Electrically-driven ultra-large-displacement well cementation equipment

A super-large, well-cementing technology, applied in the direction of mechanical equipment, clay preparation equipment, wellbore/well components, etc., can solve the problems of high noise, high fuel consumption, and large occupied volume of diesel engines, and achieve the reduction of torque converter settings, The effect of increasing operational safety and increasing layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

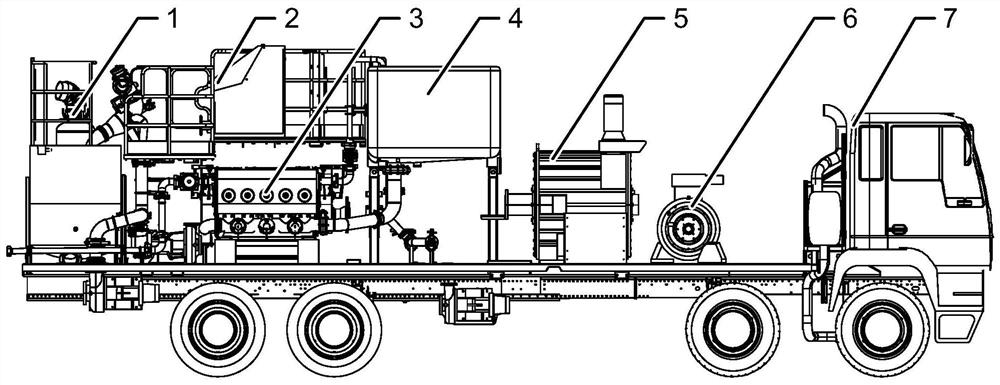

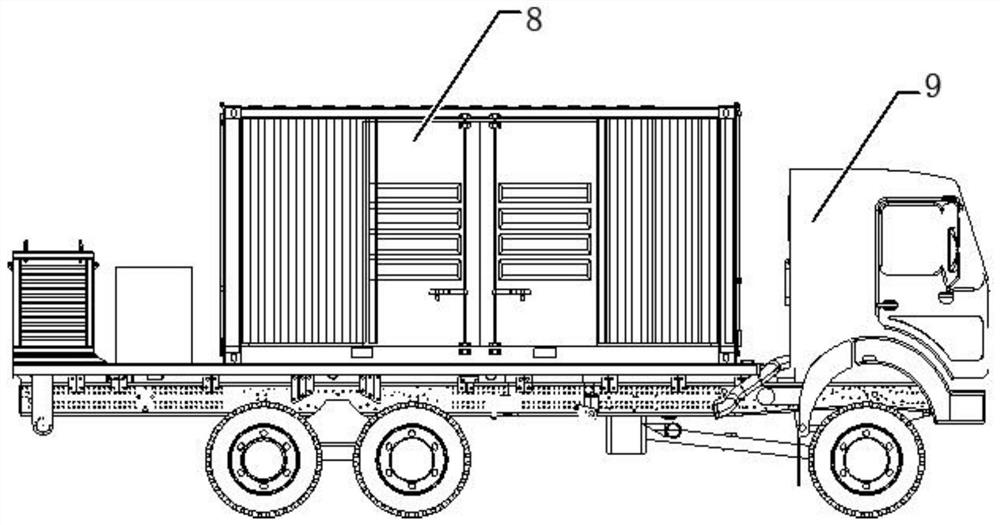

[0020] like figure 1 and 2 As shown, an electric drive ultra-large displacement cementing equipment includes a first loading body 7 and a second loading body 9, and the first loading body 7 is fixedly loaded with an auxiliary motor 6, a main motor 5, a clean water module 4, The pumping module 3, the control module 2, the hydraulic module and the mixing module 1, the first loading body 7 is also loaded with a lubrication module and an air circuit module, and the second loading body 9 is fixedly loaded with a frequency converter module 8, so The frequency converter module 8 supplies power for the auxiliary motor 6, the main motor 5, the control module 2, the lubrication module and the air circuit module loaded on the first loading body 7, and the main motor 5 provides power for the pumping module 3, The auxiliary motor 6 provides power for the clean water module 4 and the mixing module 1 through a hydraulic module. The main motor 5 is used to drive the pumping module 3, the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com