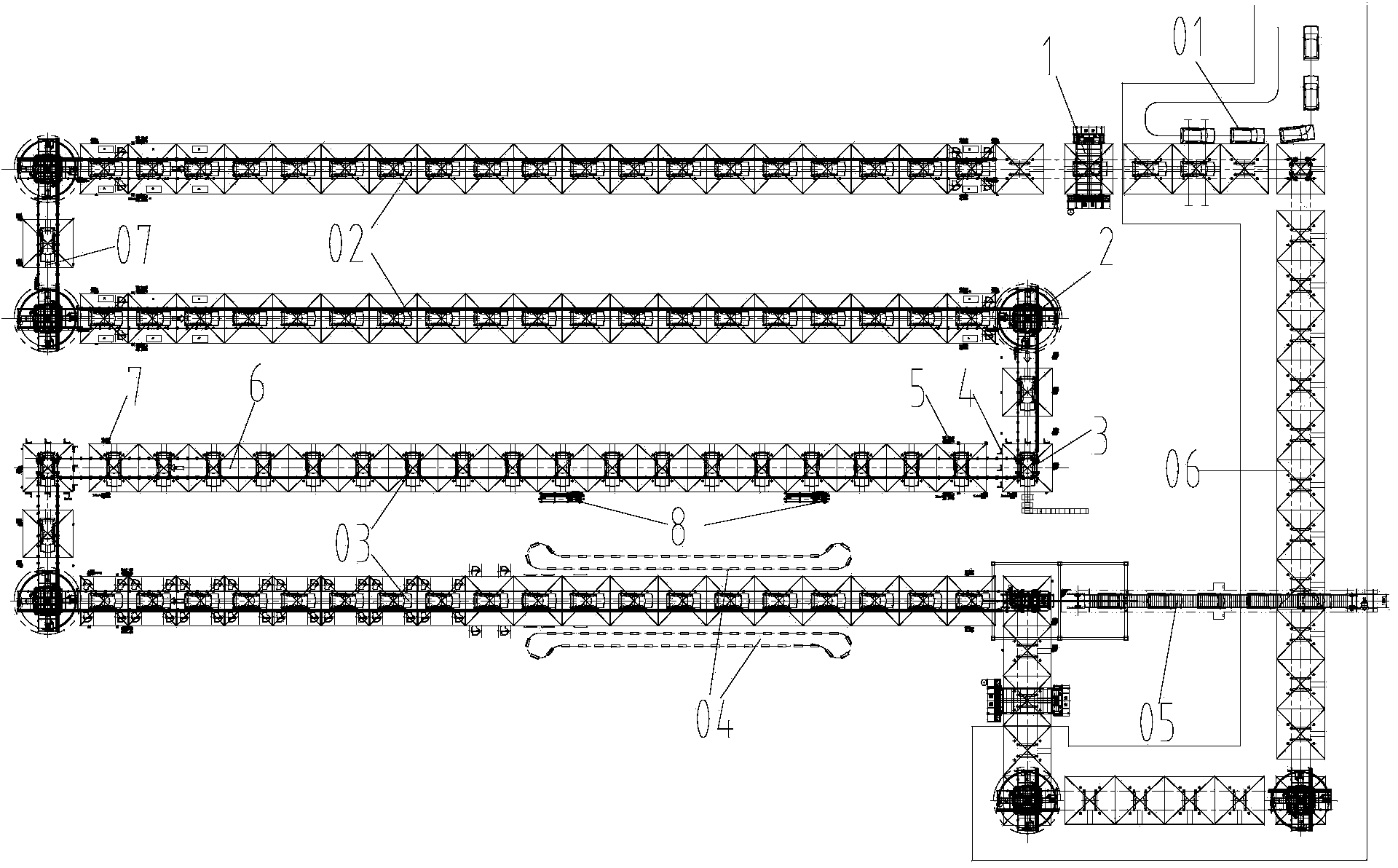

Automobile assembly sliding plate conveying line

An automobile assembly and conveying line technology, which is applied to conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of increased manufacturing cost of assembly lines, high requirements on house height, and complex structure of assembly systems, reducing installation difficulty, Improve production efficiency and optimize the effect of layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

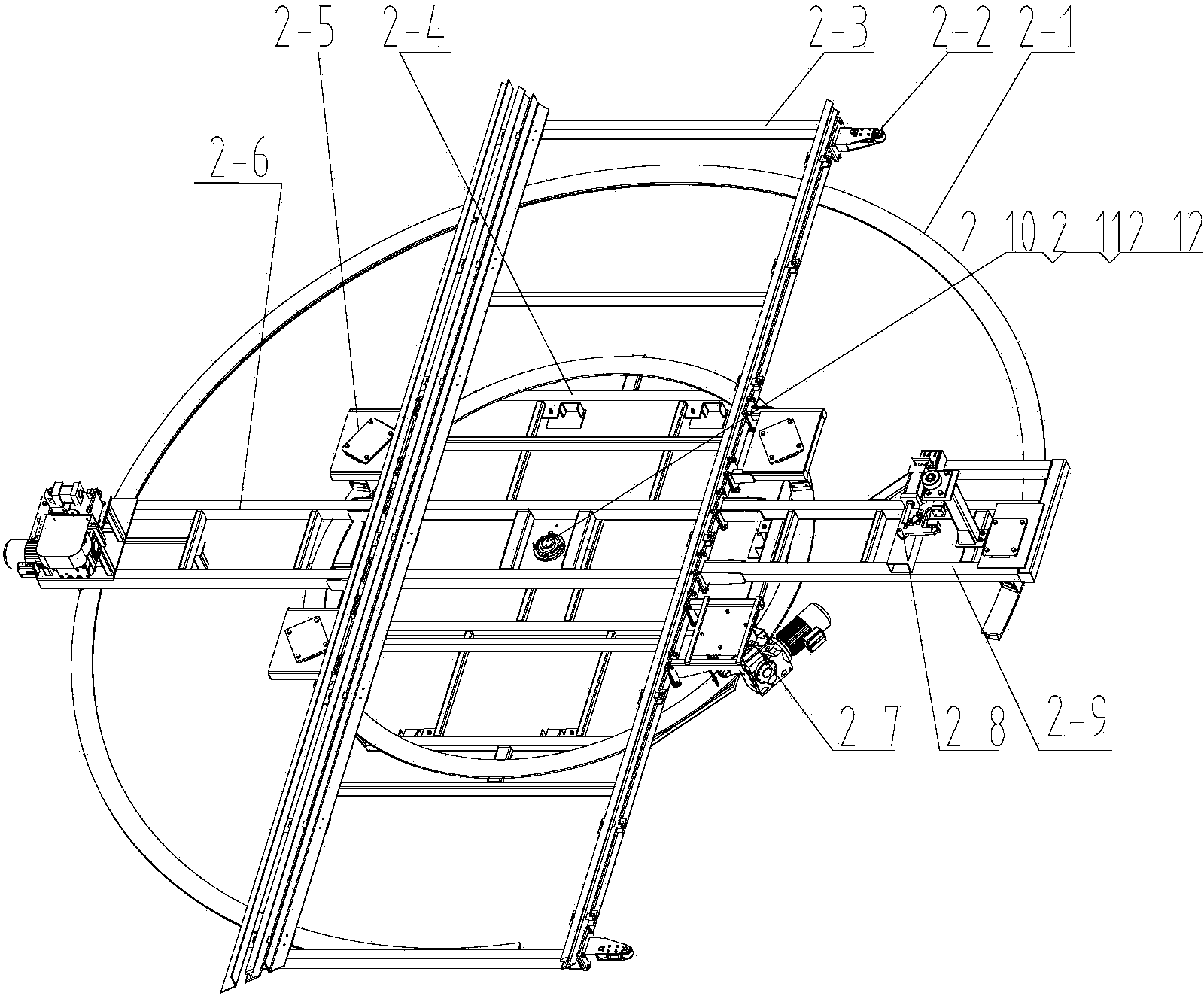

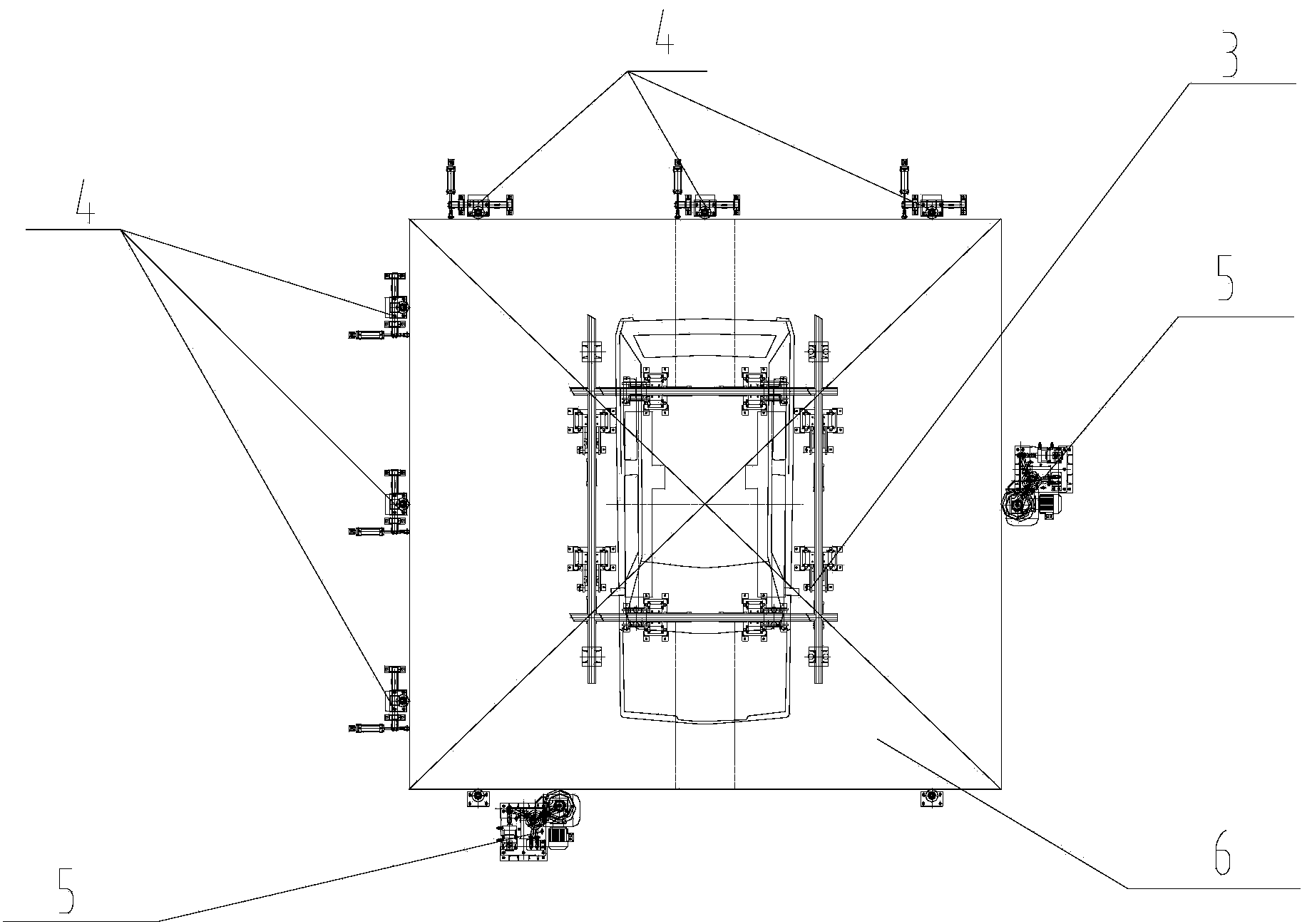

[0029] A detailed description will be given below in conjunction with the accompanying drawings and specific embodiments. In the following description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. However, the present invention can be implemented in many other ways different from those described here, and those skilled in the art can make similar extensions without violating the connotation of the present invention, so the present invention is not limited by the specific embodiments disclosed below.

[0030] The present invention provides a new type of skateboard conveying system and sub-systems, which can integrate different assembly lines on the same skateboard conveying line, thus satisfying various process requirements at the same time, which greatly improves the assembly accuracy, work efficiency and manufacturing cost of the system. A substantial increase, which can better meet the overall performance requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com