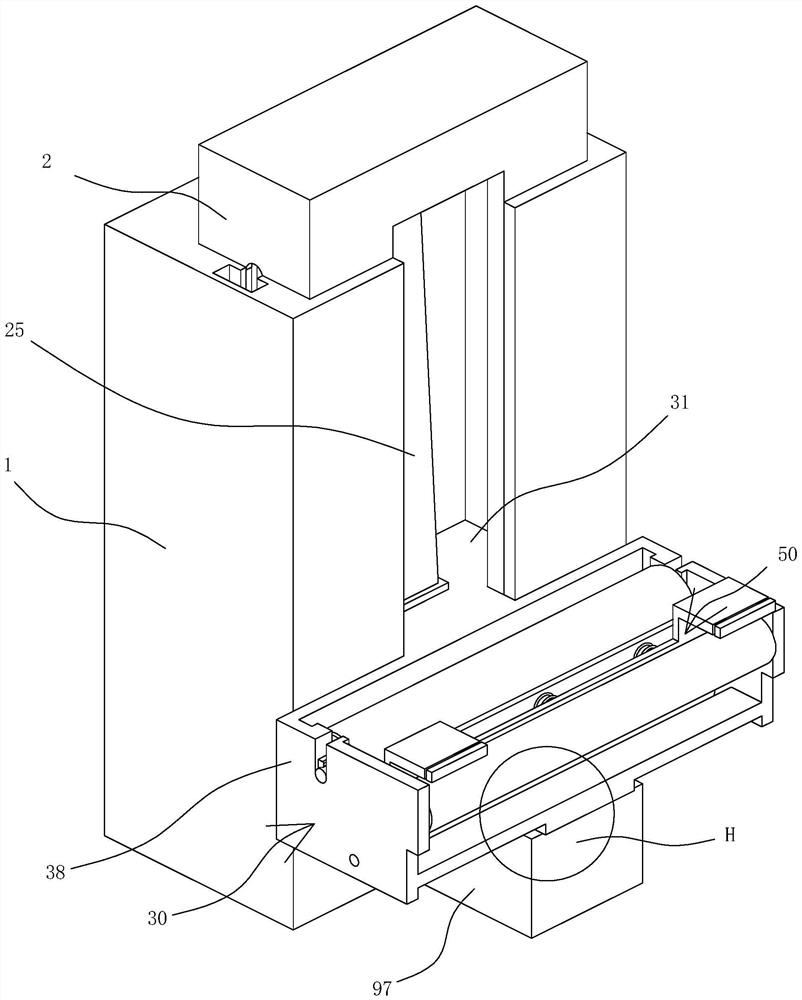

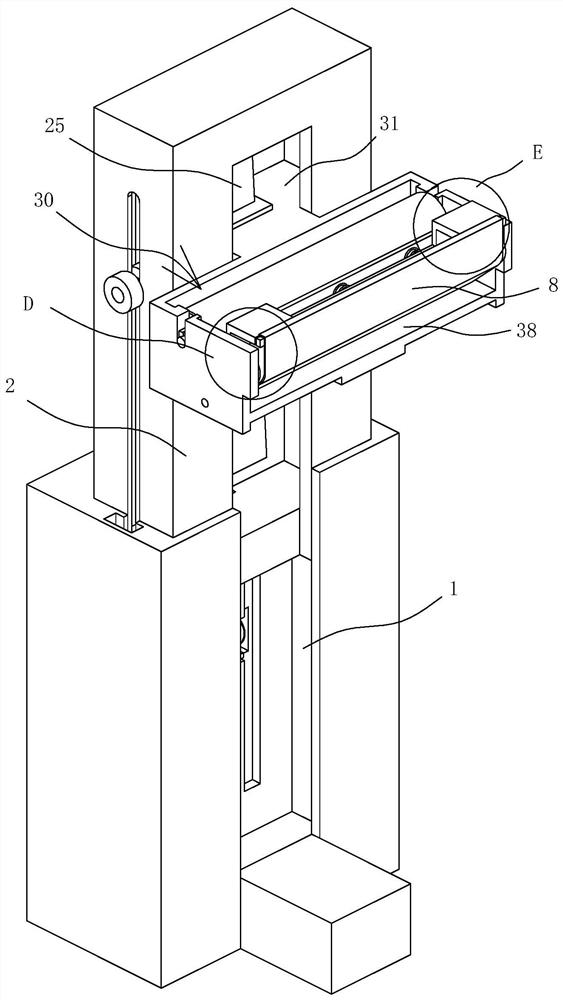

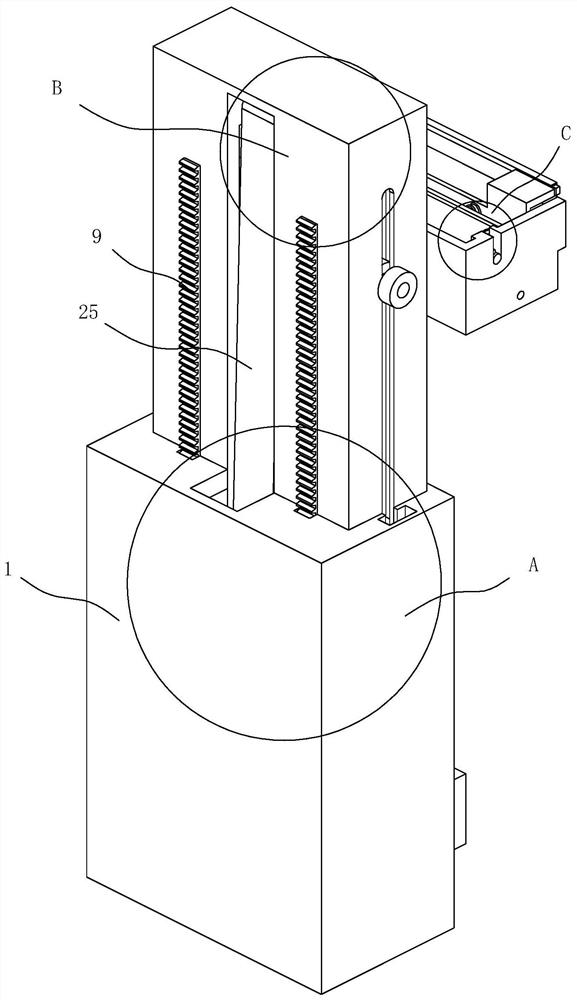

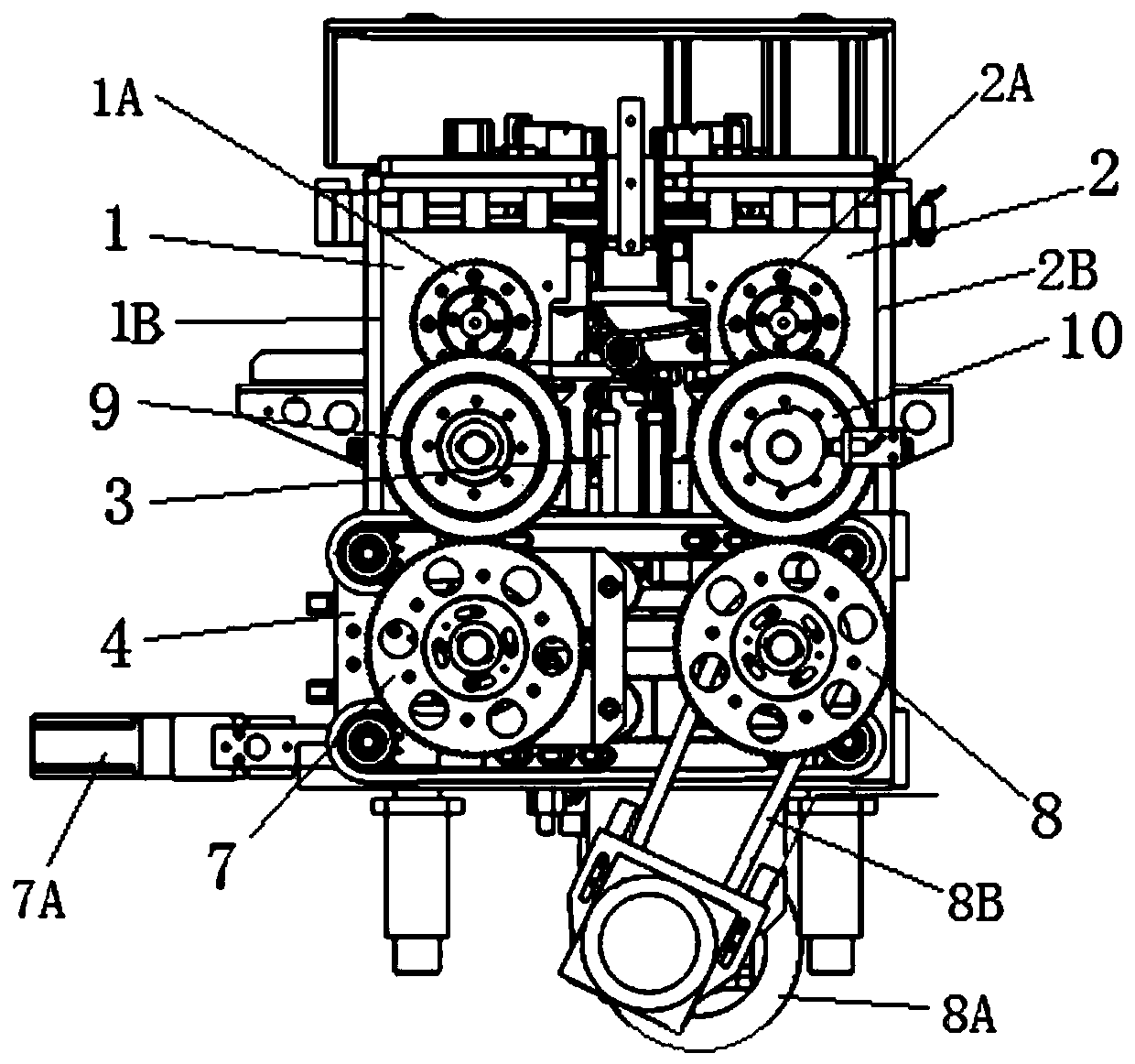

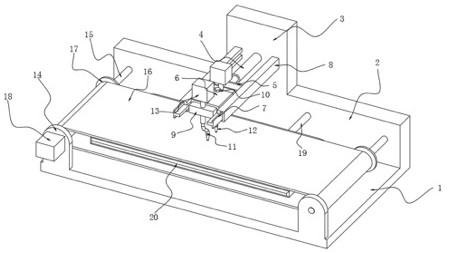

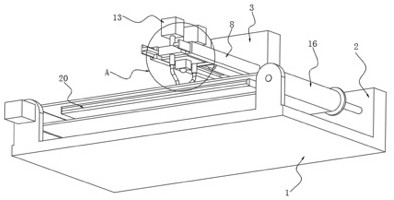

Wallpapering equipment having automatic gluing function

The invention discloses wallpapering equipment having an automatic gluing function. The wallpapering equipment comprises a base; a lifting frame is arranged at the upper end of the base; a lifting mechanism is arranged between the rear end of the lifting frame and the base; a moving mechanism for wallpapering is arranged inside the lifting frame; a power mechanism for driving the moving mechanismto move is arranged at the rear end of the base; a gluing mechanism for gluing wallpaper is arranged inside the moving mechanism; and the wallpapering equipment disclosed by the invention implements gluing of the inner side of the wallpaper during wallpapering, so that the operation steps of a user are simplified, and the work efficiency is improved.

Owner:聊城绿天使科技发展有限公司

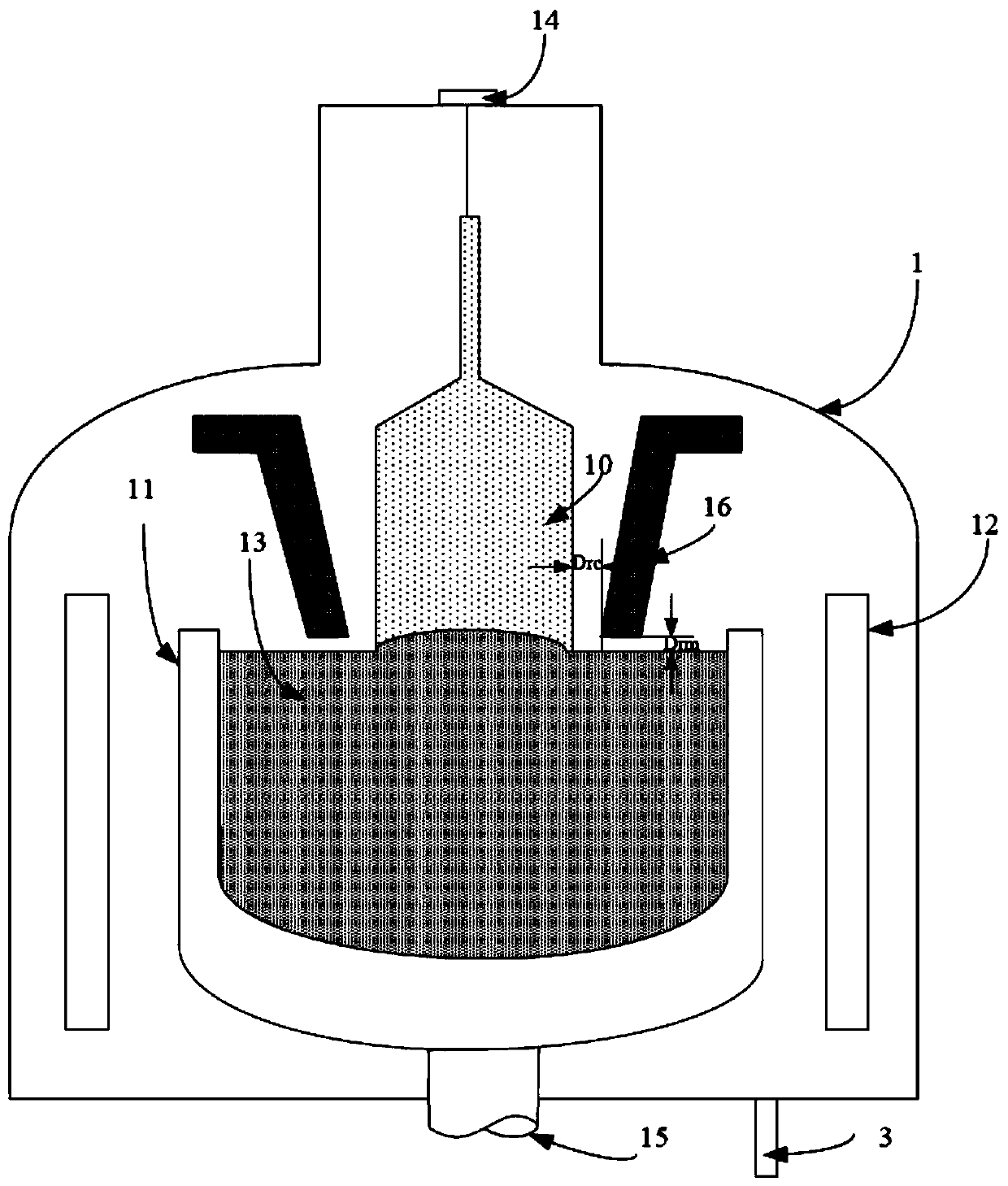

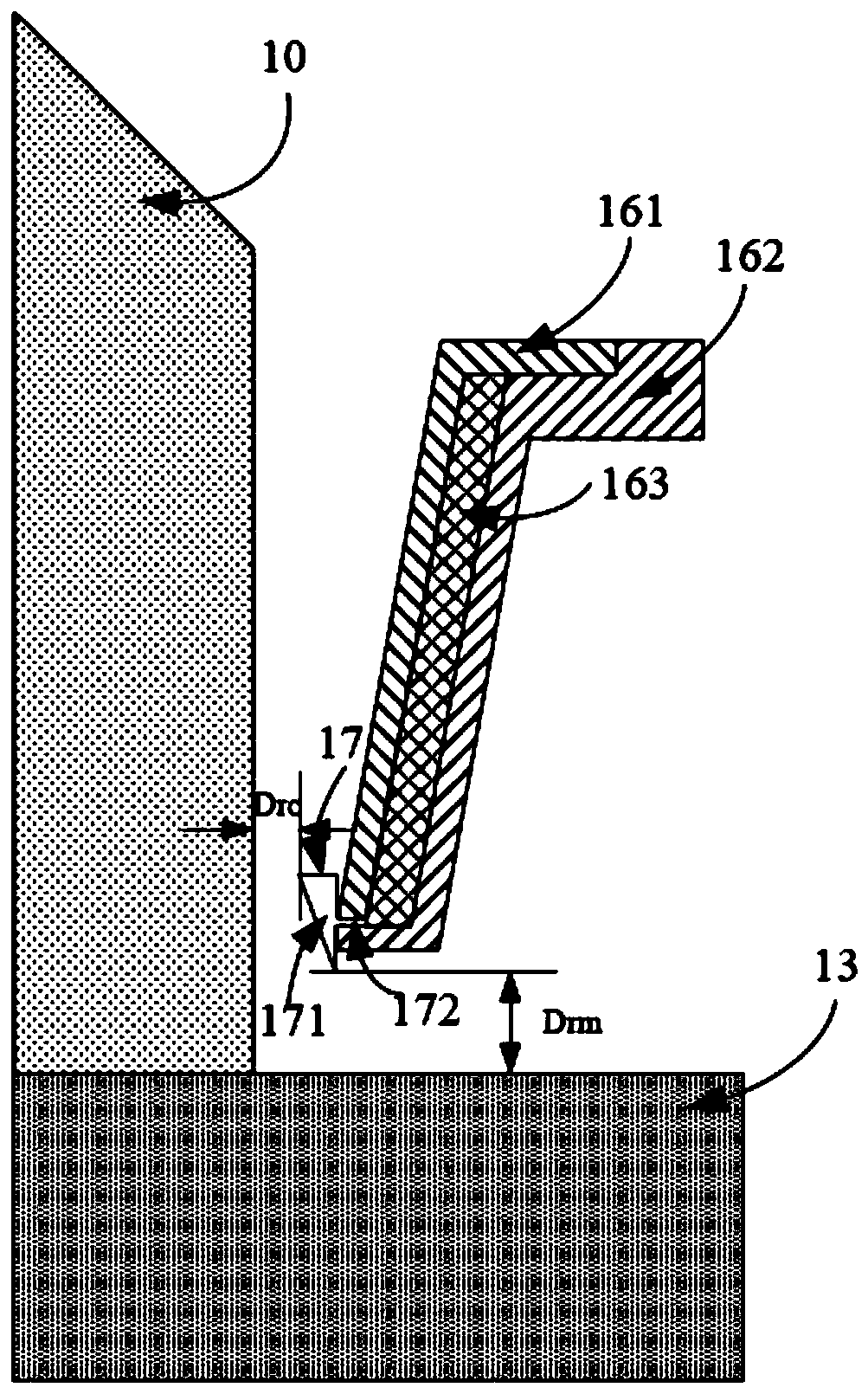

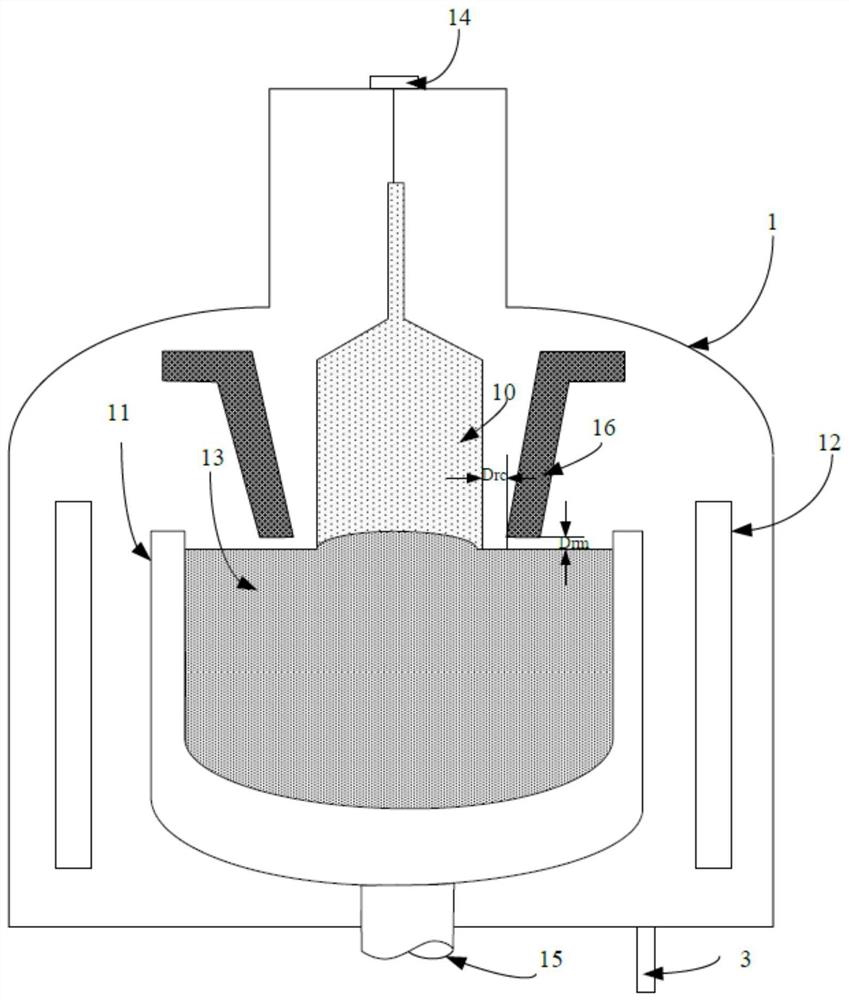

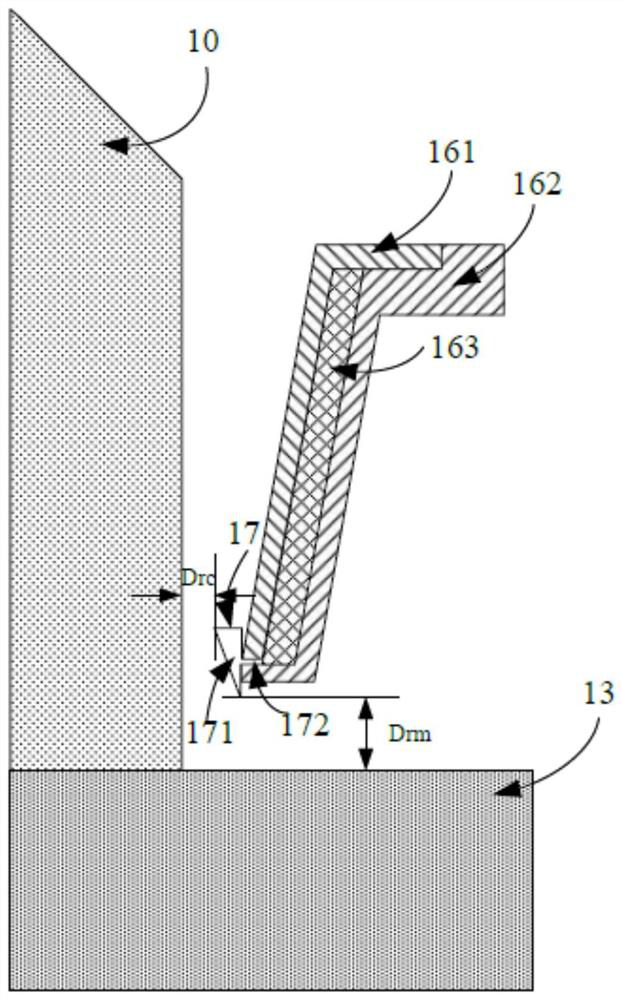

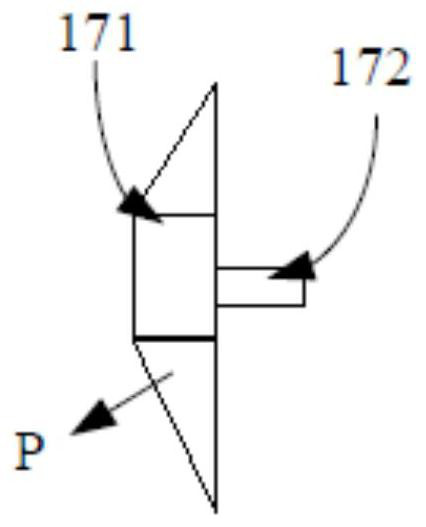

Semiconductor crystal growth device

ActiveCN111519241AStable growthFast growthPolycrystalline material growthFinal product manufactureCrystal growthCondensed matter physics

The invention provides a semiconductor crystal growth device. The device comprises a furnace body; a crucible which is arranged in the furnace body and is used for accommodating a silicon melt; a lifting device which is arranged at the top of the furnace body and is used for lifting a silicon crystal bar out of the silicon melt; and a heat shield device which comprises a guide cylinder, wherein the guide cylinder is barrel-shaped and is arranged around the periphery of the silicon crystal bar and is used for rectifying argon inputted from the top of the furnace body and adjusting the distribution of the heat field between the silicon crystal bar and the liquid level of the silicon melt; the heat shield device further comprises an adjusting device arranged on the inner side of the lower endof the flow guide cylinder, and the adjusting device is used for adjusting the minimum distance between the heat shield device and the silicon crystal bar. According to the device, the adjusting device is arranged on the inner side of the lower end of the guide cylinder, the distance between the silicon crystal bar and the heat shield device close to the silicon crystal bar is adjusted without changing the shape and position of the guide cylinder, and the crystal growth speed and quality are improved.

Owner:ZING SEMICON CORP

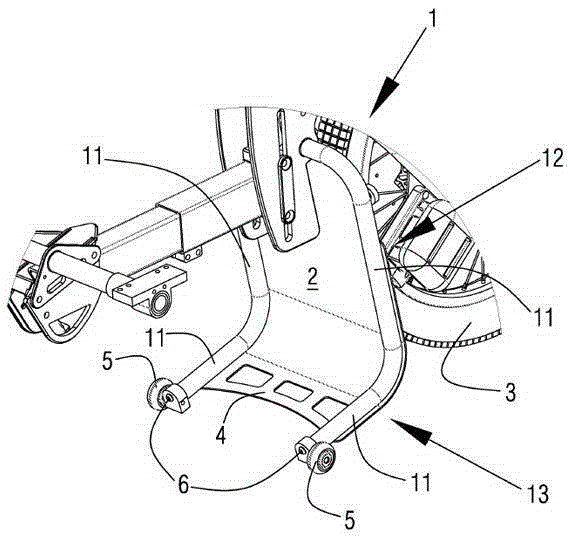

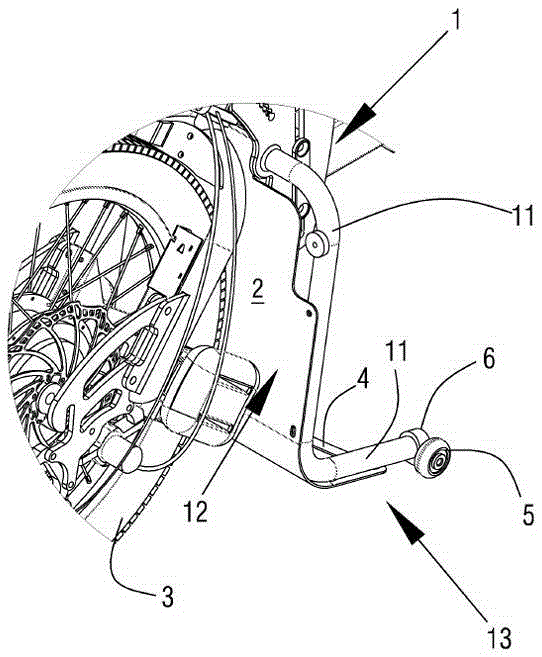

Safety device for an auxiliary wheelchair element

InactiveCN105338941AAdequate and effective protectionImprove cleanlinessWheelchairs/patient conveyanceWheelchairElectrical and Electronics engineering

Owner:BATEC MOBILITY

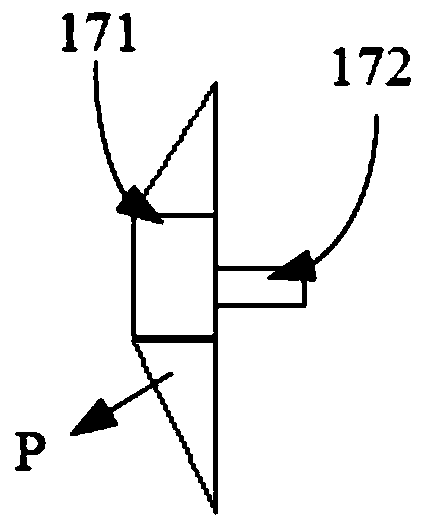

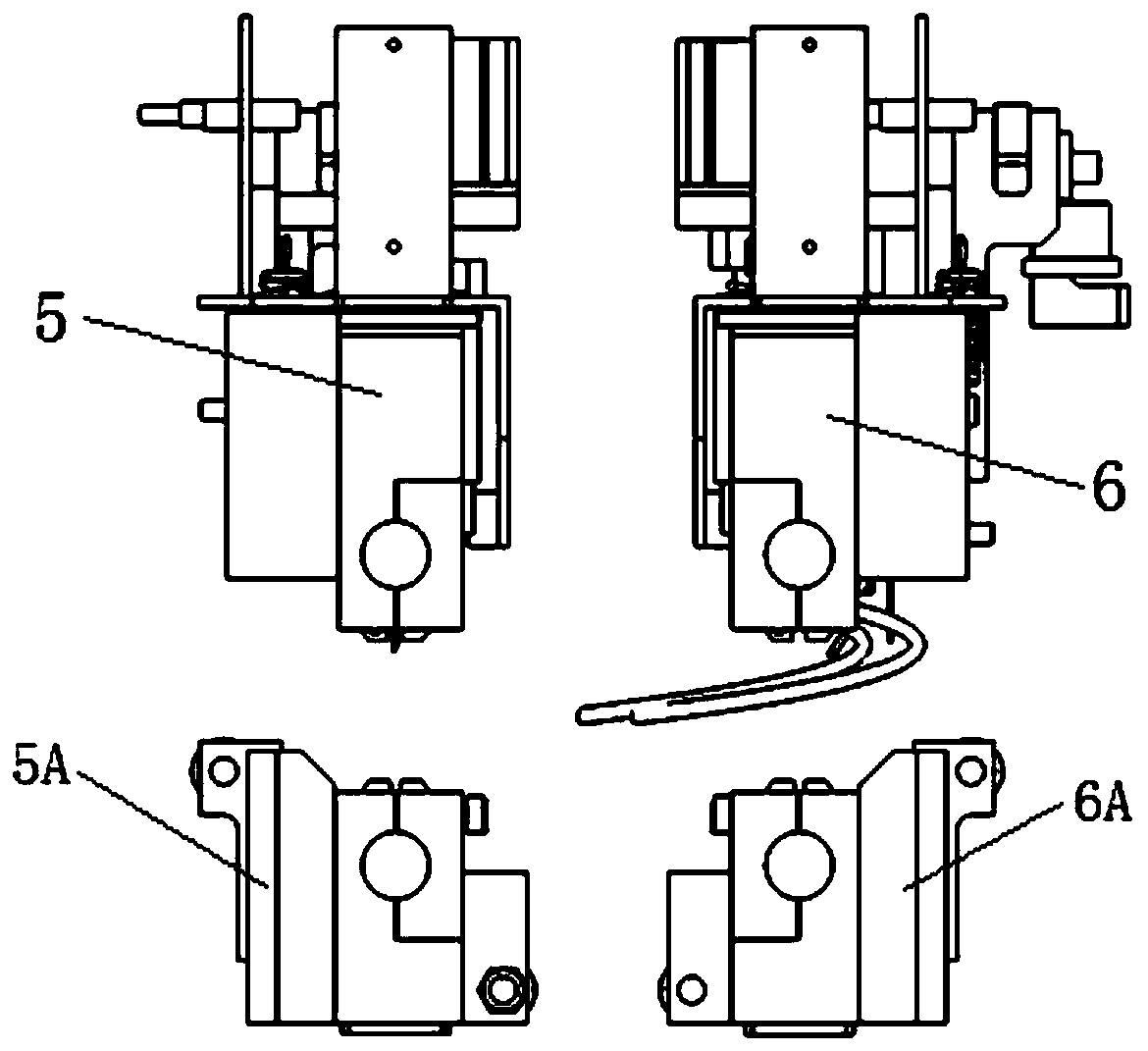

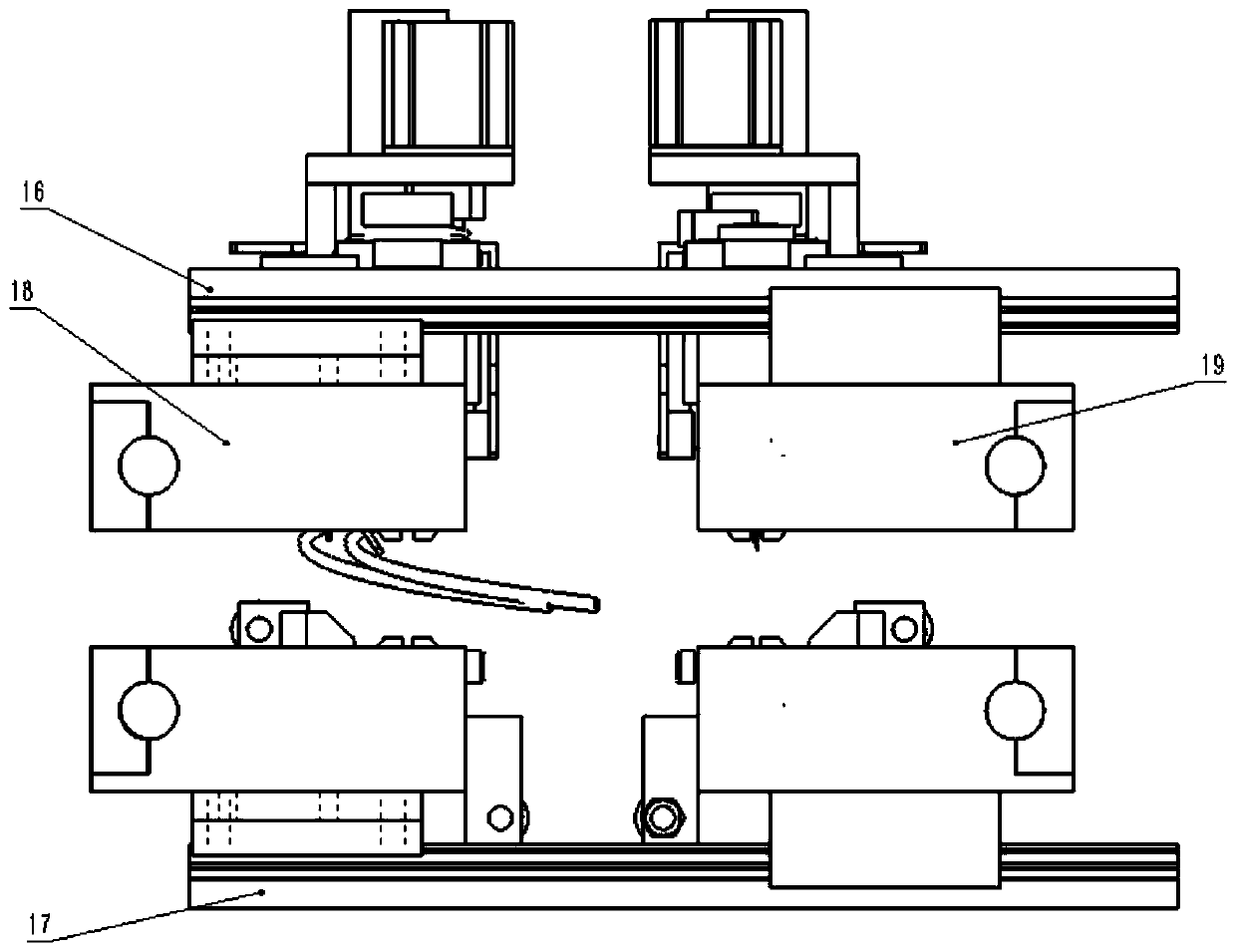

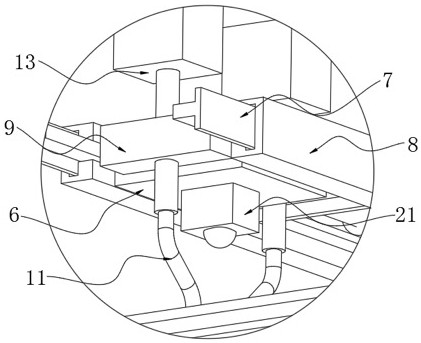

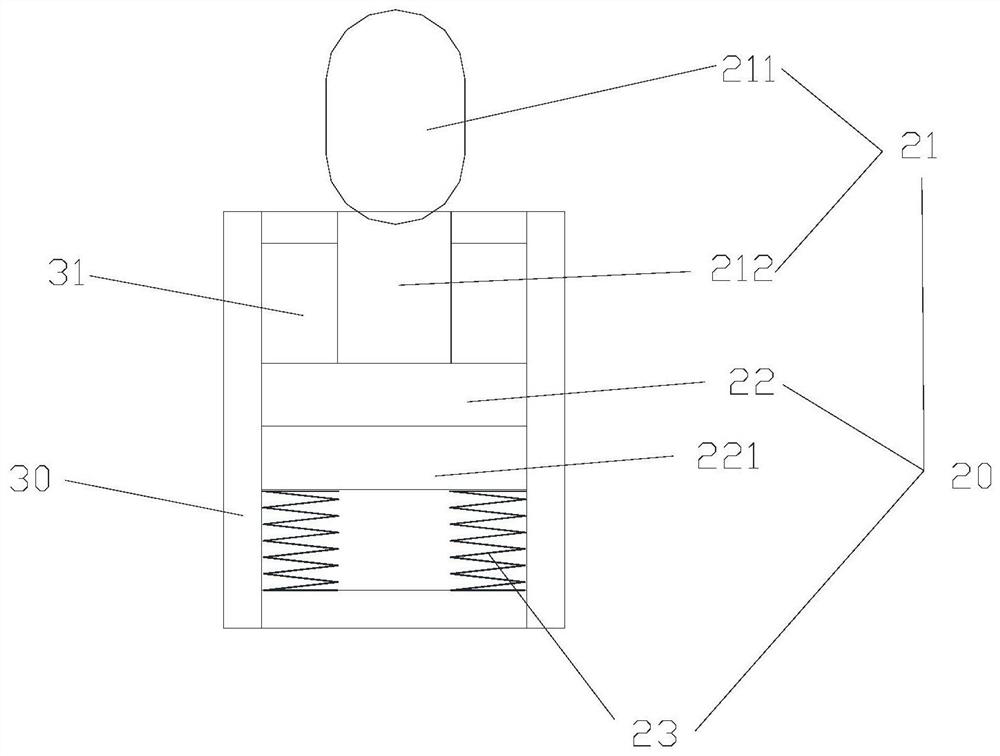

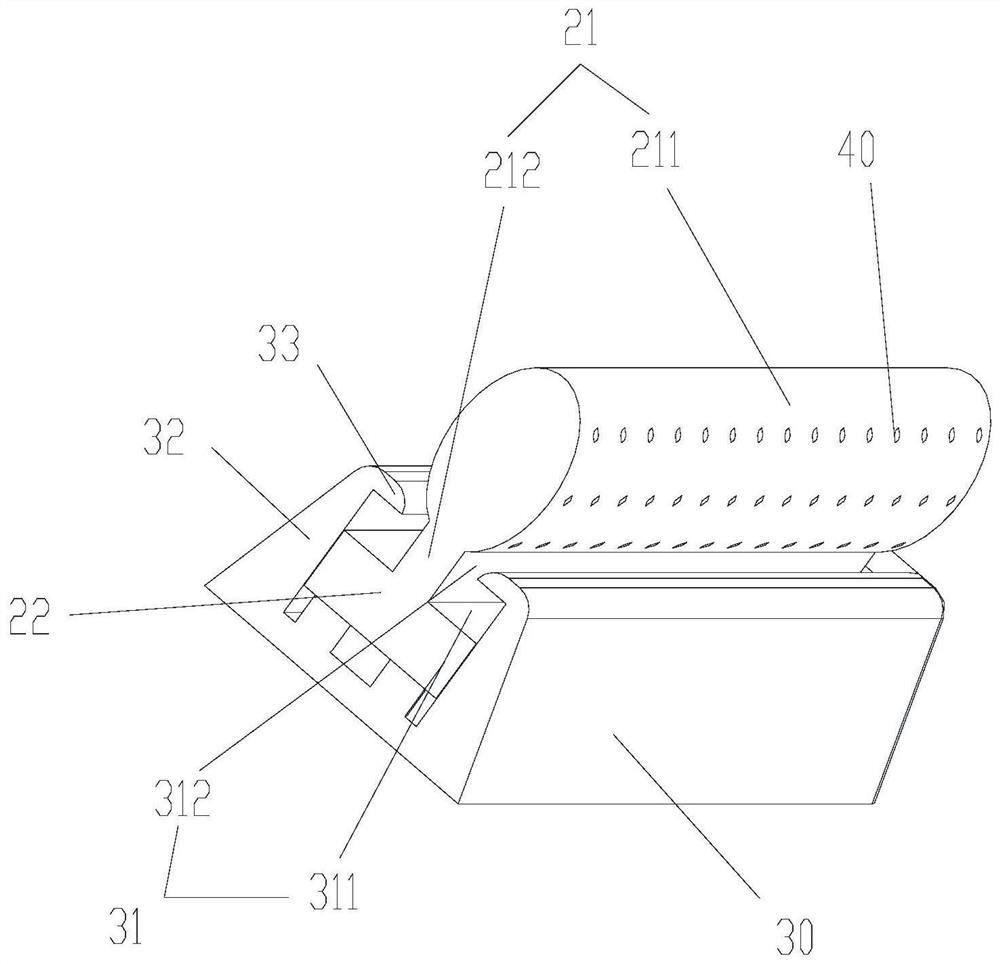

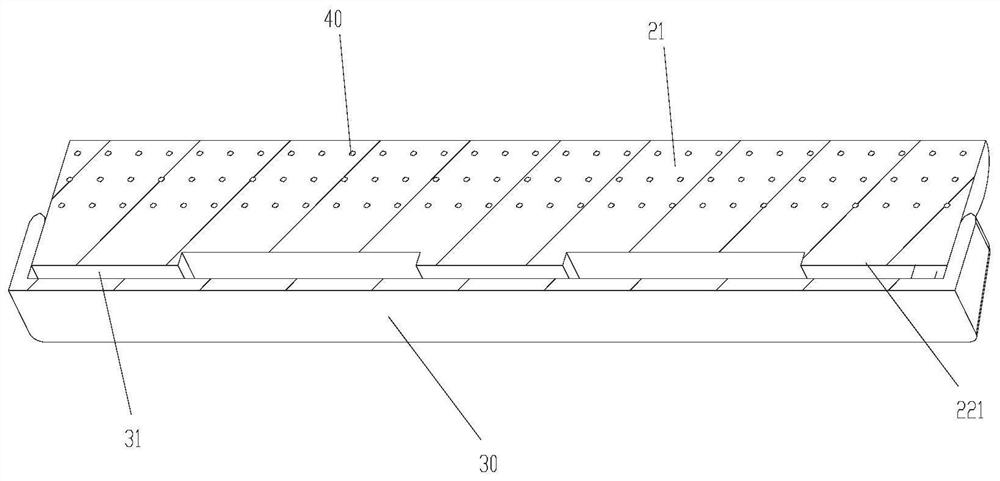

Double-transverse-sealing structure of reciprocating type packing machine

InactiveCN109835538AReduce the minimum distanceImprove efficiencyWrapper twisting/gatheringVertical planeMechanical engineering

The invention discloses a double-transverse-sealing structure of a reciprocating type packing machine. According to the technical scheme, the double-transverse-sealing structure of the reciprocating type packing machine comprises a first transverse-sealing mechanism, a second transverse-sealing mechanism and a driving mechanism, the first transverse-sealing mechanism, the second transverse-sealingmechanism and the driving mechanism are mounted in a machine shell of the packing machine, and the first transverse-sealing mechanism and the second transverse-sealing mechanism are symmetrically arranged relative to a vertical plane; the first transverse-sealing mechanism comprises a first transverse-sealing tool feeding seat and a first transverse-sealing tool discharging seat, the second transverse-sealing mechanism comprises a first transverse-sealing tool feeding seat and a second transverse-sealing tool discharging seat; and the double-transverse-sealing structure of the reciprocating type packing machine is characterized by further comprising two connecting-rod sliding rails parallel to each other and fixedly connected with the machine shell of the packing machine. According to thedouble-transverse-sealing structure of the reciprocating type packing machine, the problem that the transverse sealing speed of a single-transverse-sealing structure is slow is solved; meanwhile thedistance of tool seat centers between the two transverse-sealing mechanisms is reduced, so that the packing machine is suitable for sealing of short packing bags; and when the distance of the tool seat centers of the two transverse-sealing mechanisms is adjusted, the phase position of tool seats in the two transverse-sealing mechanisms cannot be changed.

Owner:QINGDAO FEIFAN PACKAGING MACHINERY

Liquid crystal display

ActiveUS9360695B2Prevent oxidationLower resistanceSolid-state devicesNon-linear opticsLiquid-crystal displaySemiconductor

A liquid crystal display includes: a substrate; a gate line and a data line disposed on the substrate; a semiconductor layer disposed on the substrate; first and second field generating electrodes disposed on the substrate; and a first protecting layer formed from the same layer as the first field generating electrode and covering at least a portion of the data line.

Owner:SAMSUNG DISPLAY CO LTD

Method for production of laser-induced images inside liquids

InactiveUS20060255020A1Reduce the minimum distanceQuality improvementLight effect designsThermographyShock waveLaser

One or more embodiments of the invention comprise a method for production of laser-induced images inside liquids. These images are arrangement of sparks or bubbles, or their combination, which created by the laser-induced breakdowns at the predetermining liquid areas. A method for production of high resolution laser-induced images inside liquids by the generation of the breakdowns accompanying with the decreasing shock waves is disclosed. Another embodiment of the invention comprises a method for production of the motion laser-induced images inside liquid. These images are the successions of the small light sources arrangements which replace one another in accordance with the life time of these sources (bubbles or sparks) and in accordance with human eye inertia.

Owner:TROITSKI IGOR

Display panel and display device

ActiveCN109613777AReduce power consumptionAlleviate flickeringStatic indicating devicesSolid-state devicesCapacitanceScan line

The invention discloses a display panel. The display panel includes a plurality of data lines, a plurality of scan lines and a plurality of pixels, the scan lines include main scanning electrodes andbranch scanning electrodes, and the main scanning electrode and the branch scanning electrode of the same scan line are electrically connected, and at least a part of the branch scanning electrodes extends along the extending direction of the data lines and is disposed adjacent to the data lines; and the pixels include pixel electrodes, and the pixel electrodes and the branch scanning electrodes are partially overlapped to form a storage capacitor. The invention further discloses a display device. The display panel can reduce the flicker caused by backlash while ensuring the aperture opening ratio of the pixels in the display panel.

Owner:HKC CORP LTD +1

A mobile terminal and its casing

ActiveCN102594947BReduce the minimum distanceAvoid deformationTelephone set constructionsEngineeringElectrical and Electronics engineering

Owner:HUIZHOU TCL MOBILE COMM CO LTD

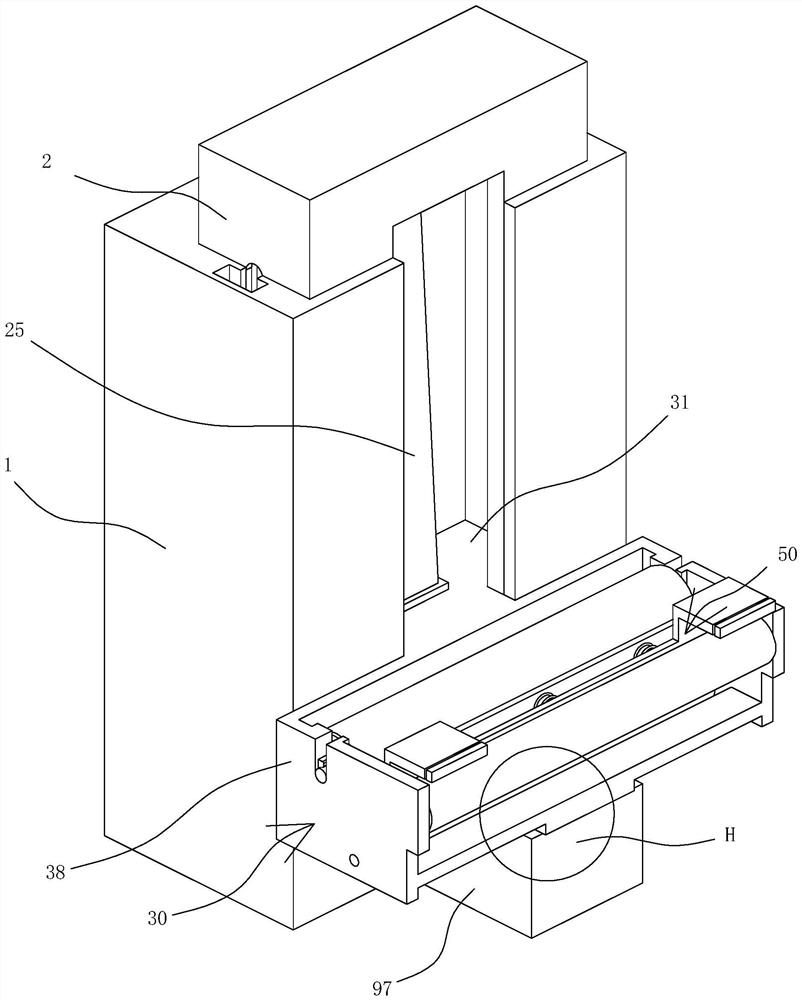

Curved surface metal strip machining tool

PendingCN114248012AReasonable structureIngenious ideaLaser beam welding apparatusMetal stripsStructural engineering

The invention provides a curved surface metal strip machining tool, and belongs to the technical field of machining equipment.The curved surface metal strip machining tool comprises a base, a rack is fixed to the top of the base, a supporting plate is fixed to the rack, two sliding rails are fixed to the front side wall of the supporting plate, a moving plate is arranged between the two sliding rails, and sliding blocks are fixed to the left side wall and the right side wall of the moving plate; the moving plates are slidably connected between the two sliding rails through two sliding blocks, a connecting plate is fixed between the two moving plates, an air cylinder is connected between the connecting plate and the supporting plate, the moving plates are connected with a first laser head and a second laser head through an adjusting mechanism, and a material moving mechanism is arranged below the first laser head and the second laser head. The whole machining tool is reasonable in structural arrangement, ingenious in conception and novel in cutting mode, the common metal strip curved surface machining mode is improved, the machining efficiency is greatly improved, multiple curvatures can be automatically adjusted, different machining requirements are met, and practicability is high.

Owner:北京星瑞达建筑工程有限责任公司

An automatic gluing wallpaper laying equipment

ActiveCN111942073BSteady lift controlLift controlPaperhangingStructural engineeringMechanical engineering

The invention discloses an automatic gluing wallpaper paving equipment, which comprises a base, a lifting frame is arranged on the upper end of the base, a lifting mechanism is arranged between the rear end of the lifting frame and the base, and a wallpaper paving device is arranged in the lifting frame. The moving mechanism, the rear end of the base is equipped with a power mechanism that drives the moving mechanism to move, and the moving mechanism is equipped with a gluing mechanism for gluing the wallpaper. The invention glues the inner side of the wallpaper when the wallpaper is laid, which simplifies the use The operation steps of personnel improve work efficiency.

Owner:聊城绿天使科技发展有限公司

Laser-computer graphics system for generating portrait and 3-D sculpture reproductions inside optically transparent material

InactiveUS7482568B2Increase contrastReduce the minimum distanceBranding equipmentSolid-state devicesGraphicsGraphic system

Embodiments of methods and laser-computer graphics systems for producing images such as portraits and 3-D sculptures formed from laser light created etch points inside an optically transparent material are disclosed. One or more embodiments of the invention comprise a method and system for simultaneously producing one or more etch points in first and second objects. In accordance with a method, a main beam is split into first and second beams, each beam having an energy level greater than that necessary to cause a breakdown in the material comprising the first and second objects. The first and second beams are directed at focal points within the first and second objects, generating etch points simultaneously therein. One or more embodiments of the invention comprise methods and systems for generating images in first and second objects. In one or more embodiments, the images are comprised of etch points having multiple gray shades and / or of etch points having iridescent qualities.

Owner:TROITSKI

A semiconductor crystal growth device

ActiveCN111519241BStable growthFast growthPolycrystalline material growthFinal product manufactureCrucibleEngineering

The present invention provides a semiconductor crystal growth device, which comprises: a furnace body; a crucible arranged inside the furnace body to accommodate silicon melt; a pulling device arranged in the The top of the furnace body is used to pull out silicon crystal rods from the silicon melt; and a heat shield device, the heat shield device includes a draft tube, and the draft tube is barrel-shaped and wraps around the silicon crystal Rods are arranged around to rectify the argon gas input from the top of the furnace body and adjust the thermal field distribution between the silicon crystal rods and the silicon melt level; wherein, the heat shield device also includes The adjustment device arranged inside the lower end of the draft tube is used to adjust the minimum distance between the heat shield device and the silicon crystal rod. According to the present invention, by setting the adjustment device inside the lower end of the draft tube, the distance between the silicon crystal rod and the device close to the heat shield can be adjusted without changing the shape and position of the draft tube, thereby improving the crystal growth speed and quality.

Owner:ZING SEMICON CORP

Washing machine inner tub and washing machine with same

ActiveCN107587310BAchieve washingAchieve dryingOther washing machinesTextiles and paperLaundry washing machineEngineering

The invention provides an inner cylinder of a washing machine and a washing machine having the same. The inner cylinder of the washing machine includes an inner cylinder body, and the inner cylinder of the washing machine further includes: a lifting rib assembly, which is arranged on the inner wall of the inner cylinder body; wherein, the lifting rib assembly At least part of it is movably arranged along the radial direction of the inner cylinder body. When the inner cylinder body is in the dehydration state, there is a predetermined dehydration distance L1 between the predetermined part of the lifting rib assembly and the central axis of the inner cylinder body; In the drying state, there is a predetermined drying distance L2 between the predetermined part of the lifting rib assembly and the central axis of the inner tube body, wherein L1 is greater than L2. The washing machine inner tub of the invention solves the problem that the clothes will cling to the tub wall during the drying process of the drum washing machine in the prior art.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com