Antibacterial and mite-suppression bed core for babies and method for manufacturing antibacterial and mite-suppression bed core

A technology for bed cores and infants, which is applied to mattresses, spring mattresses, and other seating furniture. It can solve the problems of easy layering, undisclosed proportions, and affecting strength, so as to prevent layering and eliminate sweat odor. , The effect of removing peculiar smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

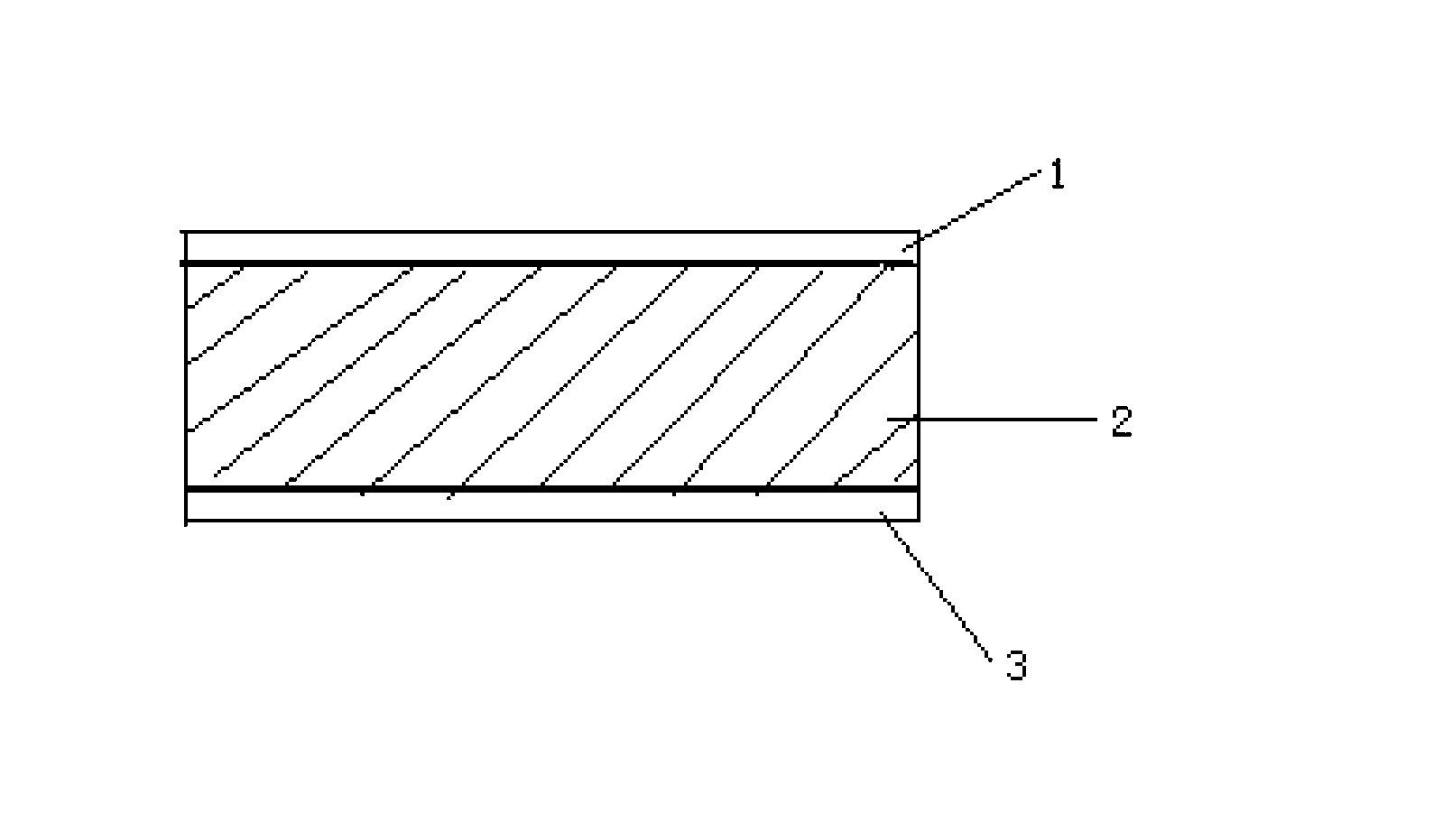

[0032] An antibacterial and mite-suppressing baby bed core, comprising at least one middle layer 2 and a surface layer arranged on the upper or lower surface of the middle layer 2, the surface layer is composed of the following components by weight percentage: 15% PLA fiber and 85% % jute fiber, the middle layer 2 is composed of the following components by weight percentage: 85% bamboo fiber and 15% PP fiber.

[0033] Its preparation method comprises the following steps:

[0034] In the first step, each component is weighed according to the required ratio, opened and mixed, pre-laid, carded, air-laid, and needle-punched to prepare the non-woven layers of the upper surface layer 1 and the lower surface layer 3 respectively. The non-woven layer of surface layer 1 and lower surface layer 2 adopts 15% PLA fiber and 85% jute fiber, and the needle punching density in the needle punching process is 88 punches / cm 2 ;

[0035] In the second step, the middle layer 2 is obtained by wei...

Embodiment 2

[0053] An antibacterial and mite-suppressing baby bed core, comprising at least one middle layer 2 and a surface layer arranged on the upper or lower surface of the middle layer 2, the surface layer is composed of the following components by weight percentage: 40% PP fiber and 60% % flax fiber, the middle layer 2 is composed of the following components by weight percentage: 60% bamboo fiber and 40% ES fiber.

[0054] Its preparation method comprises the following steps:

[0055] In the first step, each component is weighed according to the required ratio, opened and mixed, pre-laid, carded, air-laid, and needle-punched to prepare the non-woven layers of the upper surface layer 1 and the lower surface layer 3 respectively. The non-woven layer of surface layer 1 and lower surface layer 2 adopts 40% PP fiber and 60% flax fiber, and the needle punching density in the needle punching process is 44 punches / cm 2 ;

[0056] In the second step, the middle layer 2 is obtained by weigh...

Embodiment 3

[0074] An antibacterial and mite-suppressing baby bed core, comprising at least one middle layer 2 and a surface layer arranged on the upper or lower surface of the middle layer 2, the surface layer is composed of the following components by weight percentage: 30% 4080 fiber and 70% % bamboo fiber, the middle layer 2 is made up of the following components by weight percentage: 70% bamboo fiber and 30% low melting point fiber.

[0075] Its preparation method comprises the following steps:

[0076] In the first step, each component is weighed according to the required ratio, opened and mixed, pre-laid, carded, air-laid, and needle-punched to prepare the non-woven layers of the upper surface layer 1 and the lower surface layer 3 respectively. The non-woven layer of surface layer 1 and lower surface layer 3 adopts 30% 4080 fiber and 70% bamboo fiber, and the needle punching density in the needle punching process is 70 punches / cm 2 ;

[0077] In the second step, the middle layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com