Absolute pressure transducer chip and production method thereof

A sensor chip, absolute pressure technology, applied in the fluid pressure measurement using capacitance change, manufacturing microstructure devices, decorative arts, etc., can solve the problems of low sensitivity, high cost, poor compatibility, etc., to achieve good compatibility and reliability. High, high-sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The absolute pressure sensor chip and its manufacturing method will be described in detail below in conjunction with specific embodiments.

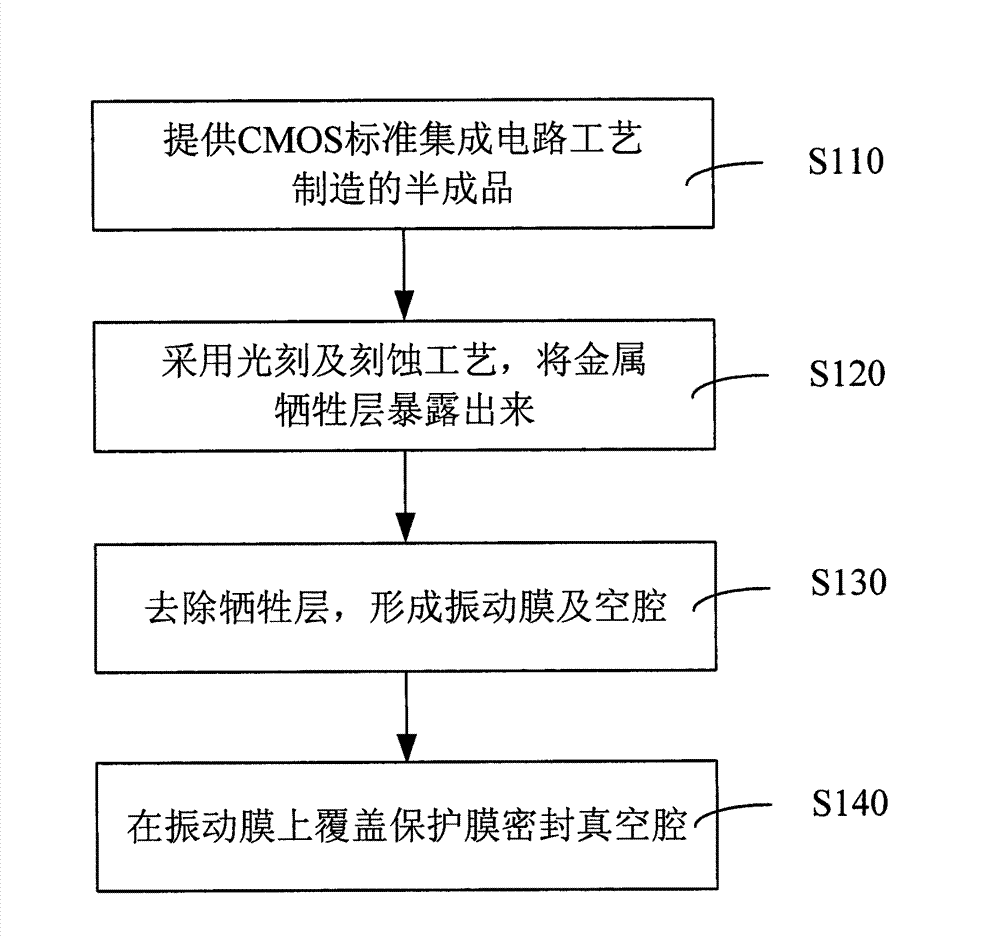

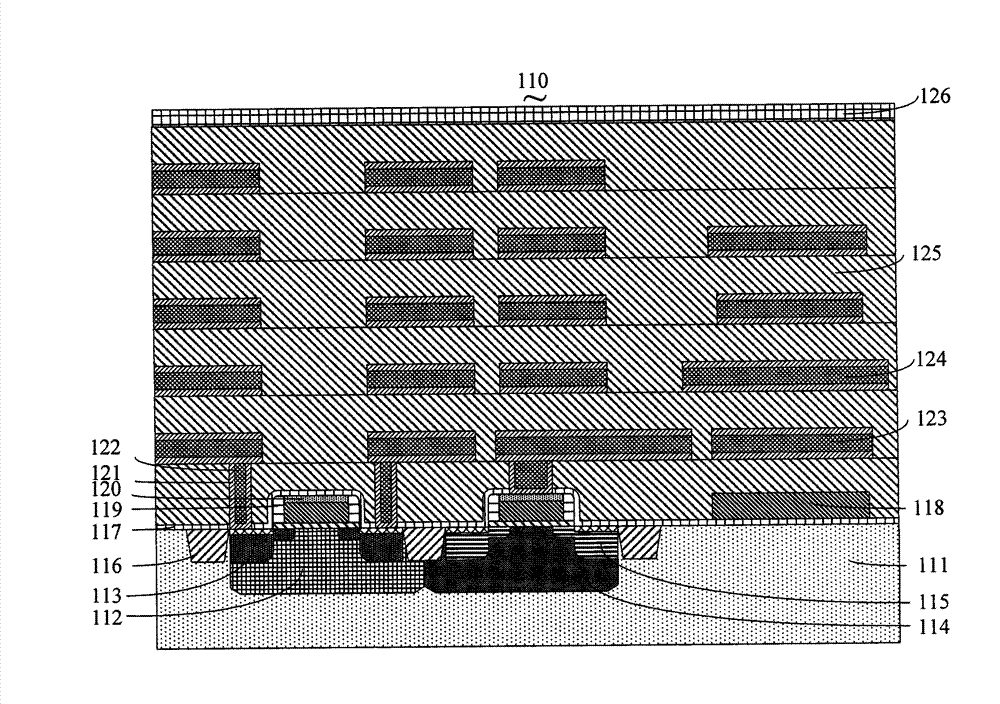

[0029] Please refer to Figure 6 , the absolute pressure sensor chip 100 of this embodiment includes a doped silicon substrate 111 . To produce an integrated circuit chip based on a standard CMOS process, this embodiment is illustrated by using a 1-layer polysilicon 5-layer metal (1P5M) standard CMOS process as an example.

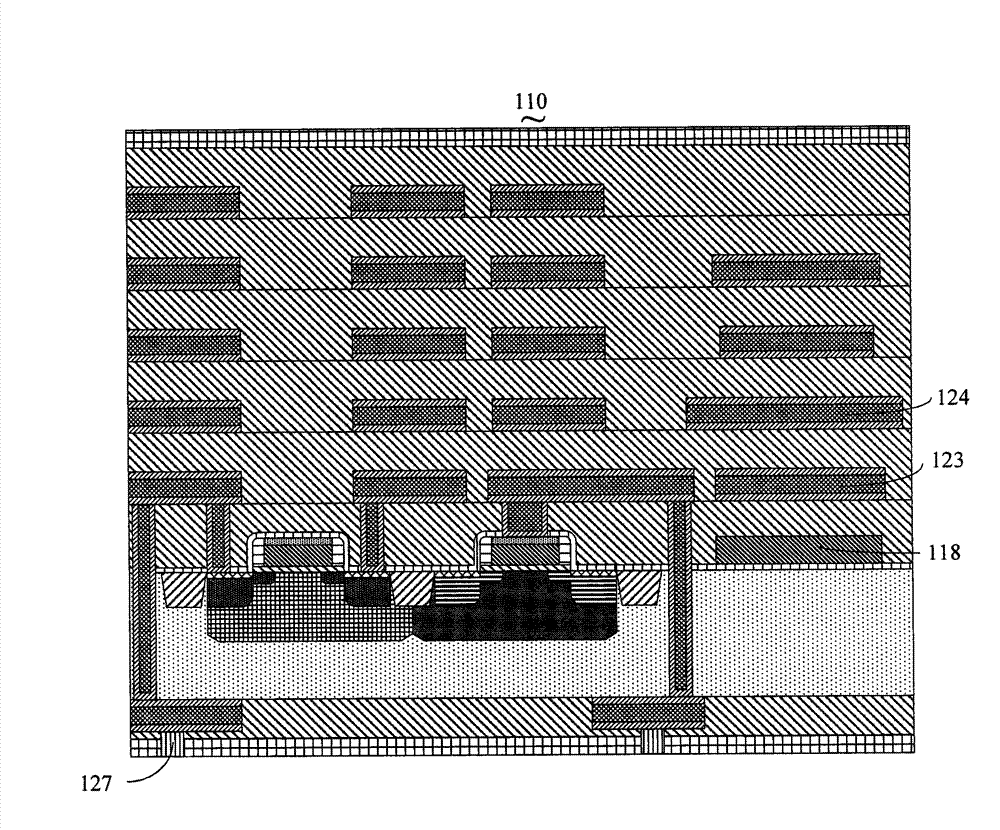

[0030] The designed pattern of the polysilicon layer 118 (as a floating gate electrode) is covered with a conductive vibrating film 130 , and the vibrating film 130 is covered with a protective film 150 to seal the corrosion hole 129 on the vibrating film 130 . The protective film 150 is a polymer film, such as parylene. The protective film 150 closes the vibrating film 130 to form a cavity 140 . The protection film 150 also covers other areas of the chip.

[0031] The backside of the doped silicon substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com