Processing technique for non-locally making smoked sheet into cut tobacco after feeding

A processing technology and tobacco sheet technology, applied in the application, tobacco, preparation of tobacco and other directions, can solve the problems of difficulty in ensuring the consistency of product sensory quality, large color change of tobacco leaves, low utilization rate, etc., to ensure the consistency of sensory quality, raw materials The effect of improving utilization and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

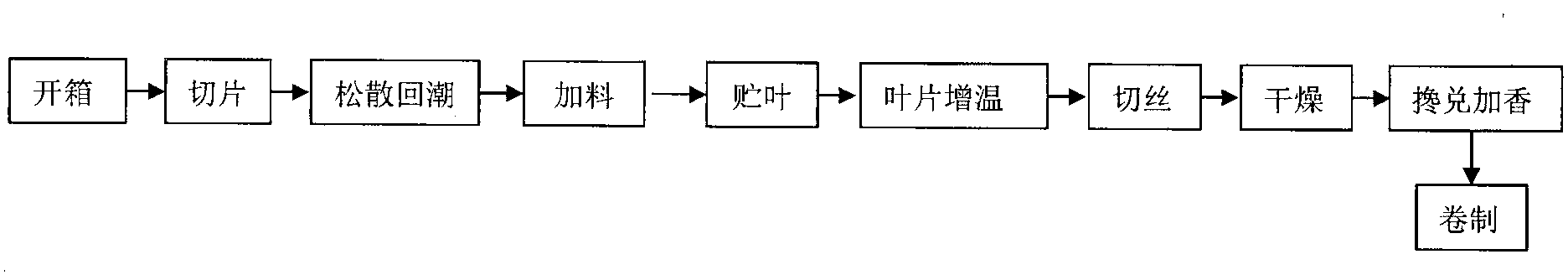

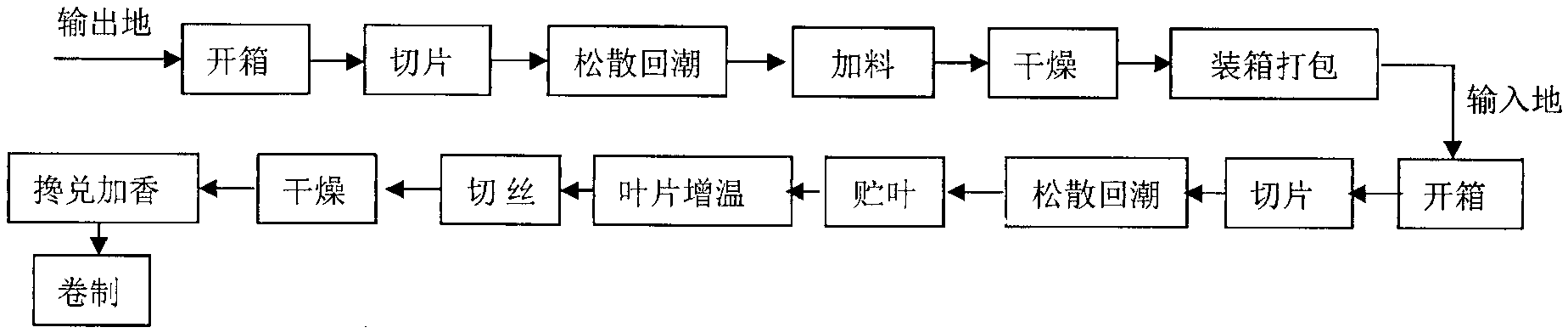

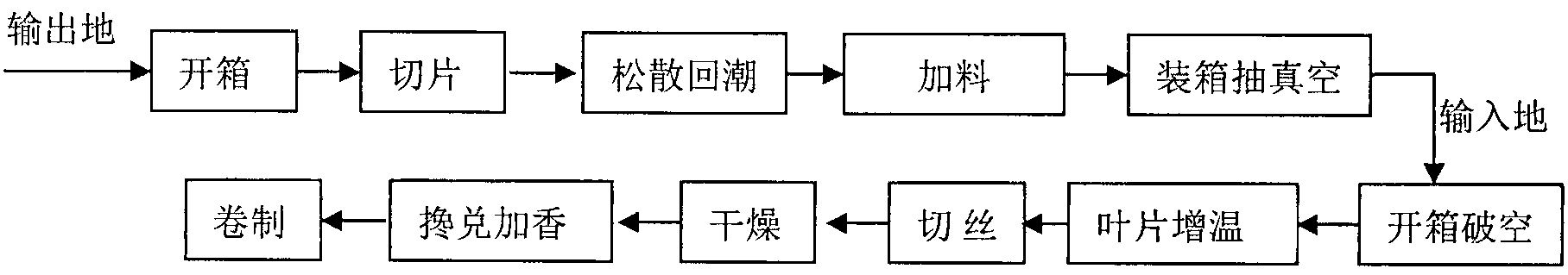

[0016] In the following, the processing technology of the present invention for the off-site silk making of tobacco slices after feeding will be further described in conjunction with the embodiments (figure drawings):

[0017] A cigarette enterprise and B cigarette enterprise carry out joint processing, the processed cigarette brand is X, cigarette enterprise A is the export place, and cigarette enterprise B is the import place.

[0018] See image 3 :After technological transformation, the cigarette enterprise set up a side line after feeding the silk, equipped with a quantitative packing system and a vacuum system, and customized the size of 1.3m×1.3m×1.3m, the lining is oak and the exterior is stainless steel In the middle is a thermal insulation sandwich, and a sealed smoke box equipped with a vacuum tester. Cigarette A cigarette company unpacks, slices, loosens, re-moisturizes and feeds the raw materials of brand X cigarettes on the spot, and then feeds the raw materials and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com