Anti-scour method for wide excavation and narrow roadway development in rock burst coal seam

A technology of rock burst and roadway, which is applied in ground mining, earthwork drilling, underground mining, etc., can solve the problems of reducing rock burst coal seam development roadway coal pillar support pressure, large deformation, etc., to reduce large deformation and Risk of rock burst, low bearing capacity, effect of reducing bearing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Exemplary embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. Although exemplary embodiments of the present invention are shown in the drawings, it should be understood that the invention may be embodied in various forms and should not be limited to the embodiments set forth herein. Rather, these embodiments are provided for more thorough understanding of the present invention and to fully convey the scope of the present invention to those skilled in the art.

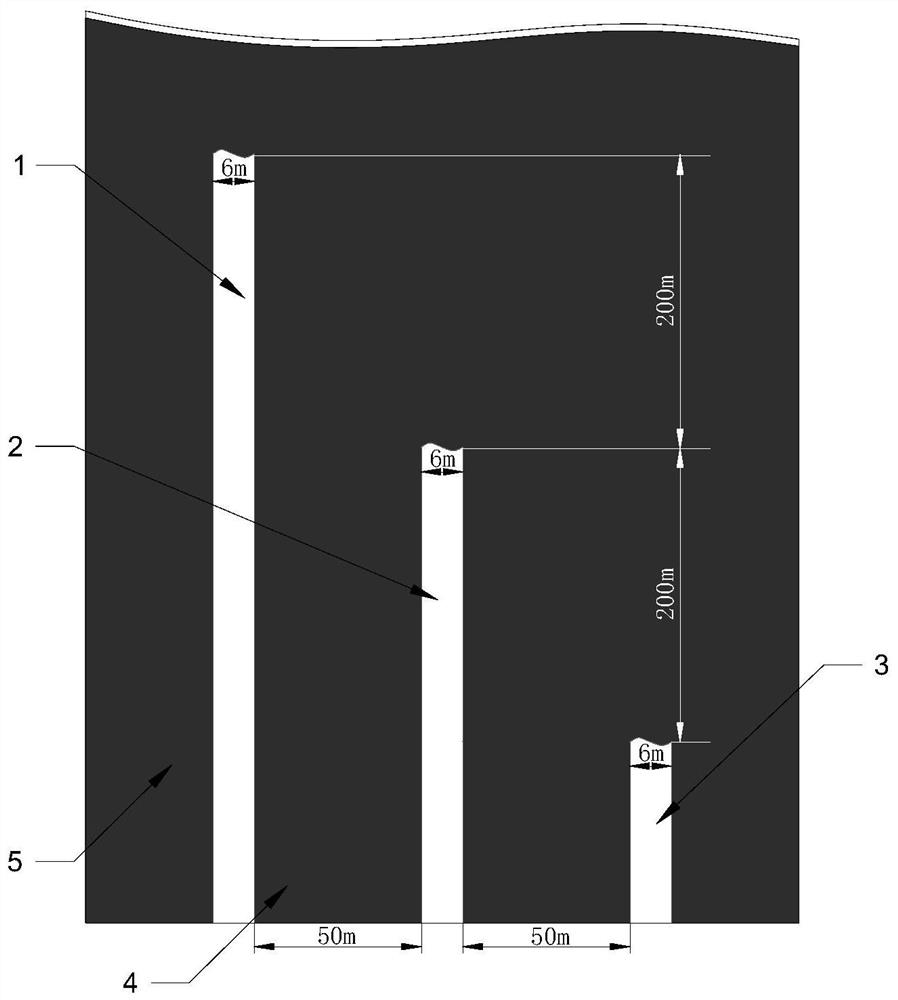

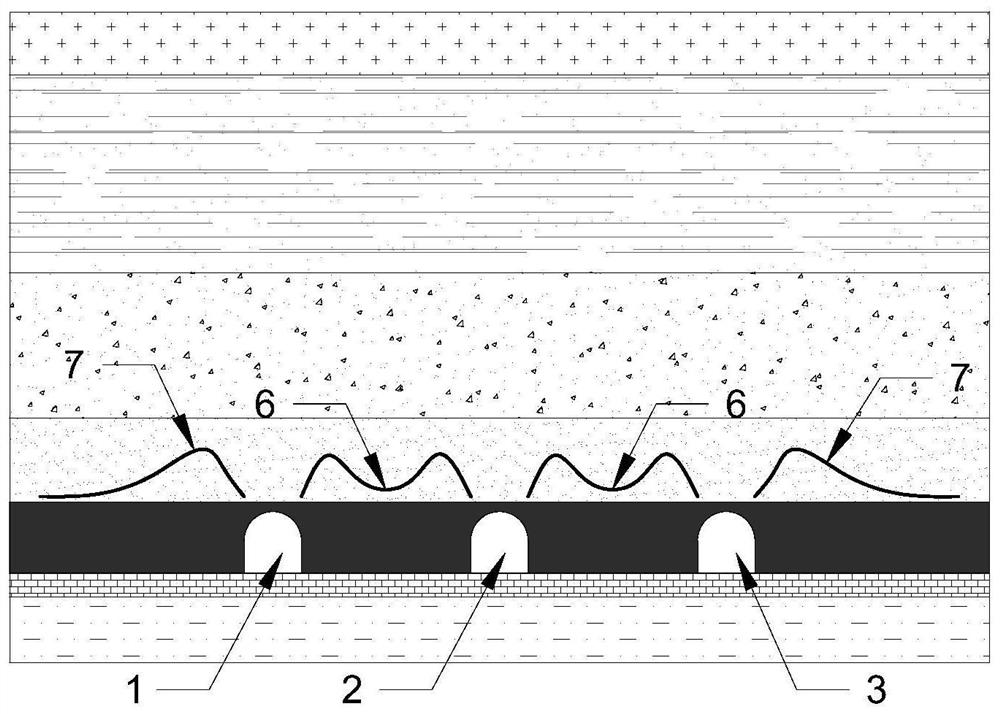

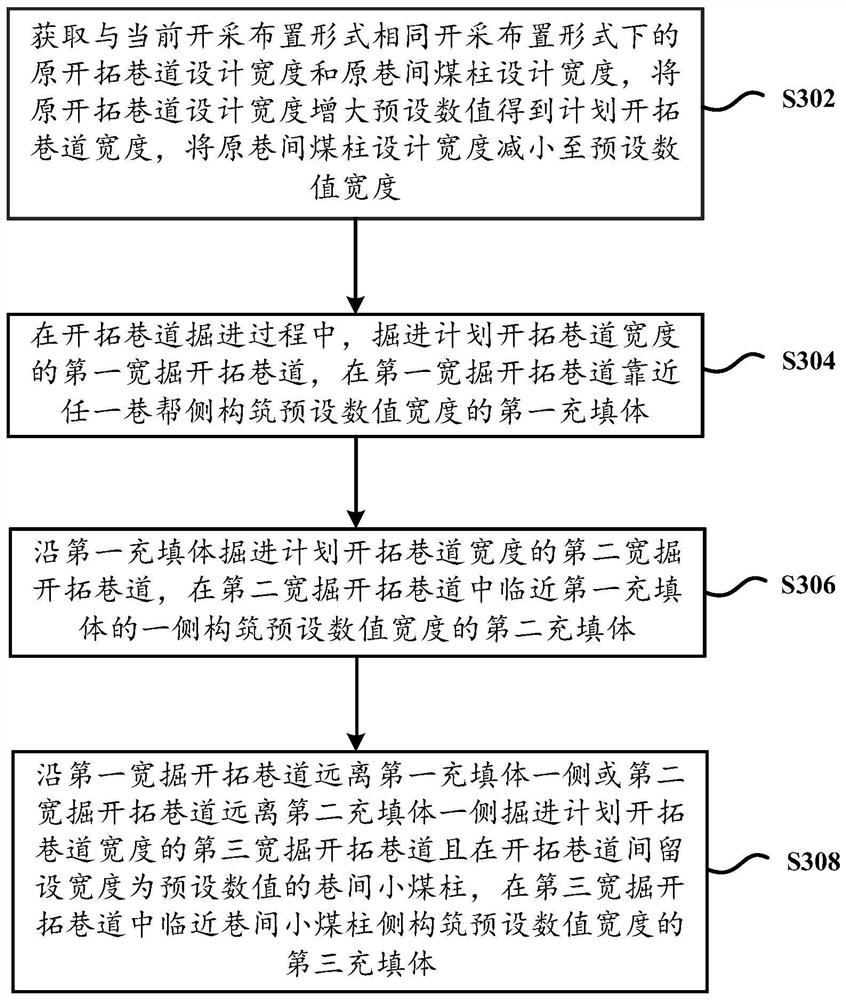

[0040] The embodiment of the present invention firstly introduces the causes of rock burst in roadways developed in coal seams. see figure 1 , figure 1 This is the commonly used coal seam development roadway layout method. From left to right, the return air roadway 1, the main transportation roadway 2 and the auxiliary transportation roadway 3 will be excavated sequentially. The excavation stagger distance is 200m, and the width of wide coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com