Stator bolts for eliminating exciter stator deformation and application method of stator bolts

A machine stator and bolt technology, which is applied in the field of exciter stator manufacturing, can solve the problems of affecting the accuracy of the iron core, low iron core strength, and large gap between bolts and bolt holes, so as to reduce the problem of accuracy deviation, improve manufacturing efficiency, and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

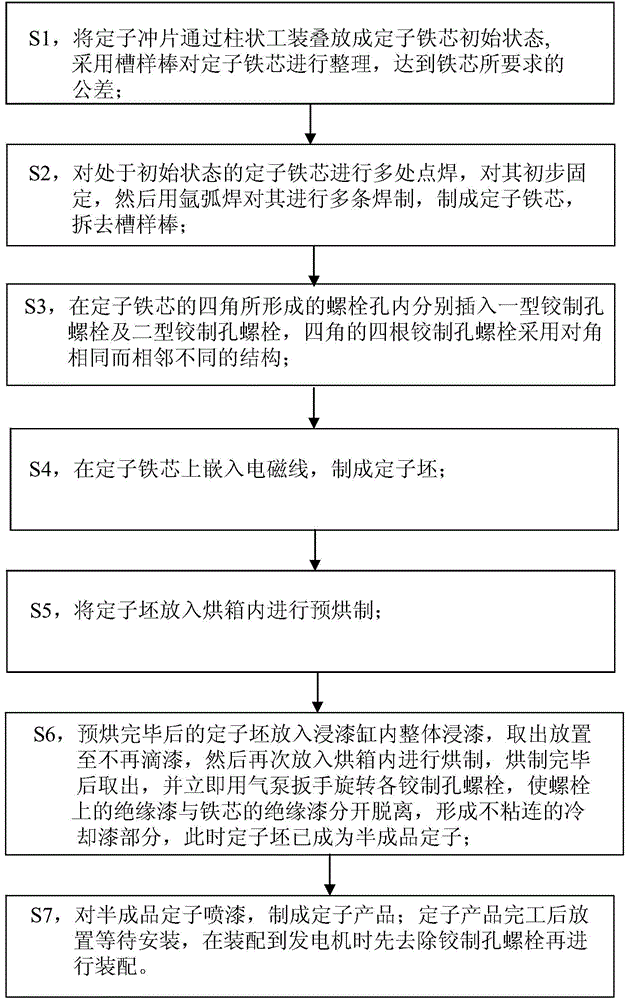

[0051] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

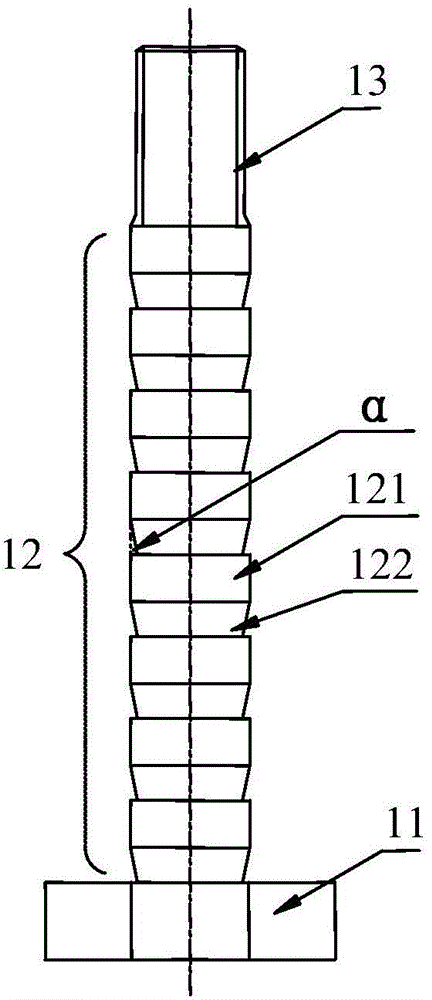

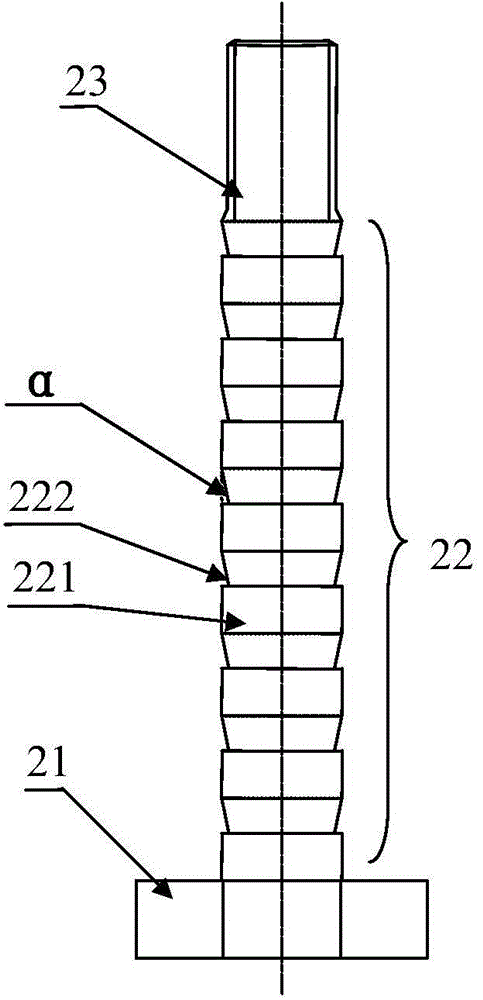

[0052] The stator bolts for eliminating the deformation of the exciter stator in the present invention refer to the fixing bolts for fixing the iron core of the exciter stator.

[0053] There are reaming hole bolts in the bolt standard parts, the shaft diameter and the matching size of the bolt hole are different according to the size of the shaft diameter, but the matching size of the bolt and the hole is basically within a few wires. If such standard parts are used for the bolts fixing the stator core of the exciter, due to the small gap between the reaming hole bolts and the bolt holes, they will stick firmly after being immersed in insulating paint, and the bolts will not be withdrawn.

[0054]The stator bolt of the present invention is a hinged hole bolt suitable for the stator iron core, which is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com