Preparation method suitable for industrial production and used for nano lithium titanate

A technology of nano-lithium titanate and lithium titanate, which is applied in the direction of electrochemical generators, electrical components, battery electrodes, etc., can solve the problem of unsuitable industrial production of nano-lithium titanate materials, unsuitable for industrial production, and difficult control of process conditions, etc. problems, to achieve the effect of short electron conduction path, cheap raw materials, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

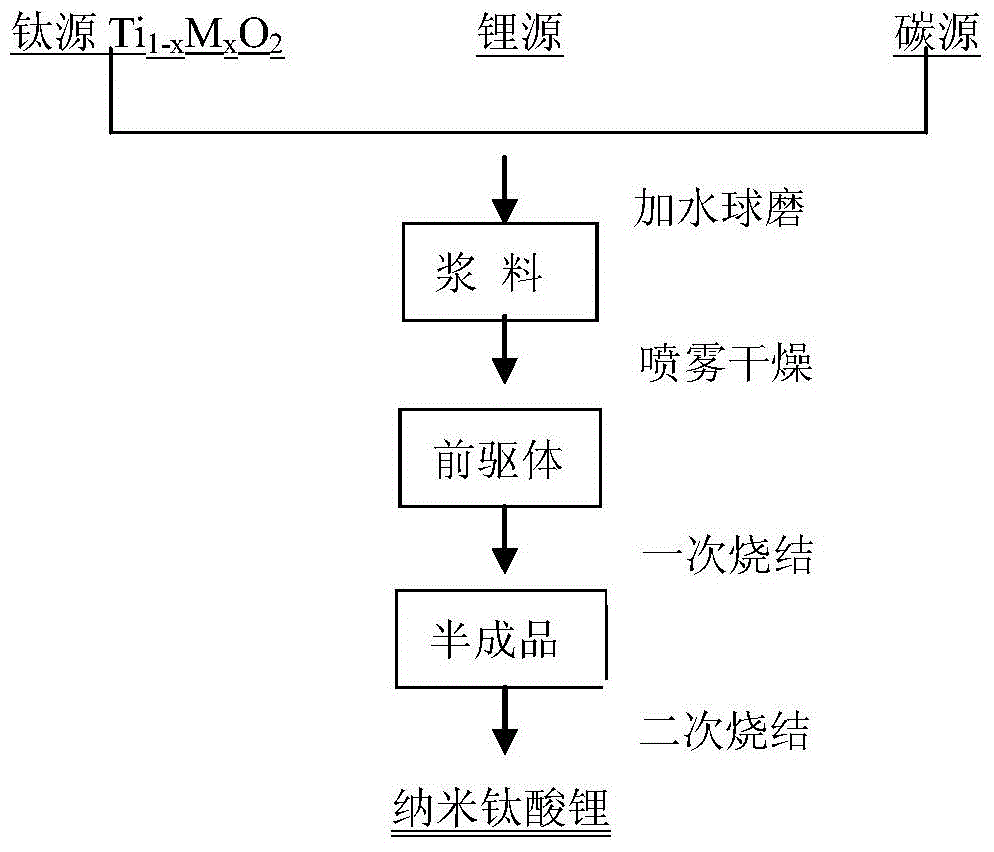

[0040] Such as figure 1 Process flow shown. Get the amorphous Ti of 50kg particle average particle size 50nm 0.99 Zr 0.01 o 2 as titanium source, Li 2 CO 3 Lithium source, according to the ratio Li:(Ti 0.99 Zr 0.01 ) (mol%)=4:5; glucose is the carbon source, and the raw materials are weighed according to the carbon content accounting for 2wt% of the final synthesized lithium titanate; pure water is added as a dispersant, and the solid content is adjusted to 50wt%, and the ball mill is mixed evenly Finally, the mixed slurry of the precursor was obtained; using spray drying equipment, the inlet temperature of the hot gas nozzle was 120°C, the outlet temperature was 100°C, the flow rate of the slurry inlet was 20ml / min, and the flow rate of the gas inlet was 30m 3 / h, spray-dry the slurry to obtain dry and loose lithium titanate precursor powder; the gained powder is placed in an atmosphere furnace and fed with N 2 Insulate at 750°C for 8 hours, naturally cool to room tem...

Embodiment 2

[0044] Such as figure 1 Process flow shown. Use 200kg of anatase Ti with an average particle size of 100nm 0.98 al 0.02 o 2 as titanium source, Li 2 CO 3 Lithium source, according to the ratio Li:(Ti 0.98 al 0.02 ) (mol%)=4:5; carboxymethyl cellulose is the carbon source, and each raw material is weighed according to the carbon content accounting for 0.5wt% of the synthesized lithium titanate; distilled water is added as a dispersant, and the solid content is adjusted to 40wt%. Mix uniformly by ball milling to obtain the mixed slurry of the precursor; use spray drying equipment, the inlet temperature of the hot gas nozzle is 180°C, the outlet temperature is 100°C, the flow rate of the slurry inlet is 30ml / min, and the flow rate of the gas inlet is 40m 3 / h, spray-dry the slurry to obtain dry and loose lithium titanate precursor powder; the gained powder is placed in an atmosphere furnace and fed with N 2 Insulate at 780°C for 12 hours, cool naturally to room temperatur...

Embodiment 3

[0046] Such as figure 1 Process flow shown. Use 500kg of anatase Ti with an average particle size of 60nm 0.995 Na 0.005 o 2 as titanium source, Li 2 CO 3 Lithium source, according to the ratio Li:(Ti 0.995 Na 0.005 ) (mol%)=4:5; polyethylene glycol is the carbon source, and each raw material is weighed according to the carbon content accounting for 1wt% of the synthesized lithium titanate; ultrapure water is added as a dispersant, and the solid content is adjusted to 55wt%, Mix uniformly by ball milling to obtain the mixed slurry of the precursor; using spray drying equipment, the inlet temperature of the hot gas nozzle is 200°C, the outlet temperature is 120°C, the slurry inlet flow rate is 25ml / min, and the gas inlet flow rate is 50m 3 / h, spray-dry the slurry to obtain dry and loose lithium titanate precursor powder; the gained powder is placed in an atmosphere furnace and fed with N 2 Insulate at 770°C for 16 hours, cool naturally to room temperature and sieve. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com