Large valve cleaning production line

A production line and valve technology, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of poor cleaning effect and low cleaning efficiency of large valves, and achieve good cleaning effect and high cleaning efficiency , the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a large-scale valve cleaning production line, comprising:

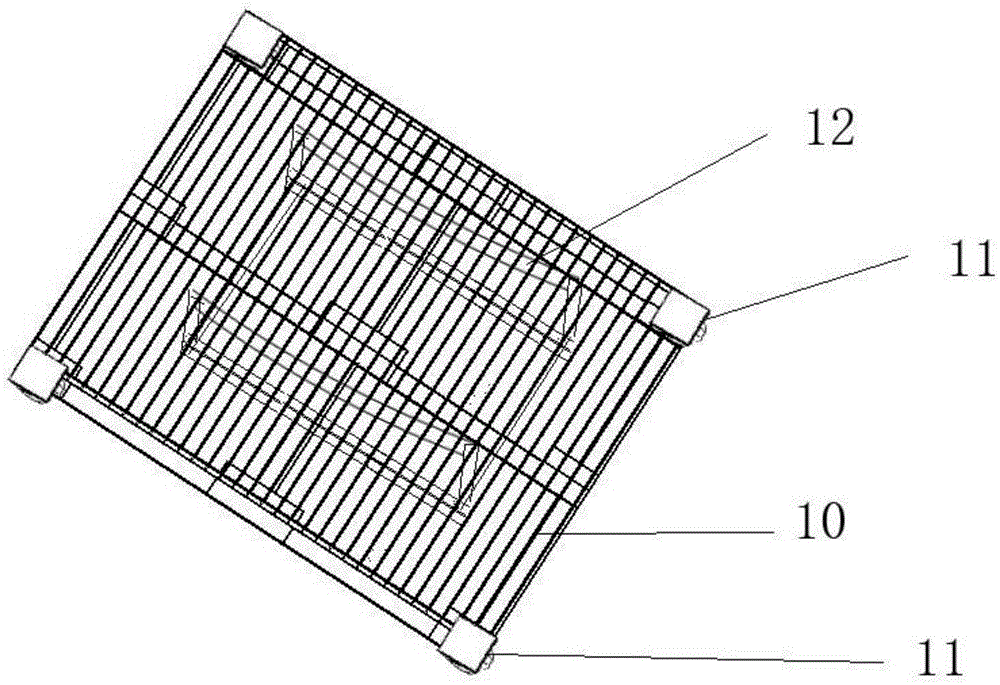

[0043] carrying device, such as figure 1 As shown, the bottom is hollowed out to carry and fix the valve;

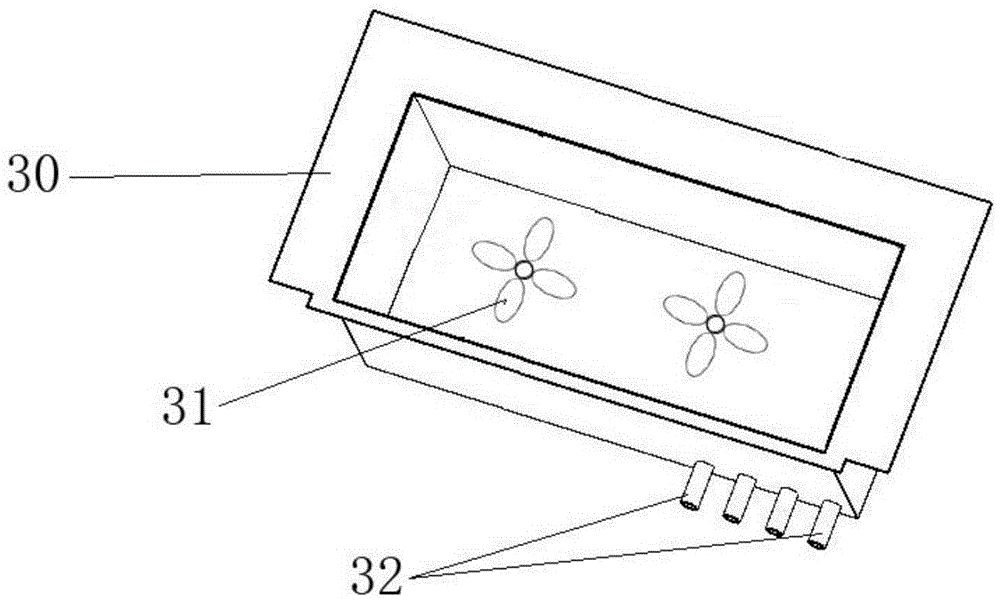

[0044] The cleaning device sequentially includes a first immersion device for rinsing the valve with cleaning liquid, a spray rinsing device for rinsing the valve in six mutually perpendicular directions with cleaning liquid, and a cleaning device for rinsing the valve with clean water. The second rinsing device for rinsing the valve, the air heating drying device for spraying hot air on the valve to dry the valve, the spraying and rinsing device includes a bottom cleaning device, an upper cleaning device, a front cleaning device, and a rear cleaning device. device, left cleaning device and right cleaning device, each cleaning device has several water outlets;

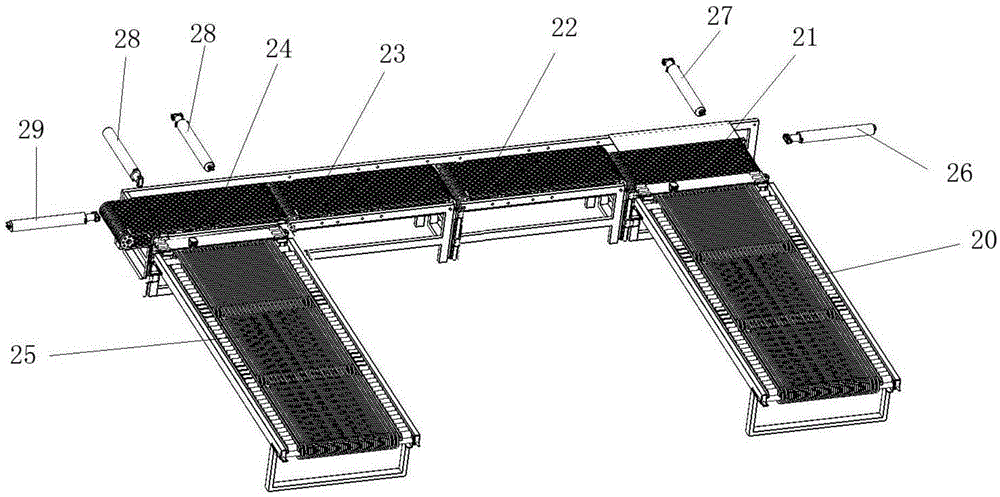

[0045] transmission devices such as figure 2 As shown, four toothed chain conveyor belts set independently of each o...

Embodiment 2

[0074] This embodiment provides a large-scale valve cleaning method, adopting the large-scale valve production line described in Embodiment 1, comprising the following steps,

[0075] S1: Use the cleaning solution to soak the valve. In this step, use the paddle to stir the cleaning solution. The rotation speed of the paddle is 100-150r / min, such as 100r / min, 120r / min, 150r / min, etc. The rotation time of the paddle is 40-50min, such as 40min, 45min, 50min, etc. After using the paddle to stir the cleaning liquid, it also includes the process of cleaning the valve with ultrasonic waves. The ultrasonic frequency is 28kHz-35kHz, such as 28kHz, 30kHz, 35kHz etc., the power is 2-2.5w / cm 2 , such as 2w / cm2 , 2.2w / cm 2 , 2.5w / cm 2 etc., ultrasonic cleaning time is 20-40min, such as 20min, 30min, 40min, etc.;

[0076] S2: Use cleaning liquid to flush the valve in six mutually perpendicular directions. In this step, the spray speed of cleaning liquid is 30-40m / s, such as 30m / s, 35m / s,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com