A Method of Rapid Inspection for the Installation of Segmented Surface Components Using Perspective Lines

A technology of surface segmentation and components, which is applied in the direction of measuring devices, instruments, surveying and navigation, etc., can solve the problems of time-consuming, difficult to guarantee the accuracy of assembly positioning, and complicated detection methods, so as to reduce the problem of accuracy deviation and fast installation accuracy , the effect of improving inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

[0018] A method for quickly inspecting the installation of curved surface segmented components by using perspective lines, comprising the following steps:

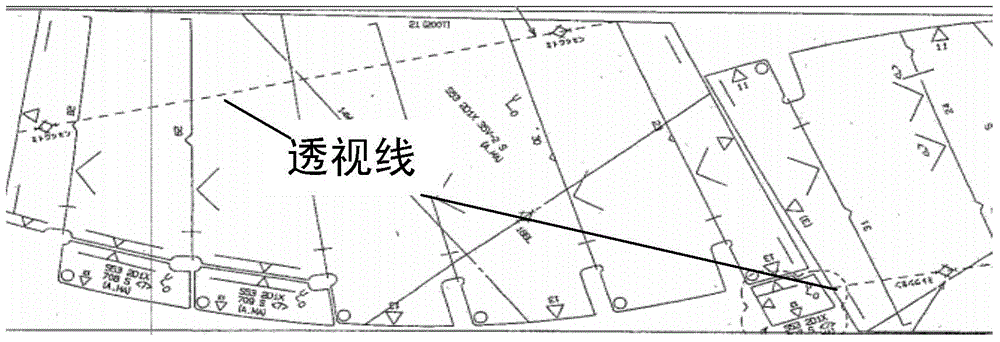

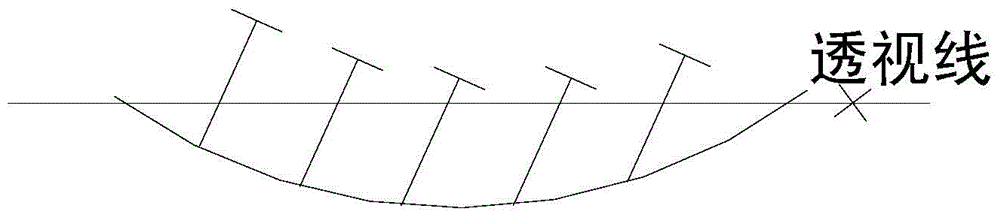

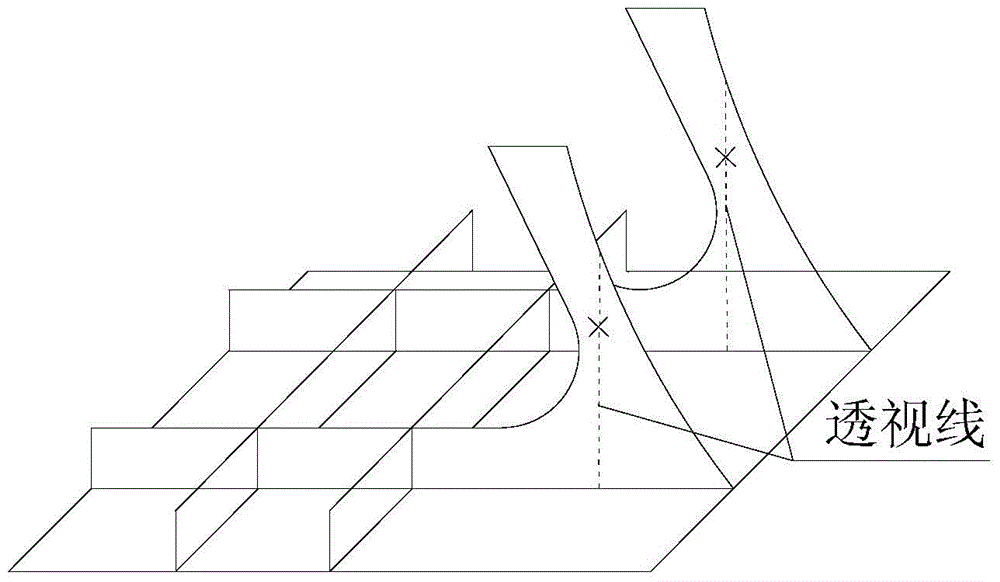

[0019] ①According to the design, design a certain longitudinal section on the component to be installed. The longitudinal section line intersecting the longitudinal section with the component to be installed is the added perspective line. When processing the installation components in sections, increase the perspective Line powder painting line;

[0020] ② Measure the angles of the segmented bow end face member and stern end face member respectively by means of a hammer and ruler to determine the accurate positioning angle;

[0021] ③ When installing the components inside the section in the middle area, observe the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com