High-gloss polypropylene-based powder coating as well as preparation method and application thereof

A polypropylene-based, powder coating technology, applied in the direction of powder coatings, coatings, etc., can solve the problems of weak resin leveling, weak reflective effect, pinholes, etc., to achieve strong coverage, improve product gloss, and strong light The effect of reflexes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

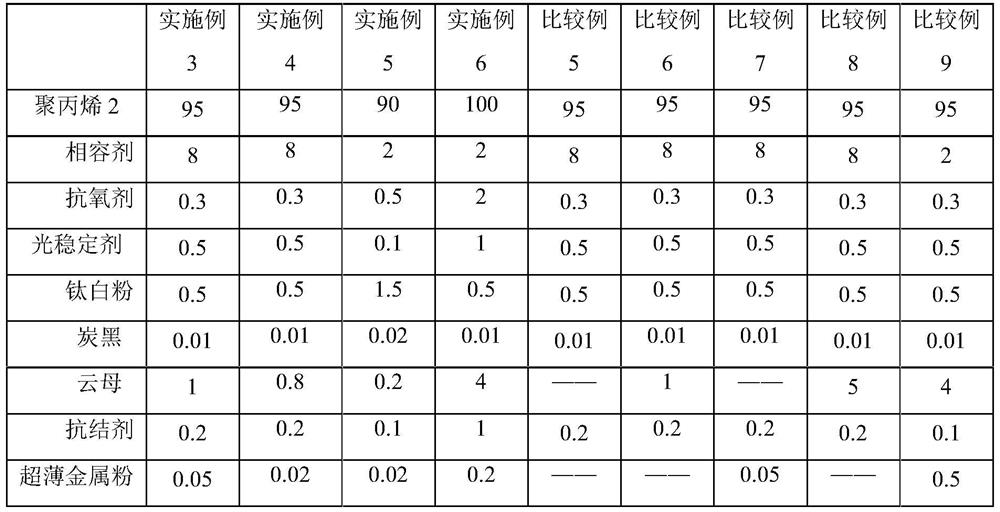

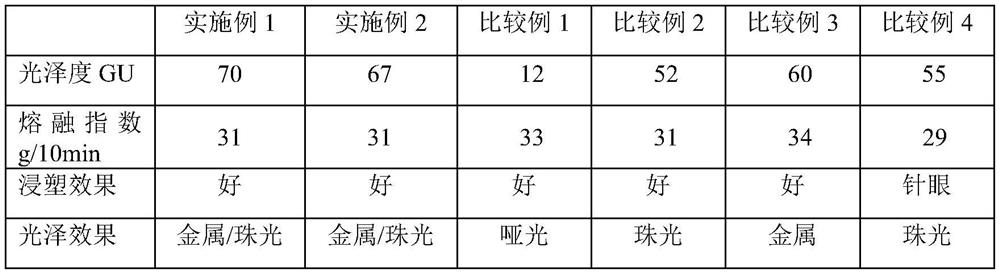

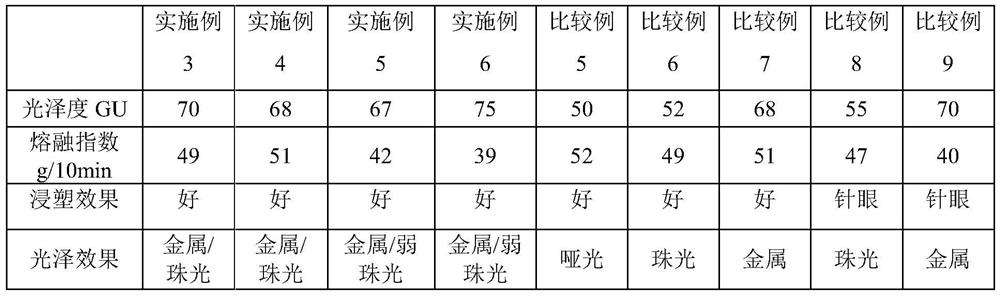

[0021] The present invention will be further described below in conjunction with the examples, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

[0022] The raw materials involved in the following examples and comparative examples and suppliers are as follows:

[0023] Polypropylene 1: BX3800, SK chemical, South Korea;

[0024] Polypropylene 2: R390, SK chemical, South Korea;

[0025] Compatibilizer: CMG5701, Jiayirong Polymer (Shanghai) Co., Ltd.;

[0026] Antioxidant: Antioxidant 1010 (Irganox 1010), CAS No.: 6683-19-8, BASF, Germany;

[0027] Light stabilizer: light stabilizer 622 (Tinuvin 622), CAS number: 65447-77-0, BASF, Germany;

[0028] Titanium dioxide: R907, DuPont, USA;

[0029] Carbon black: 660R, Ningbo Haishu Yongshen Trading Co., Ltd.;

[0030] Mica powder: HZ760M, Changzhou Huazhu Pigment Co., Ltd.;

[0031] Anticaking agent: Aerosil R972...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com