Building wall surface painting device

A technology for building walls and flour, applied in the direction of construction and building structure, can solve the problems of affecting the efficiency of painting, requiring a long time, and labor intensive, and achieve the effect of reducing labor intensity, improving painting effect, and improving painting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

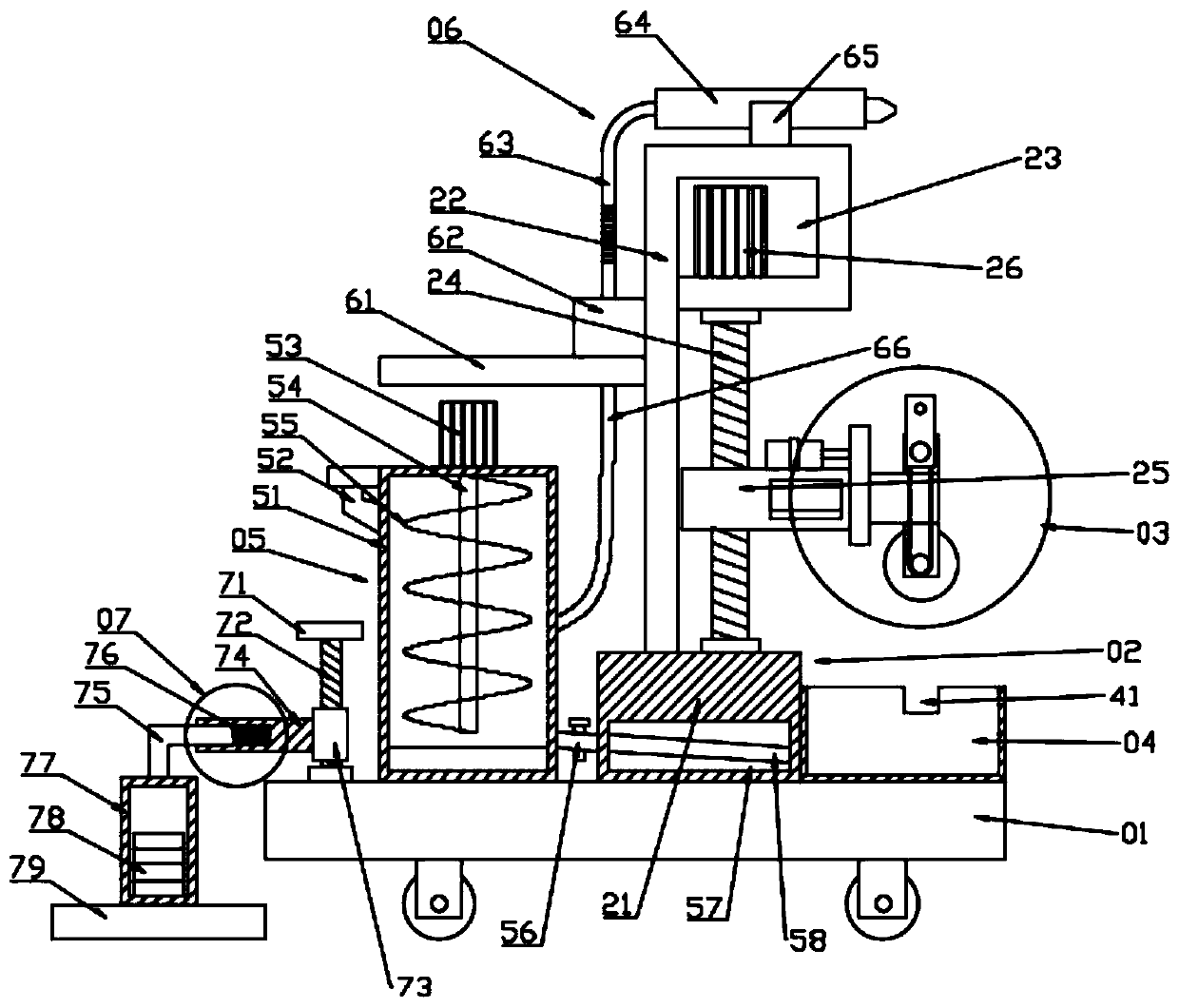

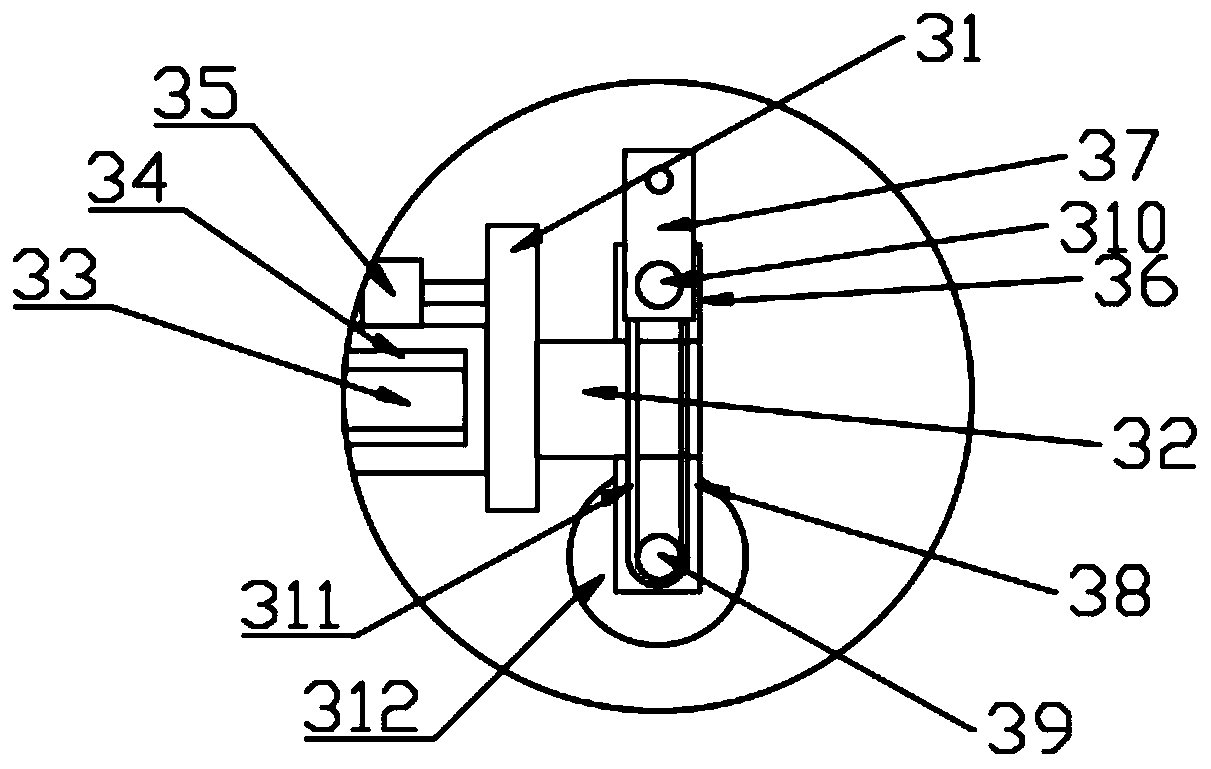

[0027] see Figure 1~3 , in an embodiment of the present invention, a building wall painting device includes a base 01, a connection assembly 02 is fixed on the base 01, a painting assembly 03 is movably connected to the connection assembly 02, and the wall surface can be painted by the painting assembly 03, The connecting assembly 02 can drive the painting assembly 03 to move in the vertical direction, and then paint different positions on the wall, which is very simple and practical; the bottom of the painting assembly 03 is provided with a collection box 04, and the collection box 04 is equipped with a painting The paint is conveniently painted by the painting assembly 03 through the collection box 04; the base 01 is also provided with a material preparation assembly 05, and the painting paint can be stirred by the preparation assembly 05, and the preparation assembly 05 communicates with the collection box 04, Then the painted paint after stirring will be transferred to th...

Embodiment 2

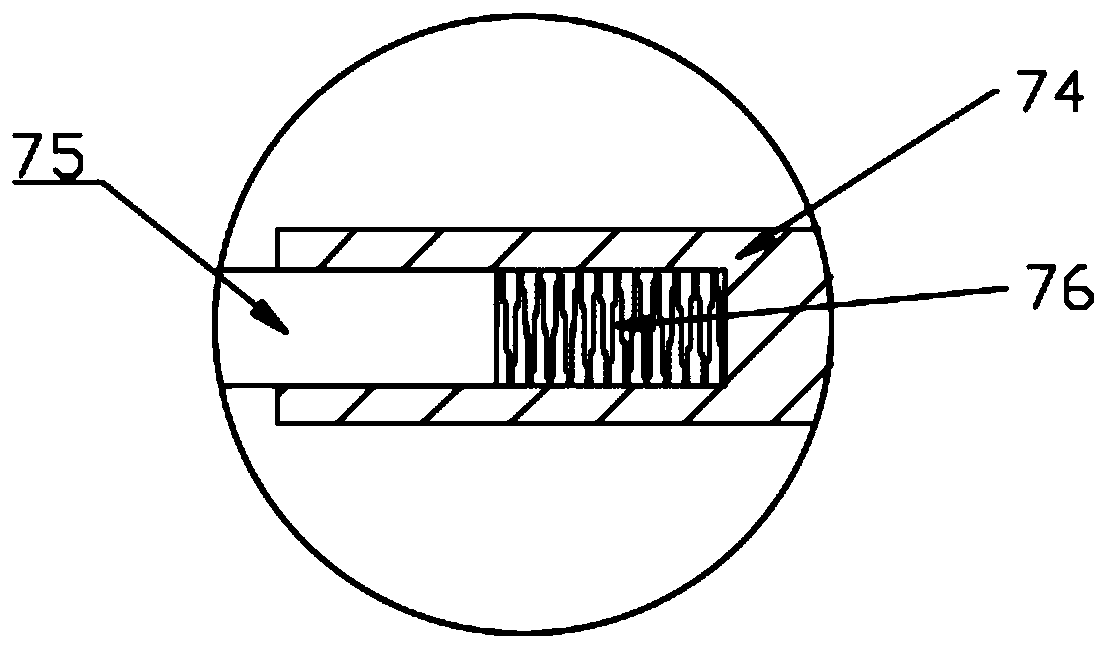

[0038] The base 01 is also provided with a limit adjustment assembly 07, through which the limit adjustment assembly 07 can be limited to the current position as a whole without affecting the painting of the wall; the limit adjustment assembly 07 includes a rotating connection on the base The second threaded rod 72 on 01, the second threaded rod 72 is fixed with an adjustment block 71, the second threaded rod 72 can be driven to rotate by rotating the adjustment block 71, and the second threaded rod 72 is threadedly connected with a moving sleeve 73, When the second threaded rod 72 rotates, it can drive the moving sleeve 73 to move in the vertical direction, one end of the moving sleeve 73 is fixedly connected with the second connecting block 74, and the second connecting block 74 is slidably connected with a fixed rod 75, and The fixed rod 75 is connected with the second connecting block 74 through the spring 76. During the painting process, due to the force, the base 01 will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com