Dry type iron-core starting reactor for cold water medium-pressure unit of air conditioner

A technology for starting electricity and cooling water, which is applied in the direction of motor generator/starter, transformer/inductor core, transformer/inductor parts, etc. It can solve the problems of low insulation level, large separation distance, and low electric strength. Achieve the effect of enhancing insulation strength, saving material cost, and good effect of impregnating paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable the public to fully understand the technical essence and beneficial effects of the present invention, the applicant will describe in detail the specific implementation of the present invention below in conjunction with the accompanying drawings, but the applicant's description of the embodiments is not a limitation to the technical solution. Changes in the form of the inventive concept rather than in substance should be regarded as the protection scope of the present invention.

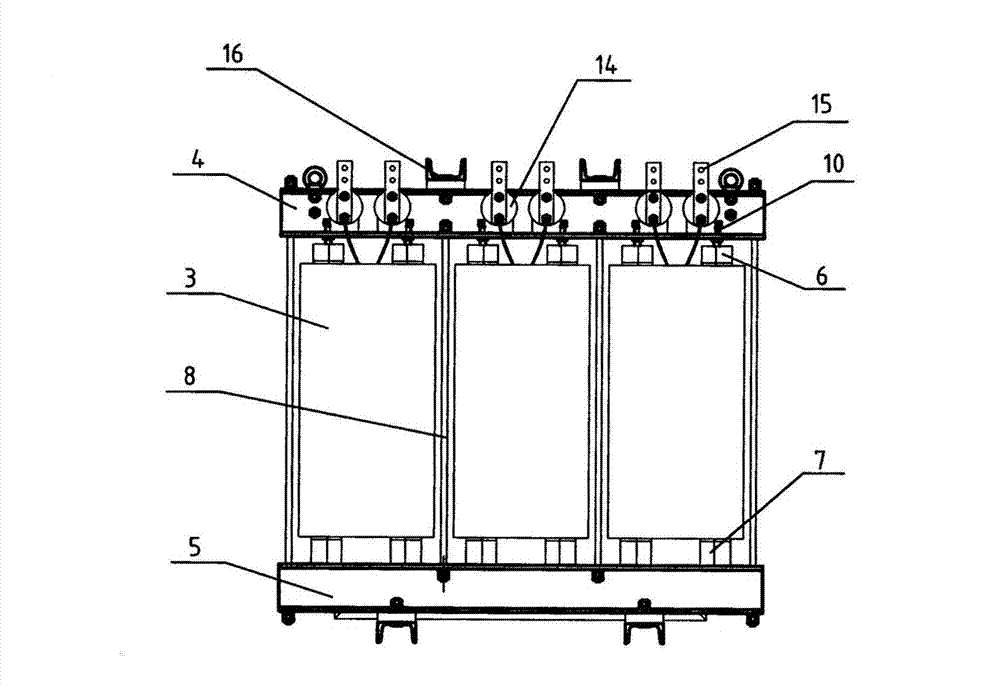

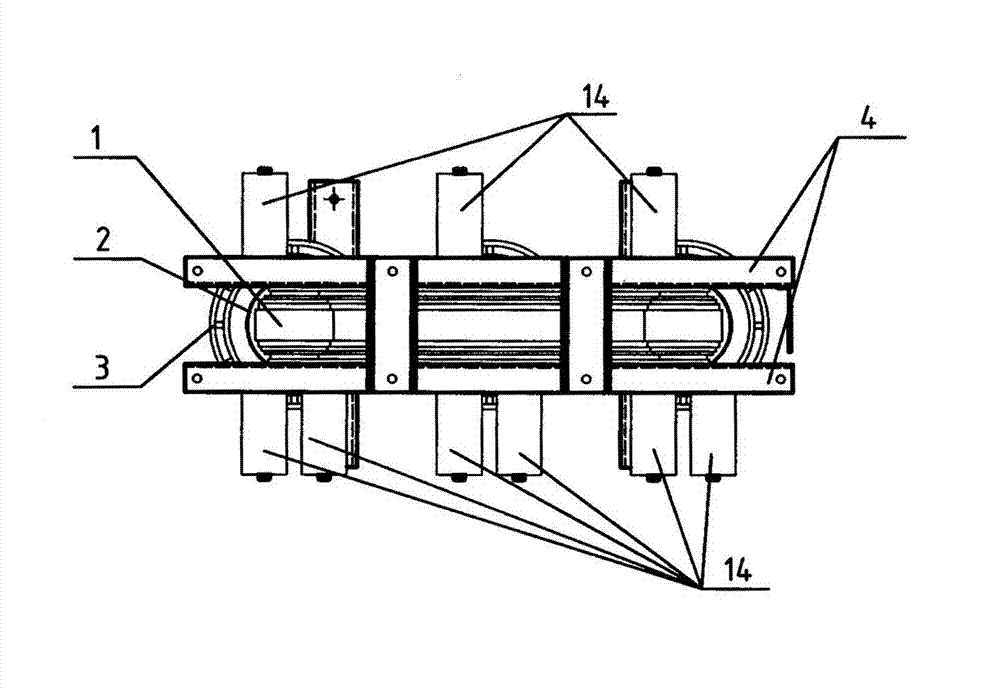

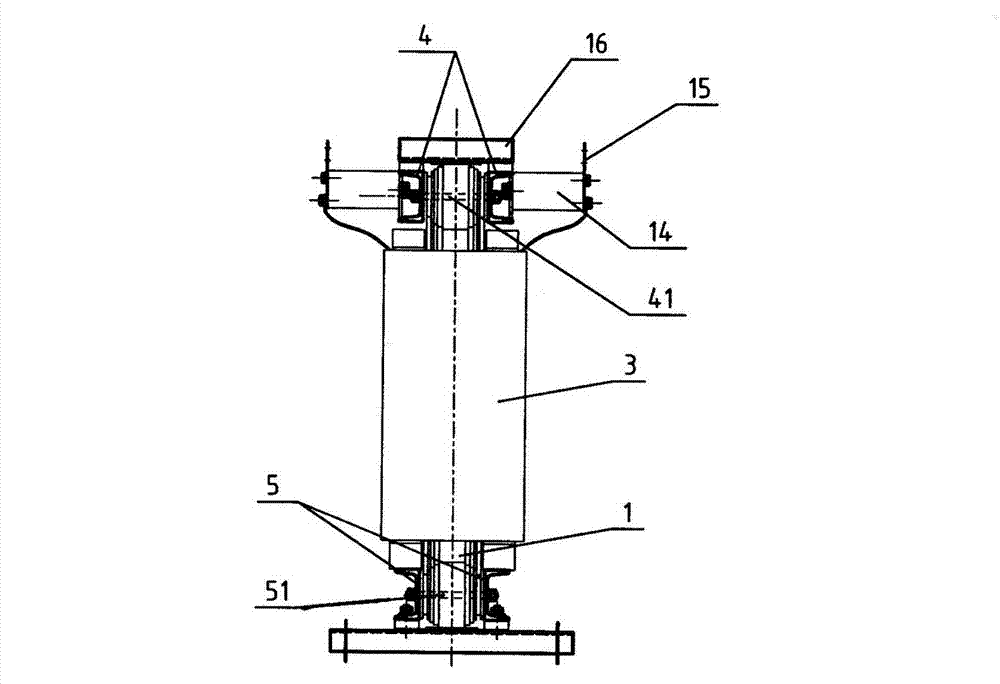

[0020] see figure 1 , figure 2 , image 3 and combine Figure 4 , Figure 5 , a dry-type iron-core starting reactor for air-conditioning cold water pressure units, including an iron core 1, an insulating cylinder 2, a coil 3 wound on the outside of the iron core 1, a pair of upper clamps 4, and a pair of lower clamps 5 , Upper spacer 6, lower spacer 7, pull screw 8, first strut 9, second strut 9' and pressure nail 10. The iron core 1 is formed by stacking silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com