Shutter-style multiple row synchronous metering device

A technology of metering device and ram, which is applied in the direction of packaging, etc., to achieve the effect of large metering range, reducing powder content and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

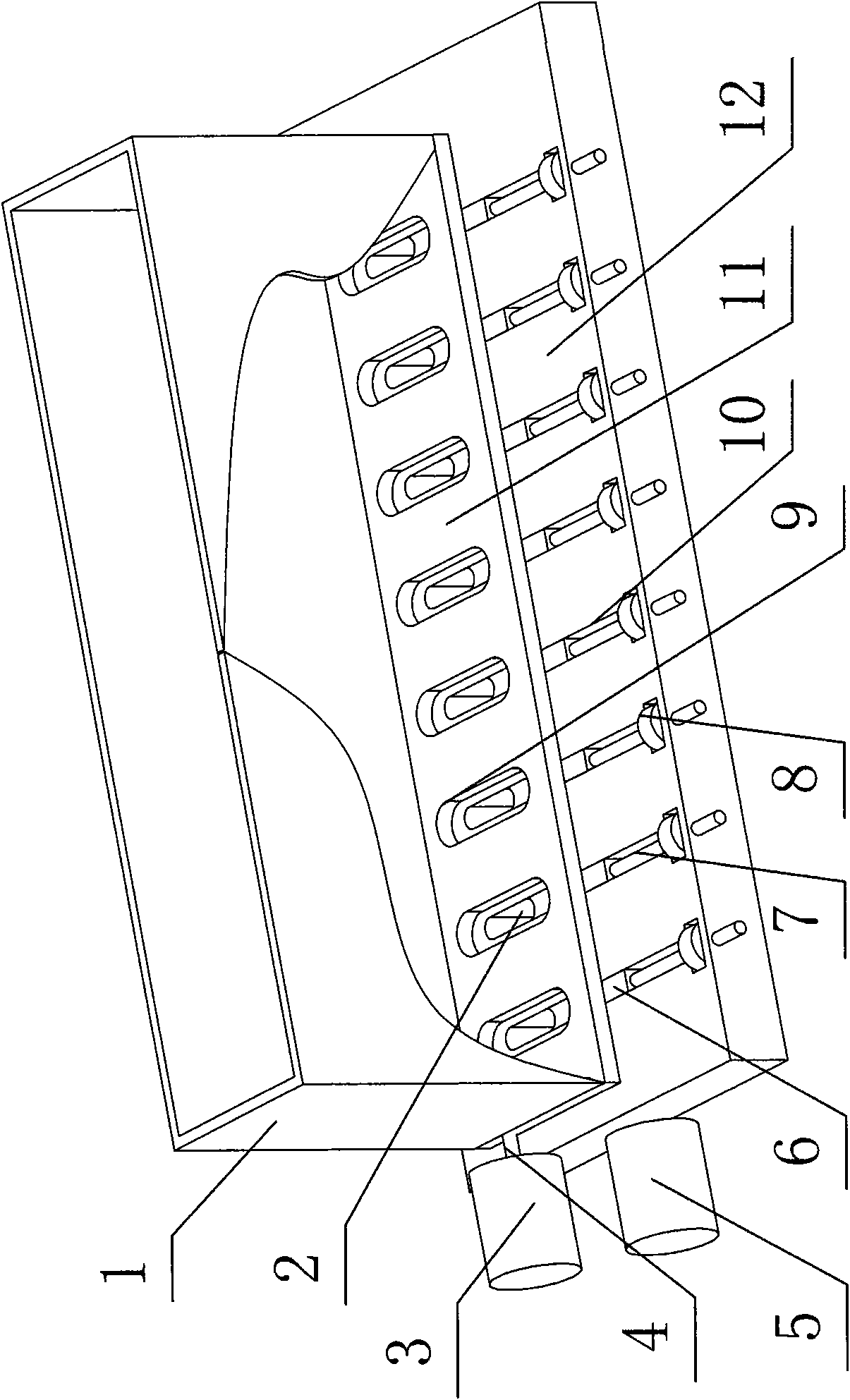

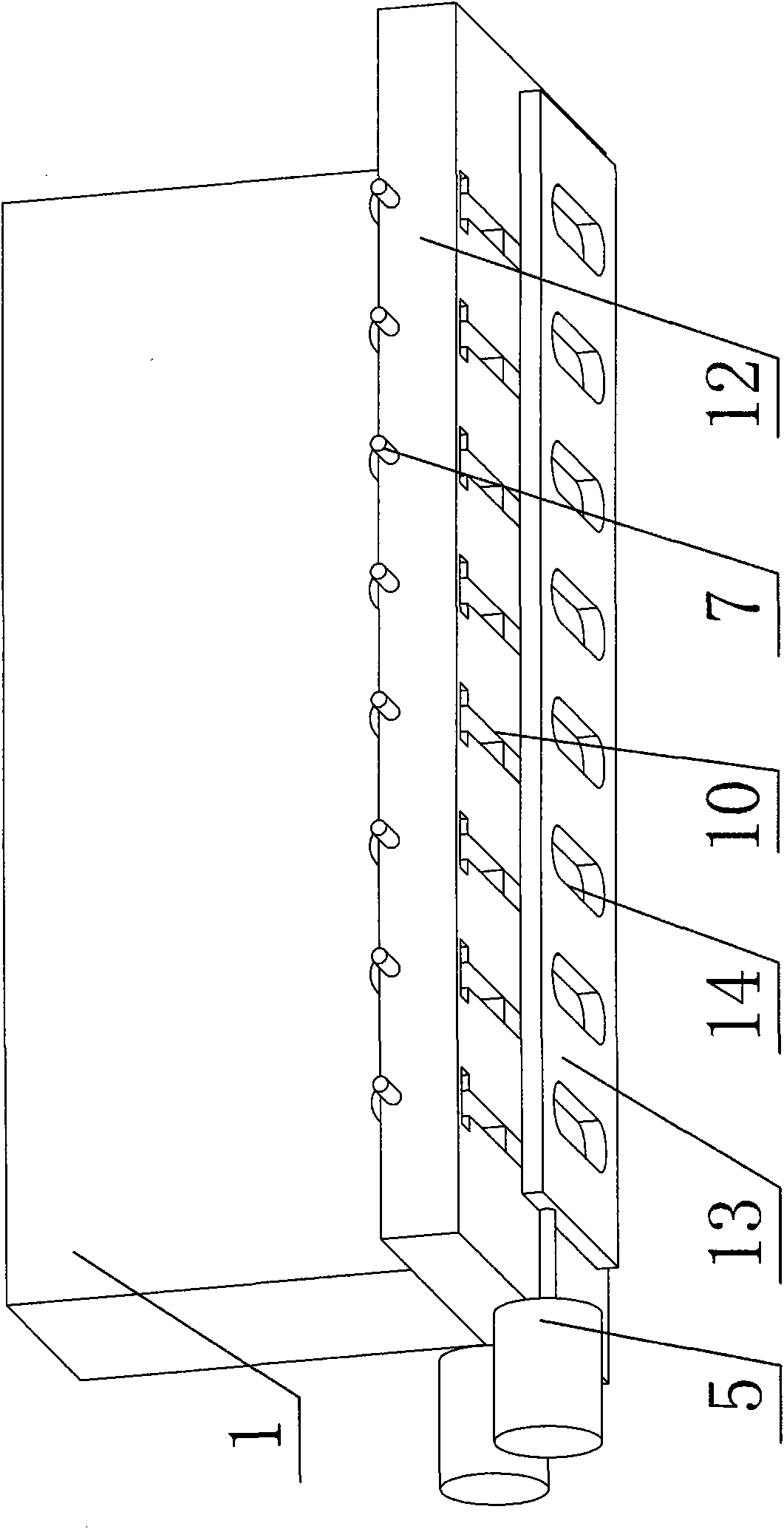

[0009] See attached Figure 1-2 , in the present embodiment, this ram-type multi-column synchronous metering device has a rectangular scraper 11, a metering plate 12 and a sealing plate 13 arranged successively below its hopper 1, wherein the hopper 1 is a cuboid box with an open upper surface body structure, and the hopper 1 and the scraper 11 are fixedly connected as one. The scraper 11 and the sealing plate 13 form a gate structure, and the two plates are provided with long grooves, which are respectively the long groove 9 of the scraper and the long groove 14 of the sealing plate, and the left side of the scraper 11 passes through the piston rod 4 It is connected with the cylinder 3, and the left side of the sealing plate 13 is also connected with the cylinder 5. The long groove 10 of the metering plate 12 is wider, and the metering plate 12 itse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com