Environment-friendly fiber framework material impregnation liquid, preparation method thereof and application of liquid

A fiber skeleton and dipping liquid technology, applied in the field of dipping liquid, can solve problems such as harm to human health and environmental pollution, and achieve the effects of reducing occupational hazards, easy operation and good dipping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

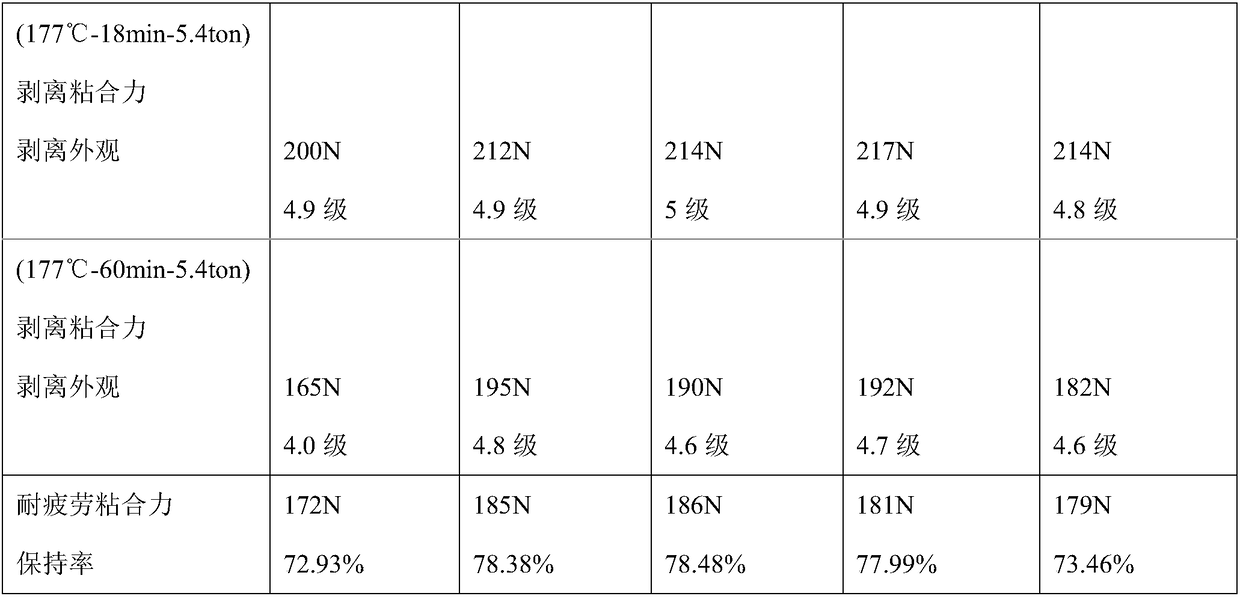

Examples

preparation example Construction

[0025] The preparation process of the environment-friendly fiber skeleton material dipping liquid is as follows: stirring and aging the raw material components at 20-35° C. for 6-12 hours.

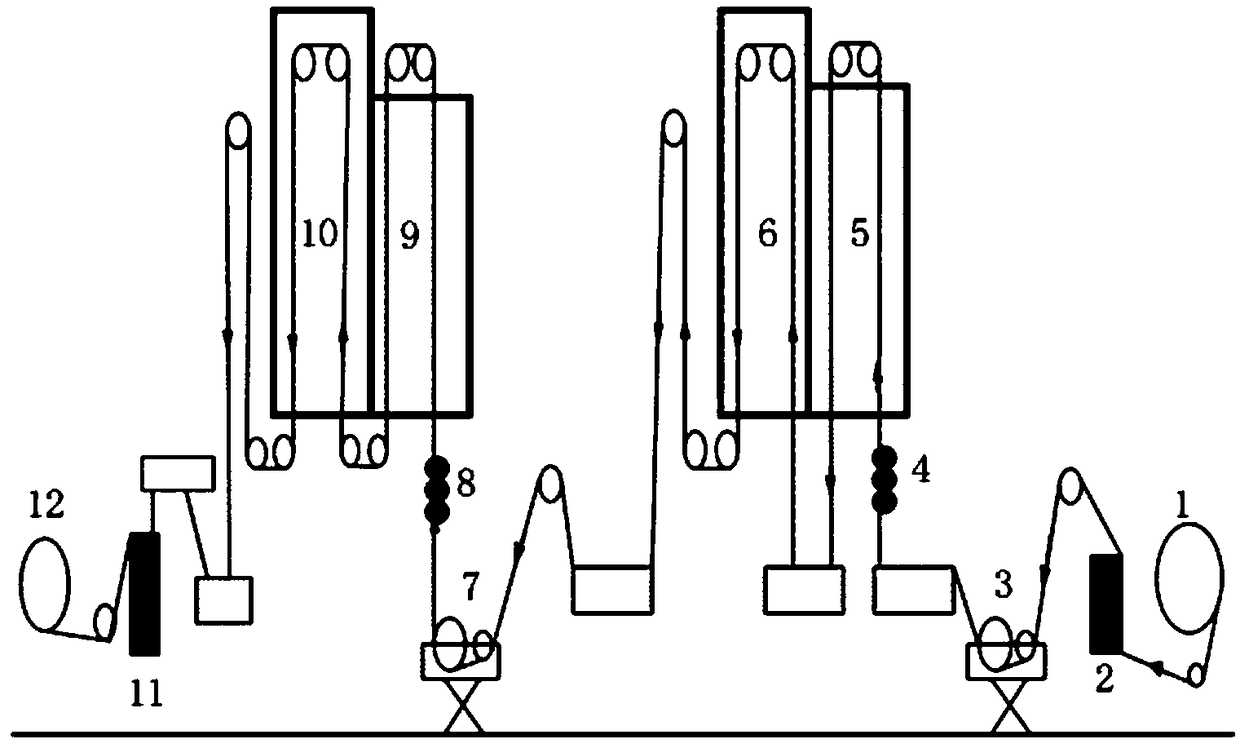

[0026] The dipping process of the environmentally friendly fiber skeleton material dipping solution: the fiber skeleton material is coated with the dipping solution by a two-bath dipping method; the fiber skeleton material is first immersed in the first bath dipping solution, and the dipping After drying and heat treatment, dry at 100-200 ° C, heat treatment at 180-240 ° C for 0.1-10 minutes; after the first bath of dipping liquid treatment, then dip in the environment-friendly fiber skeleton material dipping liquid , drying at 100-200°C, and heat treatment at 180-240°C for 0.1-10min.

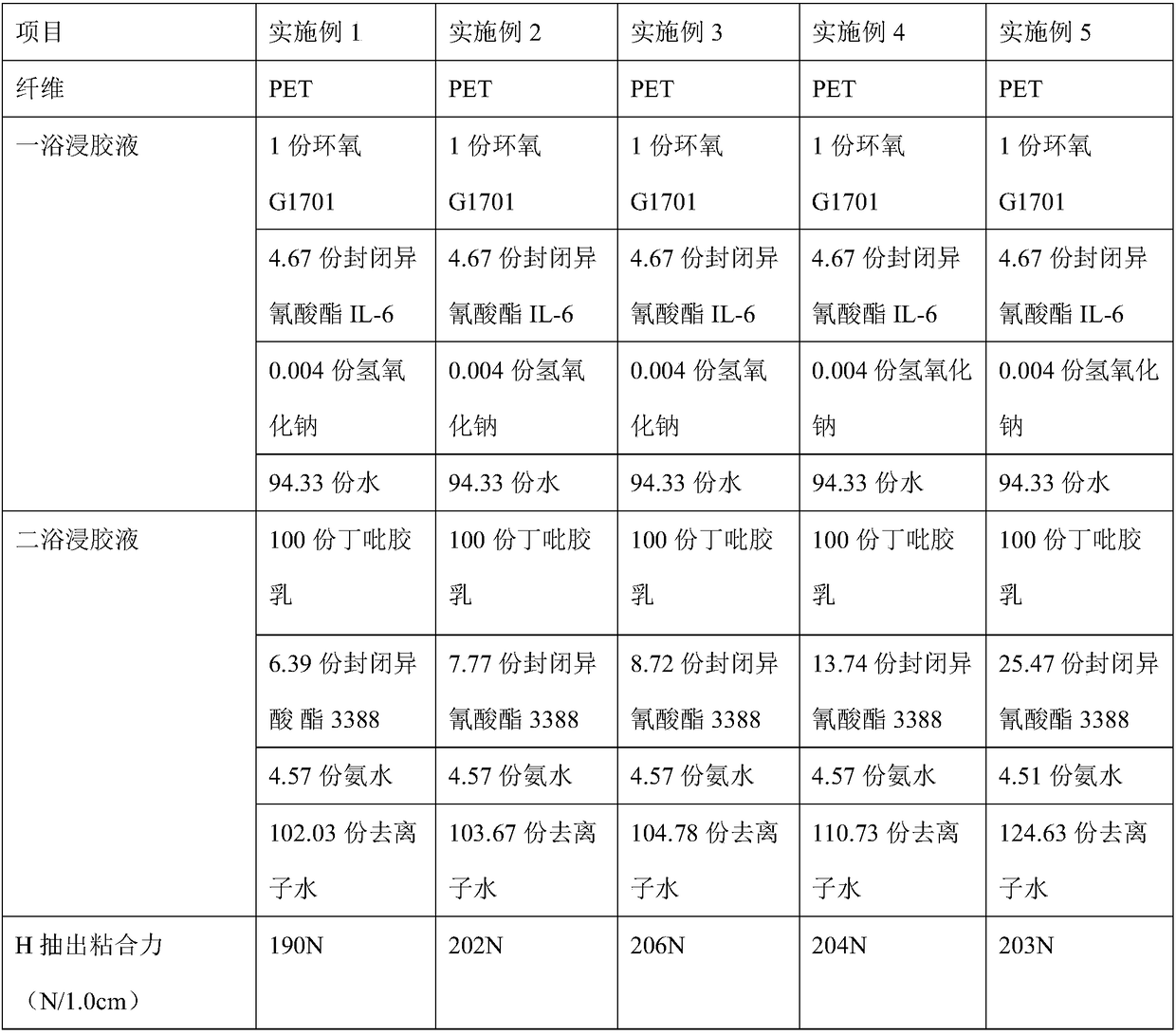

[0027] The formula of the first bath dipping solution is: the mass content of each component is 0.003%-0.005% of sodium hydroxide, 0.5%-2% of polyfunctional glycidyl ether, 2%-8% of caprolactam-blocked isoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com