Optical transmission spherical surface detector

A detection device and optical transmission technology, applied in the direction of optical devices, measuring devices, optics, etc., can solve the problems affecting the surface finish of the tested spherical surface, the difficulty of sample processing, and the damage of the tested spherical surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

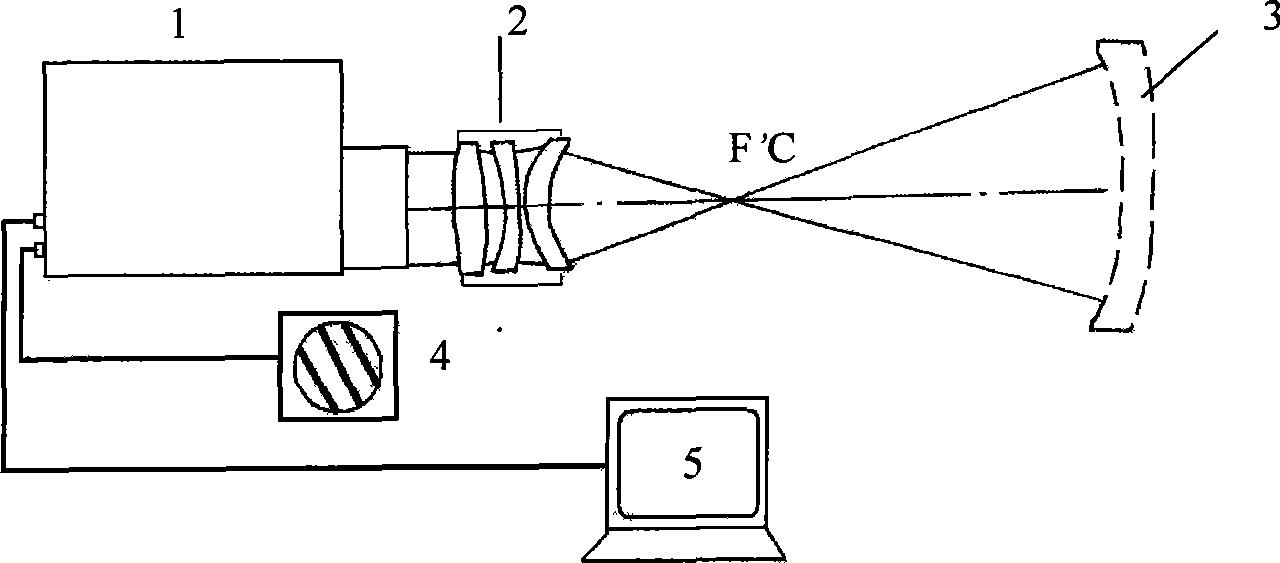

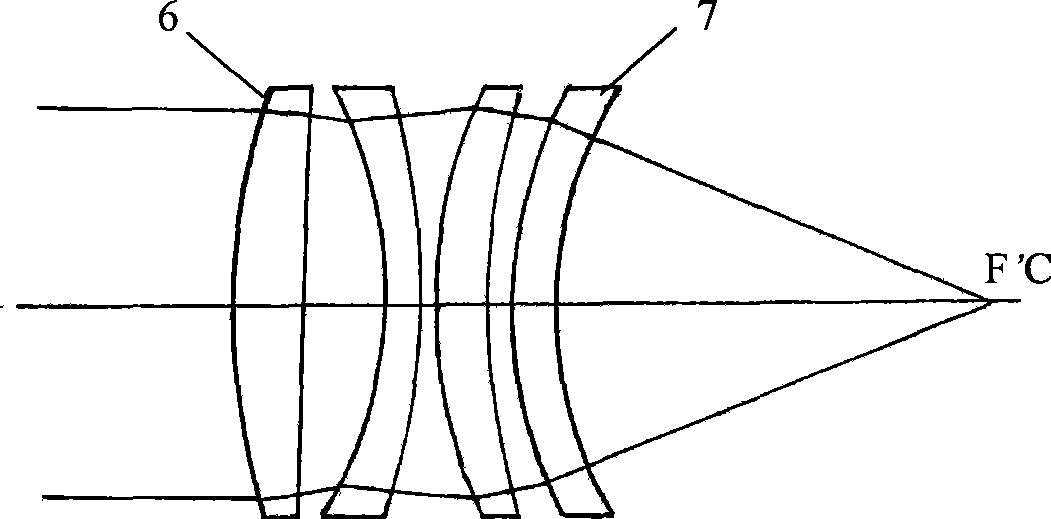

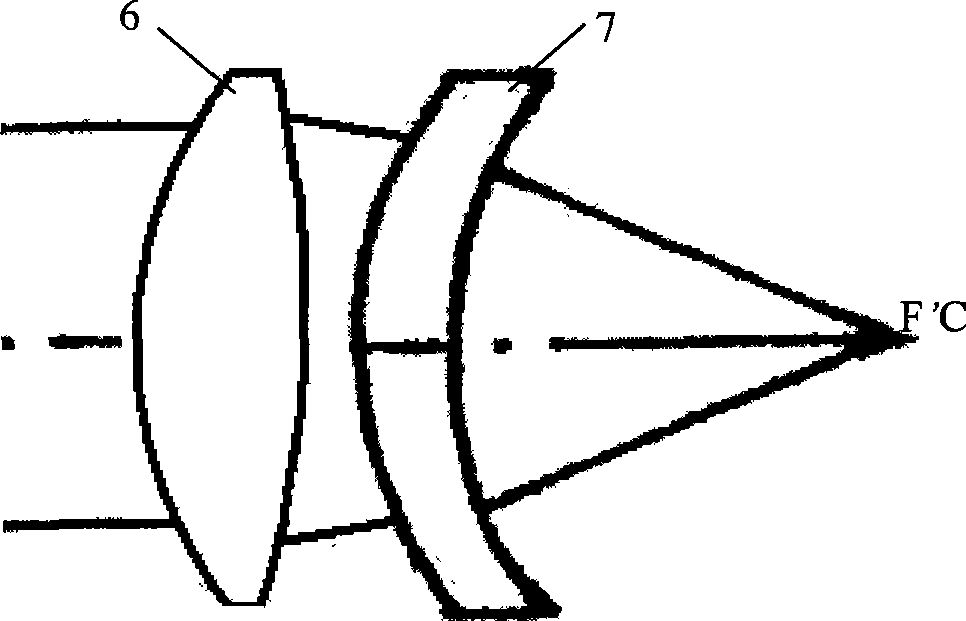

[0015] see figure 1 , according to the optical transmission spherical detection device that the present invention makes, it is made up of digital wave surface interferometer 1, transmission spherical surface apparatus 2, interferogram monitor 4 and computer 5, and digital wave surface interferometer 1 is the digital based on single interferogram processing The wavefront interferometer or the phase-shifting digital wavefront interferometer based on phase-shifting technology, the interferogram monitor 4 is used to display the interferogram reflecting the spherical surface shape to be tested, and the computer 5 is embedded with a digital image acquisition system and interferogram processing software, The transmission spherical device 2 is located on the outgoing light path of the digital wave surface interferometer 1, and it is composed of 2 to 4 optical positiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com