Honeycomb preparation process

A preparation process and honeycomb technology, applied in the field of preparation of honeycomb structural materials, can solve the problems affecting the quality of honeycomb products, difficult to control the uniformity of dipping, and uneven density of honeycomb blocks, so as to improve quality and market competitiveness, easy to operate, Even dipping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

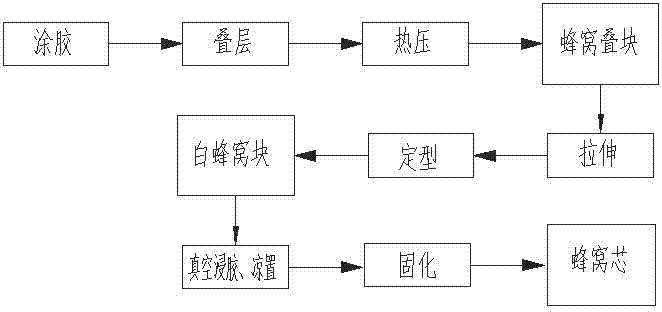

[0032] Such as Figure 1-2 As shown, a grid hole has a side length of 1.83mm and a density of 48kg / m 3 The preparation technology of aramid paper honeycomb comprises the following steps:

[0033] (1) Use the aramid paper with a thickness of 0.04mm as the base material, use the glue roller embedded with the core strip glue to apply the glue, then stack the multi-layer glued aramid paper in staggered layers, and finally heat it with a hot press machine Press to make a honeycomb stack. When hot pressing, preheat the hot press at 100°C for 30-60 minutes, gel: 120-160°C for 90-150 minutes, cure: 170-190°C for 2-4 hours, and press at a pressure of 5-7 MPa.

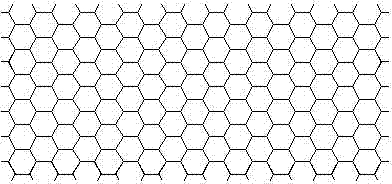

[0034] (2) Stretch the honeycomb laminated block through a stretching machine at 5-25mm / min to form a figure 2 The regular hexagonal honeycomb cells shown in the figure are then shaped in an oven at a high temperature at 200-250°C for 1-2 hours to make a white honeycomb block.

[0035] (3) Dipping the white honeycomb block ...

Embodiment 2

[0045] Such as Figure 1-2 As shown, a grid hole has a side length of 4.5mm and a density of 100kg / m 3 The preparation process of carbon fiber honeycomb comprises the following steps:

[0046] (1) Use carbon fiber cloth with a thickness of 0.2mm as the base material, apply glue with a glue roller embedded with core strip glue, then laminate the carbon fiber cloth after multi-layer glue coating, and finally use a hot press machine to heat press, Made into honeycomb stacks. When hot pressing, preheat the hot press at 100°C for 30-60 minutes, gel: 120-160°C for 90-150 minutes, cure: 170-190°C for 2-4 hours, and press at a pressure of 5-7 MPa.

[0047] (2) Stretch the honeycomb laminated block through a stretching machine at 5-25mm / min to form a figure 2 The regular hexagonal honeycomb cells shown in the figure are then shaped in an oven at a high temperature at 200-250°C for 1-2 hours to make a white honeycomb block.

[0048](3) Dipping the white honeycomb block at least onc...

Embodiment 3

[0058] Such as Figure 1-2 As shown, a grid hole has a side length of 2.75mm and a density of 144kg / m 3 The preparation technology of aramid paper honeycomb comprises the following steps:

[0059] (1) Use the aramid paper with a thickness of 0.2mm as the base material, use the glue roller embedded with the core glue to apply the glue, and then laminate the multi-layer glued aramid paper, and finally heat it with a hot press machine Press to make a honeycomb stack. When hot pressing, preheat the hot press at 100°C for 30-60 minutes, gel: 120-160°C for 90-150 minutes, cure: 170-190°C for 2-4 hours, and press at a pressure of 5-7MPa.

[0060] (2) Stretch the honeycomb laminated block through a stretching machine at 5-25mm / min to form a figure 2 The regular hexagonal honeycomb cells shown in the figure are then shaped in an oven at a high temperature at 200-250°C for 1-2 hours to make a white honeycomb block.

[0061] (3) Dipping the white honeycomb block at least once in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com