Assembly measuring device and method of tiny parts in narrow space based on industrial fiberscope

A technology for measuring tiny parts and assemblies, used in measuring devices, optical devices, instruments, etc., it can solve the problem of industrial endoscope staying, unable to perform accurate measurement, unable to achieve rapid and accurate acquisition of information on tiny parts and their assembly process, etc. problem, to achieve the effect of simple structure and extended use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the patent of the present invention are described in detail below in conjunction with technical solutions and accompanying drawings.

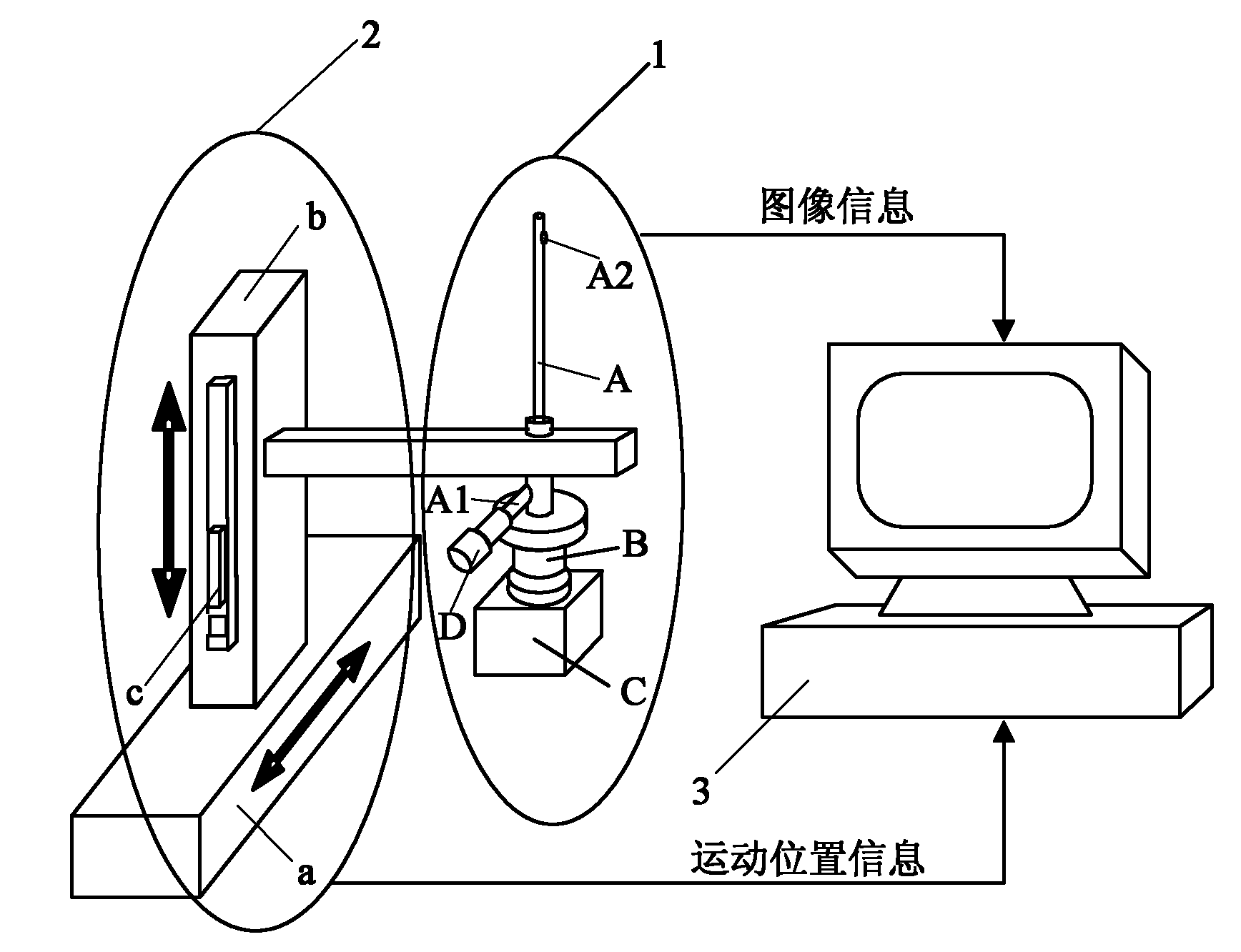

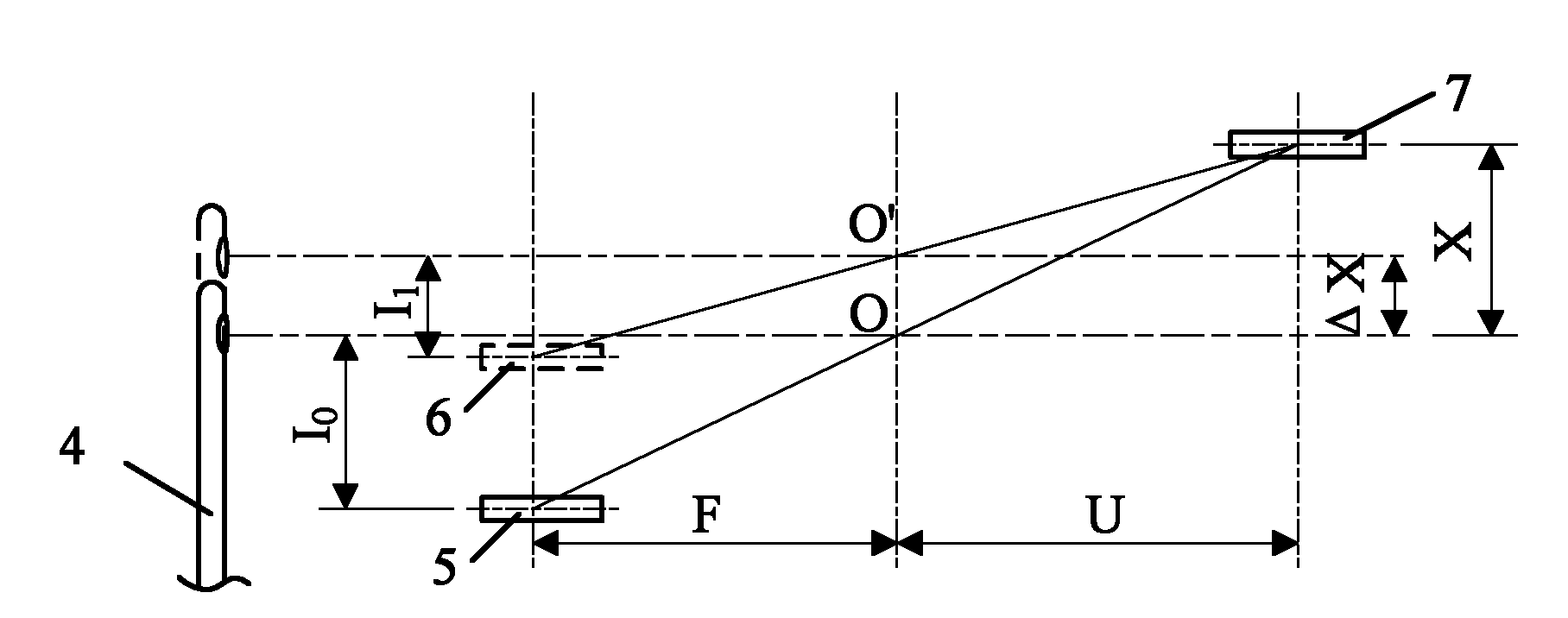

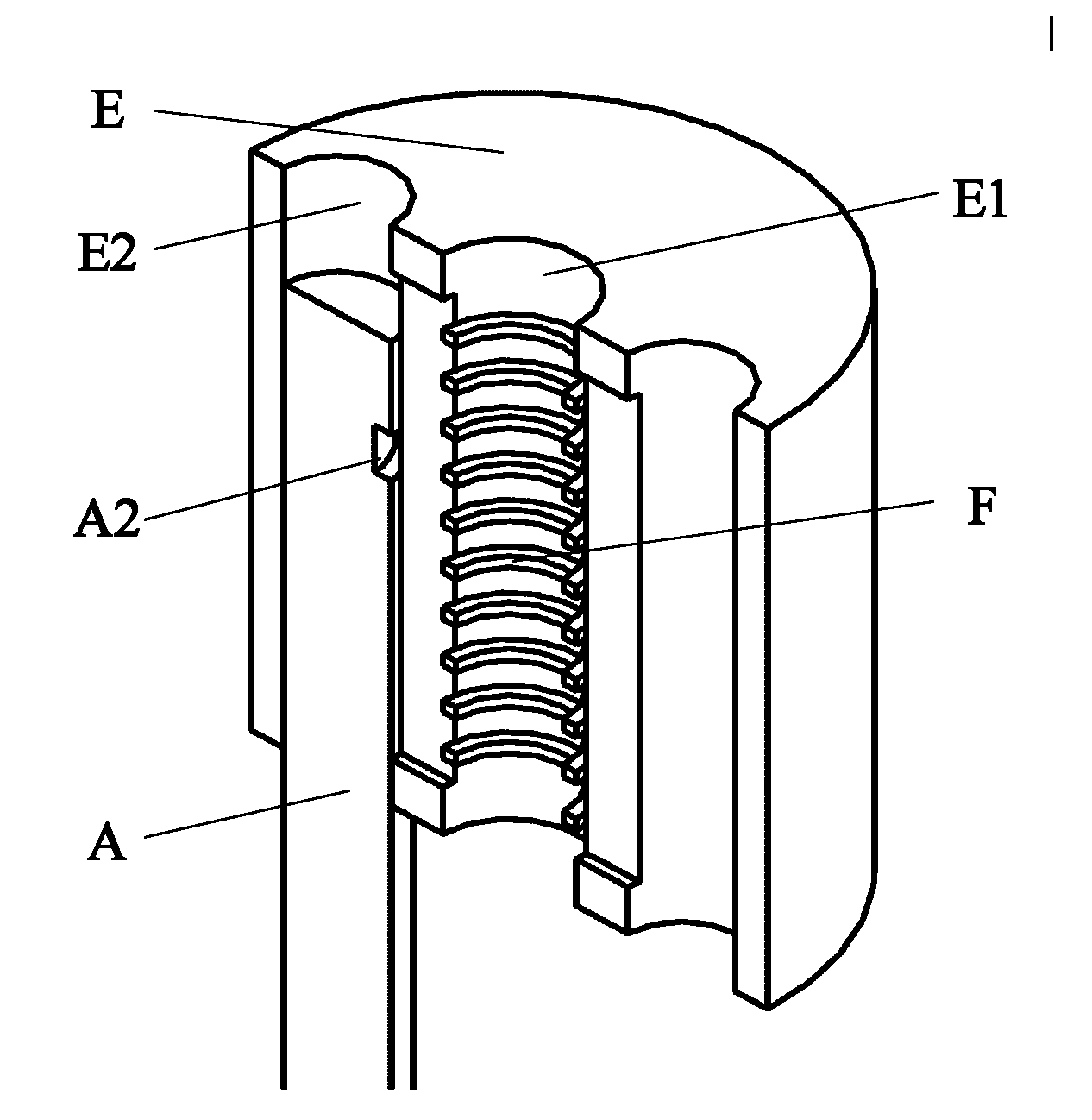

[0022] The industrial endoscope assembly measurement system consists of an endoscope inspection device 1 , a precision linear motion platform 2 and a computer 3 . It is used to detect the stacking information of thin circular discs F with a diameter of 6.2mm. The thin ring sheet F is stacked in the cylinder stacking hole E1 in the stacking mold E. In order to realize the observation, an original process hole E2 with an inner diameter of 6 mm on the stacked mold is used to extend into the endoscope, and a 0.6 mm slit is opened between the process hole and the stacked hole for endoscopic image acquisition.

[0023] The endoscope inspection device consists of industrial endoscope A, lens B, digital camera C and light source D. The precision linear motion platform is composed of precision linear guide rails a, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com