Numerically controlled multi-functional surface grinding machine

A surface grinding machine, multi-functional technology, applied in the direction of grinding machine, machine tool suitable for grinding workpiece plane, grinding machine parts, etc. Compact, cost-effective and productive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

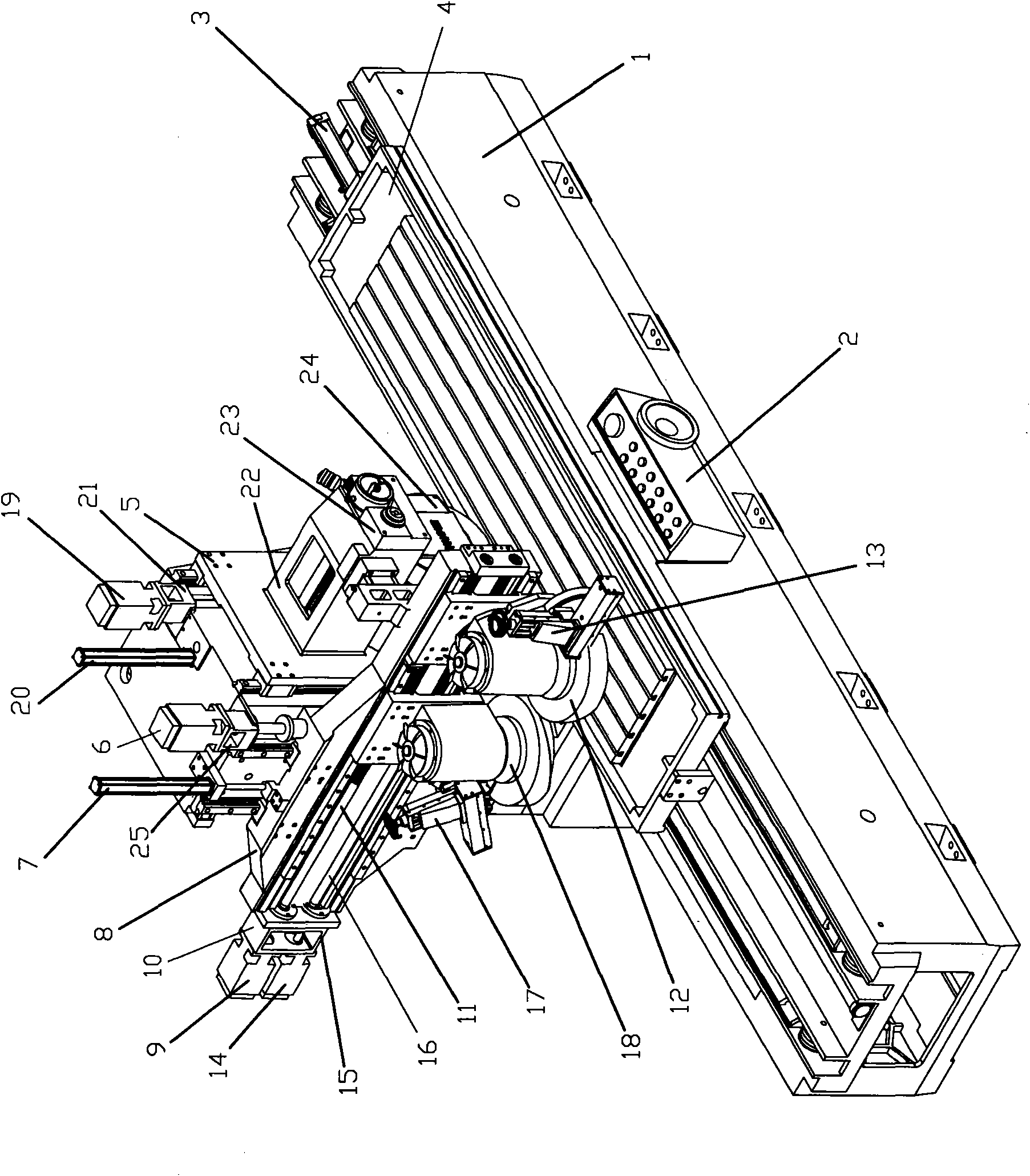

[0031] refer to figure 1 , a kind of numerical control multifunctional surface grinding machine of the present invention, comprises a column 5, a vertical grinding head mechanism, a horizontal grinding head mechanism, an operation box 2, a workbench mechanism and a base 1, the vertical grinding head mechanism and the horizontal grinding head mechanism The head mechanism is all located on the column 5, and the column 5, the operation box 2 and the workbench mechanism are all located on the base 1.

[0032] The vertical grinding head mechanism includes a fourth servo motor 6, a fourth reduction gear 25, a first balancing device 7, a beam 8, a first vertical grinding head unit and a second vertical grinding head unit. The fourth servo motor 6, the first balancing device 7 and the beam 8 are all installed on the column 5, the fourth reduction device 25 is installed on the fourth servo motor 6, the first vertical grinding head unit and the second vertical grinding head unit are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com