Medicine plate baiting mechanism of box packing machine

A cartoning machine, medicine plate technology, applied in packaging and other directions, can solve the problem of no discovery, and achieve the effect of simple mechanism and convenient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

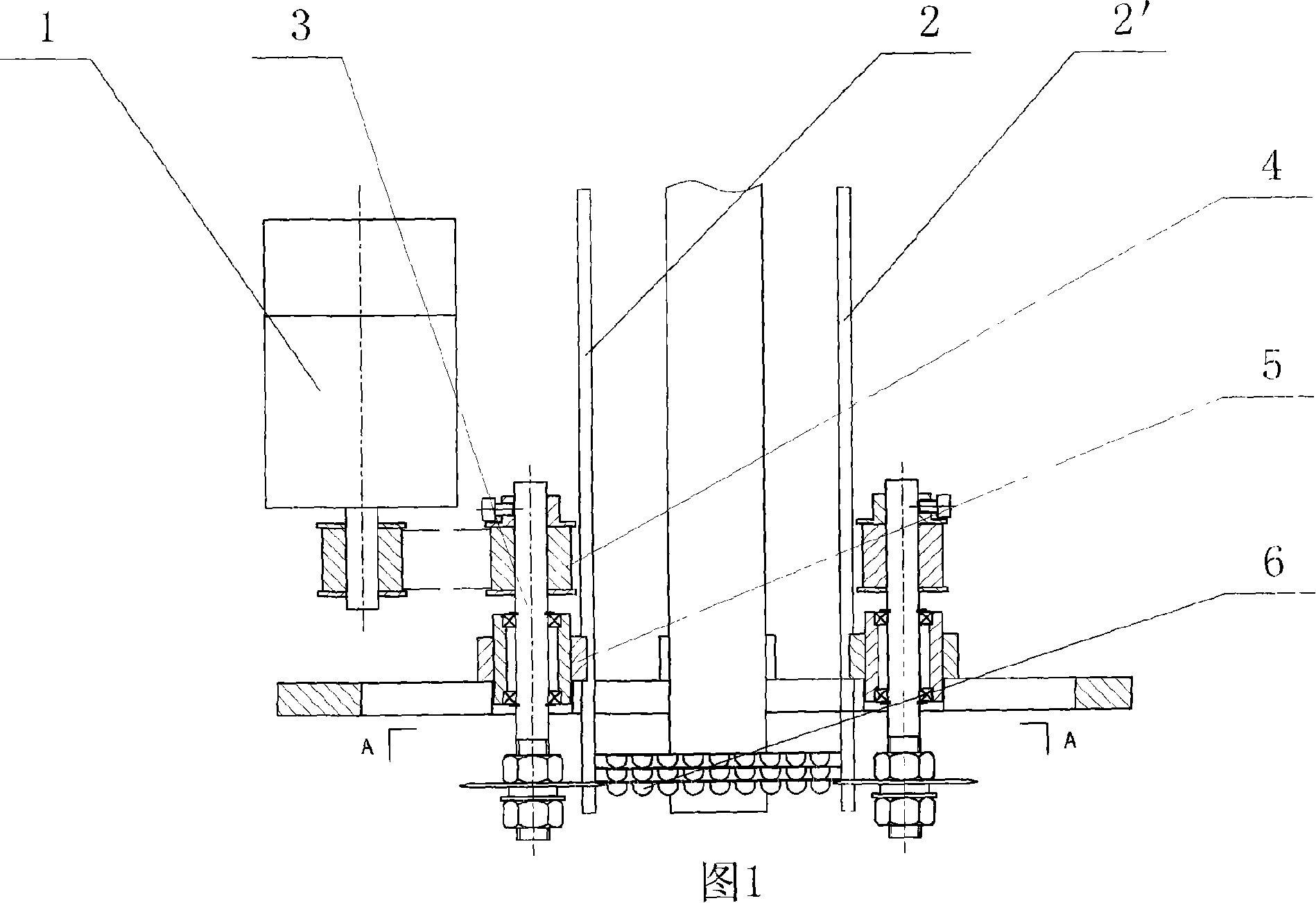

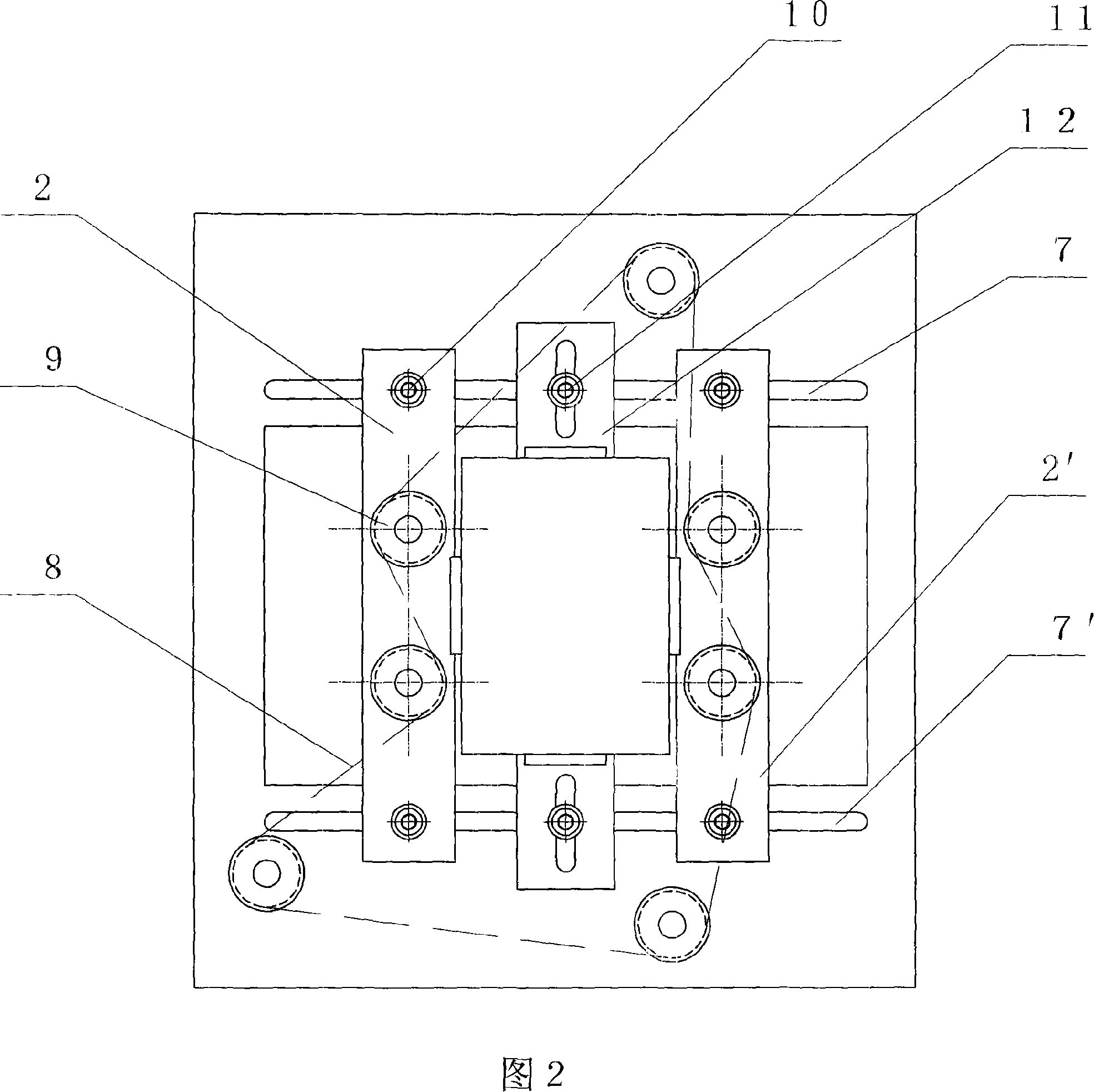

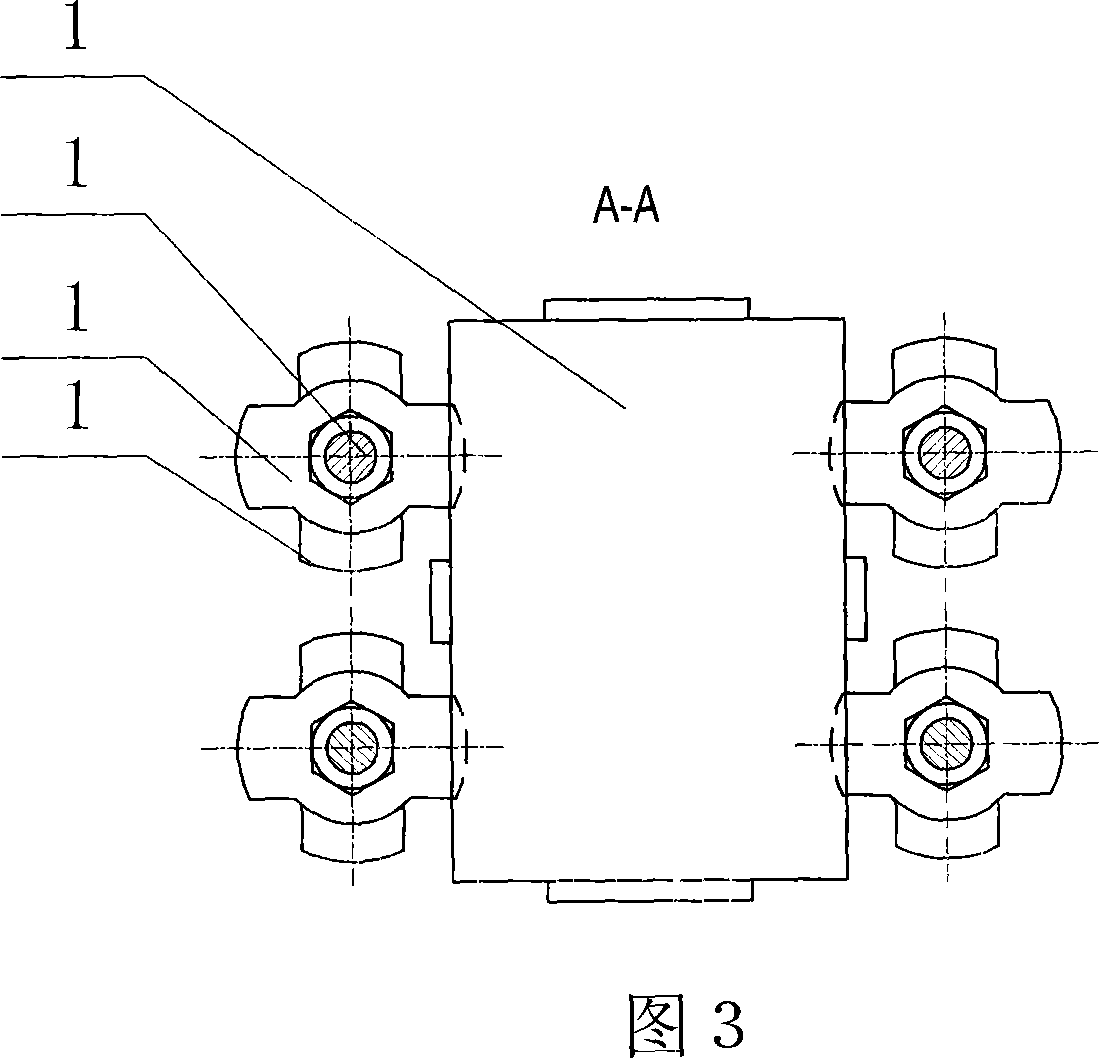

[0010] As shown in the figure, the drug plate blanking mechanism of the cartoning machine includes a motor 1 and a material warehouse. The motor adopts a servo motor and is electrically connected to a programmable controller, and the programmable controller is used to control the servo motor. The material storehouse is composed of up, down, left, and right adjustment plates, and two upper baffles 4 and lower baffles 5 are respectively installed on the left and right adjustment plates 2, 2', and the upper baffles 4 and the lower baffles 5 are fixed on the same rotating shaft 3, and set in the word "ten", the distance between the upper baffle plate 4 and the lower baffle plate 5 should be greater than the thickness of the medicine plate 6, and a synchronous wheel 9 is installed on one of the rotating shafts 3, and the synchronous wheel 9 passes through the synchronous belt 8 and The rotating shaft of the motor 1 is connected by transmission, and the other rotating shafts 3 are al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com