Indexing turntable multi-station vibration worktable for powder explosive small cartridge charger

A technology of rotary table and rotary table, which is applied in the storage of ammunition, ammunition, weapon accessories, etc., and can solve the problems of large area occupation, high labor intensity, and multiple operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

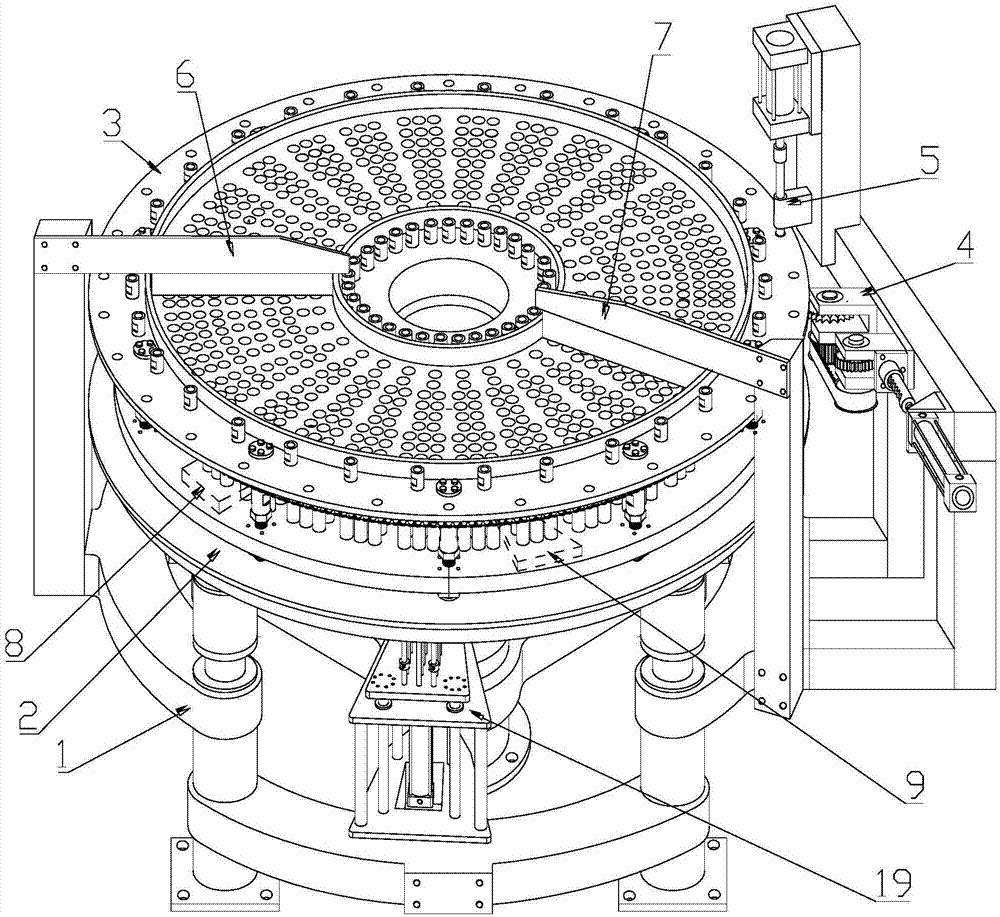

[0068] see figure 1 , an indexing rotary disc type multi-station vibrating workbench used for powdery explosives and small drug coil charging machines, including a base 1, a vibrating disc 2, an indexing rotary workbench 3, a workbench turning mechanism 4, and a working table Position positioning mechanism 5, left baffle plate 6, right material baffle plate 7, empty pipe suction mechanism 8, gland pipe jacking mechanism 9 and medicine volume ejection mechanism 19.

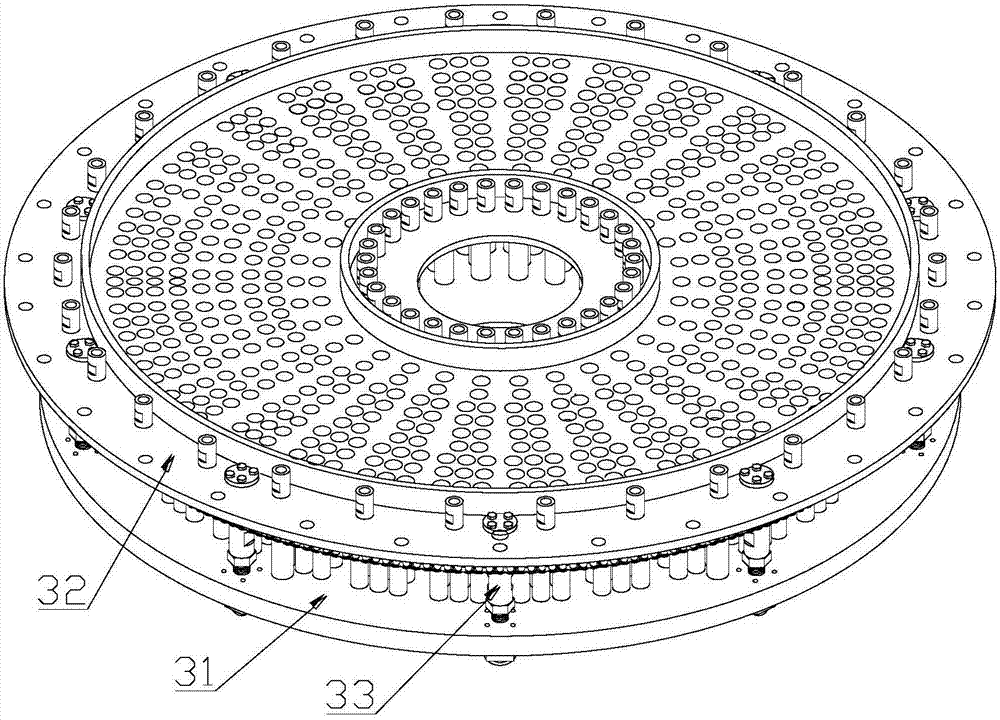

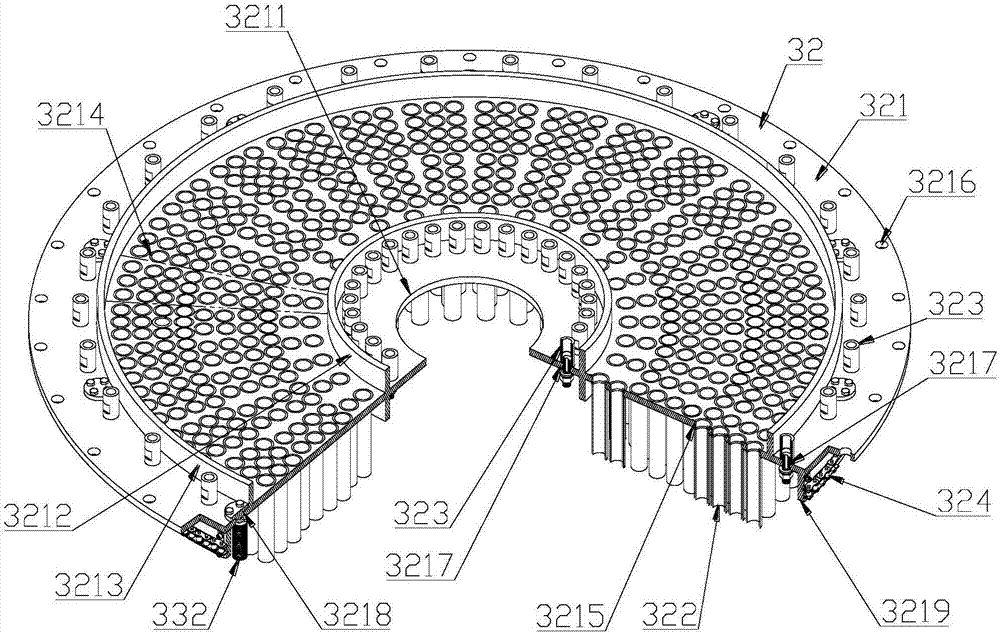

[0069] see figure 2 , the indexing rotary table 3 is a double-layer disc-shaped structure, ten first adjustable supports 33 are arranged between the double-layer discs, the lower layer is provided with a lower rotary table 31, and the upper layer is provided with an upper rotary table 32, In the annular area between the inner retaining ring 3212 and the outer retaining ring 3213 of the upper rotary disk 32, there are upper positioning holes 3215 distributed in a honeycomb shape along the radial direction, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com