Reduction pot setup method in stove and reducing furnace constructed by the method

A reduction tank and reduction furnace technology are applied in the metal vacuum smelting reduction furnace, and the metal vacuum smelting reduction tank is installed in the reduction furnace, which can solve the problems of insufficient heat utilization, large deformation of the reduction tank, inconvenient feeding, etc. The effect of improving heat utilization rate, improving production efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

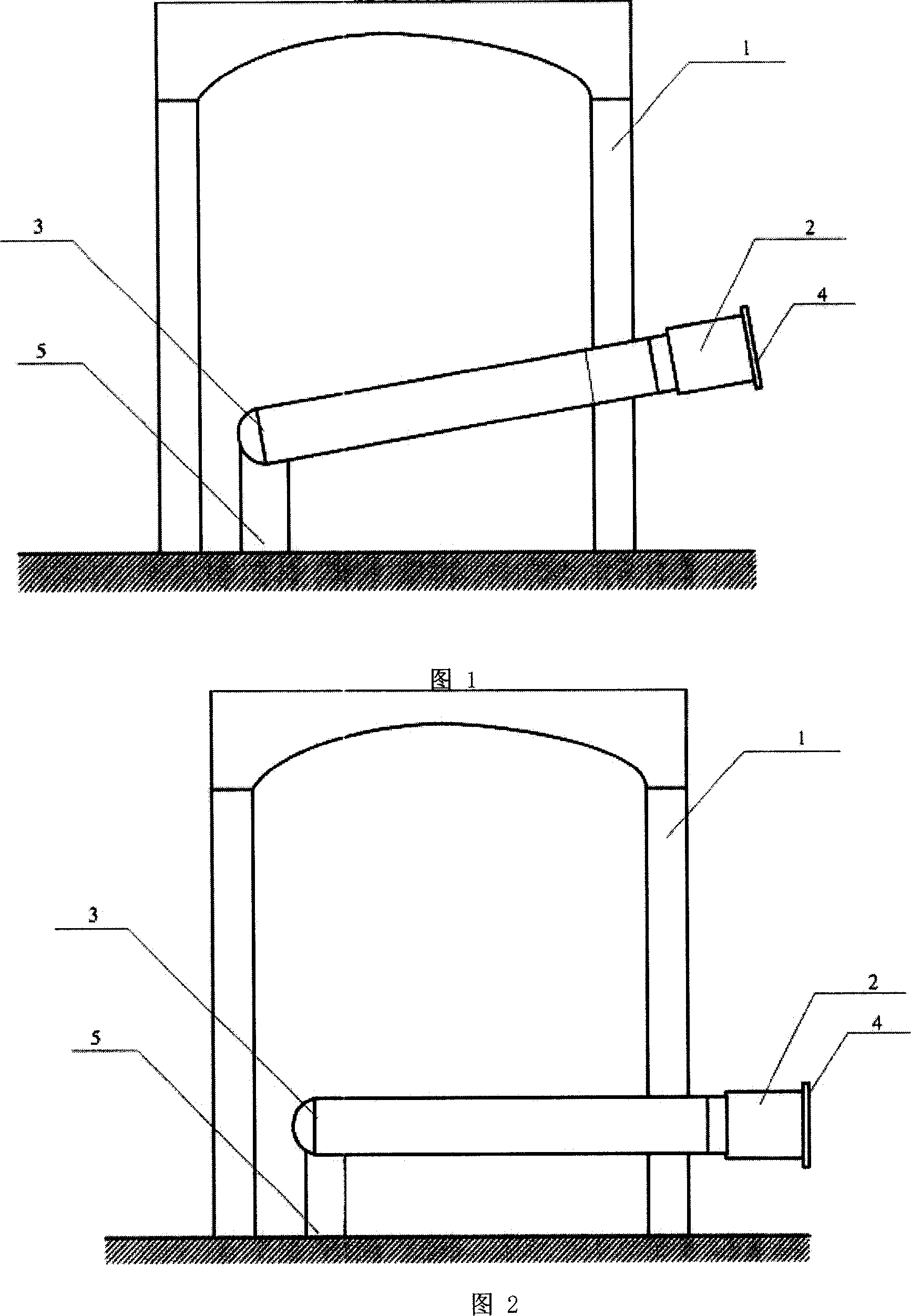

[0011] Embodiment: The following is an example of an inclination angle of 10° to illustrate a specific implementation.

[0012] The installation method of the metal vacuum smelting reduction tank in the furnace is that the closed end of the reduction tank faces downwards, and the opening end of the reduction tank faces upwards, and is installed obliquely in the reduction furnace kiln body. A metal vacuum smelting reduction furnace constructed by this method is shown in Figure 1, with the closed end of the reduction tank facing down and the open end facing up, and placed in the reduction furnace kiln body 1 at an inclination angle of 10°; the reduction tank 3 The open end of the kiln is supported by the reduction furnace kiln body 1, and the closed end is supported by the support 5 built in the reduction furnace. The crystallizer 2 is connected with the reduction tank 3, and the crystallizer 2 is fed into the reduction tank 3. After the feeding is completed, the The feed port e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com