Composite corrugated paperboard buffering cushion base

A corrugated cardboard and corrugated board technology, applied in the field of composite corrugated cardboard buffer pad base, can solve the problems of cumbersome packing process, high cost of packaged materials, and unguaranteed safety, so as to improve transportation safety and guarantee The effect of transportation safety and reducing the difficulty of packing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

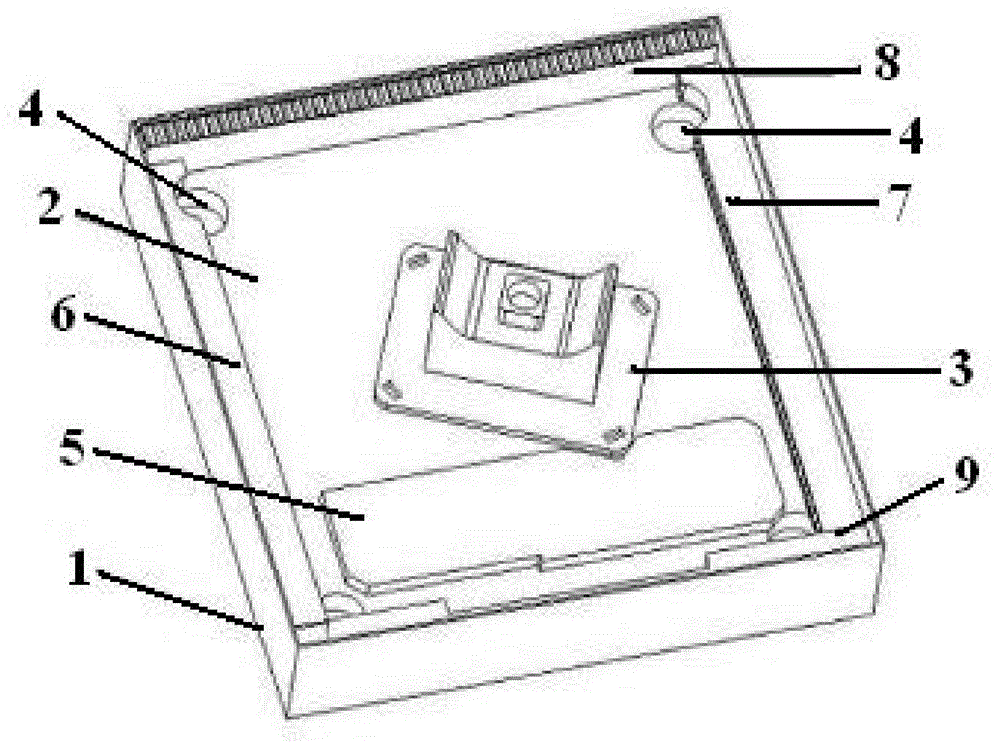

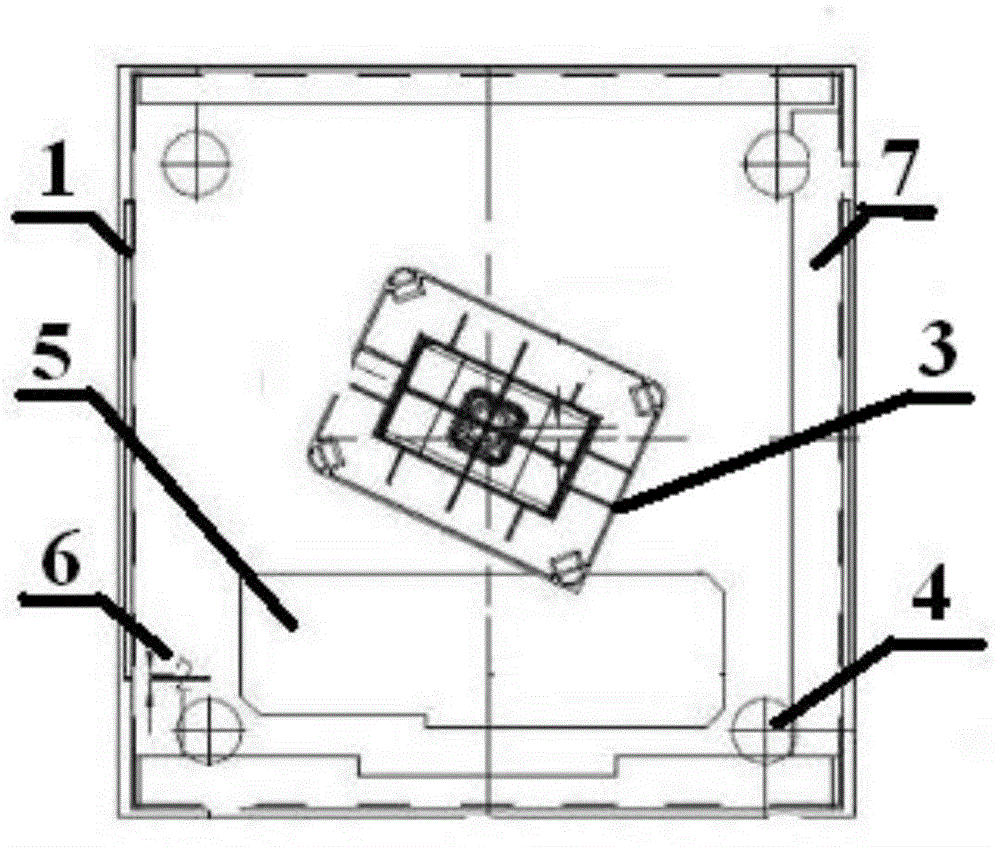

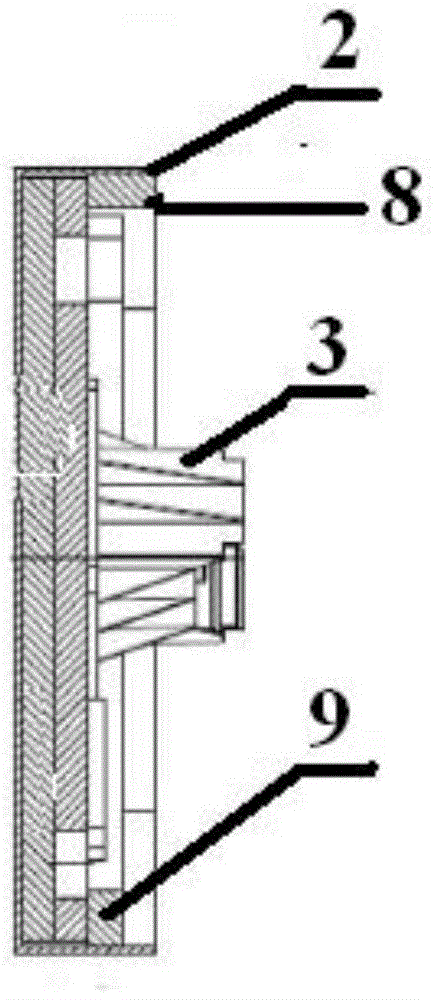

[0023] A composite corrugated cardboard buffer cushion base, including a cushion skeleton 1 folded from corrugated cardboard and a buffer body 2 bonded to the skeleton 1 and made of honeycomb cardboard. The middle part of the buffer body 2 is There are slots on it, and the base of the buffer pad also includes a plastic support 3, which is fixed on the slot of the buffer body by embedding; sockets 4 are preset around the base of the buffer pad, and the buffer pad The base is connected to the edge pad through the socket 4; the buffer body 2 is fixed with a positioning corrugated board 5; the left honeycomb panel 6, the right honeycomb panel 7, the front honeycomb panel 8 and the rear honeycomb panel are bonded around the buffer body 2. Honeycomb panel9.

[0024] When packing, place the base of the TV set facing downwards and put it in alignment with the plastic support 3. The base and the plastic support 3 form a lock and key structure, and then form a stable triangular structur...

Embodiment 2

[0026] A composite corrugated cardboard buffer cushion base, including a cushion skeleton 1 folded from corrugated cardboard and a buffer body 2 bonded to the skeleton 1 and made of honeycomb cardboard. The middle part of the buffer body 2 is There is a slot on it, and the cushion pad base also includes a plastic support 3, and the plastic support 3 is fixed on the slot of the buffer body by bonding; sockets 4 are preset around the cushion pad base, and the cushion pad base The pad base is connected with the edge pad through the socket 4; corrugated cardboard is bonded around the buffer body 2.

[0027] When packing, place the base of the TV set facing downwards and put it in alignment with the plastic support 3. The base and the plastic support 3 form a lock and key structure, and then form a stable triangular structure with the positioning corrugated board 5, and then place the edge pads along the four sides of the TV. Insert it into socket 4, close the upper cover of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com