Mask aligner mask platform adopting magnetic suspension technology

A lithography machine and magnetic levitation technology, used in microlithography exposure equipment, photolithography process exposure devices, etc., can solve the problems of low air-floating bearing capacity, low supporting rigidity, low impact resistance, etc., and achieve impact resistance and anti-interference. The effect of low capacity, reduced component wear and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

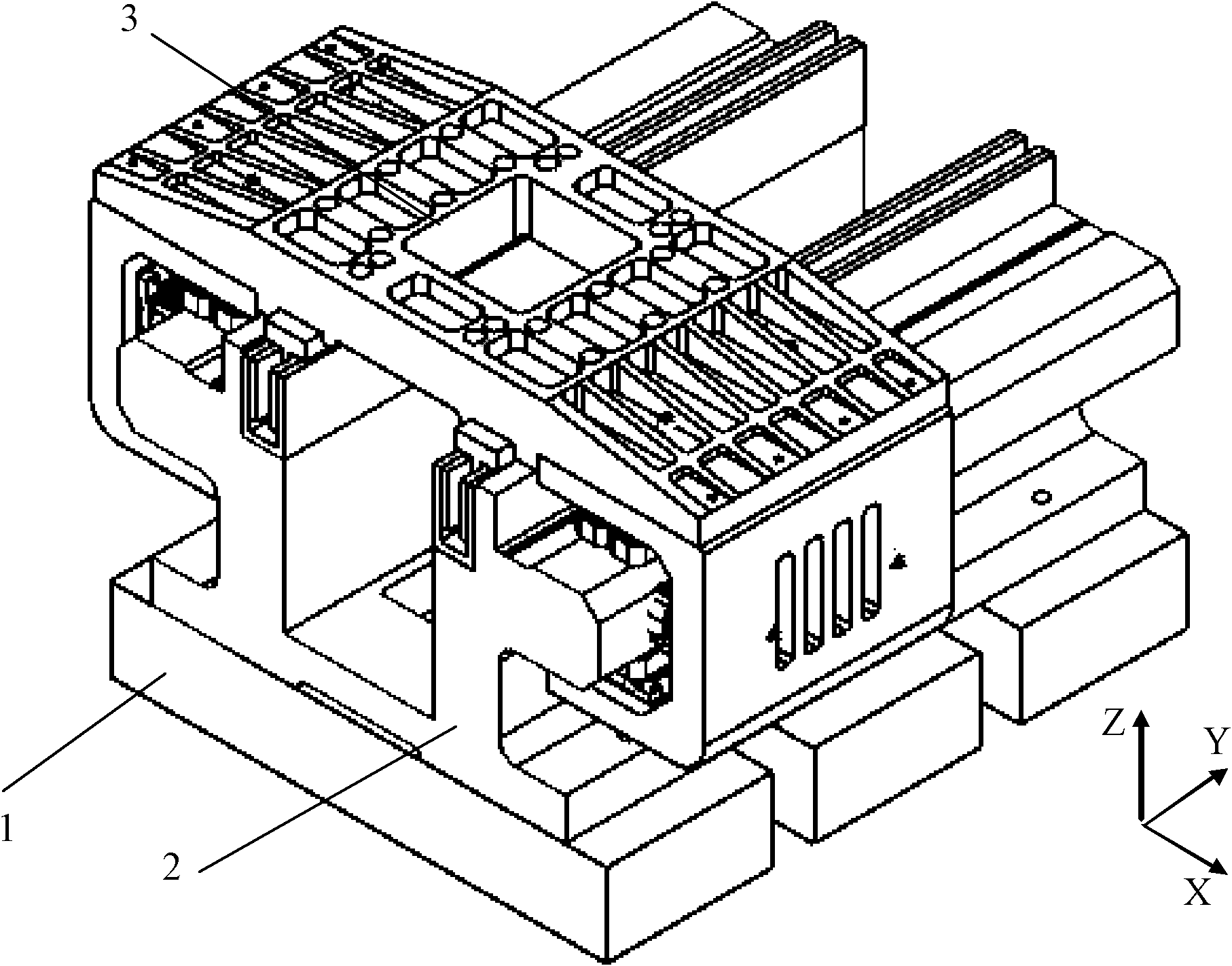

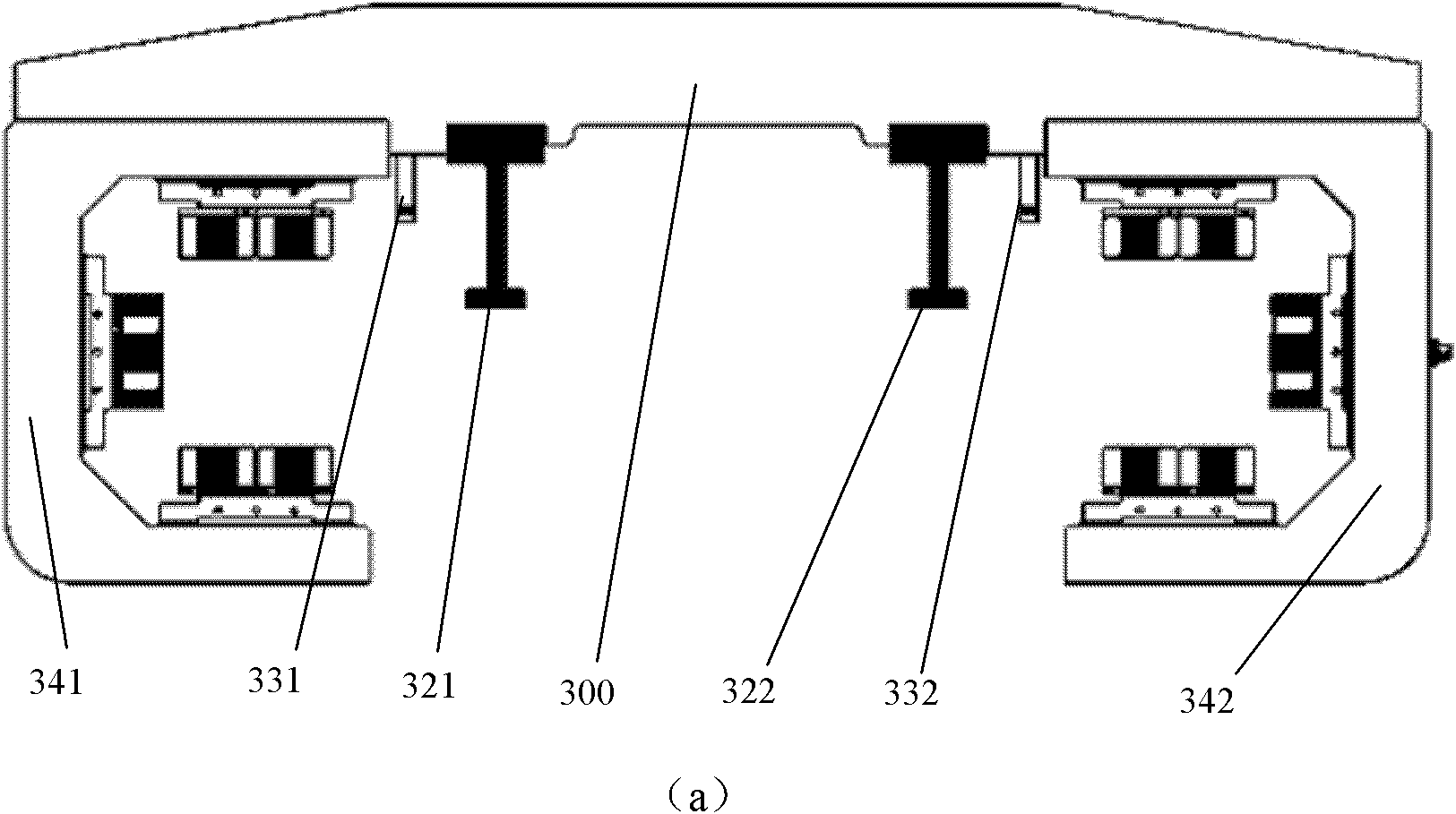

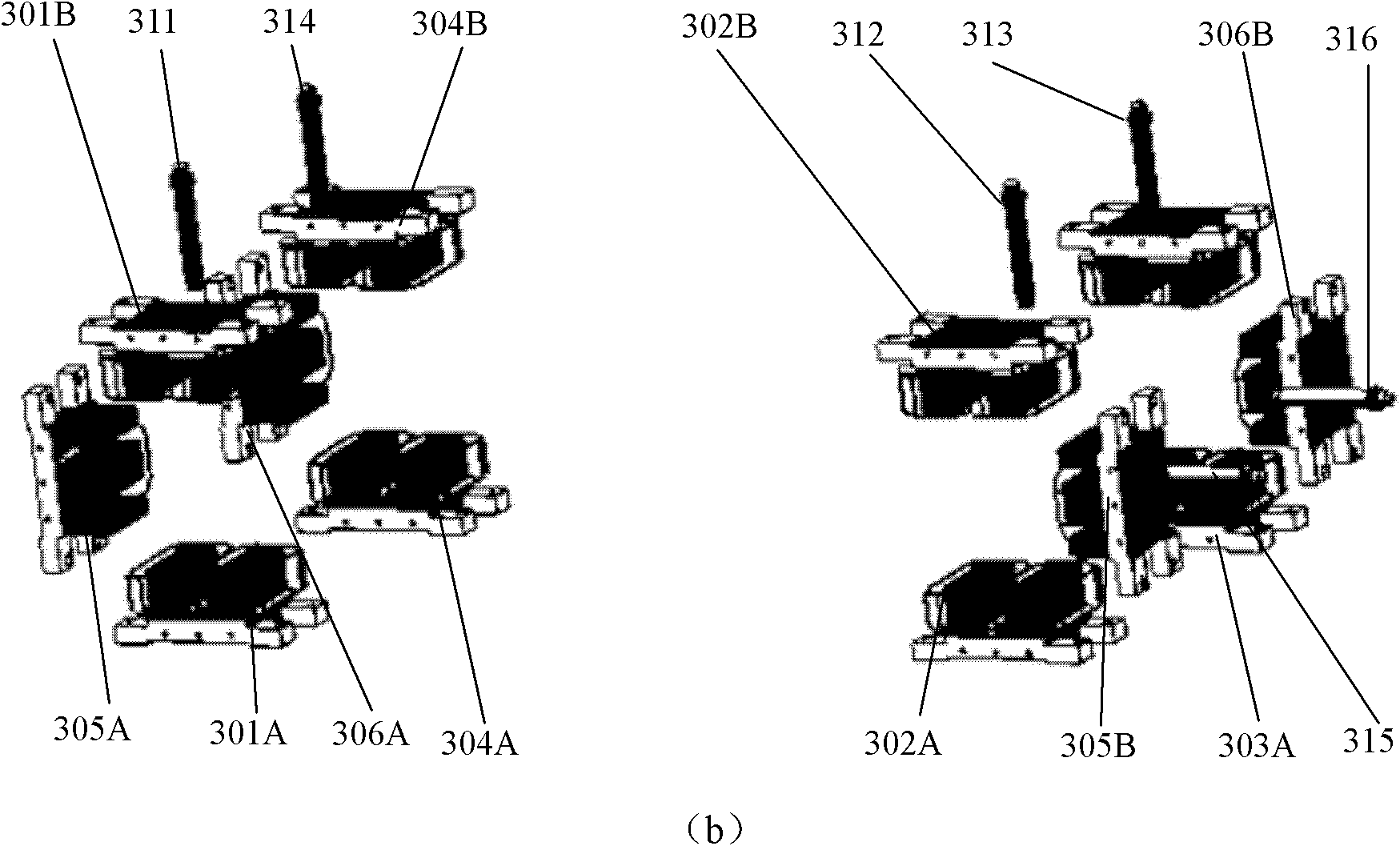

[0065] Example 1: The overall structure of the mask table of the lithography machine is as follows figure 1 As shown, from bottom to top, it consists of three parts: granite foundation 1, five-sided precision guide rail 2, and suspension body 3. The surface of the guide rail corresponding to the electromagnet is polished and homogenized, so that the flatness and verticality of the surface of the processed guide rail reach 1 μm. The structure of the suspended part is as figure 2 As shown in a, it includes magnesium alloy C-shaped left support plate 341, right support plate 342, aluminum alloy connector 300 (materials such as magnesium alloy and aluminum alloy have lower density and higher specific strength than rigidity compared with cast iron), 12 Block electromagnet 301A, 301B, 302A, 302B, 303A, 303B, 304A, 304B, 305A, 305B, 306A, 306B (as figure 2 b), 6 eddy current displacement sensors 311, 312, 313, 314, 315, 316, 2 linear motor movers 321, 322, 2 grating ruler readin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com