Curved surface metal strip machining tool

A technology for processing tools and metal strips, which is applied in the field of curved surface metal strip processing tools, can solve the problems of cumbersome fixing of workpieces and low efficiency, and achieve the effects of convenient operation, ingenious conception and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

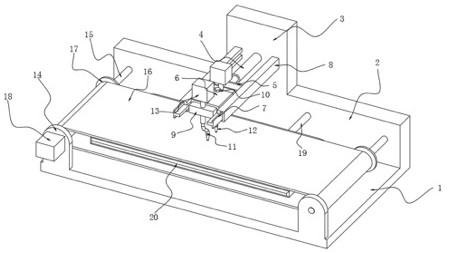

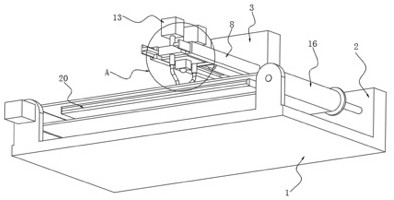

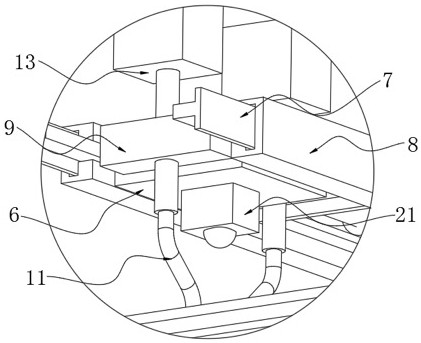

[0023] see figure 1 - image 3 , the present invention provides the following technical solutions: a curved metal strip processing tool includes a base 1, a frame 2 is fixed on the top of the base 1, a support plate 3 is fixed on the frame 2, and two slides are fixed on the front side wall of the support plate 3. Rail 8, a moving plate 6 is arranged between the two sliding rails 8, sliders 7 are fixed on the left and right side walls of the moving plate 6, and the moving plate 6 is slidably connected between the two sliding rails 8 through the two sliding blocks 7 A connecting plate 5 is fixed between the two moving plates 6, a cylinder 4 is connected between the connecting plate 5 and the support plate 3, and the first laser head 11 and the second laser head 12 are connected on the moving plate 6 through an adjustment mechanism. A material transfer mechanism is provided below the first laser head 11 and the second laser head 12, and an electromagnet plate 20 is arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com