Water dispersible powder syrup for oleophylic treatment and product applying powder syrup

A technology for dispersing powder and paste, which is applied in the field of water-dispersible paste and cosmetics added with the water-dispersible paste, which can solve problems such as safety hazards and environmental pollution, and achieve product safety, no organic solvent pollution, and dispersibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the manufacture of the water-dispersed particulate titanium dioxide slurry of lipophilic surface treatment:

[0037] Mix 40kg of particulate titanium dioxide, 60kg of water, 2kg of triethoxyoctylsilane, and 1kg of fatty alcohol polyoxyethylene ether-9 in a homogeneous mixer for 30 minutes, and heat at 90°C for 1 hour.

[0038] Effect after treatment: compare sample 1 with the same solid particulate titanium dioxide aqueous solution and Example 1, comparative sample 1—dissolve 40g of particulate titanium dioxide in 60g of water and stir well. Take the product of Example 1 and Comparative Sample 1 of the same weight and apply it on the back of the hand. After a little drying, rinse with water. It can be observed that the powder slurry of Example 1 has obvious residues, showing excellent water resistance.

Embodiment 2

[0039] Embodiment 2: the manufacture of the water-dispersed particle mixed iron oxide slurry of lipophilic surface treatment:

[0040] Mix 35kg of particulate iron oxide, 60kg of water, 1.75kg of triethoxyoctylsilane, and 0.75kg of fatty alcohol polyoxyethylene ether-9 in a homogeneous mixer for 30 minutes, and heat at 90°C for 1 hour.

[0041] Effect after treatment: compare the comparative sample 2 with the same solid particulate iron oxide aqueous solution and Example 2, comparative sample 2—dissolve 35g of particulate iron oxide in 60g of water, and stir well. Take the product of Example 2 and the product of Comparative Sample 2 of the same weight and smear it on the back of the hand. After a little drying, wash it with water. It can be observed that the powder slurry of Example 2 has obvious residues, showing excellent water resistance.

Embodiment 3

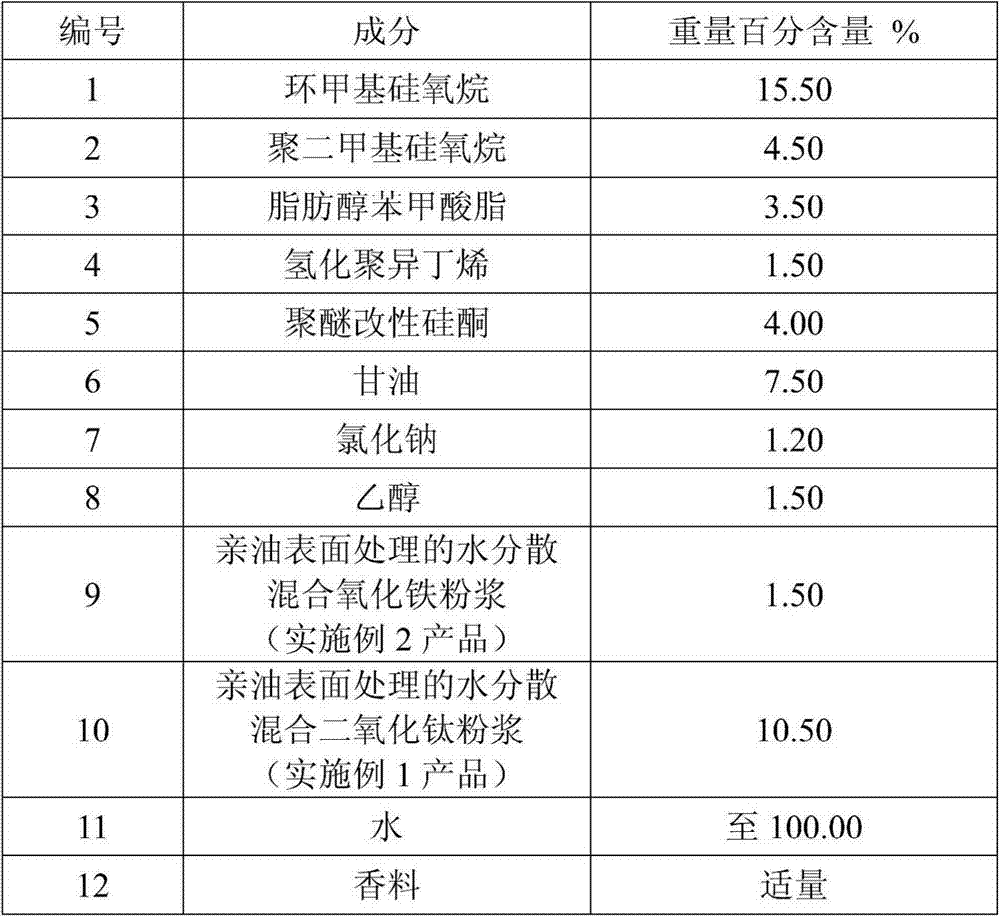

[0042] Embodiment 3:: the manufacture of foundation, its component and proportioning are as shown in table 1:

[0043] Table 1

[0044]

[0045]

[0046] At 80°C, the oil phase mixed components (1) to (5) were uniformly dissolved. Slowly add the water phase obtained by uniformly mixing and dissolving components (6) to (11) at 80°C to the oil phase, disperse uniformly with a homomixer and cool, add components (12) and (13), and stir Then make the foundation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com