Automatic line design for ballast packing box packing procedure

A box-packing and ballast technology, applied in packaging and other directions, can solve the problems of poor positioning accuracy, high rigidity requirements of the manipulator, problems in workpiece grasping and placement, and achieve the effect of easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

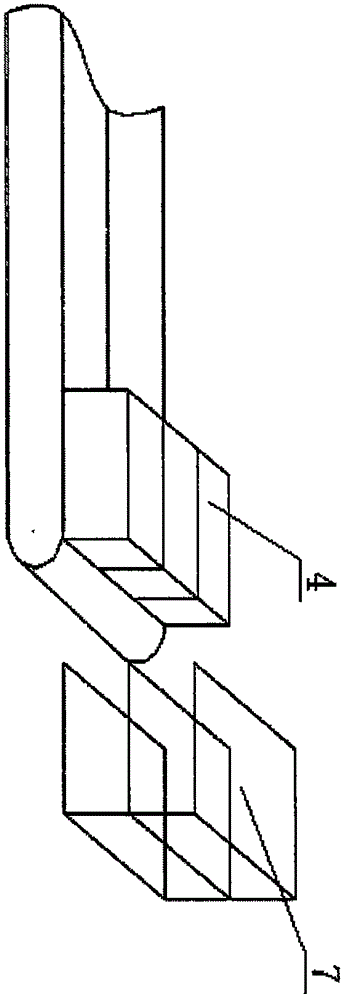

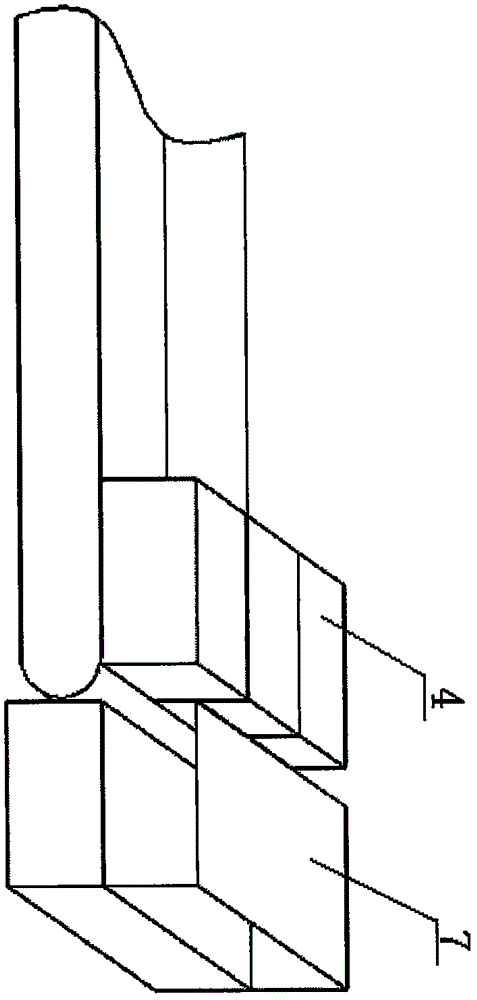

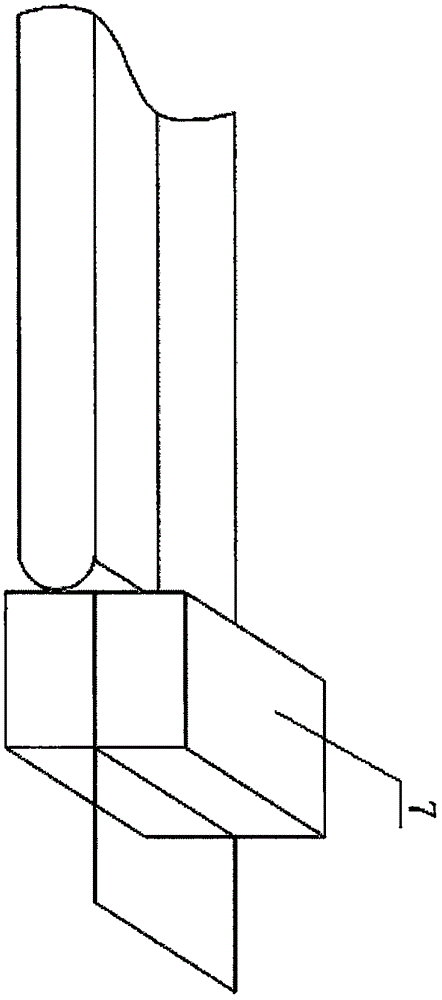

[0029] Such as Figure 4 to Figure 6 The shown automatic line design for the packing process of ballast packaging boxes includes a workbench 1, a conveyor belt 3 and a support frame 8 arranged on the workbench 1, and a guiding device and a pushing device installed on the workbench 1. And a moving device installed on the support frame 8, and a clamping device connected to the moving device; a plurality of packaging boxes 4 are placed on the conveyor belt 3;

[0030] The guide device includes left and right guide plates 34 and 35 fixed on both sides of the conveyor belt 3, a limit plate 6 movably installed above the conveyor belt 3 through a double cylinder 2 and a push box arranged outside the left guide plate 34 Mechanism, and a baffle 26 arranged below the clamping device; the left and right guide plates 34, 35 are arranged in a trapezoidal structure; the box pushing mechanism consists of a box pushing cylinder 5 and a box pushing cylinder connected to the box pushing cylinder 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bore | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com