Engine camshaft

A camshaft and engine technology, applied to engine components, machines/engines, mechanical equipment, etc., to achieve the effects of reducing fuel consumption, increasing layout space, and reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below through specific embodiments and in conjunction with the accompanying drawings.

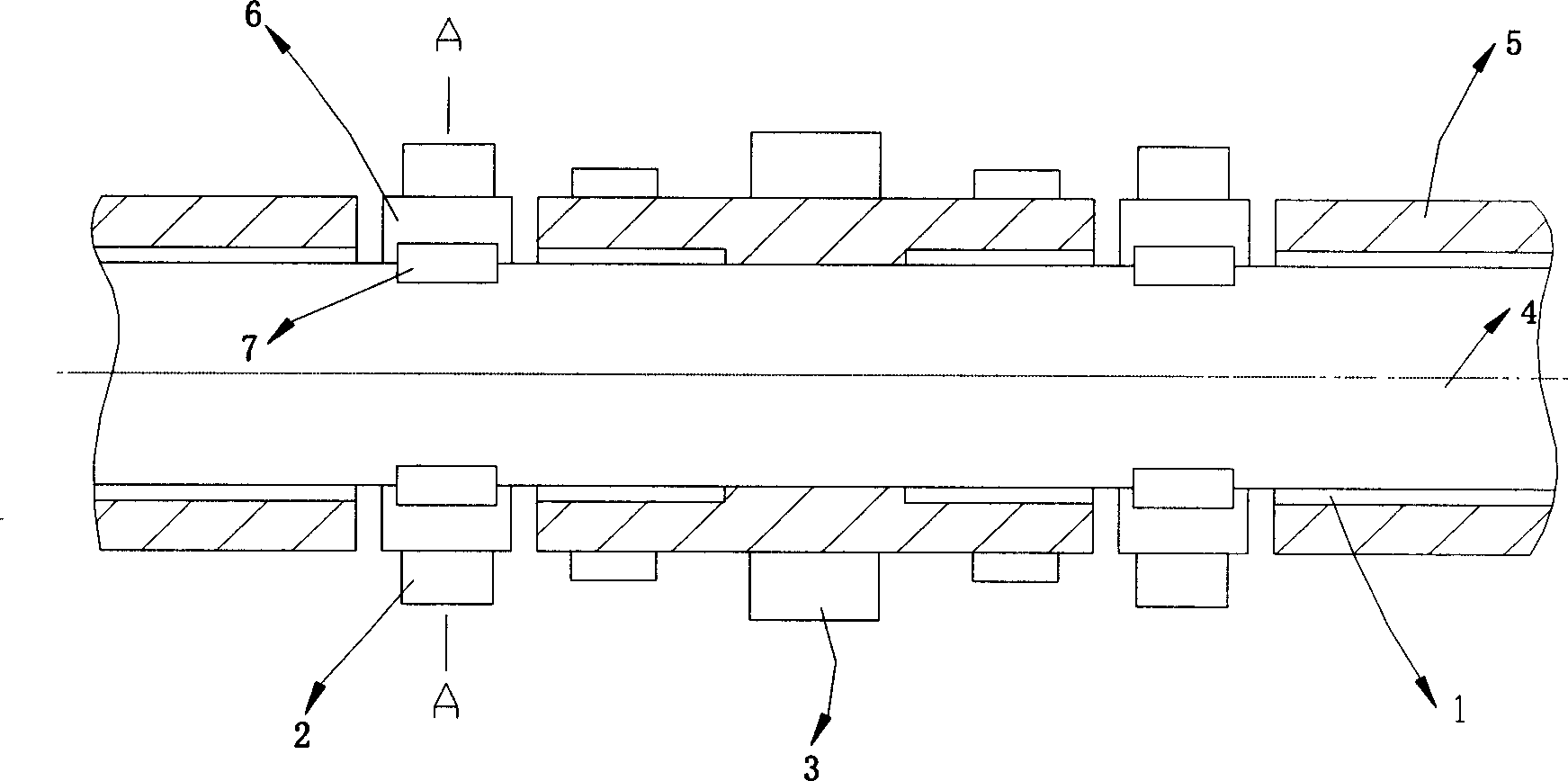

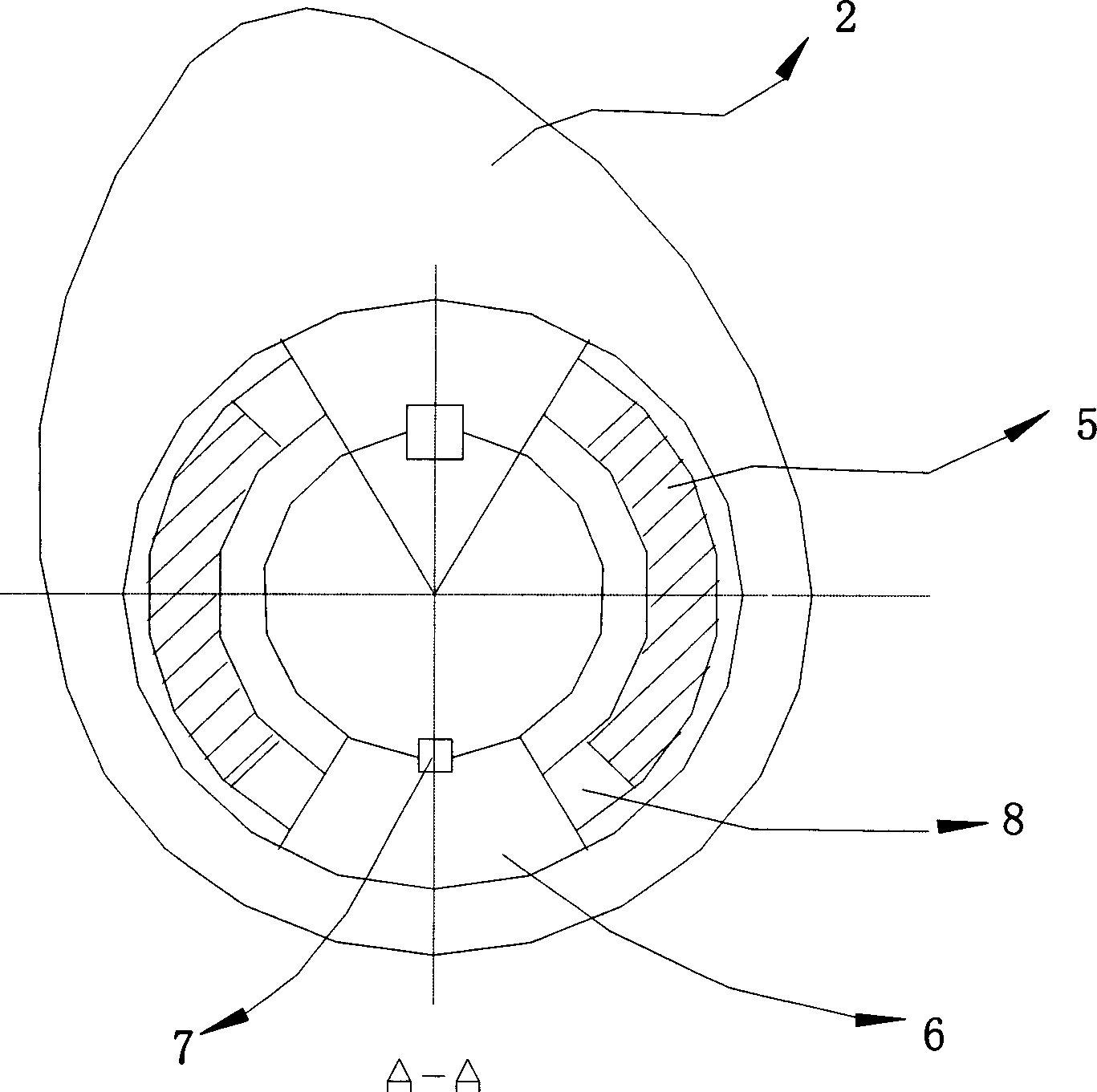

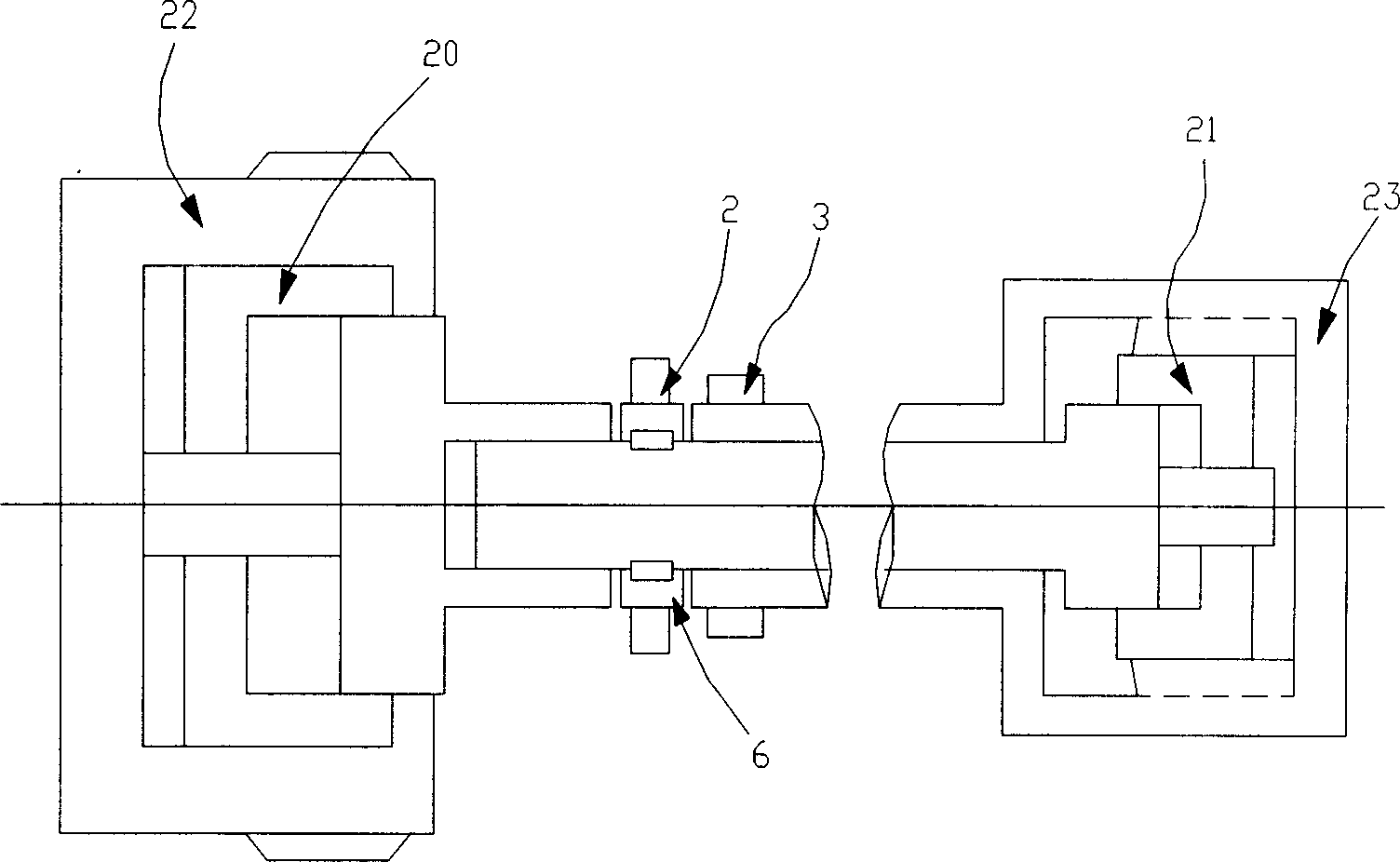

[0016] Such as figure 1 The engine camshaft includes a shaft body 1 and an intake cam 2 and an exhaust cam 3 distributed and fixedly connected to the shaft body 1. The shaft body 1 is designed in such a way that the shaft body 1 consists of inner The shaft 4 and the outer shaft 5 are composed; the intake cam 2 is fixedly connected to the inner shaft 4, and the exhaust cam 3 is fixedly connected to the outer shaft 5. Through the driving mechanism, the inner shaft 4 and the outer shaft 5 can be relatively rotated, thereby Drive the intake cam 2 and the exhaust cam 3 to move relative to each other to achieve the best gas timing.

[0017] The combined shaft body 1 has the same installation arrangement as the single overhead camshaft, but it can achieve a technical effect better than that of the single overhead camshaft, because: the combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com