Method for producing soluble polyester fiber sirospun untwisted towel yarn

A technology of polyester fiber and production method, which is applied in the field of siro-spun non-twisted towel yarn of easily soluble polyester fiber, can solve the problem of unsatisfactory quality of non-twisted towel yarn, poor towel softness and water absorption, and water-soluble vinylon is not easy to dissolve, etc. problem, to achieve the effect of excellent softness and warmth retention, stable loop shape, and strong water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

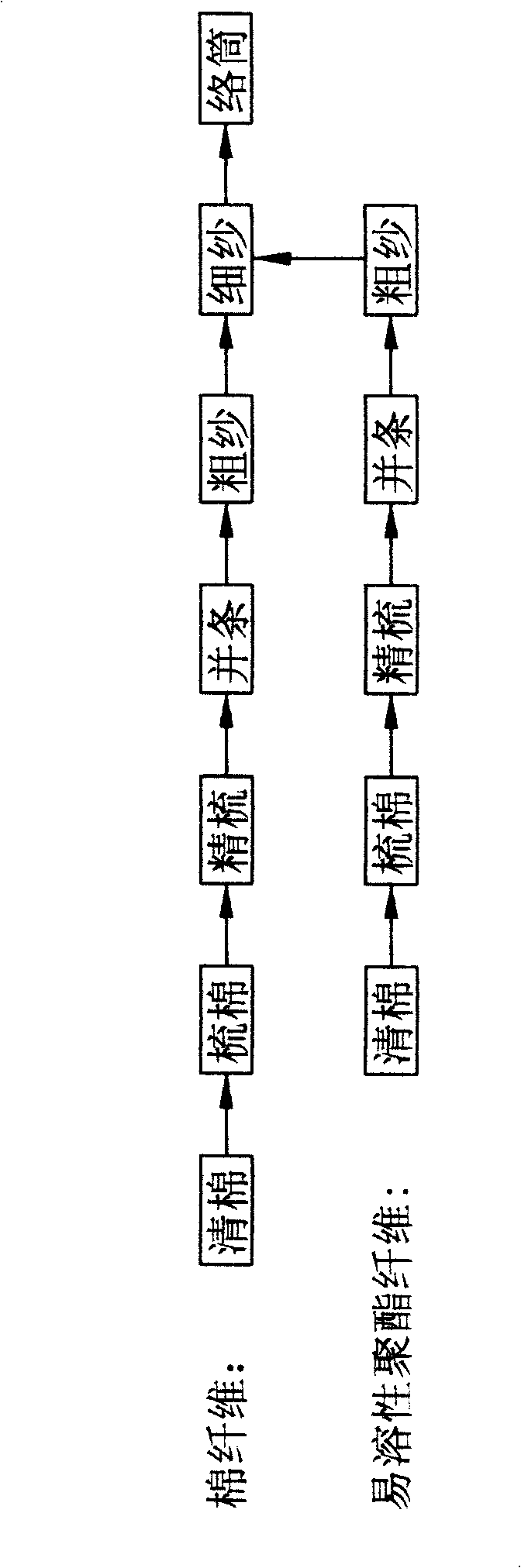

[0010] A kind of production method of soluble polyester fiber siro spinning untwisted towel yarn of the present invention, its technological process is as follows: (the blending ratio of soluble polyester fiber and cotton fiber is soluble polyester fiber content accounts for total fiber 25% of the amount)

[0011] 1. Cotton cleaning

[0012] 1. Make full use of the loosening and cleaning effect of the cotton box mechanical beater, and use no or less air supplementation in the trash area to reduce the recovery of fine impurities and increase the trash;

[0013] 2. Appropriately slow down the speed of the lap roller of the cleaning machine to about 12r / min, and at the same time speed up the cotton feeding speed of each opening and counting;

[0014] 3. On the premise of ensuring the quantitative process, increase the mechanical operation speed of the cotton box, strengthen the cotton stripping effect, achieve less flower return, less tumbling, and reduce bunching and neps.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com