Electronic atomizer

A technology for electronic atomizers and atomizing tubes, which is applied in the field of tobacco, etc., and can solve problems such as atomizers failing to pass the test, battery short circuit, and smoke liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

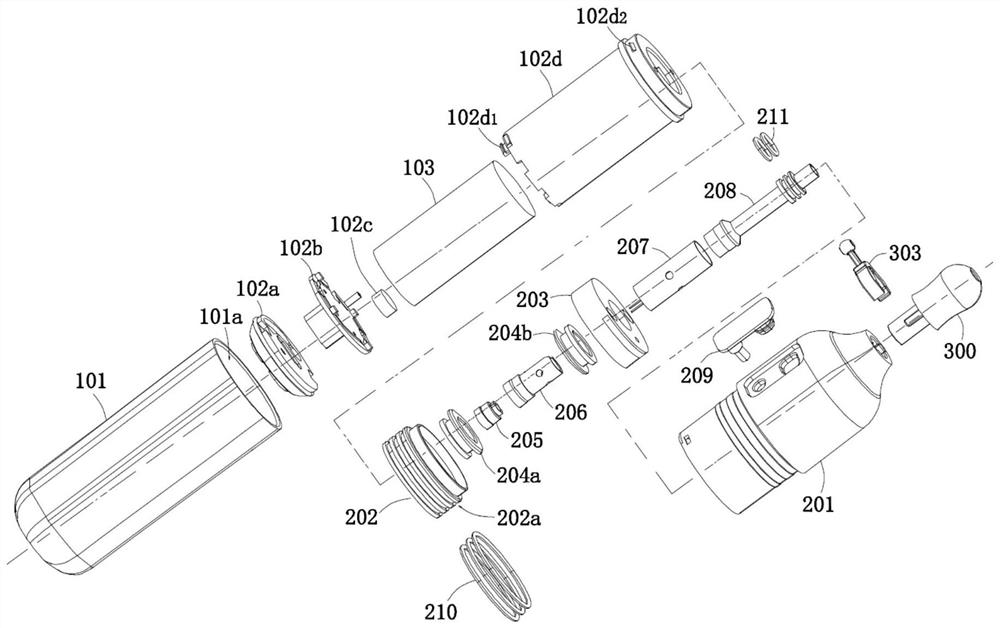

[0050] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

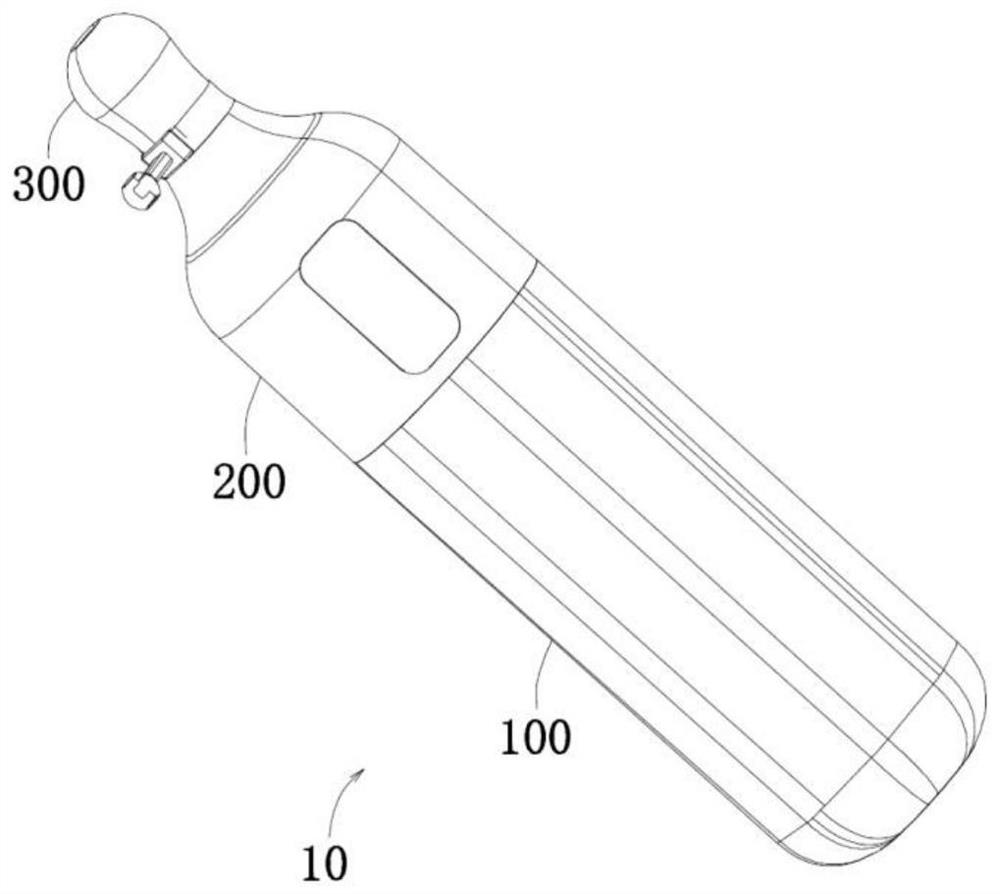

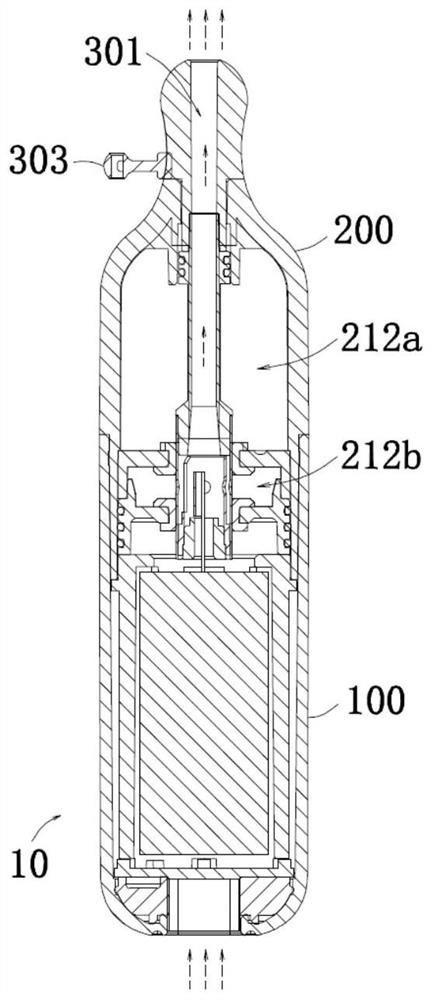

[0051] Such as Figure 1-Figure 13 As shown, in the first embodiment of the atomizing body and the atomizer of the present invention, the atomizer 10 includes a housing component 100 , an atomizing body 200 and a suction nozzle 300 .

[0052] Wherein, the atomizing body 200 is used to generate smoke.

[0053] Specifically, the atomizing body 200 includes an upper cavity 201 , sealing seats (corresponding to 202 and 203 ) and an atomizing element 400 .

[0054] The upper chamber 201 is formed as a hollow cylinder or a flat cuboid, and an oil storage chamber (corresponding to 212 a and 212 b ) is formed in the upper chamber 201 , and its two ends are configured as open structures.

[0055] Specifically, the opening 214 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com