Reusing treatment immersion cleaning agent for PET bottle flake

A technology of dipping and bottle flakes, which is applied in the direction of detergent compounding agent, detergent composition, surface active detergent composition, etc., which can solve the problem of no removal of pollutants, unreachable washing effect, and non-targeting, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

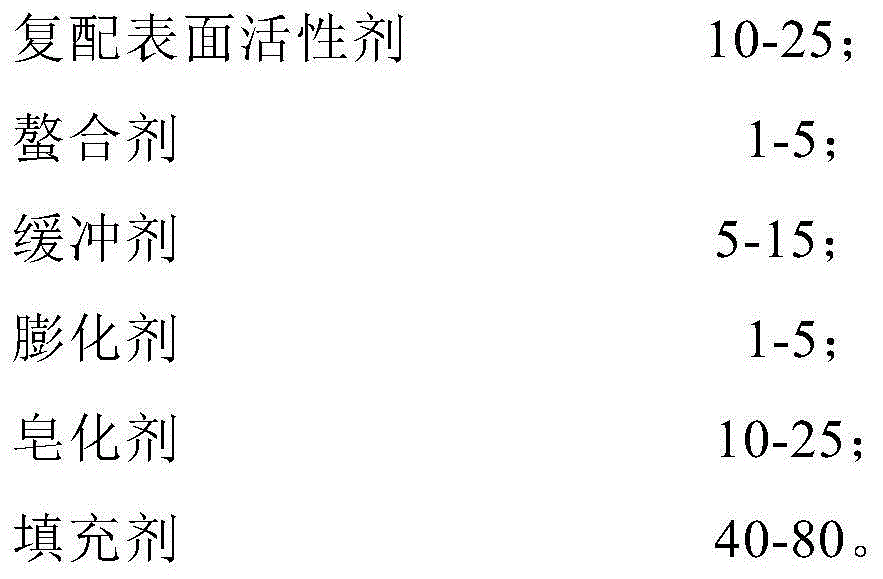

[0033] A kind of PET bottle flake reuse processing soaking agent, is formed by mixing the raw materials of following components and parts by weight:

[0034]

[0035] The detergent can be prepared as a powder by general drying or vacuum drying, and is suitable for soaking recycled PET bottle flakes.

[0036] When the leaching agent prepared in this example and the commercially available tablet washing agent A are used for rinsing of general PET bottle flakes (there is no similar product sold in the market, compared with PET tablet washing agent), the rinsing effects are compared as shown in Table 1 :

[0037] Table 1

[0038]

[0039] Analysis of Table 1 shows that for general PET bottle flakes, the commercially available tablet washing agent A has no rinsing effect and cannot remove the infiltration residue in the capillary pores of PET, but the rinsing agent of this embodiment can achieve the effect.

Embodiment 2

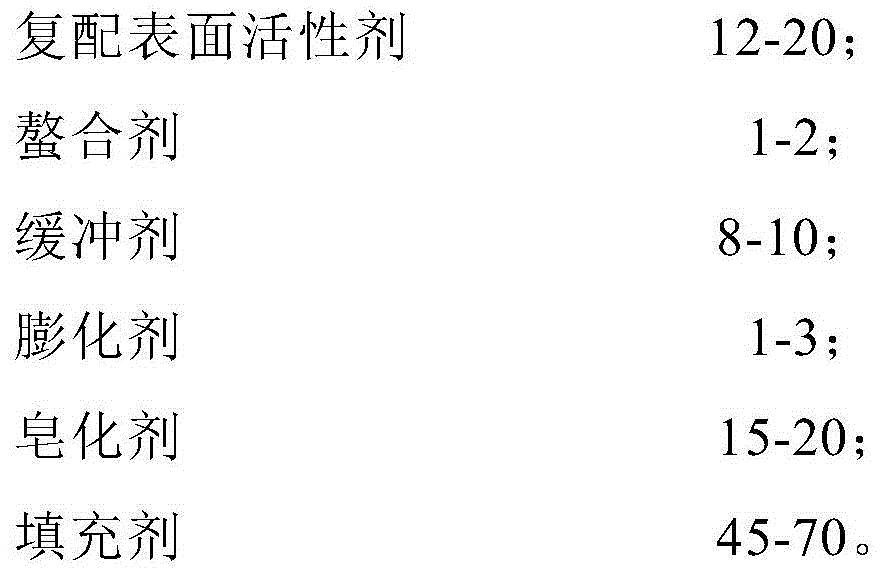

[0041] A kind of PET bottle flake reuse processing soaking agent, is formed by mixing the raw materials of following components and parts by weight:

[0042]

[0043] The detergent can be prepared as a powder by general drying or vacuum drying, and is suitable for soaking recycled PET bottle flakes.

[0044] When the leaching agent prepared in this example and the commercially available tablet washing agent B are used for rinsing PET oil bottle tablets (there is no similar product sold in the market, compared with the PET washing tablet), the rinsing effect comparison is shown in Table 2 :

[0045] Table 2

[0046]

[0047] Dilution ratio

[0048] Analysis of Table 2 shows that for PET oil bottle tablets, the commercially available washing tablet B has no soaking effect and cannot remove the infiltration residue in the capillary pores of PET, but the soaking agent of this embodiment can achieve the effect.

Embodiment 3

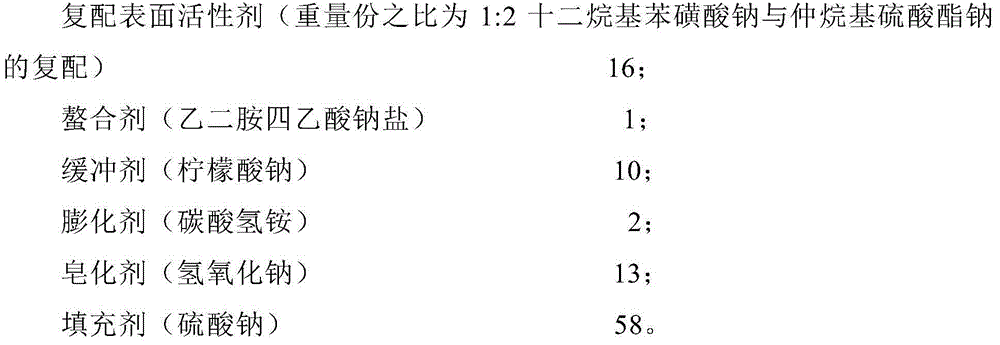

[0050] A kind of PET bottle flake reuse processing soaking agent, is formed by mixing the raw materials of following components and parts by weight:

[0051]

[0052] The detergent can be prepared as a powder by general drying or vacuum drying, and is suitable for soaking recycled PET bottle flakes.

[0053] When the leaching agent prepared in this example and the commercially available tablet washing agent C are used for rinsing of general PET bottle flakes (there is no similar product sold in the market, compared with the PET washing tablet), the rinsing effects are compared as shown in Table 3 :

[0054] table 3

[0055]

[0056] Solubility

[0057] Analysis of Table 3 shows that for general PET bottle flakes, the commercially available tablet washing agent C has no rinsing effect and cannot remove the infiltration residue in the capillary pores of PET, but the rinsing agent of this example can achieve the effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com