Residual liquid removing device

A residual liquid and liquid injection port technology, applied in the field of residual liquid removal devices, can solve the problems of high cost, low efficiency, large consumption of non-woven fabrics, etc., and achieve the effects of reducing production cost, easy waste liquid, and efficient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

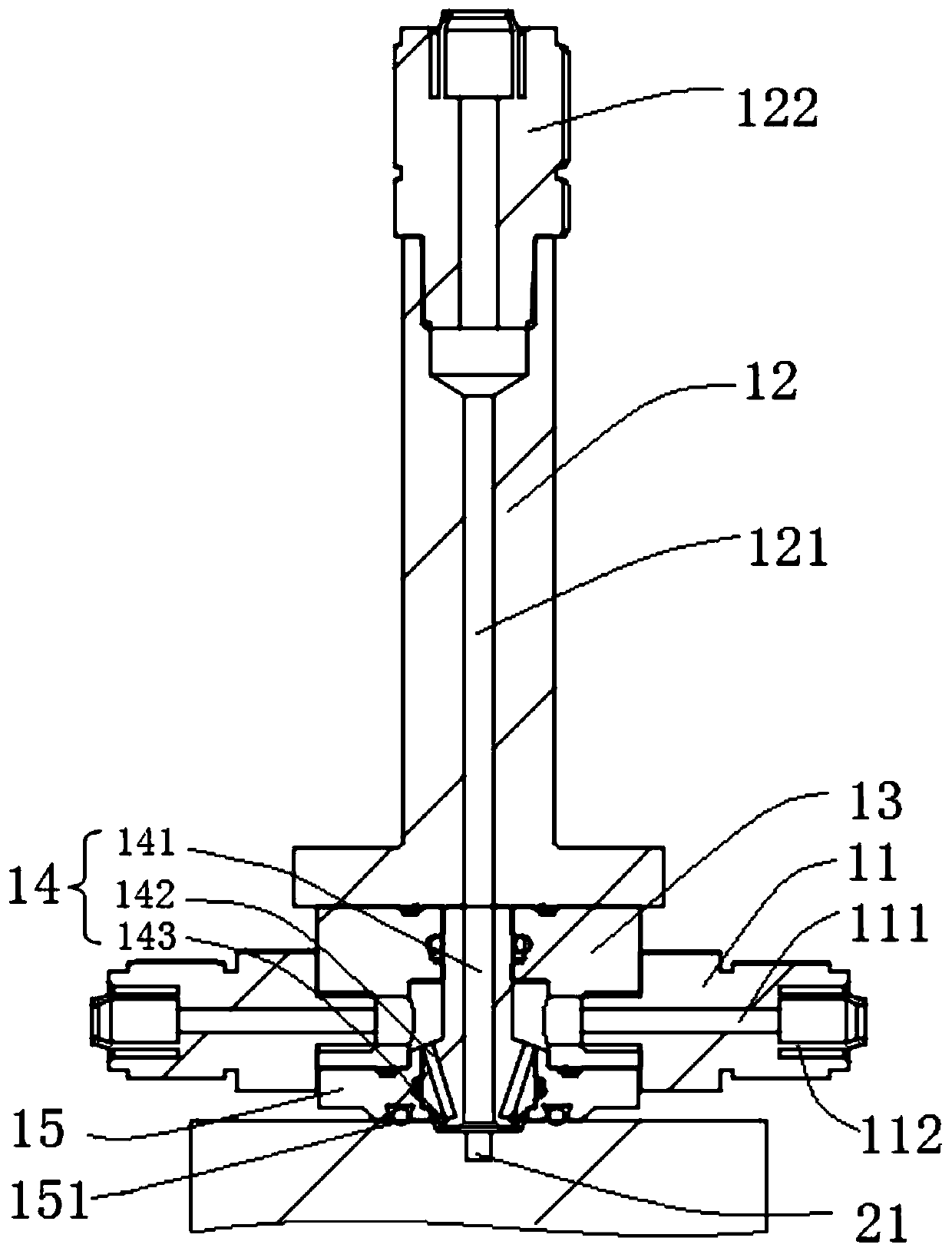

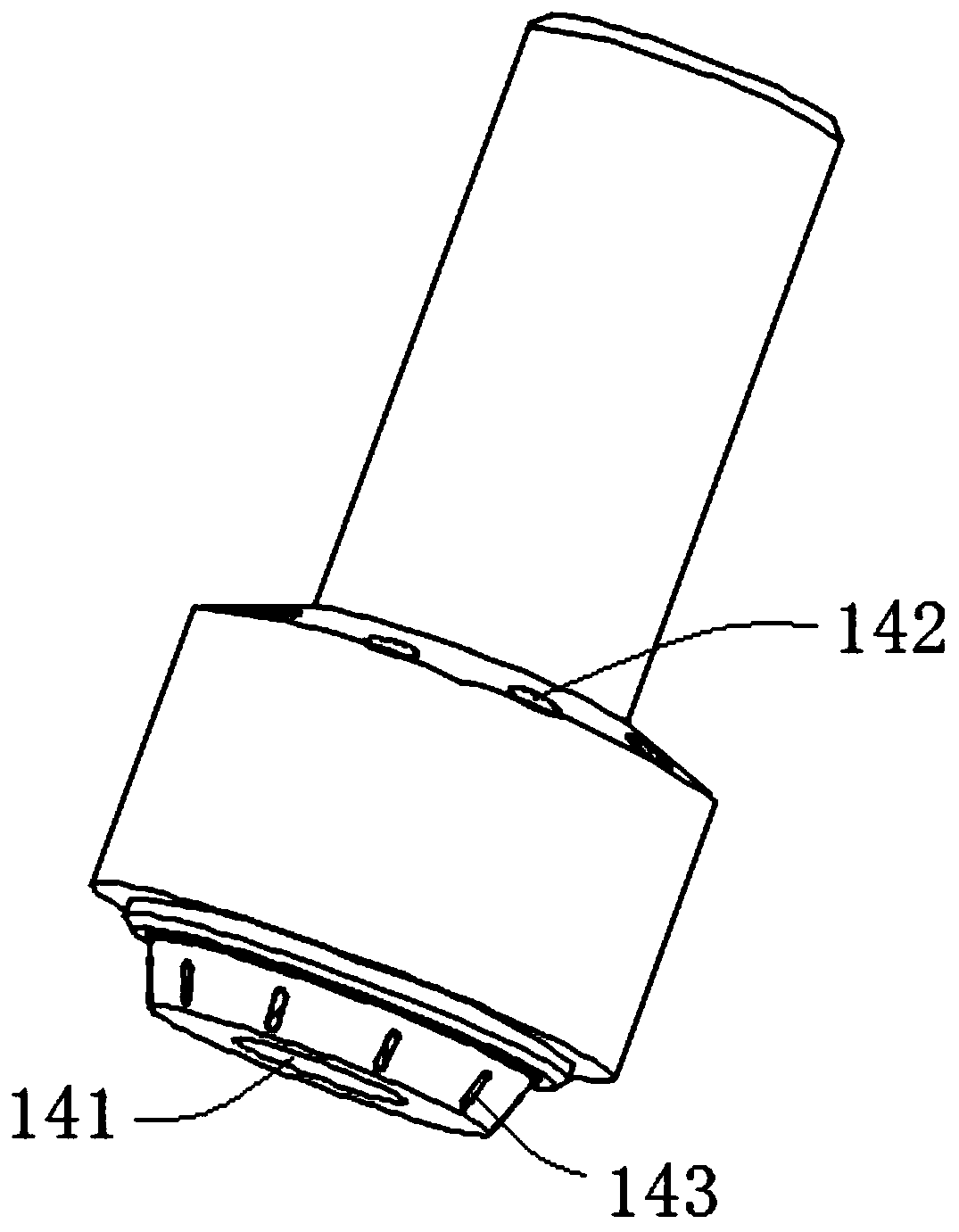

[0045]The cleaning head assembly 14 in the first embodiment is provided with a plurality of air ducts, specifically, including at least one first air duct 142 and at least one second air duct 143, the first air duct 142 and the second air duct 143 one by one Correspondingly connected, one end of the first air duct 142 communicates with the second air duct 143, and the other end communicates with the air intake pipe 11, and one end of the second air duct 143 abuts against the battery liquid injection port 21, so that the compressed air passes through the first The air channel 142 and the second air channel 143 spray on the liquid injection port 21 of the battery. In order to accelerate the compressed air passing through the first air passage 142 after entering the second air passage 143, the aperture of the first air passage 142 is larger than the aperture of the second air passage 143, and the first air passage 142 and the second air passage 143 If the first air duct 142 is ar...

Embodiment 5

[0057] The cleaning head assembly 54 provided in the fifth embodiment differs from the fourth embodiment in that a second air passage 542 and a third air passage 543 are respectively provided at the ends of the first air passage 541, and the second air passage 542 and the third air passage 543 The ends of the third air channel 543 are all in contact with the battery liquid injection port 21, so that the compressed air can be sprayed at the battery liquid injection port 21 from two directions, and the atomization effect is improved. It should be noted that the designer can choose a reasonable combination method according to actual needs, that is, the first air duct 541 can be combined with the second air duct 542 and the third air duct 543, or one of them can be combined, as long as it can Realizing the atomization effect is all allowed by this application.

[0058] The residual liquid removal device provided in Embodiments 3 to 5 includes at least one inlet pipe 11 (eight inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com