Automatic gas shielded welding device of longitudinal gap in steel pipe cavity

A technology of gas shielded welding and internal longitudinal seam, which is applied in the direction of auxiliary equipment, welding equipment, welding equipment, etc., can solve the problems of difficult to guarantee weld quality, low production efficiency, welder injury, etc., and achieve improved welding efficiency, convenient operation, The effect of avoiding harm to persons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

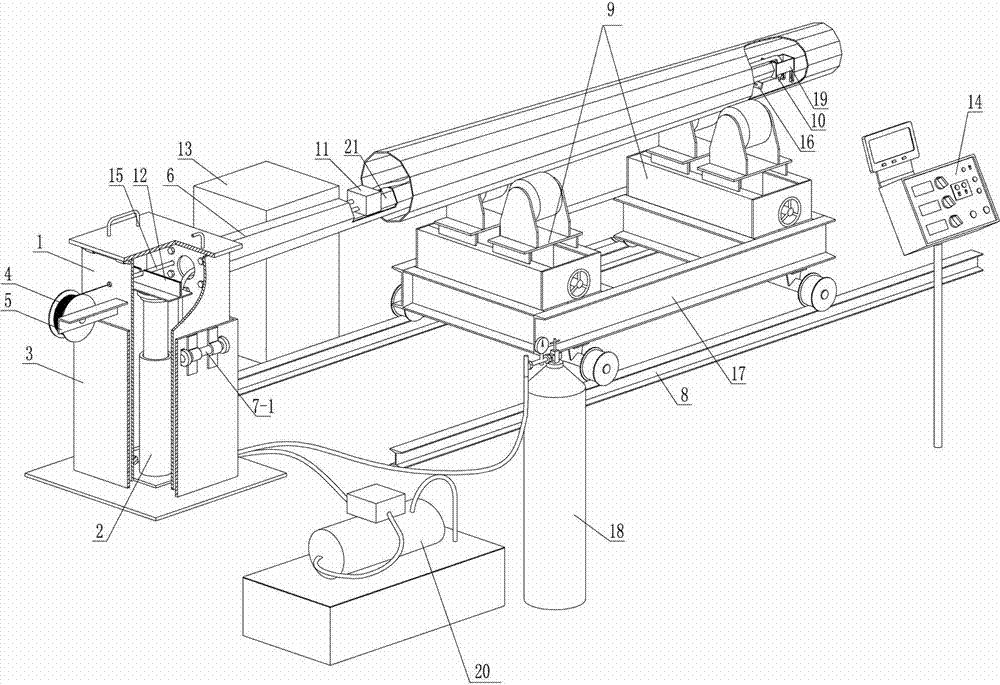

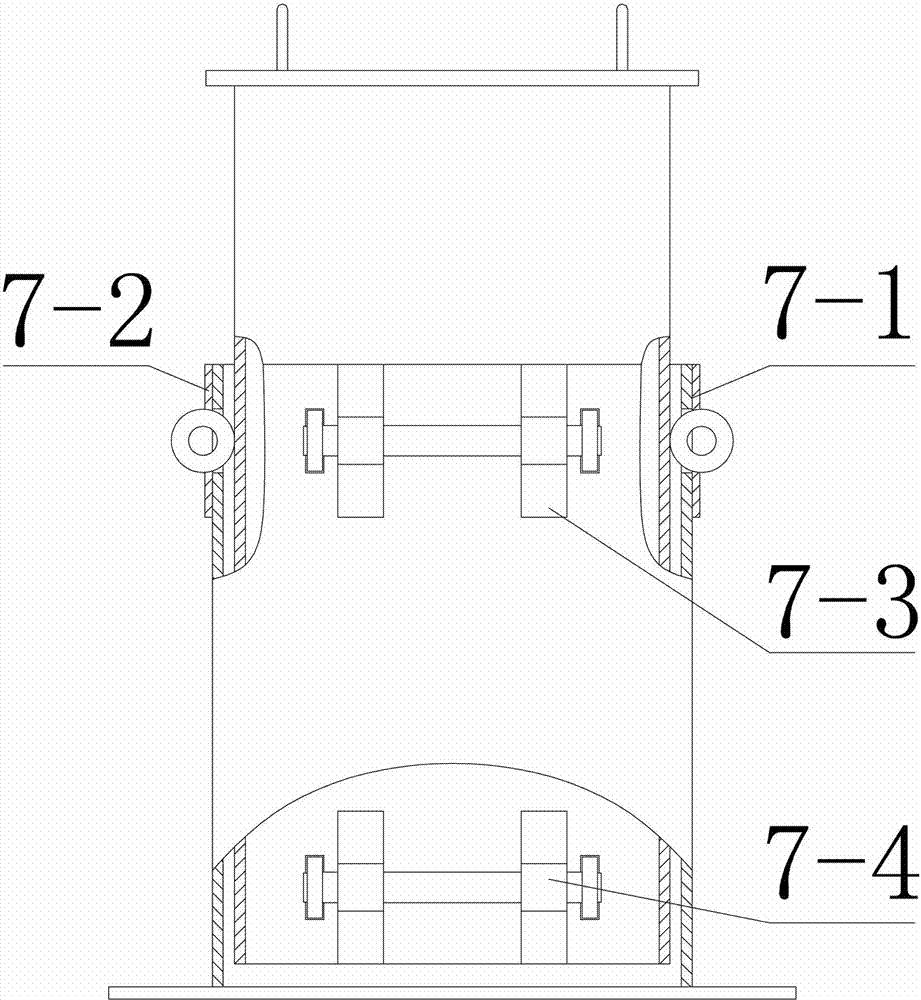

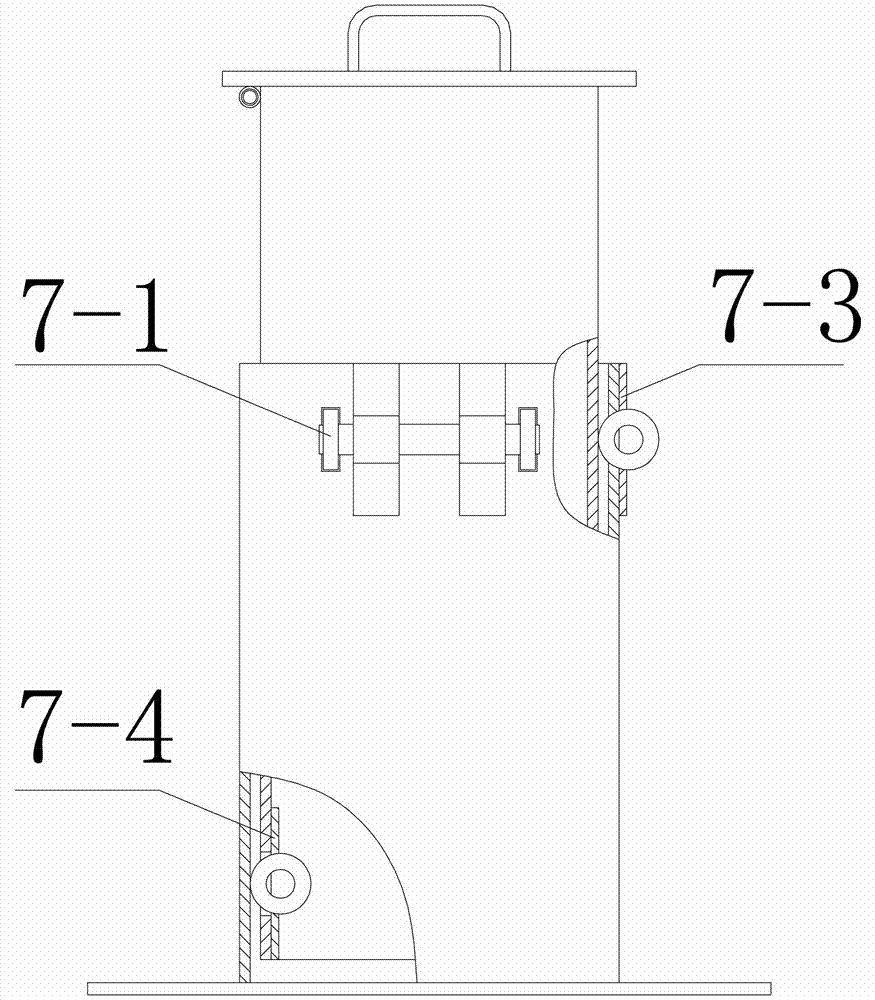

[0023] as attached figure 1 Shown, the present invention comprises machine head, support arm 6, running gear, welder 13, welding torch 10, control box 14, support wheel frame 19; Described machine head is a box type, and it comprises outer machine head 3 and is arranged on The inner machine head 1 in the head 3 is provided with a lifting cylinder 2 inside the outer machine head 3, and the lifting oil cylinder 2 is connected with the oil pump 20 arranged on the outside of the outer machine head 3 through an oil pipe, and is fixedly installed in the inner machine head 1 Support beam 12; as attached figure 1 , 2 , 3, the present invention sets the lifting guide wheel A 7-1, the lifting guide wheel B 7-2 and the lifting guide wheel C 7-3 on the outer upper part of the outer machine head 3 respectively, and the lifting guide wheel A 7- 1. The guide wheels on the lifting guide wheel B 7-2 and the lifting guide wheel C 7-3 pass through the side wall of the outer machine head 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com