Medical instrument cleaning and drying equipment for surgical operation

A technology for medical equipment and drying equipment, applied in drying, dryer, lighting and heating equipment and other directions, can solve the problems of low cleaning efficiency, high energy consumption, no drying equipment, etc., to improve the immersion effect, Guaranteed cleaning and improved cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

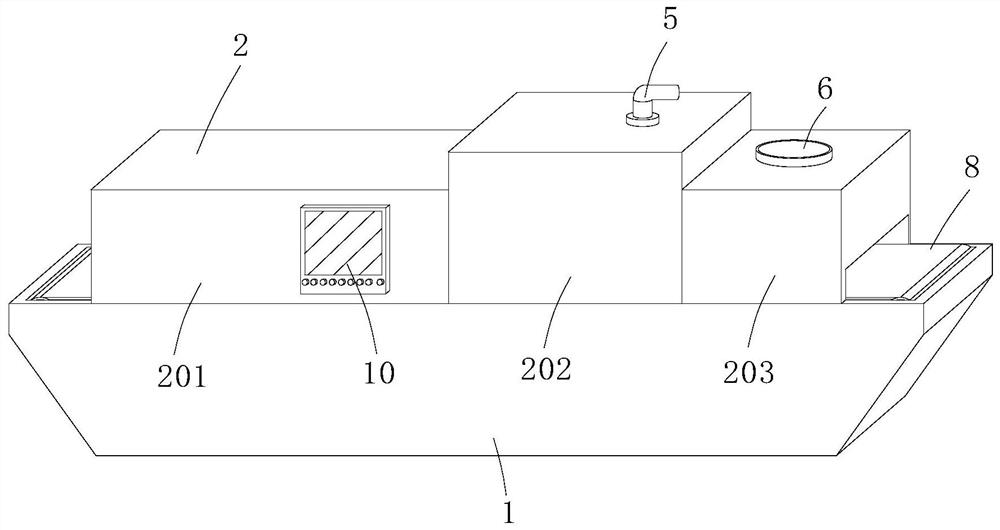

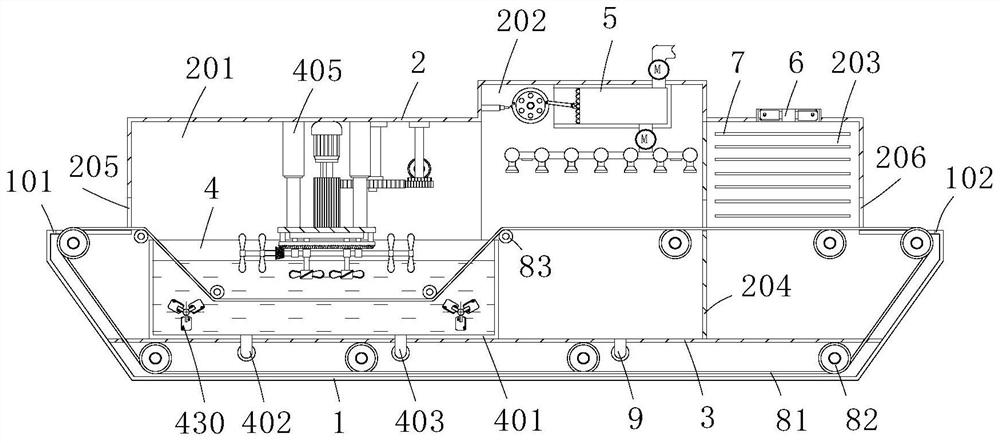

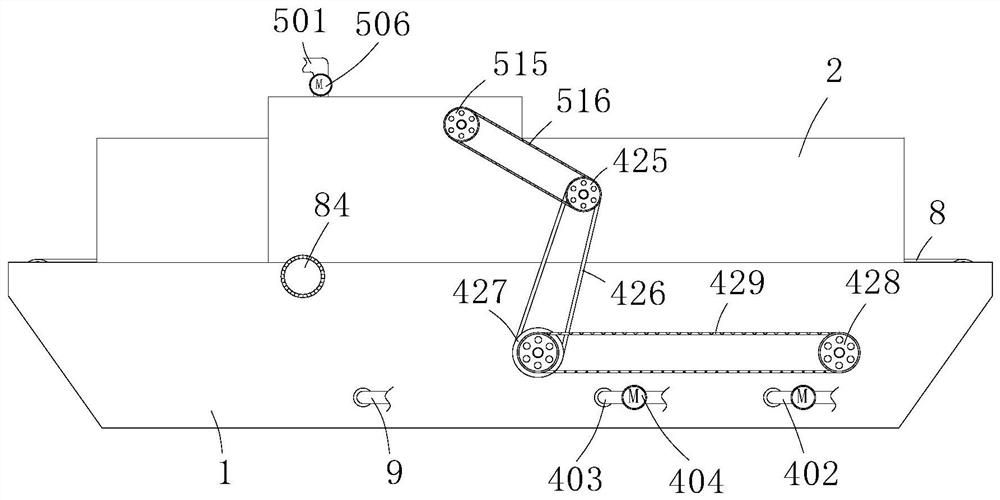

[0038] A cleaning and drying equipment for surgical medical instruments, comprising a lower case 1 and an upper case 2 which are integrally connected up and down. There is a transmission mechanism 8 for transporting medical instruments, and the upper chassis 2 is respectively provided with an equipment inlet 205 and an equipment outlet 206 on both sides corresponding to the input and output ends of the transmission mechanism 8, and the inner cavity of the lower chassis 1 and the upper chassis 2 is along the The direction of movement is sequentially the soaking chamber 201, the spraying chamber 202 and the drying chamber 203, and the spraying chamber 202 and the drying chamber 203 are separated by a vertical compartment plate 204, the soaking chamber 201 and the spraying chamber The cavity 202 is respectively provided with a mixing immersion mechanism 4 and a spray cleaning mechanism 5;

[0039] In this example, if figure 2 As shown, the top wall of the drying chamber 203 is ...

Embodiment 2

[0059] The difference between this embodiment and embodiment 1 is that, as Figure 4 As shown, the lower edge of the rotating disc 407 is fixedly equipped with a plurality of stirring rods 417 distributed in an annular array, and the lower end of the stirring rods 417 runs through the middle of the ring gear 415 and is connected with a fixed mixing wheel 418. When rotating, through the connection of the stirring rod 417, the fixed mixing wheel 418 extending downward into the cleaning liquid is driven to rotate along the rotating disk 407 as the center, so as to improve the immersion effect of the medical device under the liquid surface of the cleaning liquid and ensure that the medical device cleanliness.

[0060] Refer to Example 1 for other undescribed structures.

[0061] According to the cleaning and drying equipment for surgical medical instruments in the above-mentioned embodiments of the present invention, the medical instruments to be cleaned are placed on the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com